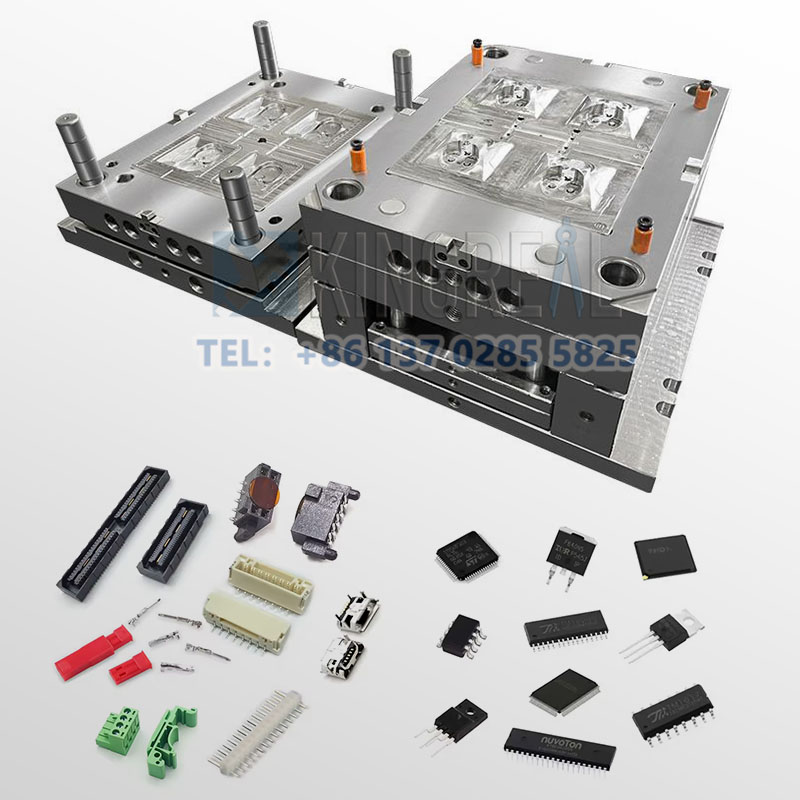

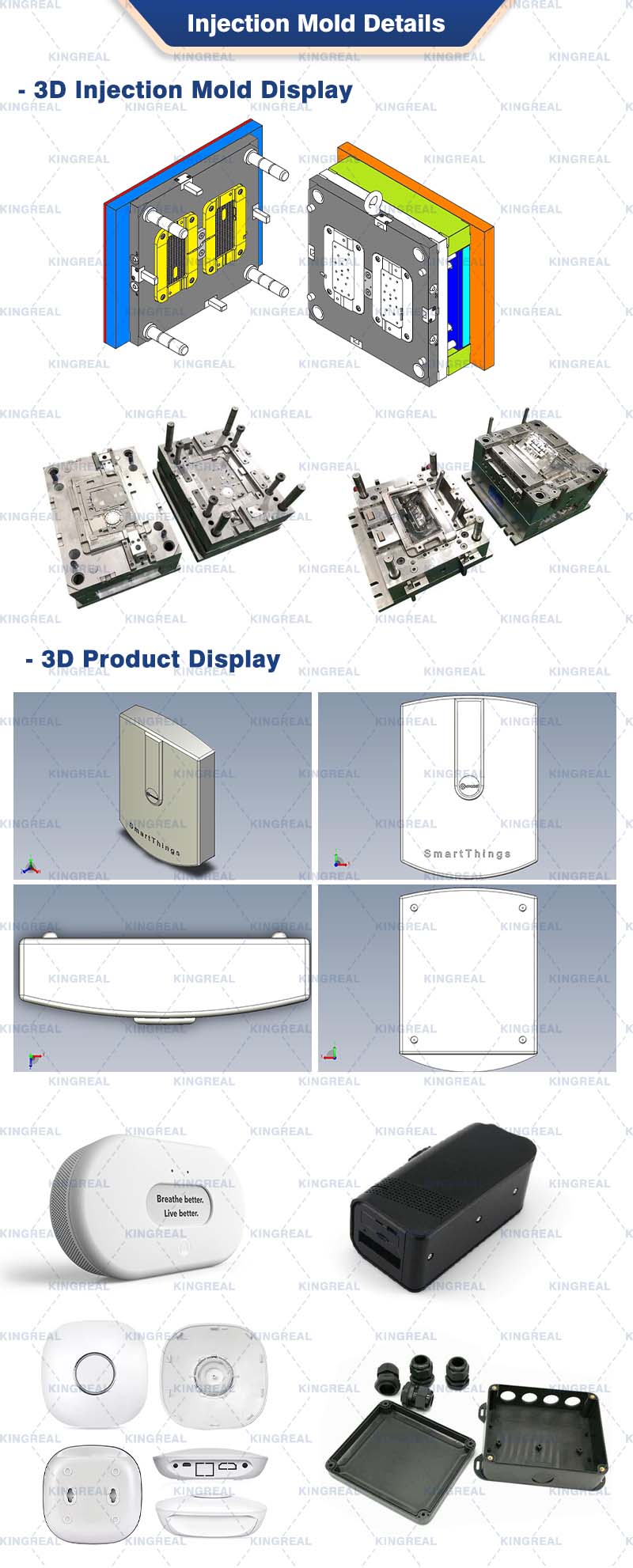

Full Solution For Electronic Component Injection Molds

——

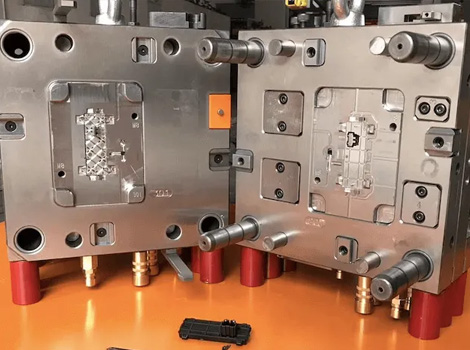

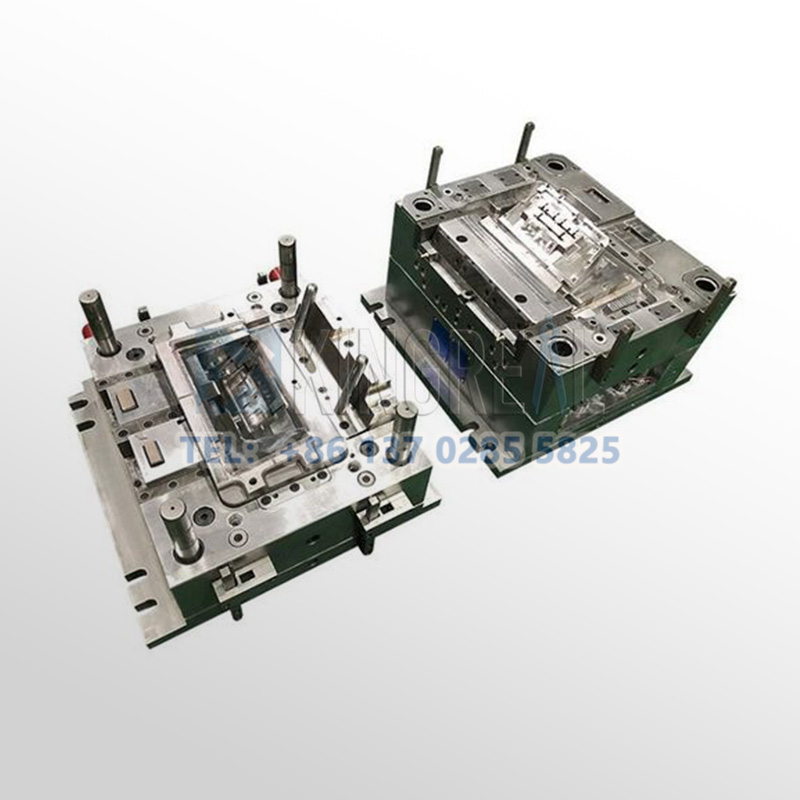

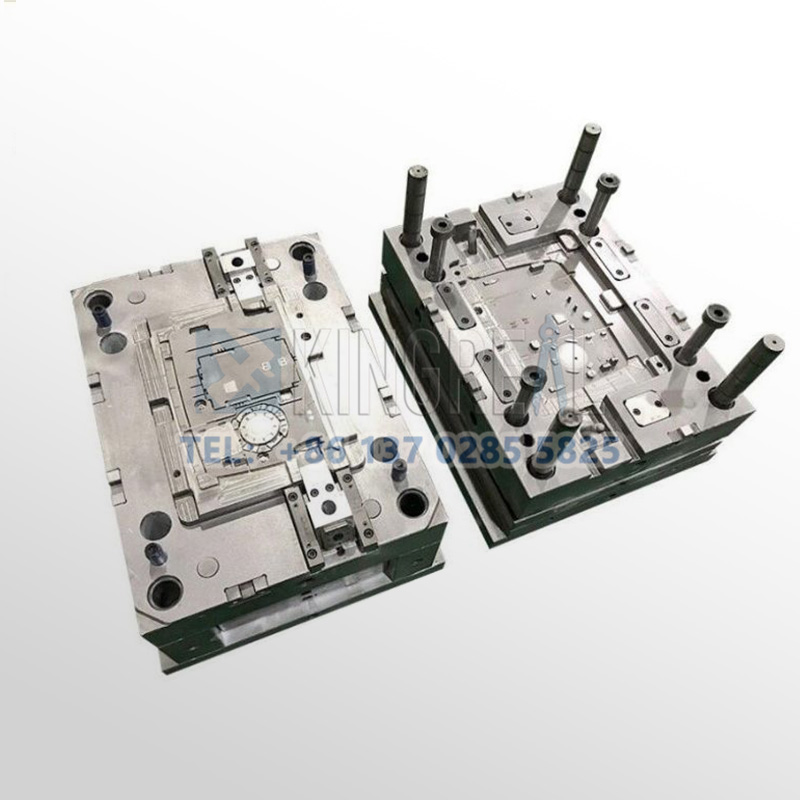

KRMOLD is one of the leading injection mold manufacturers in China, and has been successfully designing and producing high-precision injection molds for customers in the automotive, medical, consumer electronics, and home furnishings industries to solve their production challenges of product quality, precision, and throughput. Among them, electronic component injection mold is the most popular and common injection molding tool in the field of electronics industry, through the analysis of electronic components or electronic product parts in terms of size, appearance, heat resistance and electrical insulation and other aspects of the needs of the design of high-precision injection molding tool.

No matter how complex your electronic component production needs are or what quality problems you encounter in your current production, you can let us know and KRMOLD will provide one-stop design and production of injection molds to meet your needs.KRMOLD electronic component molds have already successfully completed the production of internal components of electronic devices (e.g., board mounting brackets, connector housings, battery compartments, heatsinks components) and Precision connector components (e.g., various plugs, sockets, and other connector housings for electronic assemblies).

Electronic Component Injection Molding Process

——

TEI brake pads, brake discs, and brake steel pipes are suitable for car size four or six piston brake calipers. P60ES is equipped with 355 discs (18 inch front wheels) for modification

Insert molding refers to the injection molding process, the pre-prepared metal or other material inserts into the mold, and then injected into the plastic, so that the insert and plastic into one, forming a product with composite functions. Commonly used in the need to integrate metal parts with plastic parts of electronic products, such as connectors, sensors, switches, etc..

Raw Material Of Electronic Component Injection Molds

——

1. Raw materials for electronic injection molded components

Consumer electronic components often need to have excellent electrical insulation, heat resistance, high impact toughness and dimensional stability to meet the needs of electronic components in actual production and use. The following raw materials are commonly used:

ABS: excellent impact resistance, toughness and processability, good surface gloss, suitable for cell phone shells, consumer electronics products, etc.

PC: high transparency, heat resistance, good impact resistance, commonly used in shell parts requiring high visual effect and structural stability.

PP : Good chemical stability and heat resistance, light weight, commonly used in lightweight design of electronic components.

PA: High mechanical strength and abrasion resistance, suitable for internal structural components and brackets.

2. Electronic Component Injection Molds Material

Generally speaking the injection molding of electronic components need to meet the production characteristics such as high mirror polishing, resistance to abrasion and insulating properties, so the injection molding molds for electronic components are usually considered in the selection of raw materials:

P20, 718, H13 tool steel injection mold: high wear resistance, high strength, high temperature characteristics (such as H13 steel can withstand high temperatures of more than 300 ℃), suitable for high-volume, high-precision production.

S136, SUS420 stainless steel injection molds: strong corrosion resistance, suitable for contact with chemical additives or high humidity environment, to meet the waterproof structure of electronic components injection molding production

7075, 6061 aluminum alloy injection mold: lightweight, good thermal conductivity, suitable for small batch trial production or complex structure molds

Why choose plastic injection molding for electronic component production?

——

“Advantages of Choosing Plastic Injection Molding to Help Solve the Production of Electronic Components”

●Cost Effectiveness: Plastic injection molded electronic component products typically have lower material and processing costs compared to metal processing, which significantly reduces unit costs, especially in high volume production. At the same time, the cost of plastic raw materials (such as ABS, PP) is only 30% -50% of the cost of metal, and injection molding can reduce the secondary processing (such as cutting, soldering), the overall cost reduction of 20% -40%

●Production efficiency: injection molding is suitable for mass production, can be manufactured in a short period of time a large number of parts with high consistency, to meet the demand for high productivity of electronic products. A single cycle of the injection molding machine takes only 15-120 seconds, making it suitable for high volume production (e.g., millions of connectors). Automated processes (e.g., robotic pickup) to reduce labor costs, scrap rate can be controlled below 0.8%.

●Meet the needs of multi-material production: electronic component injection molds can be matched with a variety of engineering plastics, such as ABS, PC, POM, etc., to achieve different mechanical properties, electrical properties and appearance characteristics of plastic electronic products, to meet a variety of application requirements.

About KRMOLD

—

KRMOLD focuses on the field of precision mold design and production, with a manufacturing team of 200+ professional technicians, a technical R&D team of 30+ engineers, and a full-cycle service team covering pre-sales consultation to after-sales maintenance, providing full-process services ranging from mold design, precision processing to injection molding.

KRMOLD Mold is equipped with international first-class equipment such as CNC machining centers, Japan Makino precision spark machine, Japan Shadick wire cutting machine, Japan Toshiba injection molding machine and other domestic and international famous brands of production equipment, to achieve ± 0.002mm processing accuracy, to meet the needs of a variety of high-precision plastic injection molds.

As a long-term mold supplier for Ford, Mercedes-Benz, BMW and other Fortune 500 companies, Kingreal Mold has delivered more than 500 sets of automotive lighting molds, interior parts molds and other cooperative projects, Kingreal Mold produces injection molds for the automotive industry, medical industry, furniture industry, consumer electronics industry and so on.

FAQ: How to get a quote for custom injection molds?

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).