Full Solution For Smart Home Integration Injection Mold

——

With the rapid development of Internet of Things (IoT), Artificial Intelligence (AI) and 5G technologies, the smart home industry is witnessing unprecedented growth. Smart home products cover a wide range of fields such as smart speakers, smart door locks, smart lighting, smart home appliances, etc., and market demand continues to rise. Smart home products usually use high-precision plastic components, which are produced by pumping hot-melt plastics into molds to produce the precise shapes required for smart homes through injection molding of smart technology components.

The development of the smart home industry has placed higher demands on injection mold manufacturing, including light-weighting, complex structure molding, high surface finish, and multi-material integration. In order to meet the needs of the smart home industry, KRMOLD is continuously advancing and optimizing its injection mold design and manufacturing.

Advantages of Plastic Injection Molding

——

1 . Production cost control: Plastic injection molding is an efficient and highly automated production method that helps smart home products achieve large-scale mass production. The injection cycle time for a plastic part is usually between 30 seconds and 2 minutes, which greatly improves production efficiency.

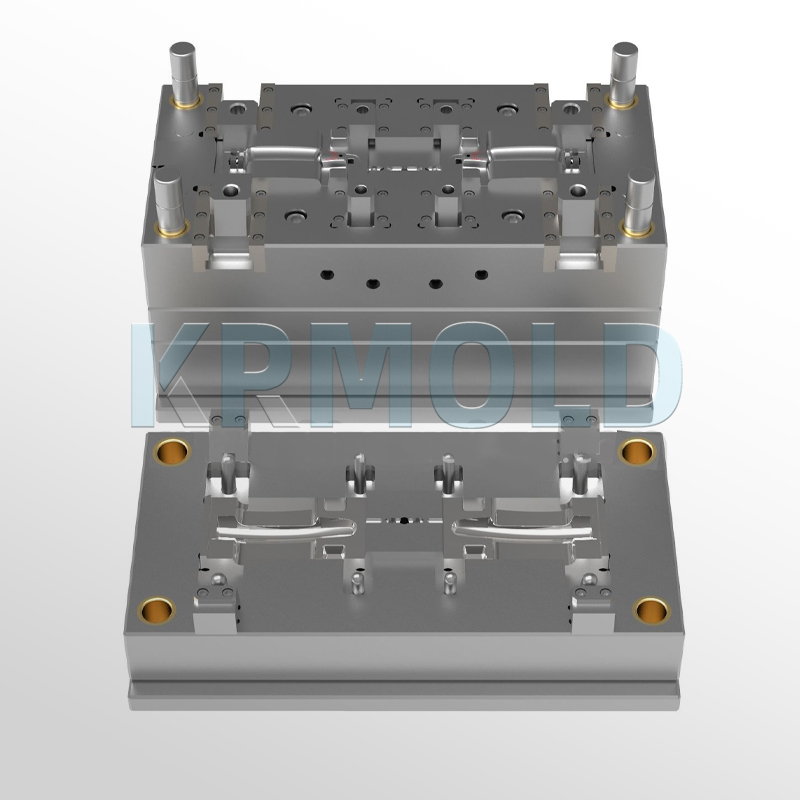

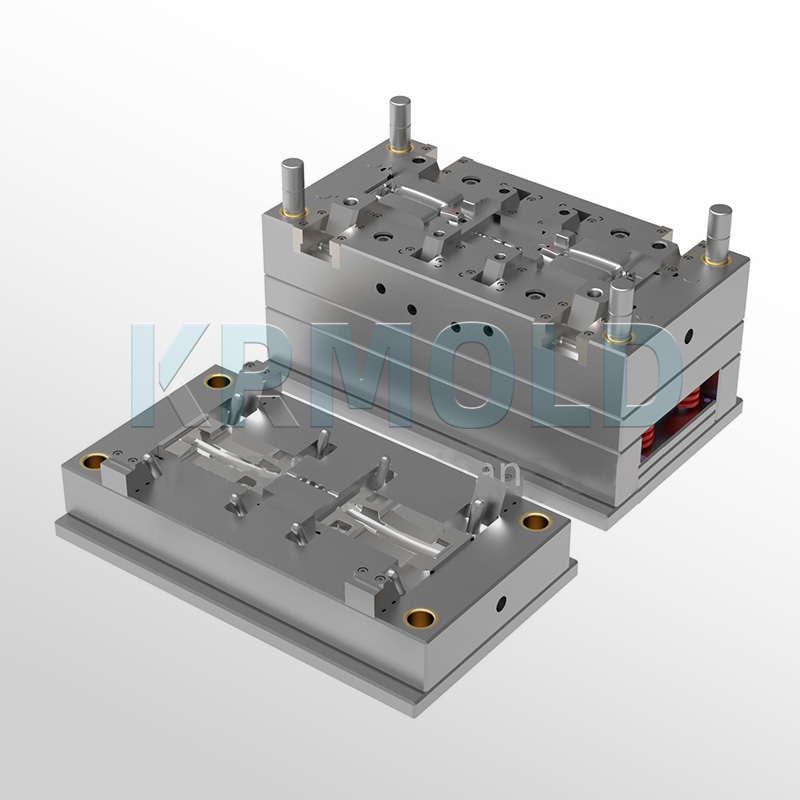

2. Precision molding to improve quality: Adopting micron-level precision injection molding technology ensures that complex structural parts such as smart door lock card slots and smart camera lens housings reach ±0.01mm precision.

3. Lightweight design: the shell of the smart door lock adopts engineering plastics molded by injection molding, which can reduce the weight of the product and make the installation more convenient, and at the same time, it also has the characteristics of impact resistance, abrasion resistance and anti-static.

Smart Home Injection Mold Advantage

——

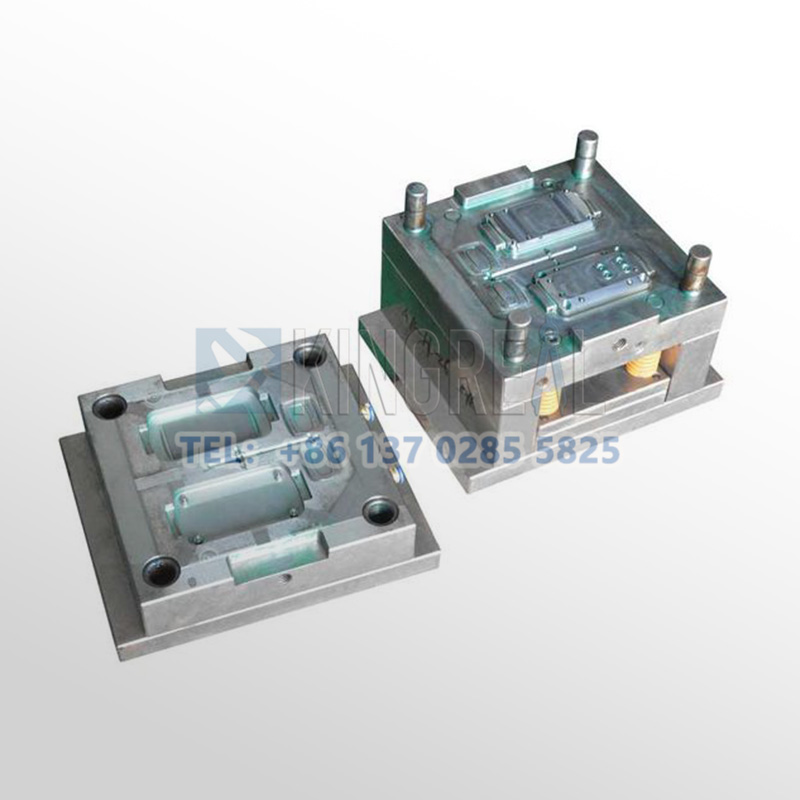

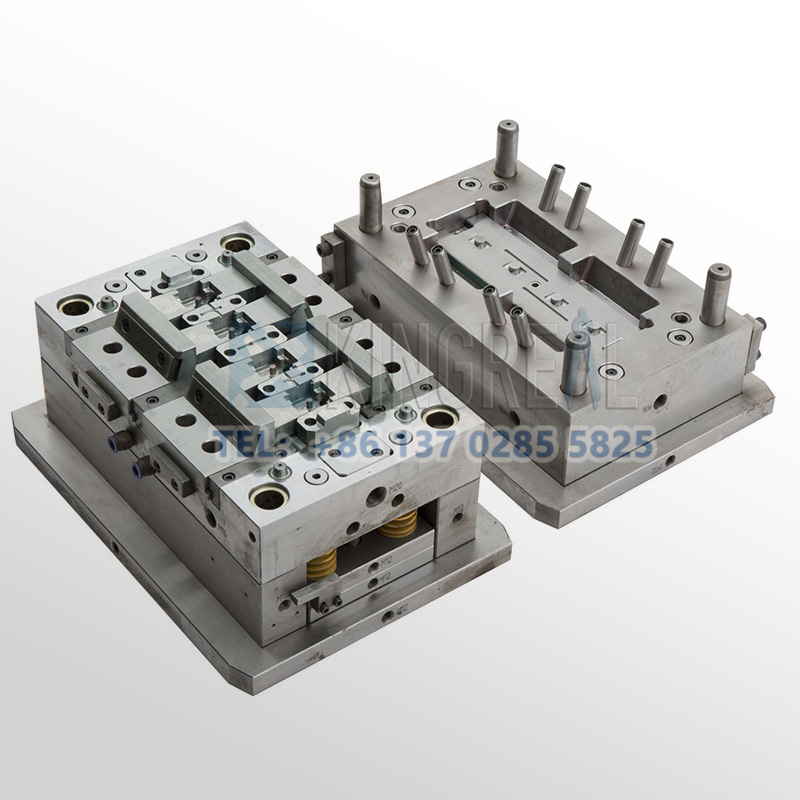

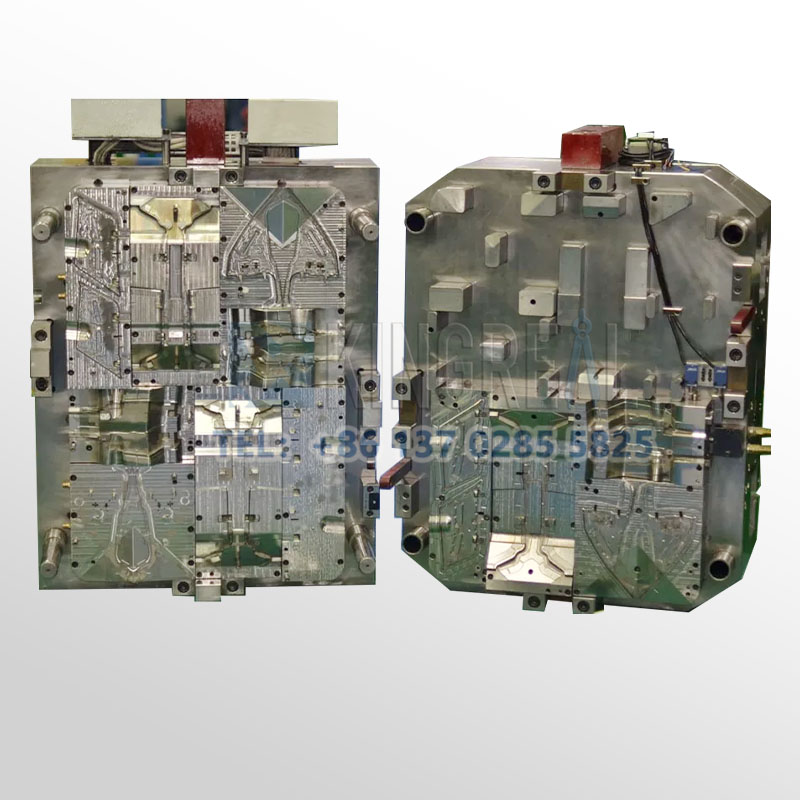

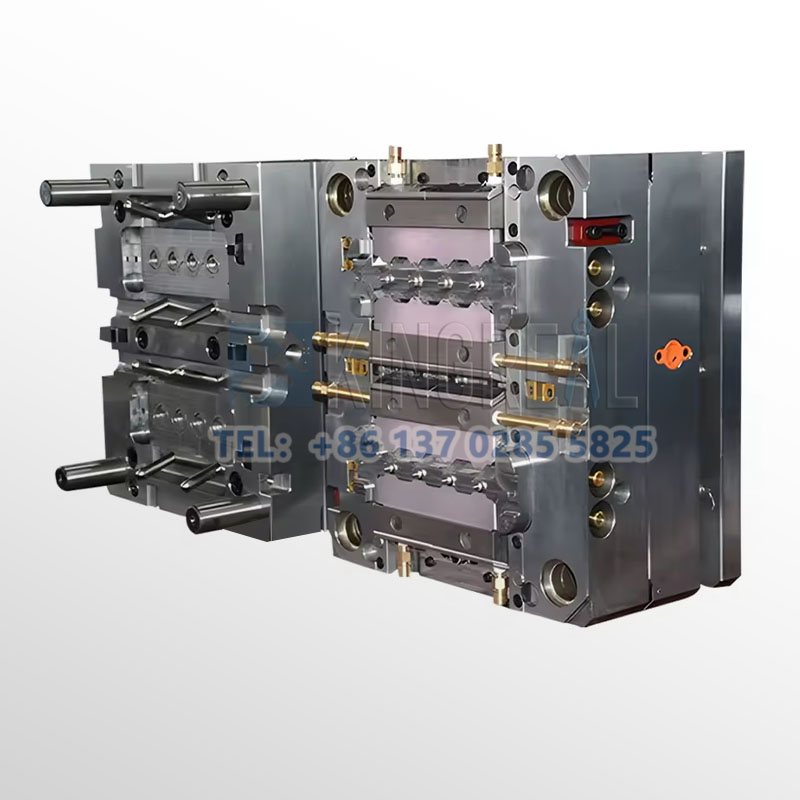

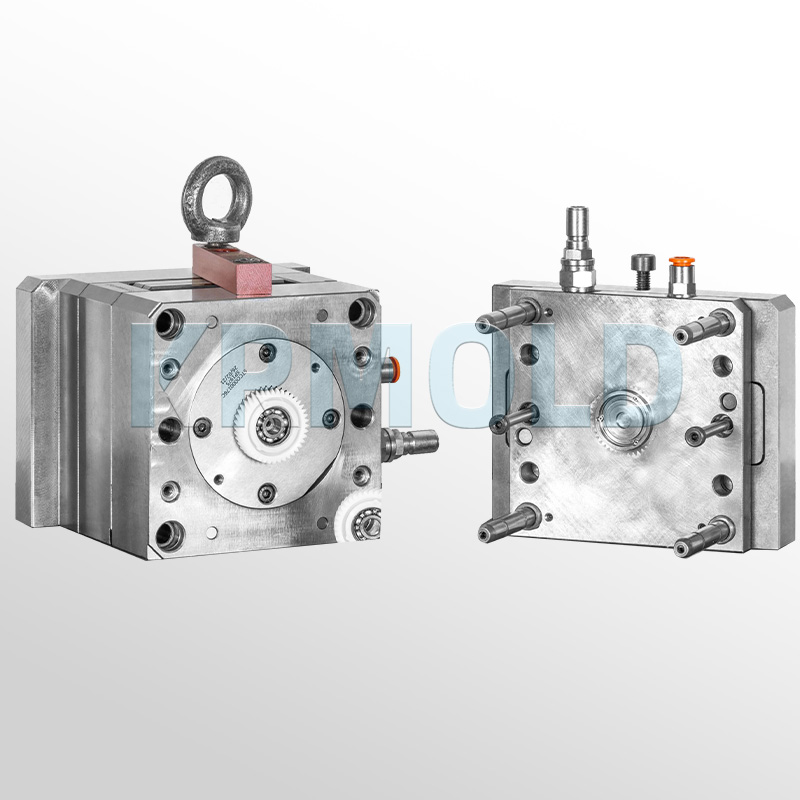

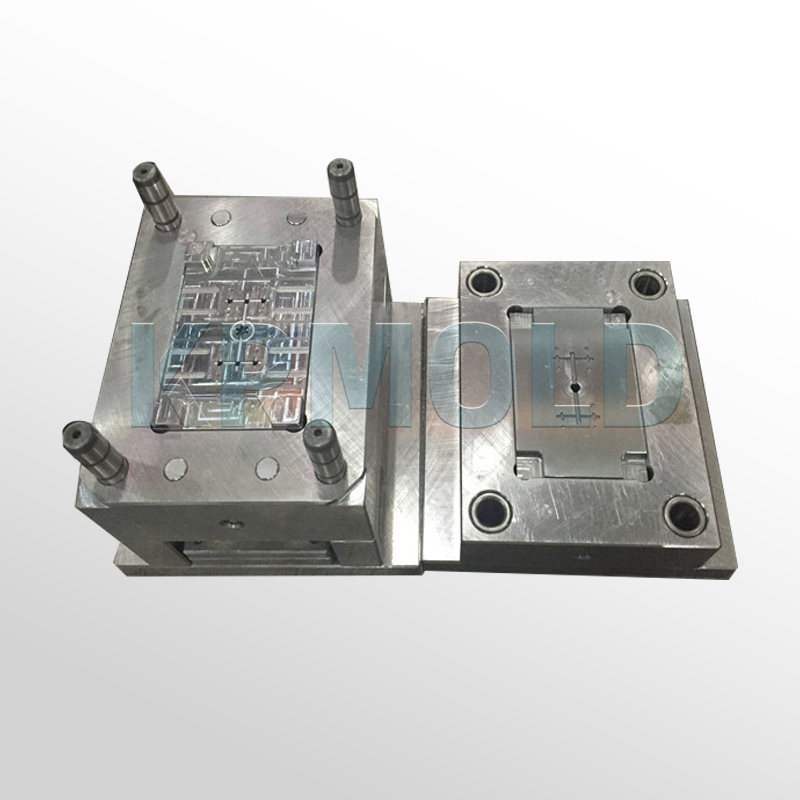

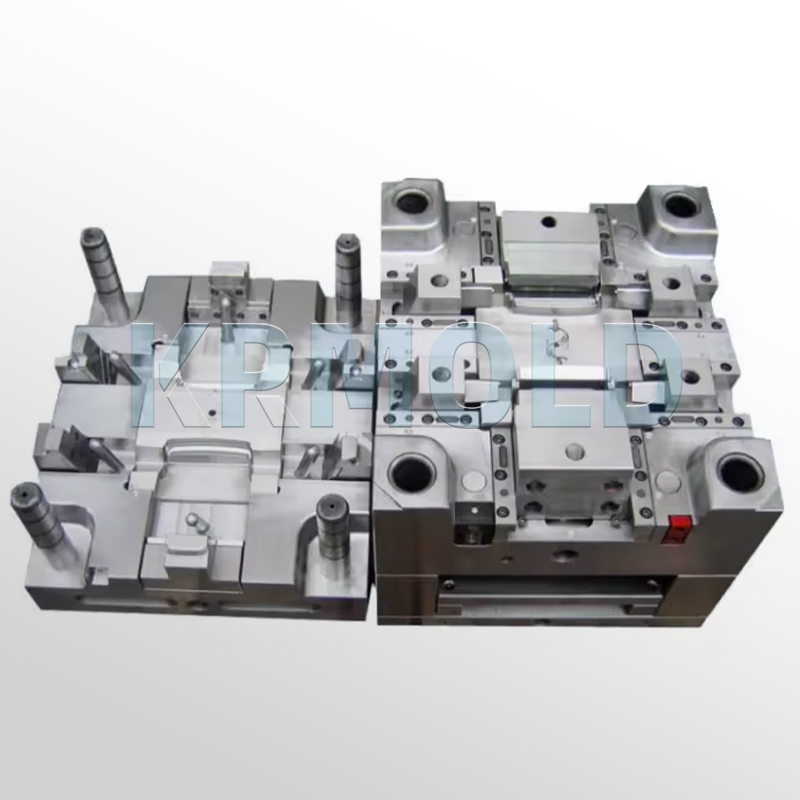

1.Precision injection mold manufacturing process: KRMOLD adopts CNC machining, EDM (electric discharge machining) and other precision manufacturing technologies when manufacturing injection molds, so that the precision of the molds reaches ±0.01mm, which helps to realize the injection molding of small and complex structural parts such as the shell of the smart bracelet and the buttons of the smart remote control.

2. Mold surface processing technology: KRMOLD injection mold provides polishing, electroplating, chrome plating and other fine processing technology to meet the demand for mirror polishing effect of smart home products.

3. Modular mold design: KRMOLD injection molds provide modular mold design to adapt to different models of smart furniture products, while the use of multi-cavity mold design, a set of molds can be produced at the same time a number of the same or different parts to improve production efficiency.

Common Injection Molding Processes

——

“In the manufacture of smart home products, 2K injection molding (two-color injection molding) and insert injection molding are two important molding processes. The injection molds produced by KRMOLD can conceal different injection molding processes and help smart home customers to enhance the functionality, aesthetic appearance, structural strength and service life of their products, which are widely used in smart speakers, smart door locks, smart remote controls, smart lighting devices and other products.”

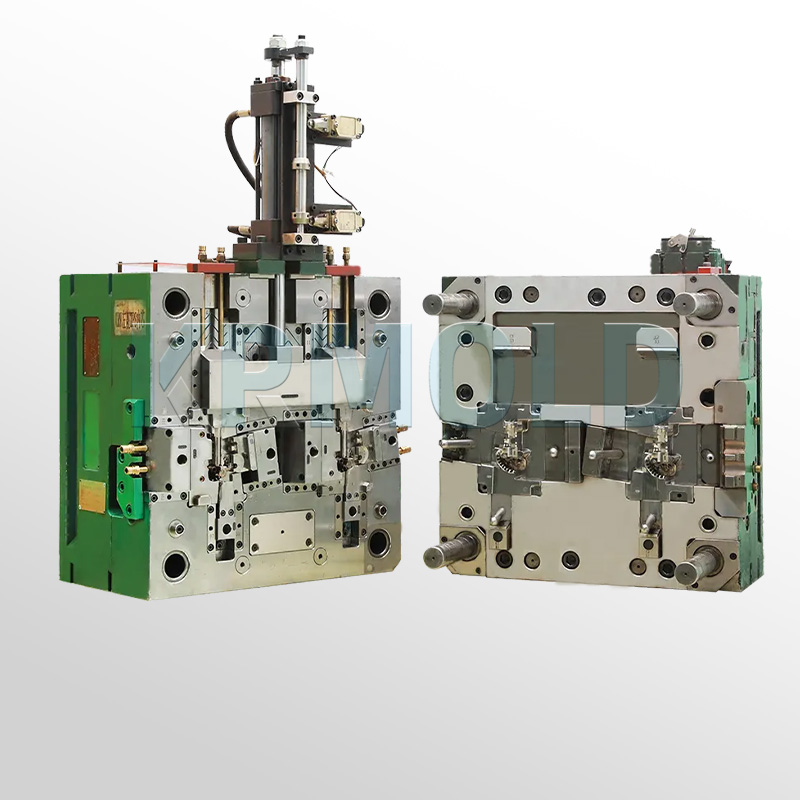

Two-shot injection molding or two-shot injection molding refers to the use of two different plastic materials or two different colors of materials in two different injection units on the same injection molding machine in the same mold for two-shot injection molding, so as to obtain products with different colors and different material characteristics. Common two-color injection-molded smart home products include smart remote control buttons, smart door lock panels and smart speaker shells.

Insert Molding is a process in which metal, glass, electronic components, other plastic parts and other inserts are placed into the mold beforehand and then injected into the plastic so that it is tightly combined with the insert. Common Insert Molding smart home products include insert molding of smart door locks, smart sockets, smart switches and smart speakers.

Gas-assisted Injection Molding

Gas-assisted injection molding is a process of injecting high-pressure gas (usually nitrogen) into the molten plastic to form a cavity structure on the basis of traditional injection molding, thus reducing the amount of material used, lowering shrinkage and concavity, and improving the strength and dimensional stability of the product.KRMOLD injection molds are capable of implementing the gas-assisted injection molding process to help produce a wide range of smart home products, such as the shells of smart speakers, smart door lock knobs, and handles of smart appliances, and so on. It is characterized by lower material usage and cost reduction.

In-Mold Decoration (IMD) is an injection molding technology in which a decorative film (with patterns and textures) is pre-positioned in the mold and molded into the plastic part. Compared with the traditional surface coating or film, IMD process can improve the aesthetics, abrasion resistance and corrosion resistance of the product. KRMOLD injection molds combined with IMD injection molding process help to produce smart switch panels, smart door lock touch panels and smart home appliance control panels, etc., to achieve the effect of integrating the decorative layer with the plastic parts.

FAQ:

——

1. Why is the cost of mold opening higher?

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

2. What should be the focus of the mold acceptance criteria?

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

3. What are the key factors affecting the mold cost?

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).