1/What KRMOLD Provides?

KRMOLD provides high-quality and comprehensive consumer electronics injection mold solutions to customers in the consumer electronics industry. From consumer electronics injection mold design to consumer electronics injection mold manufacturing, KRMOLD ensures accurate, high-quality, and timely delivery.

KRMOLD can provide customers with:

√ Conceptualization

√ CAD Design

√ Mold Manufacturing

√ Production and Quality Assurance

2/What is Consumer Electronics Injection Mold?

Designed expressly for creating complicated plastic components, consumer electronics injection molds find broad application in the consumer electronics sector. These consumer electronics injection molds enable mass manufacture of high-precision plastic parts without sacrificing product quality, which is vital for electronic devices requiring great tolerances and endurance.

Using their deep engineering knowledge and cutting-edge design capabilities, KRMOLD engineers customize premium consumer electronics injection molds depending on the particular project needs of our clients. KRMOLD consumer electronics injection molds let consumers experience the whole process from first idea to final product.

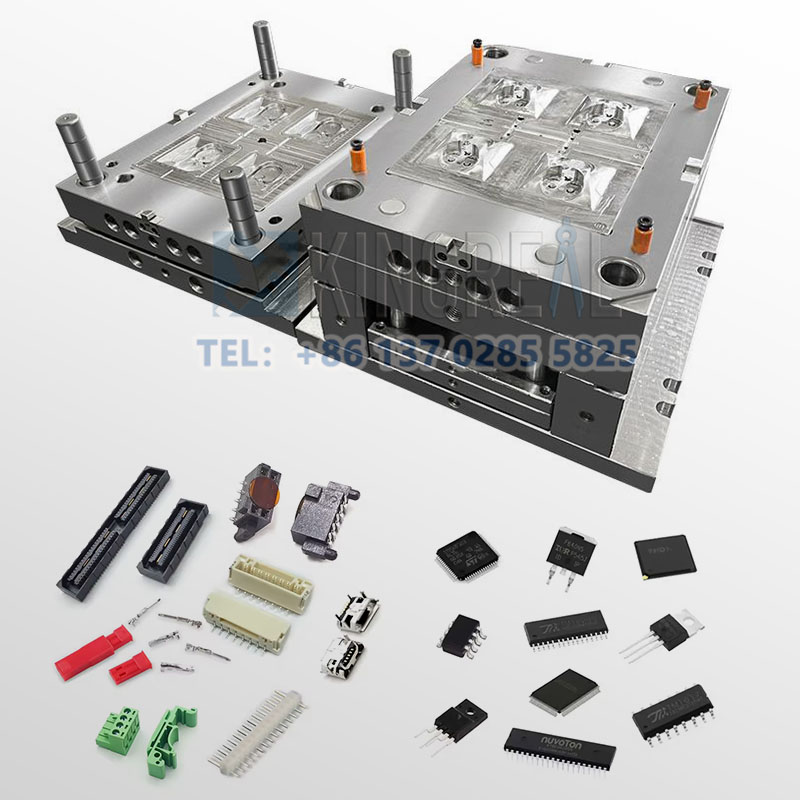

In the consumer electronics field, KRMOLD consumer electronics injection molds can produce a variety of common plastic products, including:

Consumer electronics injection mold for casings

These casings are widely used in products such as laptops, smartphones, game controllers, and wearable devices. They not only effectively protect internal components but also enhance the product's aesthetic appeal.

Consumer electronics injection mold for components and accessories

Buttons and switches are indispensable components in electronic devices, typically manufactured using consumer electronics injection mold. Common buttons include power buttons, function keys, volume controls on game controllers and remote controls, etc. These components are designed to provide good tactile feedback and ensure sufficient durability under frequent use.

Consumer electronics injection mold for connectors and ports

Connectors such as HDMI, audio jacks, and USB are crucial in electrical equipment. They require high precision to ensure proper operation and reliable connections between devices.

Consumer electronics injection mold for internal structural components

Consumer electronics injection molds can also produce internal structural components, including brackets, holders, and retainers for securing circuit boards, batteries, and other precision electronic products.

3/Advantages of KRMOLD Consumer Electronics Injection Mold Manufacturing

Rationality of consumer electronics injection mold design

During the consumer electronics injection mold design process, KRMOLD engineers fully consider the product's structural characteristics, dimensional accuracy requirements, and the feasibility of the injection molding process. First, the parting line is rationally designed to ensure that the product's demolding requirements are met and to minimize marks left on the product surface, thereby guaranteeing appearance quality. Second, accurate calculation of the consumer electronics injection mold shrinkage rate is very important. Different plastic materials have different shrinkage features, therefore the shrinkage rate must be precisely calculated based on material properties and the real product specifications to prevent dimensional variations. Moreover, improving the gate and runner design of the consumer electronics injection mold guarantees equal filling of the molten plastic inside the consumer electronics injection mold cavity. Swiftly lowering weld lines and pressure loss during injection molding.

Material selection for consumer electronics injection mold

When selecting suitable mold materials, KRMOLD engineers consider not only basic properties such as strength, hardness, and wear resistance, but also pay particular attention to the material's processing performance and thermal stability. For high-precision consumer electronics injection molds, materials with good dimensional stability and low heat treatment deformation rates, such as high-quality alloy steel and pre-hardened steel, are prioritized. Simultaneously, material purity and quality consistency are ensured to prevent internal defects from affecting mold precision and performance. When selecting plastic materials, engineers choose appropriate plastic types and grades based on the product's usage requirements and performance characteristics to guarantee product quality and performance.

Precision control in manufacturing

During the manufacturing process of precision consumer electronics injection molds, KRMOLD strictly controls the processing precision at every stage. First, high-precision machining equipment and advanced processes, such as high-speed milling, electrical discharge machining (EDM), and wire EDM, are employed to ensure the dimensional and surface quality of consumer electronics injection mold parts. Second, quality inspection during the machining process is strengthened. High-precision measuring instruments are used to monitor and control the dimensional, shape, and positional accuracy of mold parts in real time, promptly identifying and correcting machining errors. Simultaneously, attention is paid to environmental control, maintaining appropriate temperature, humidity, and cleanliness in the workshop to avoid the impact of environmental factors on consumer electronics injection mold machining accuracy.

Precise assembly and debugging operations

During consumer electronics injection mold assembly, KRMOLD staff strictly adhere to process requirements to ensure the assembly accuracy and fit clearances of parts. For critical mating parts, such as the core and cavity, and the slider and guide rail, fine grinding and debugging are performed to ensure that the fit accuracy meets design standards. During the debugging phase, injection molding process parameters, such as injection pressure, speed, holding time, and cooling time, are optimized based on product quality to ensure that the product's dimensional accuracy, appearance quality, and performance meet requirements.

4/Features of KRMOLD Consumer Electronics Injection Mold

| Multi-material compatibility | KRMOLD consumer electronics injection molds can handle a wide range of materials, including common plastics like ABS and PC, as well as more advanced materials such as TPU and bio-based materials, meeting diverse project needs and varying performance requirements. |

| High production speed | Using KRMOLD consumer electronics injection molds, customers can achieve production volumes of tens of thousands of pieces per day. A single consumer electronics injection mold can produce multiple finished products simultaneously (e.g., a consumer electronics injection mold that produces eight products at once). The entire production process requires no manual intervention; the injection molding machine automatically melts the plastic and injects it into the consumer electronics injection mold. A robotic arm removes the product, which is then laser-engraved, inspected for defects, and finally packaged and stored, ensuring high efficiency and accuracy. |

| Stable quality for consumer electronics injection mold | KRMOLD consumer electronics injection molds achieve a machining precision of 0.01 mm, with an error not exceeding 0.1 mm. This results in plastic products with consistent surface texture and precise dimensions, ensuring that every product meets high quality standards. |

Contact KRMOLD for more information about consumer electronics injection molds!