"Home appliances injection molds can produce a range of high-quality plastic parts for these appliances, including refrigerator drawers, television housings, air conditioner housings, doorbell housings, and fan blades. KRMOLD offers precision home appliances injection mold customization services to support global home appliance brands."

Diversity and Applications of Home Appliances Injection Mold

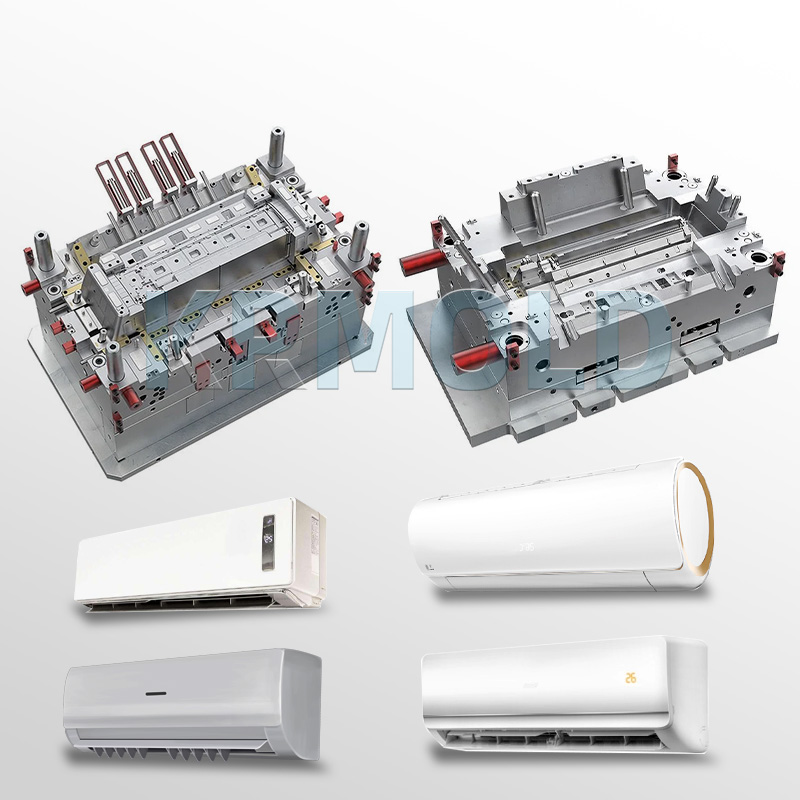

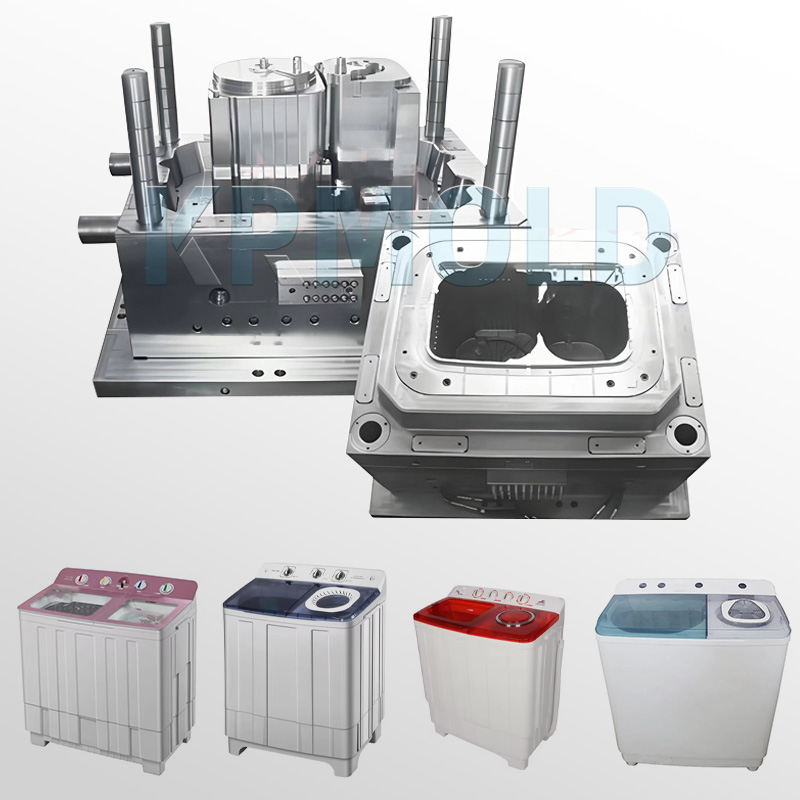

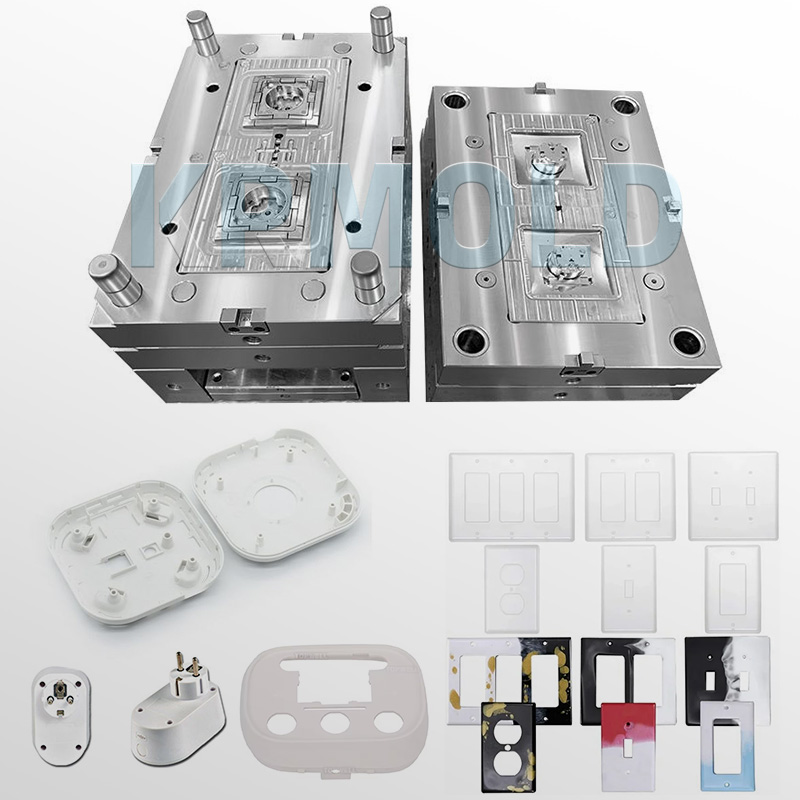

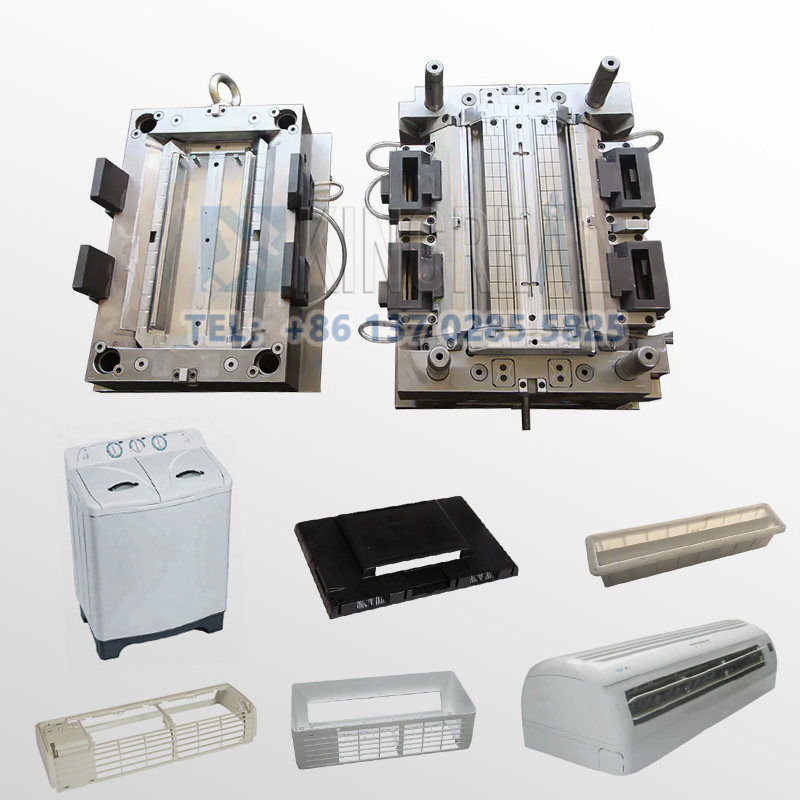

Home appliances injection molds encompass a wide range of products, including washing machine plastic injection mold, air conditioning panel injection mold, refrigerator plastic parts injection mold, TV back cover injection mold, household appliance shell injection mold, plastic fan blade injection mould, plastic chair injection mold, doorbell plastic shell injection mold, and plastic plug socket injection mold. Their applications are extensive, capable of producing numerous components that make up a complete home appliance.

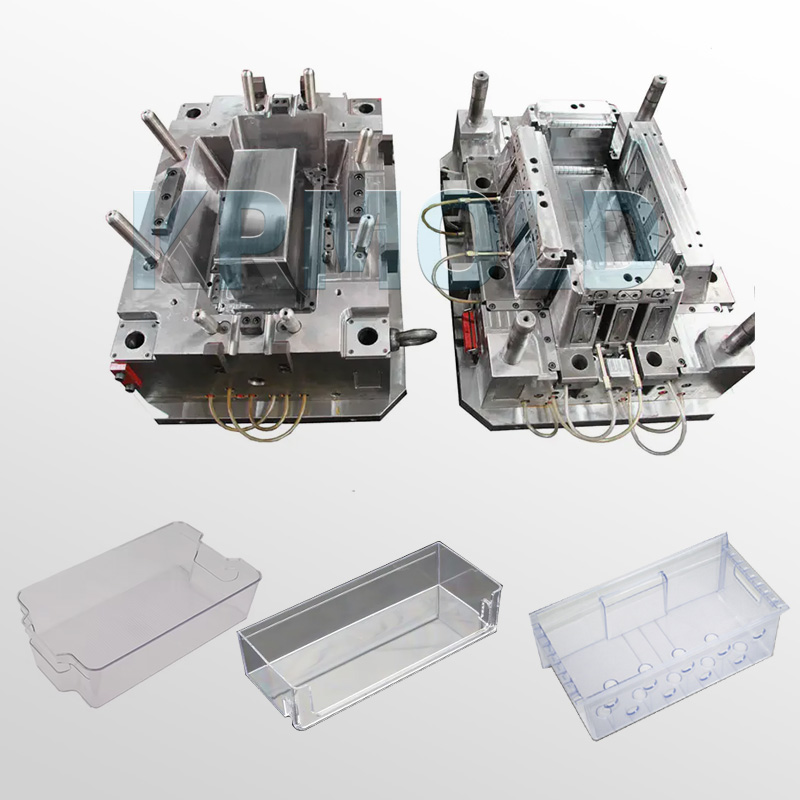

↘Taking refrigerators as an example, sliding drawer frames and interior shelves for storing condiments and jars are typically manufactured using refrigerator plastic parts injection molds. Refrigerator and freezer door handles, as well as many components used in ice makers (such as the plastic swivel for on-demand ice making), are also precisely manufactured using refrigerator plastic parts injection molds, ensuring both functionality and aesthetics.

↘Washing machine plastic injection molds also play a crucial role in washing machines and dryers. These machines contain numerous injection-molded components, including detergent dispensers, control knobs, and housings. These components must be robust, durable, and waterproof to withstand the high temperature and humidity environment inside the equipment.

↘Air conditioning panel injection molds are also indispensable in the production of air conditioners. Grilles, fan blades, and housing units are all essential precision plastic components for air conditioners. Through air conditioning panel injection mold, manufacturers can produce components with complex geometries, high heat resistance, and excellent ventilation and cooling performance. The efficiency of air conditioning panel injection molds makes the production of these components more efficient and cost-effective.

↘In television and entertainment systems, TV back cover injection molds are widely used to manufacture speaker grilles, remote control housings, and television housings. These components not only require precise design but also good durability and aesthetics to meet high consumer standards.

Advantages of KRMOLD Home Appliances Injection Mold Manufacturing

| Mold Assembly | KRMOLD household appliance shell injection mold design and manufacturing team consistently considers the assembly area structure during the development of household appliance shell injection molds to ensure the tolerances and precision of plastic parts, ultimately achieving excellent assembly results. This attention to detail is key to KRMOLD success in the industry. Furthermore, precision machining of the household appliance shell injection mold is also a crucial factor affecting assembly quality. KRMOLD machining centers utilize gantry CNC milling machines with dimensions of 4200 * 1800 cm and a depth of 600-800 mm, meeting the processing and manufacturing needs of various air conditioning panel injection mold and washing machine injection mold. This advanced processing equipment ensures high precision and efficiency in the mold production process. |

| Mold Quality Control | At KRMOLD, each plastic chair injection mold undergoes rigorous quality control during processing. After each process, the quality inspection department performs dimensional checks to ensure that every product meets the qualification rate. KRMOLD staff utilizes coordinate measuring machines with a tolerance of 0.01mm to effectively control the precision of each dimension, ensuring the production of high-quality parts that meet customer requirements. |

| Aesthetically Pleasing Molds | The KRMOLD team also places special emphasis on the appearance quality of its products, employing a proprietary three-step polishing process to ensure that every appliance component has a flawless finish. This process begins with initial polishing using 1200# oil, followed by meticulous sanding with 2500-3000# sandpaper, and finally, fine polishing with a wool ball. This series of processes results in injection molded parts with a smooth and refined appearance, meeting the market's high demands for aesthetics. |

| Professional Mold Testing Center | In addition, KRMOLD has its own testing center equipped with over 35 injection molding machines, ranging in tonnage from 80 tons to 2250 tons. Each plastic plug socket injection mold undergoes high and low pressure testing before production, and is subjected to maximum performance and injection stability testing under conditions of at least 8 hours of continuous operation. This series of rigorous tests ensures the reliability and durability of each plastic plug socket injection mold in actual use. |

Features of KRMOLD Home Appliances Injection Mold

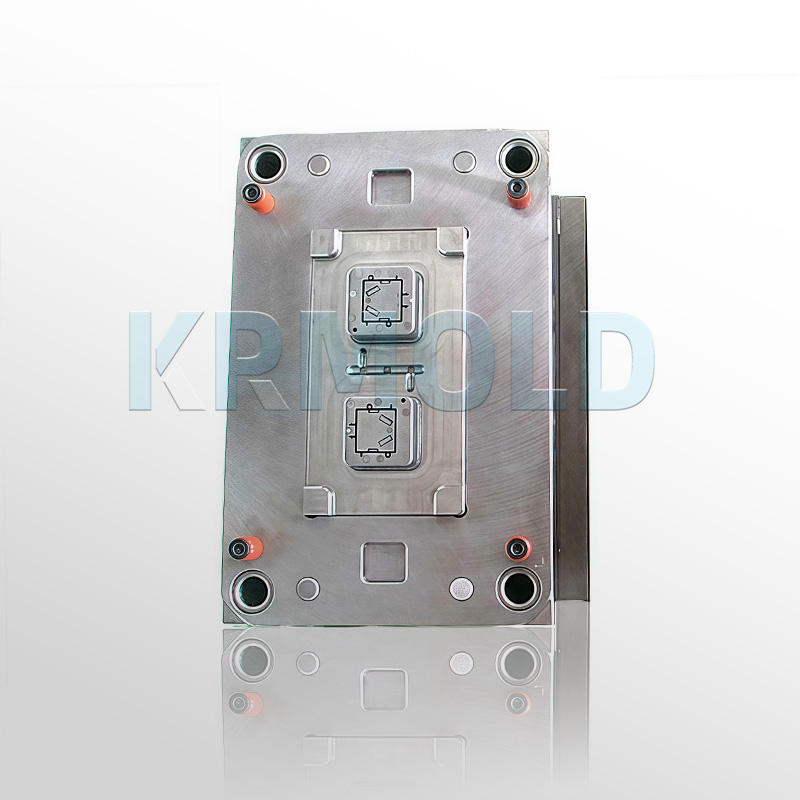

Precision Switch Socket Plastic Injection Molds: Switch socket plastic injection molds can precisely create intricate shapes and complex designs, using high-pressure injection to inject molten plastic into the deepest and smallest parts, achieving high-quality production results.

-High-Efficiency Plastic Fan Blade Injection Mould: Plastic fan blade injection mould enable mass production, meeting high demand with minimal setup time and low cost. Initial plastic fan blade injection mould can be reused for long-term production, increasing the output of similar products.

-Reusable Air Conditioning Panel Injection Molds: This repeatability ensures perfect fit of each assembled part, minimizing waste and defects in the production process and improving overall production efficiency.

-Low Cost for Washing Machine Plastic Injection Mould: While the initial cost of designing and manufacturing washing machine plastic injection mould may be high, the unit production cost gradually decreases as production scales up, significantly improving economic efficiency.

-Precise Surface Finishing for Doorbell Plastic Shell Injection Mould: Surface-finished doorbell plastic shell injection mould ensure the precision of molded parts, reducing the need for secondary processing such as painting, trimming, or machining, thereby reducing labor costs, saving time, and allowing parts to be assembled immediately.

Contact KRMOLD for more information on home appliances injection molds!