What Is Multi Cavity Injection Molding?

——

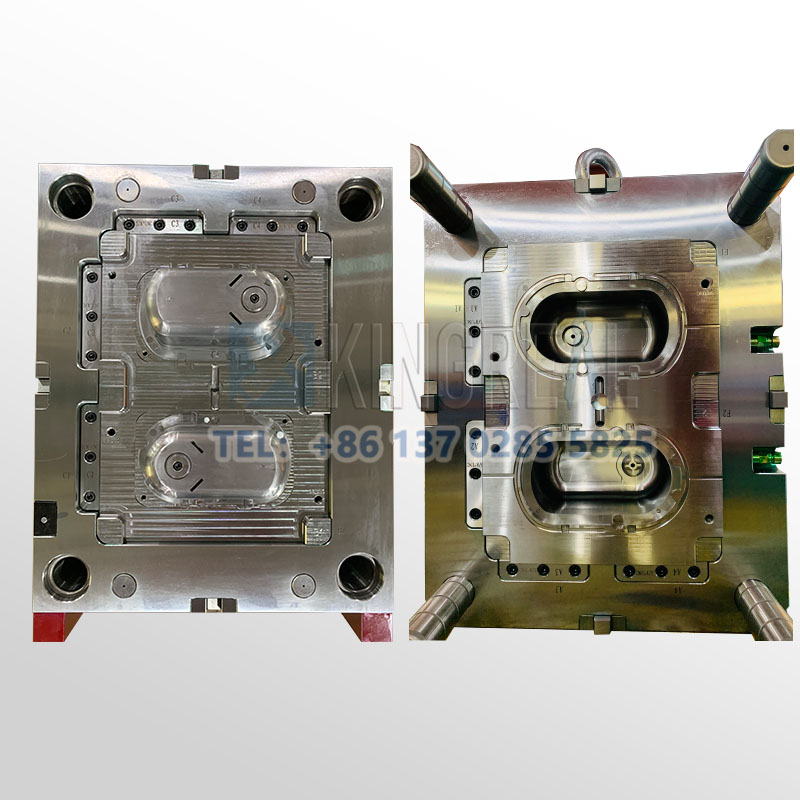

Multi-cavity injection molding uses a multi-cavity injection mold, by integrating multiple identical cavities in the same mold, each cavity replicates the geometry and structure of the product, the injection molding process is usually a high-pressure injection of molten plastic into the main manifold to uniformly fill all the cavities, to achieve the simultaneous production of a number of the same parts within a single injection molding cycle. Customized multi-cavity injection molds are used to meet the needs of high-volume production of a variety of plastic parts and components, increasing production efficiency and output.

As a professional manufacturer in the field of injection molds, KRMOLD is committed to providing customers with complete injection mold design and production solutions, and designing injection molds based on customers' actual production needs. In the automotive, medical, consumer electronics and home appliance industries, where the demand for small parts is growing, KRMOLD designs multi-cavity injection molds to meet the demand for large-scale injection molding production to achieve mass production of parts.

What Is Multi Cavity Injection Molding Process?

——

1.Material Preparation

According to the raw materials of the parts to be injection molded, suitable plastic raw materials (such as PP, ABS, PC, PA, etc.) are selected and dried to remove moisture and prevent molding defects.

2.Plastic Melting

The screw of the injection molding machine heats up the plastic to melt it to the set temperature, and the molten plastic is mixed uniformly in the screw, and the proper viscosity is maintained to ensure fluidity.

3.Injection & Filling

Injecting molten plastic into the runners and cavities of a multi-cavity injection mold. Ensure that the runners are evenly distributed so that the plastic fills all cavities simultaneously to avoid uneven weight or defects in the product.

4.Packing & Cooling

After injection molding is completed, pressure is applied after filling to prevent plastic from shrinking and to increase product density. Plastic is cured in the multi-cavity injection mold, and cooling waterways are used to ensure uniform mold temperatures and to reduce warping and deformation.

5.Mold Opening & Ejection

The multi-cavity injection mold opens and the product is released from the cavity. The product is pushed out of the mold through the ejection system. Multi-cavity molds should ensure that all products are released smoothly at the same time to avoid sticking or deformation.

What Is Advantage Of Multi Cavity Injection Molding?

——

Multi-cavity injection mold can achieve a single molding can produce several parts, such as one out of 60 or even one out of 128, etc., suitable for automotive parts, electronic housings and other high-volume demand. The use of multi-cavity injection molds can reduce the energy consumption of equipment and labor costs spread over more products, the economy is significant.

Multi-cavity injection mold cavity consistency design ensures dimensional tolerances, stable mechanical properties, reducing batch differences. Improve the material utilization rate is high, reduce waste.

By replacing the injection mold or adjusting the parameters, it can be adapted to different materials and complex structures, and can be used in conjunction with insert injection molding.

Application For Multi Cavity Injection Molding

——

| Industries Product | Technical Requirements |

Bumpers Injection Mold, instrument panels injection mold, connectors injection mold. High strength, temperature resistance, high-volume production | |

| Consumer Electronics | Mobile phone housings injection mold, keypads injection mold, charger assemblies injection mold. High surface finish, dimensional accuracy |

| Medical Devices | Syringes injection mold, infusion tubes injection mold , surgical instrument housings injection mold. Bio-compatibility, aseptic molding |

| Packaging Industry | Bottle Caps injection mold, Food Containers injection mold. Light-weighting, rapid prototyping cycles |

How to solve the melt flow imbalance in multi-cavity molds?

——

"In the injection molding process, there are many reasons for melt flow imbalance, among which flow imbalance caused by temperature change is especially difficult to detect and avoid, thus bringing great inconvenience to injection molding production. So, what is a good way to solve it?"

In multi-cavity molding, it is very difficult to get a uniform and balanced melt flow into each cavity. A variety of factors, such as different gate sizes or inconsistent shear patterns in the runner system, can lead to unbalanced melt flow. In hot runner systems, flow imbalances caused by temperature variations at the hot gate are particularly troublesome and not easy to diagnose. Temperature variations in the hot runner not only lead to undermolding or flanging of the cavities during the same injection cycle, but also to different conditions in the same cavity during different injection cycles.

Installing pressure sensors in each cavity should be considered a good solution, which will help to improve the accuracy of the process. By analyzing the cavity pressure data obtained, the effectiveness of the chosen solution can be evaluated and feedback from the closed-loop system can be provided to the injector.

At this point, when the pressure in the mold cavity reaches a preset value, the injector enters the injection phase. By installing pressure sensors, the user is able to clearly see the different pressure peaks between cavities, and even observe which cavity fills first and reaches the highest pressure peak during each injection.

From the injection mold design point of view, KRMOLD uses CAE simulation tools to optimize the runner design, predict the melt flow behavior, adjust the size of manifolds or add overflow zones, and balance the shear heat difference, in order to solve the flow balance problem from the mold design point of view.

About KRMOLD

——

KRMOLD focuses on the field of precision mold design and production, with a manufacturing team of 200+ professional technicians, a technical R&D team of 30+ engineers, and a full-cycle service team covering pre-sales consultation to after-sales maintenance, providing full-process services ranging from mold design, precision processing to injection molding.

KRMOLD Mold is equipped with international first-class equipment such as CNC machining centers, Japan Makino precision spark machine, Japan Shadick wire cutting machine, Japan Toshiba injection molding machine and other domestic and international famous brands of production equipment, to achieve ± 0.002mm processing accuracy, to meet the needs of a variety of high-precision plastic injection molds.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).