Description of Doorbell Plastic Shell Injection Mould

——

With the increasing popularity of smart homes, market demand for doorbell plastic shell injection mould is growing. KRMOLD specializes in producing precision doorbell plastic cover injection mould.

These smart doorbells not only offer the functionality of traditional doorbells and peepholes, but also incorporate a variety of intelligent features, including remote monitoring via mobile phone, automatic alarms, and video calls. This makes doorbells a vital component of modern home security.

To date, KRMOLD has provided efficient doorbell plastic shell injection mould solutions to clients in multiple countries. Leveraging its sophisticated mold-making technology, KRMOLD ensures short lead times, long doorbell plastic cover injection mould life, and high-quality finished products.

Specifications of Doorbell Plastic Shell Injection Mould

——

| Product Description | ODM plastic injection molding |

| Plastic Materials: | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS, PEEK, HDPE, TPU, PET, PPO,...etc. |

| Standard: | ISO9001:2008 |

| Other materials: | Rubber, Silicone rubber, LSR,Aluminum, Zinc,Copper...Metal...etc. |

| Quality: | ROHS and SGS standard |

| Feature: | Non marking and Non flash |

| Size: | According to your 2D, 3D Drawing |

| Color,Quantity,Unit price,Tooling cost,Tooling size: | To be discussed |

| Package: | Standard exported Wooden box packed, Fumigation process(upon required) |

To be discussed | In-Mold Decoration, Injection Mould, Plastic Mold, Overmould, 2K Mould, Die-Casting Mould, Thermoset Mold, Stack Mold, Interchangeable Mold,Collapsible Core Mold, Die Sets, Compression Mold, Cold Runner System LSR Mold,...etc. |

Mould Base: | Hasco Standard, European Standard, World Standard |

Mould Base Material: | LKM, FUTA, HASCO, DME,...etc. Or as per Customer's Requirement. |

Surface Finish: | Texture(MT standard), High gloss polishing |

Cavity/Core Steel: | P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 ...etc. |

Hot/ Cold Runner | HUSKY, INCOE, YDDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand...etc. |

Mould Life: | 5,000 to 1,000,000 Shots. (According to your working environment.) |

Design & Program Software: | CAD, CAM, CAE, Pro-E, UG, Soild works, Moldflow, CATIA....etc. |

Equipment: | High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine for trial out mold from 50-3000T available. |

Advantages of KRMOLD Doorbell Plastic Cover Injection Mould

——

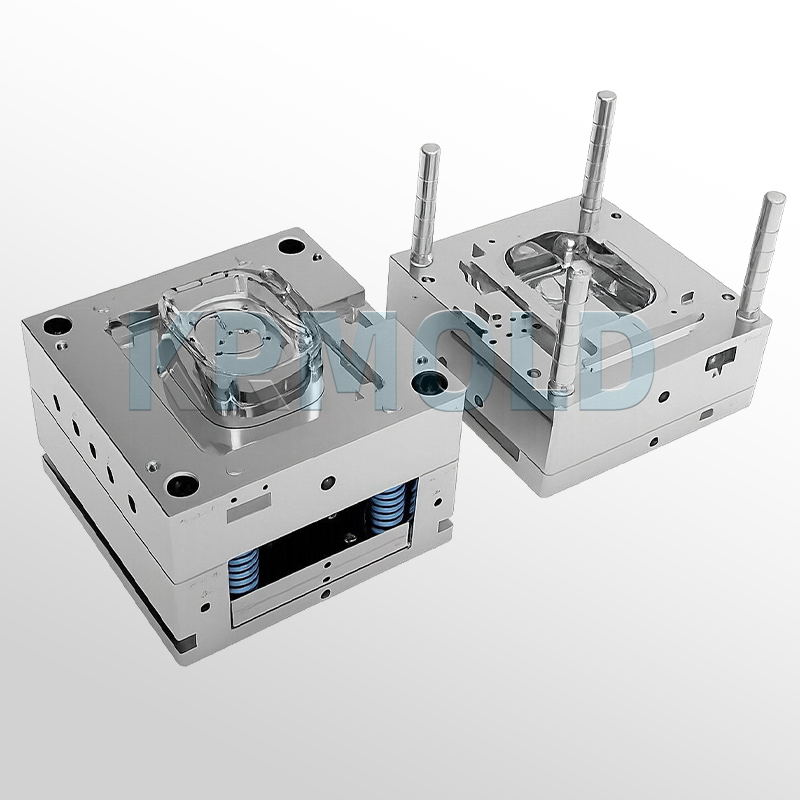

(1)Appearance design for doorbell plastic shell injection mould

As a home product, the design of a doorbell must align with the user's aesthetic and home style, while also balancing functionality and ease of use. KRMOLD pays attention to every detail, ensuring the doorbell's housing is both aesthetically pleasing and practical when designing the doorbell plastic cover injection mould.

To enhance the surface quality and finish of the housing, KRMOLD perform appropriate surface treatments during the doorbell plastic shell injection molds manufacturing process, such as grinding and polishing, to ensure a refined appearance.

(2)Dimensional and structural design for doorbell plastic cover injection mould

The design of the doorbell plastic shell injection mould takes into account the product's dimensions and structure to ensure mold precision and stability. KRMOLD also prioritizes ease of assembly and maintenance, striving to provide the best user experience.

(3)Material selection for doorbell plastic cover injection mould

KRMOLD utilizes durable, wear-resistant, and high-temperature-resistant materials to ensure the quality and longevity of the doorbell plastic shell injection molds.

Commonly used ABS material offers excellent strength, rigidity, and impact resistance, meeting the durability requirements of smart doorbell housings.

It also offers excellent chemical and heat resistance, making it suitable for chemicals and high temperatures found in various household environments. Based on the properties of ABS material, we optimally design and control the injection molding process parameters to ensure the required filling performance and curing results.

(4)Waterproof design for doorbell plastic cover injection mould

Taking into account the operating environment of the doorbell, KRMOLD incorporated waterproofing into the doorbell plastic shell injection molds design to adapt to varying climates. This design ensures the product's stability in all weather conditions.

(5)Manufacturing and processing for doorbell plastic cover injection mold

During the manufacturing and processing of the doorbell plastic shell injection molds, KRMOLD select appropriate processing technologies and equipment, such as CNC machining centers and EDM machines.

The processing of mold components, including the cavity, core, demolding system, and cooling system, ensures that the required precision and dimensions are met.

KRMOLD focus on the precision and dimensional control of mold components to ensure the quality and stability of the injection molding process. Through a strict quality management system, KRMOLD ensure that every doorbell plastic cover injection mold meets high standards.

Design Key Points of KRMOLD Doorbell Plastic Shell Injection Mould

——

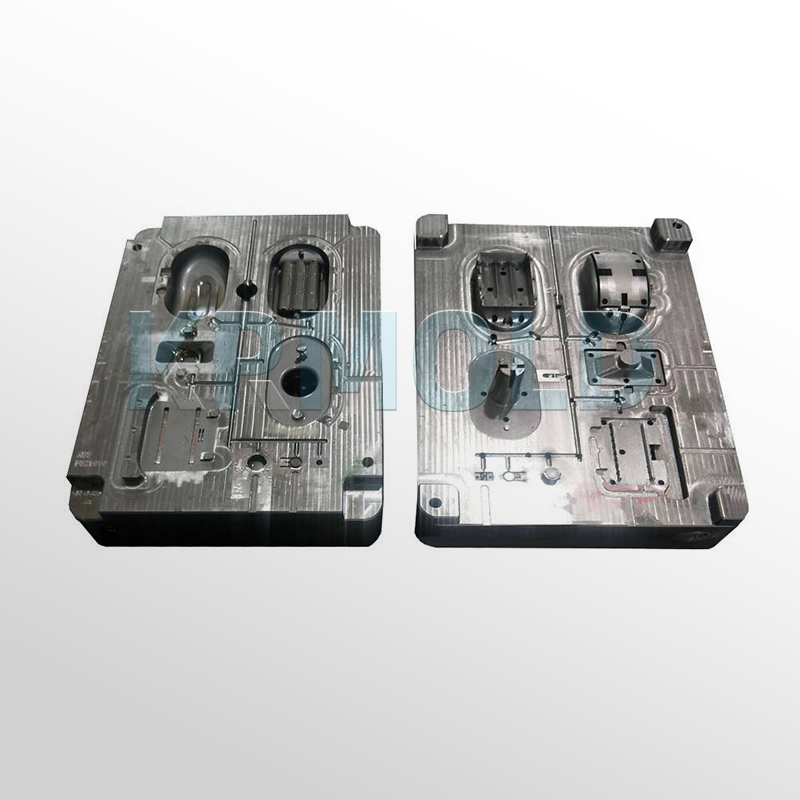

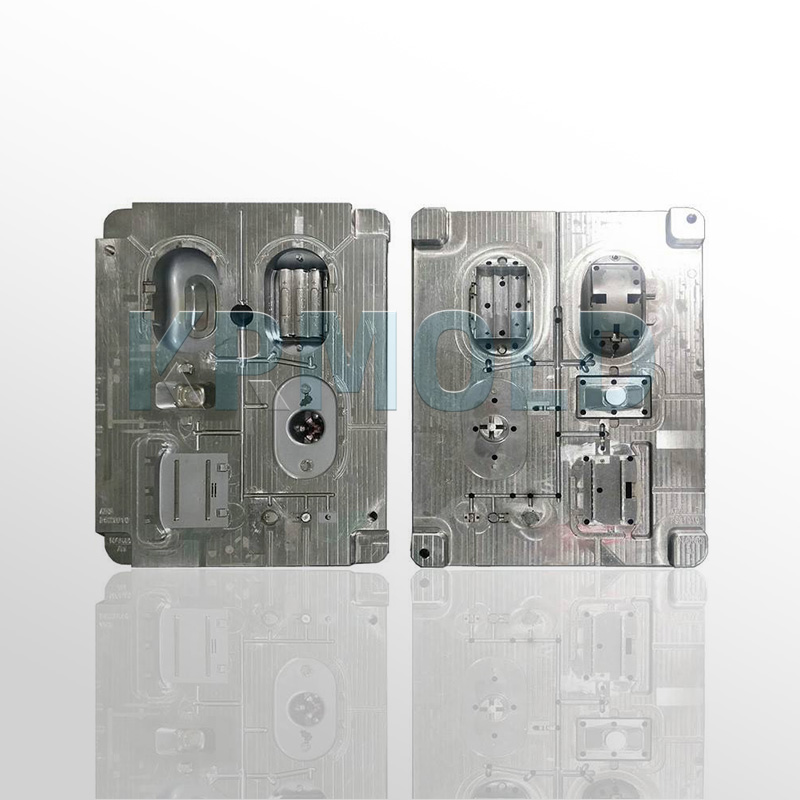

(1)Doorbell plastic cover injection mould design

When designing the doorbell plastic shell injection mould, KRMOLD first determine the mold structure, including the cavity, core, demolding system, and cooling system. KRMOLD ensure that the doorbell plastic shell injection mould’ precision and dimensions meet the required specifications to ensure the quality and stability of the injection molding process.

(2)Doorbell plastic cover injection mould flow analysis

Using mold flow analysis software, KRMOLD import the CAD model of the doorbell and set injection molding process parameters, such as injection speed, temperature, and pressure. Through mold flow analysis, we simulate the melt flow, filling, and cooling processes during the injection molding process, assessing filling performance, defects such as bubbles and short shots, and optimizing injection molding process parameters to ensure high-quality finished products.

(3)Cooling system design for doorbell plastic shell injection mould

A rationally designed cooling system ensures effective cooling during the injection molding process, improving production efficiency and product quality.

(4)Doorbell plastic cover injection mould release system design

Designing an appropriate doorbell plastic shell injection mould release system based on the shape and requirements of the doorbell ensures smooth demolding and avoids damage and deformation.

(5)Injection sequence and injection point location for doorbell plastic cover injection mould

Determine the injection sequence and injection point location to ensure that the plastic fully fills the mold cavity and avoids voids and defects.

Full Process of Customizing Doorbell Plastic Cover Injection Mould

——

-Process and Structural Analysis: Analyze the product molding process, doorbell plastic shell injection mould structure, and manufacturing process to ensure doorbell plastic cover injection mould life meets customer requirements.

-Mold Design: Design the complete doorbell plastic shell injection mould structure and machined parts, and define assembly and injection molding process requirements.

-Problem Prediction: Thoroughly analyze plastic part appearance quality defects (such as shrinkage) or doorbell plastic cover injection mould structure issues (such as parting surface and gate settings) before doorbell plastic shell injection mould opening.

-Doorbell plastic cover injection mould Appearance Inspection: Ensure the mold is free of rust, dents, or other defects.

-Mold Transportation: Doorbell plastic shell injection mould must be shipped with mold locks to ensure sturdy, rust-proof packaging.

-Mold Documentation: A complete set of doorbell plastic cover injection mould consumable parts and maintenance materials are provided upon delivery.

Through this series of steps, KRMOLD ensures that every doorbell plastic shell injection mould meets our customers' high standards and produces high-quality products. Choosing KRMOLD ensures you receive industry-leading injection mold solutions, helping you successfully launch your smart home products.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).