The quality inspection workshop of the injection mold manufacturing workshop is the core link to ensure mold accuracy and product quality. The KRMOLD factory is equipped with high-precision injection mold inspection equipment such as mold clamping machine, two-dimensional and three-dimensional to form a key inspection system.

1. The mold clamping machine applies controllable pressure through the hydraulic system to close the upper and lower molds, eliminate the assembly gap and calibrate the matching accuracy of the parting surface and the slider. Its core structure includes a hydraulic pump, a rack, a mobile workbench and a PLC control system, which supports rapid mold change and safety protection.

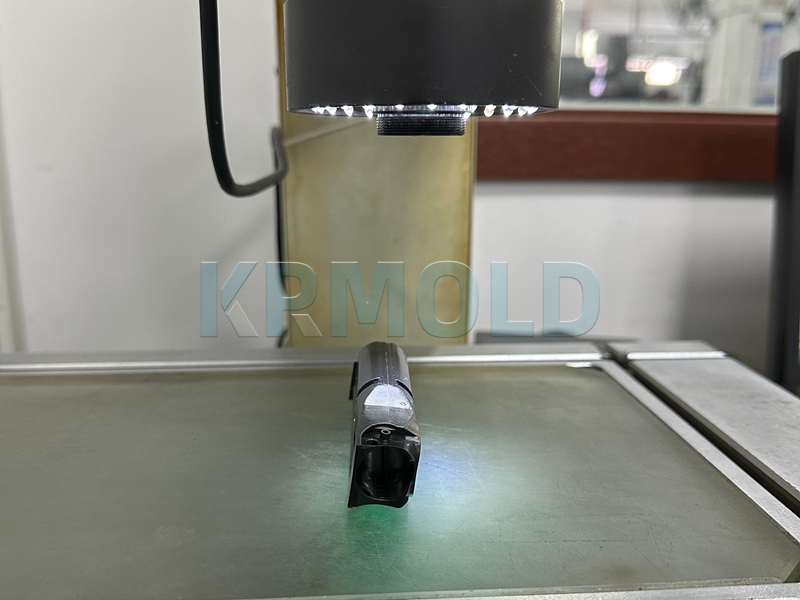

2. The two-dimensional inspection equipment measures the plane dimensions and surface defects of the mold and product through optical imaging technology, with an accuracy of up to ±0.002mm. With the automatic loading and unloading of the manipulator, batch inspection can be realized, such as rapid screening of micro-channel size deviations in medical mold production.

3. The three-dimensional coordinate measuring machine obtains three-dimensional coordinate data through contact probes or laser scanning, detects the geometric tolerances of the injection mold cavity and inserts, with an accuracy of ±0.005mm, generates inspection reports in real time, and monitors the stability of the mold production process.