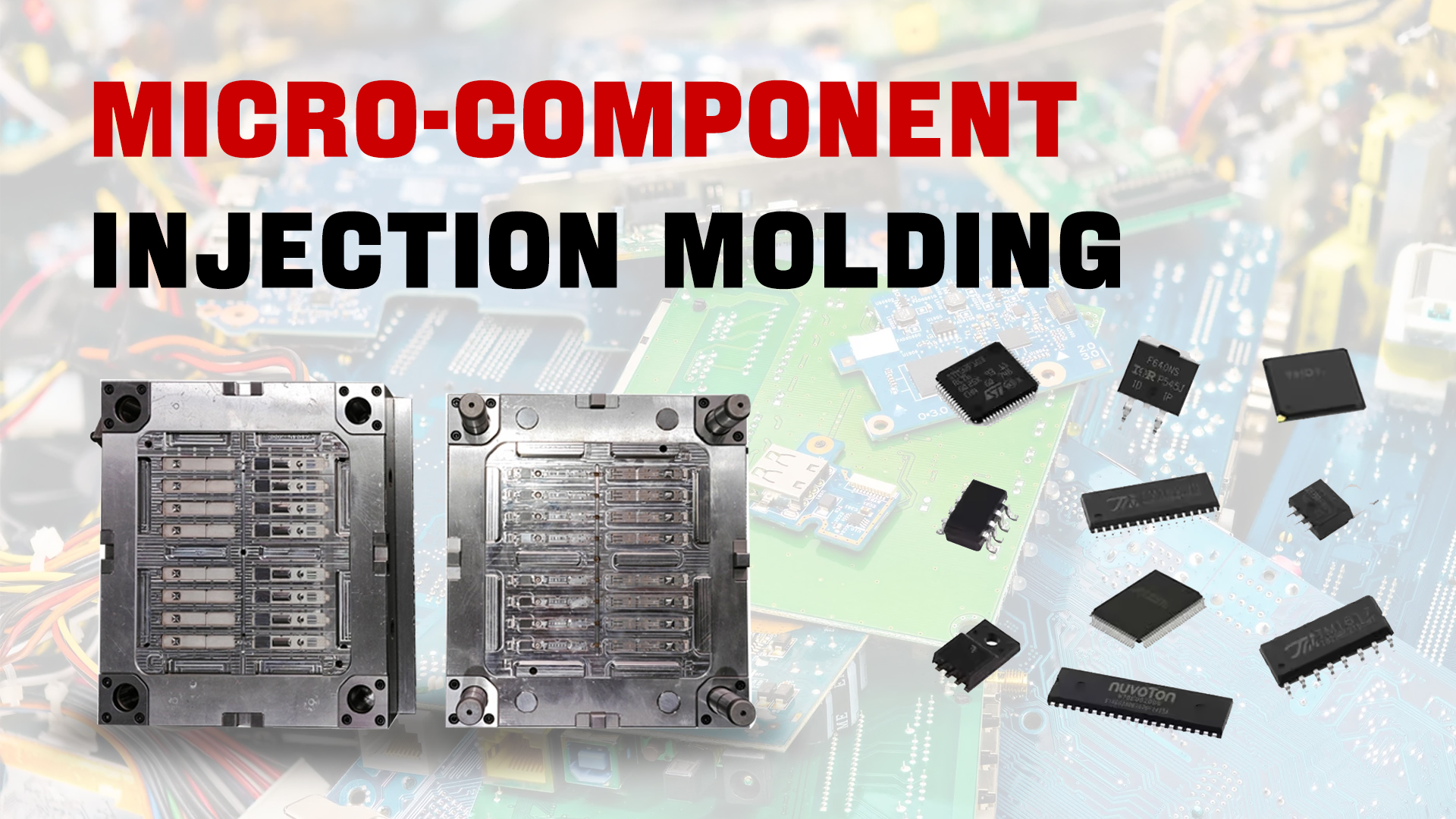

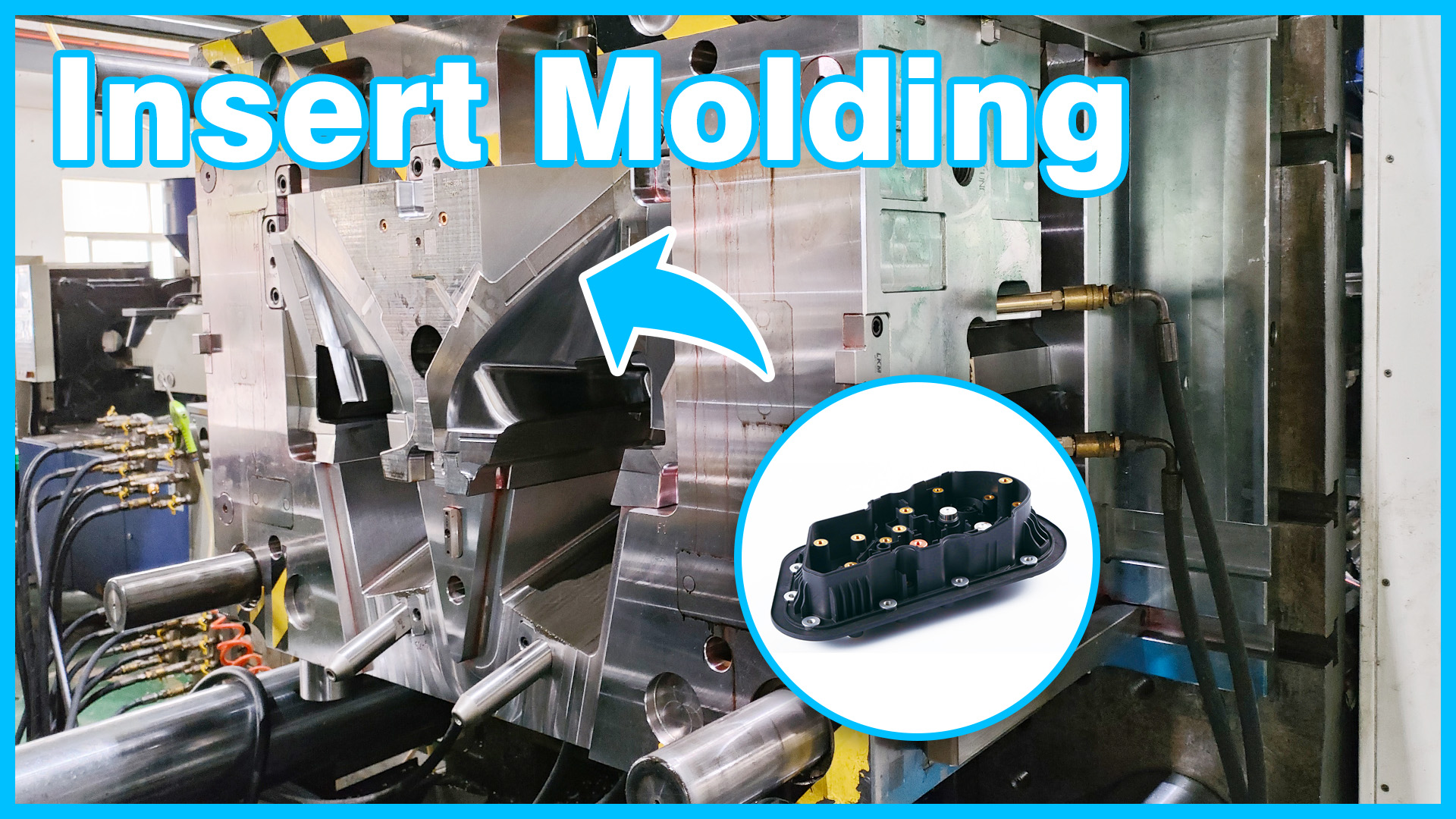

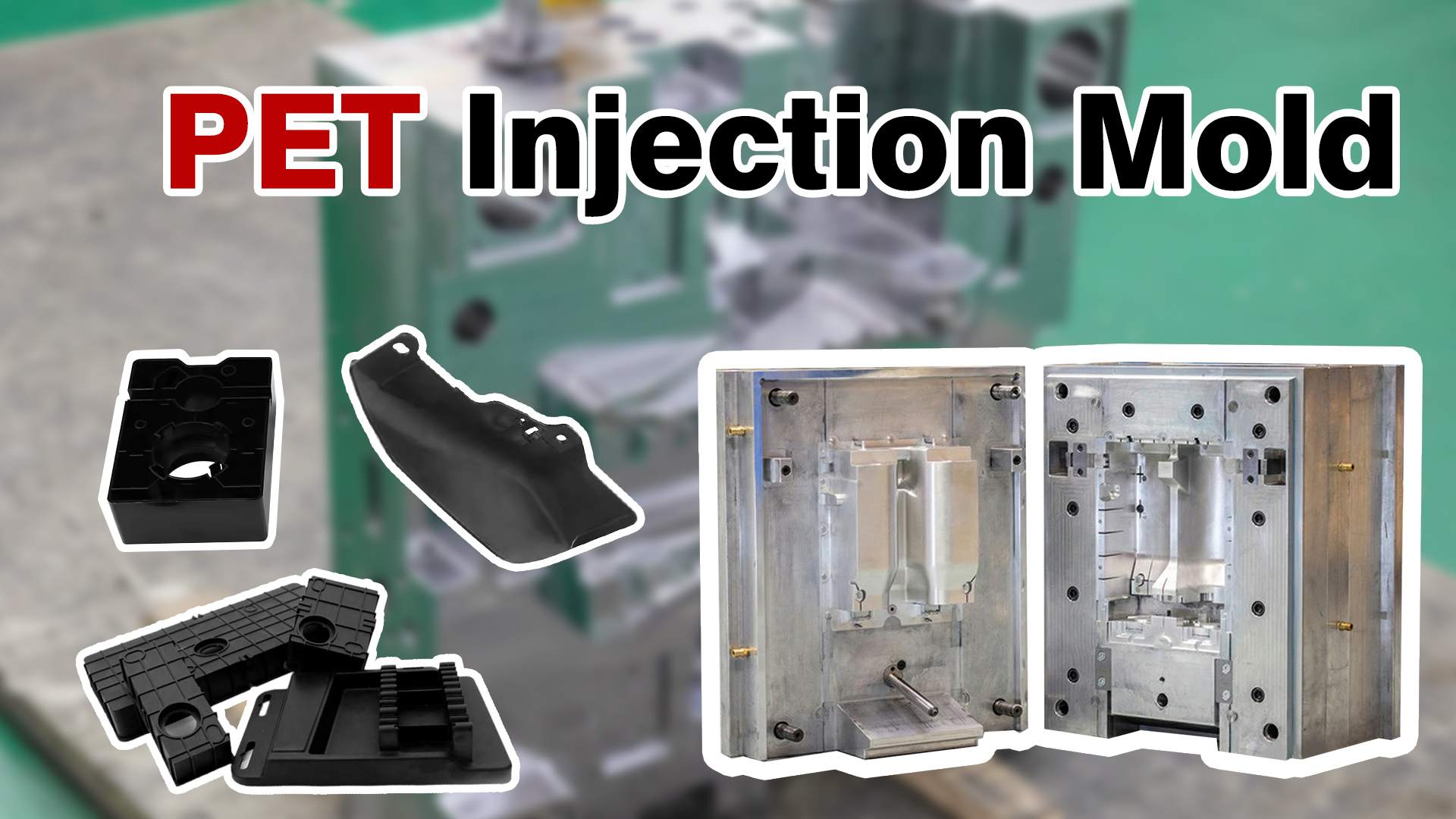

This page showcases how KRMOLD plastic injection molds (including automotive center console frame injection mold, centrifuge tube injection mold, switch socket plastic injection mold, waste bin injection mold, etc.) process and mold various plastic materials to ultimately produce high-quality plastic products. KRMOLD hopes these videos will be helpful in your plastic injection mold selection process. For further assistance, please feel free to contact KRMOLD!

Plastic injection molds are tools used to process various thermoplastic or thermosetting plastics into various shapes and sizes. The desired product is formed by injecting molten plastic into the mold cavity and allowing it to solidify during cooling. KRMOLD offers a variety of plastic injection molds, allowing customers to choose the appropriate injection material based on their needs.

When discussing plastic injection mold manufacturing plans with KRMOLD engineers, please be sure to specify the required injection material. Different materials will directly affect the plastic injection mold design. For example, some high-melting-point materials may require mold materials with high temperature resistance; if the mold material cannot meet these temperature requirements, it can lead to plastic injection mold damage. Furthermore, materials with poor flowability may require longer holding times and more complex runner designs in the plastic injection mold to ensure adequate filling. The different shrinkage rates of various materials necessitate allowing appropriate margins in plastic injection mold design to ensure dimensional accuracy of the finished product. Incorrect shrinkage rate estimation can lead to improper plastic injection mold design, thereby affecting the dimensional and appearance quality of the finished product.