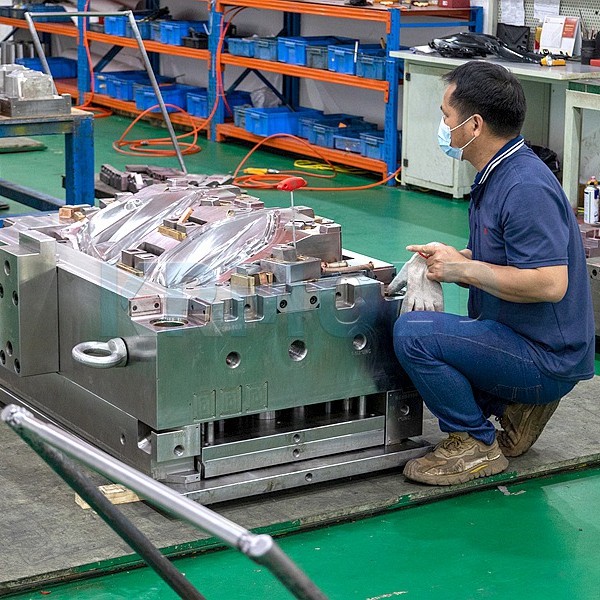

KRMOLD is committed to providing customers with plastic injection molds for various industries, including automotive injection mold, medical device injection mold, home appliance injection mold, consumer electronics injection mold, packaging injection mold, and custom plastic injection mold. KRMOLD understands the unique needs of customers in different industries; therefore, KRMOLD will provide customized plastic injection mold solutions based on specific customer requirements to meet their specific injection molding needs. The following are commonly used injection molding processes. You can click on the video to learn more specific information.

1. What are the Applications of KRMOLD Plastic Injection Molds?

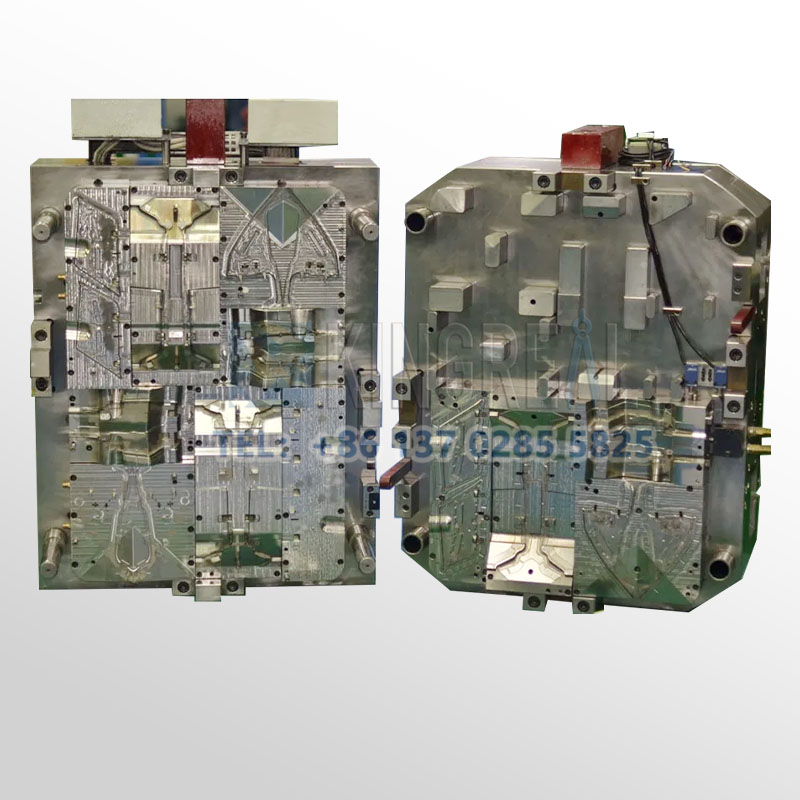

1.1 Automotive Injection Molds

KRMOLD provides a variety of plastic injection molds for the automotive industry, including automotive control panel injection mold, automotive door handle injection mold, and plastic car side mirror injection mold. These plastic injection molds not only require high precision and durability but also meet stringent safety standards to ensure consumer safety.

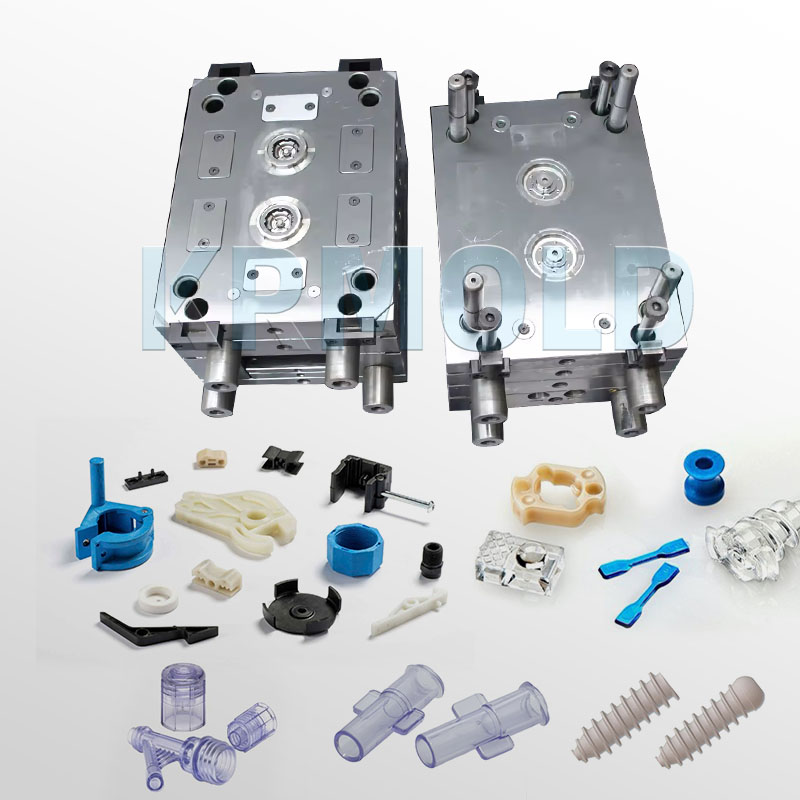

1.2 Medical Device Injection Molds

In the medical industry, KRMOLD plastic injection molds offer extremely high precision and reliability, suitable for producing plastic parts for medical devices and equipment. KRMOLD plastic injection molds are designed with hygiene and bio-compatibility in mind to ensure that the final product meets the stringent standards of the medical industry.

1.3 Home Appliance Injection Molds

In the home appliance industry, KRMOLD offers a variety of plastic injection molds, including washing machine plastic injection mold and plastic plug socket injection mold, for manufacturing the casings and internal components of electrical products. These plastic injection molds require excellent heat resistance and chemical corrosion resistance to meet the challenges of various working environments.

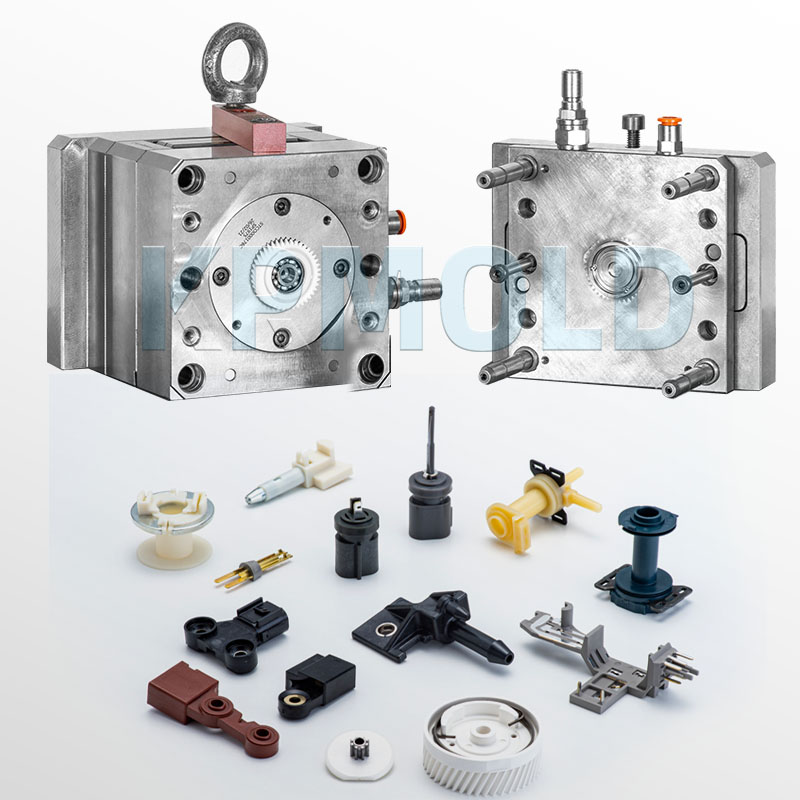

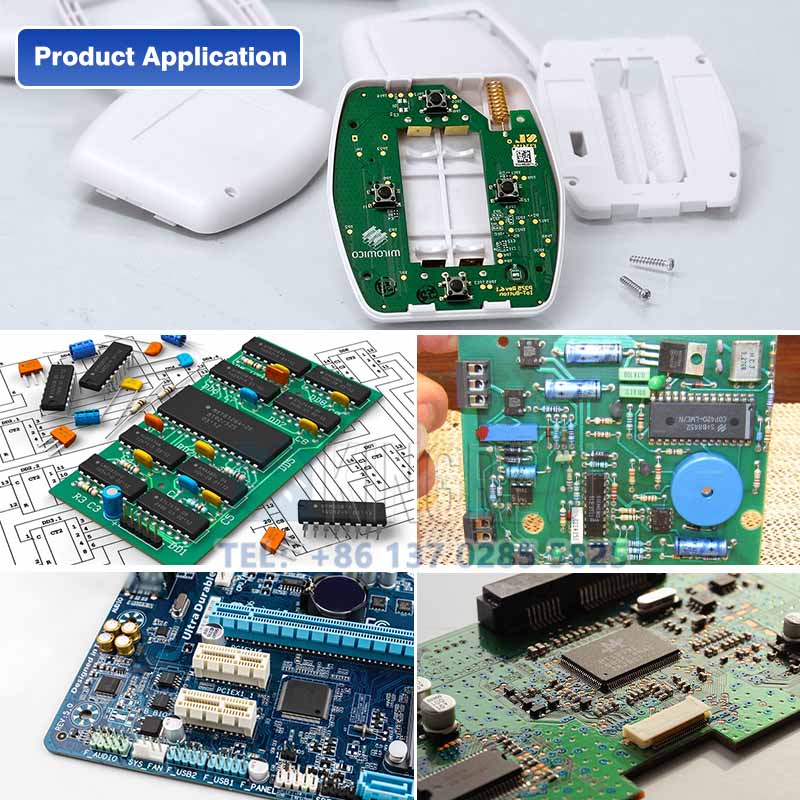

1.4 Consumer Electronic Injection Molds

In the consumer electronics industry, KRMOLD plastic injection molds can produce components with various complex shapes, such as smart device housing injection mold and electronic housing injection mold, meeting the market's dual requirements for aesthetics and functionality. These plastic injection molds are also designed with ergonomics in mind to enhance the user experience.

The packaging industry has an increasing demand for plastic injection molds, especially in the food and pharmaceutical sectors. Leveraging its technological advantages, KRMOLD offers a variety of packaging injection mold solutions, including plastic pallet injection mold and waste bin injection mold, ensuring products are not only aesthetically pleasing but also safe and reliable.

1.6 Custom Plastic Injection Molds

KRMOLD also provides highly customized plastic injection mold solutions to meet specific customer needs. Based on customer drawings, KRMOLD engineers can design and manufacture plastic injection molds that meet customer requirements, ensuring optimal molding results during production.

2. What Services and Support Does KRMOLD Offer?

1. Comprehensive Service System for Plastic Injection Molds

KRMOLD not only provides high-quality plastic injection molds but is also committed to providing comprehensive services and support to customers. Whether customers choose plastic battery case injection molds, automotive headlight holder plastic injection molds, or plastic plug socket injection molds, KRMOLD provides detailed after-sales service and technical support. This includes mold debugging, maintenance advice, and operation training. These services help customers achieve optimal results and improve production efficiency during the injection molding process.

2. Technical Support for Plastic Injection Molds

KRMOLD provides professional technical training and on-site support in its after-sales service to help customers quickly master the usage methods and precautions of the plastic injection molds, ensuring that they can fully utilize the performance of the plastic injection molds. At the same time, KRMOLD technical team will respond promptly to customer inquiries and questions, ensuring worry-free production.

3. Economic Benefits of Plastic Injection Molds

3.1 Long-Term Economic Benefits

Choosing KRMOLD high-quality plastic injection molds will bring significant long-term economic benefits to customers. For example, using high-precision plastic injection molds can effectively reduce material waste. Simultaneously, precise plastic injection mold design can also improve the pass rate and yield of molded products, reducing raw material and production costs.

3.2 Reduced Rework Costs

During the production process, due to the high precision of the plastic injection molds, rework and scrap caused by product defects can be significantly reduced. This not only saves human resources but also effectively shortens the production cycle and improves overall production efficiency.

Whether for automotive, medical, home appliances, or consumer electronics, KRMOLD provides customized plastic injection injection molds to meet the diverse needs of different industries. KRMOLD sincerely welcomes you to contact us to discuss the best applications of plastic injection molds in your business.