Injection Molding Solutions for Consumer Electronics Enclosures

——

KRMOLD is able to provide customized injection molding solutions for consumer electronics housings according to customer's production needs. Through the analysis of consumer electronics housings or other electronic products, we can design injection molds to meet the production needs. The cavity structure of the molds needs to be designed in a way that is exactly the same as the geometrical shape of the electronics housings, and the injection molds for consumer electronics housings are manufactured with precision by means of CNC machining equipment. KRMOLD

KRMOLD electronic consumer shell injection mold can help customers achieve mass production of electronic components prototype production needs, through the plastic raw materials for heating and melting into the designed mold cavity, after cooling and shaping to form the shell in line with the needs of electronic product design. As one of the important tools for the production of electronic consumer shell products, the precision, quality and molding and demolding efficiency of the injection mold determines the production efficiency of the final plastic product, such as injection convex mold (core), concave mold (cavity), which directly determines the dimensional accuracy and surface details of the shell. Therefore, how to ensure the production quality of injection molds is crucial.

How To Ensure The Quality Of Injection Molds?

——

“KRMOLD is a professional plastic injection mold manufacturer in China, focusing on the design and manufacture of plastic injection molds for nearly 20 years, dedicated to improving the high quality of plastic injection mold products for our customers.”

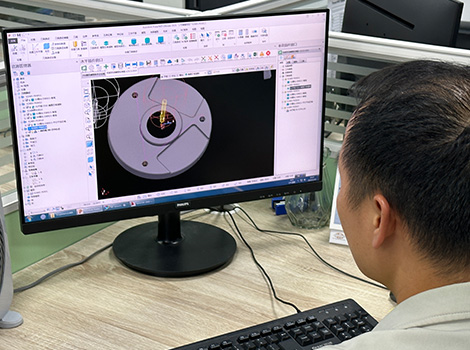

KRMOLD has a professional injection mold design team, using advanced CAD/CAE software to perform 3D modeling, flow and thermal analysis of injection molds by analyzing consumer electronics products, optimizing the design of cavities, runners, and cooling systems, and reducing thermal stress and shrinkage errors.

KRMOLD adopts international famous brand precision manufacturing equipment to ensure the manufacturing quality of electronic consumer shell injection molds, such as Japan Mori Seiki CNC machining equipment, Japan Makino EDM spark machine machining equipment and other advanced manufacturing processes, to ensure that the geometric dimensions and surface quality of each part meet the design requirements.

KRMOLD further improves the hardness and stability of the material through strict heat treatment and surface treatment processes in the processing of injection molds to reduce the risk of deformation in subsequent processing.

KRMOLD has established a complete quality inspection system for injection molds. After the manufacturing process of the injection molds is completed, KRMOLD will arrange the molds to pass through the precision testing equipment such as secondary and tertiary precision testing equipment to surprise the accuracy of the fine measurement. At the same time, KRMOLD will arrange the assembly and trial molding process of the injection molds in the factory, and install the injection molds into the injection molding machine for actual production testing to ensure the accuracy of the finished products.

Advantage Of Electronic Housing Injection Molding

——

1. Improve the production efficiency of electronic consumer shell products

Injection molding can achieve high-speed, continuous mass production, in the early stage of the mold investment dilution, the cost of each product is extremely low, very suitable for consumer electronics such as high market demand for products.

2.Realization of complex structural design

Modern electronic enclosure design often contains small openings, thin-walled structures and complex geometric shapes, injection molding process through precision molds can ensure that every detail to meet the pre-determined size and appearance requirements, thereby improving the overall quality of the product.

3.Multi-material compatibility

Electronic consumer shell can be processed ABS, PC, PP and other high-performance plastics, these materials have impact resistance, heat resistance, insulation and other characteristics, to meet the requirements of the physical properties and safety of electronic products.

Common injection molded products for consumer electronics housings

——

●Cell Phone and Tablet Housings

Injection molds are capable of producing cell phone back covers, bezels, key panels and tablet housings, which require precision molds to achieve small openings and curved details.

●Laptop and Computer Enclosures

Injection molding processes are used to create lightweight, high-strength, smooth-surface chassis and internal dividers to meet assembly requirements.

●Digital Camera and Video Camera Housings

High-precision injection molds can replicate complex optical component designs, ensuring a refined appearance and good heat dissipation.

●Smart Wearable Device Housings

Injection molds can produce smart watches, fitness bands, etc. These products are often small in size and require extremely high dimensional tolerances and precision.

●Electronic accessories shell

Injection molds are capable of producing charger housings, remote controls, headphone housings, USB port housings, etc. These products require high precision and consistency to ensure assembly quality.

FAQ:

1.How to get a quote for custom injection molds?

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

2. How long does it take to get a quote for an injection mold?

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

3. What is the lead time for injection molds?

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

4. How to ensure the dimensional accuracy of the mold and product consistency?

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software.

Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage.

Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

5. Molds are easy to wear or short life, how to improve?

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).