KRMOLD focuses on the field of precision plastic injection mold design and production, with a manufacturing team of 200+ professional technicians, a technical R&D team of 30+ engineers, and a full-cycle service team covering pre-sales consultation to after-sales maintenance, providing full-process services ranging from mold design, precision processing to injection molding. KRMOLD Mold is equipped with international first-class equipment such as CNC machining centers, Japan Makino precision spark machine, Japan Shadick wire cutting machine, Japan Toshiba injection molding machine and other domestic and international famous brands of production equipment, to achieve ± 0.002mm processing accuracy, to meet the needs of a variety of high-precision plastic injection molds.

As a long-term mold supplier for Ford, Mercedes-Benz, BMW and other Fortune 500 companies, KRMOLD has delivered more than 500 sets of automotive lighting molds, interior parts molds and other cooperative projects, KRMOLD produces injection molds for the automotive industry, medical industry, furniture industry, consumer electronics industry and so on. KRMOLD is committed to providing customers with complete production solutions, from design, production to after-sales to complete one-stop service, to help customers solve the production needs, and customers to reach a long-term cooperation and friendly relations.

1

"Injection mold quality assurance helps customers gain production benefits".

As an important process for injection molding of plastic parts, injection molds determine the appearance, precision and quality of injection molded parts. Good injection molds can help customers improve production capacity and gain better market share. As a professional injection mold manufacturer, KRMOLD insists on doing a good job in injection mold design, manufacturing and innovation, providing customers with high-quality injection molds to help customers gain long-term and stable production benefits from the dimensions of injection molding product quality and production efficiency.

2

“Complete injection mold quality inspection system. ”

KRMOLD uses three-coordinate measuring machines and two-dimensional measuring machines to carry out precise inspection processes for injection molds, and uses a mold clamping machine to accurately control the opening and closing of the mold to ensure the sealing and safety of the injection mold during the injection molding process. At the same time, the injection mold is assembled to the injection molding machine in the factory for trial molding, and the precision of the finished product is inspected and recorded. KRMOLD ensures the quality of injection molds through a complete injection mold inspection system and has passed the ISO9000 quality management system certification.

3

"Professional design capabilities, providing complete injection mold solutions."

KRMOLD is committed to providing customized injection mold design solutions for each customer, analyzing the customer's parts injection molding needs, including product appearance, production requirements, application range and environmental characteristics, and providing injection mold solutions that meet customer production needs. For example, in the automotive industry, KRMOLD analyzes the materials, production and injection molding process requirements of automotive mold parts to provide a variety of options such as embedded injection molds and multi-cavity molding injection molds.

4

"Always adhere to one-stop injection mold service"

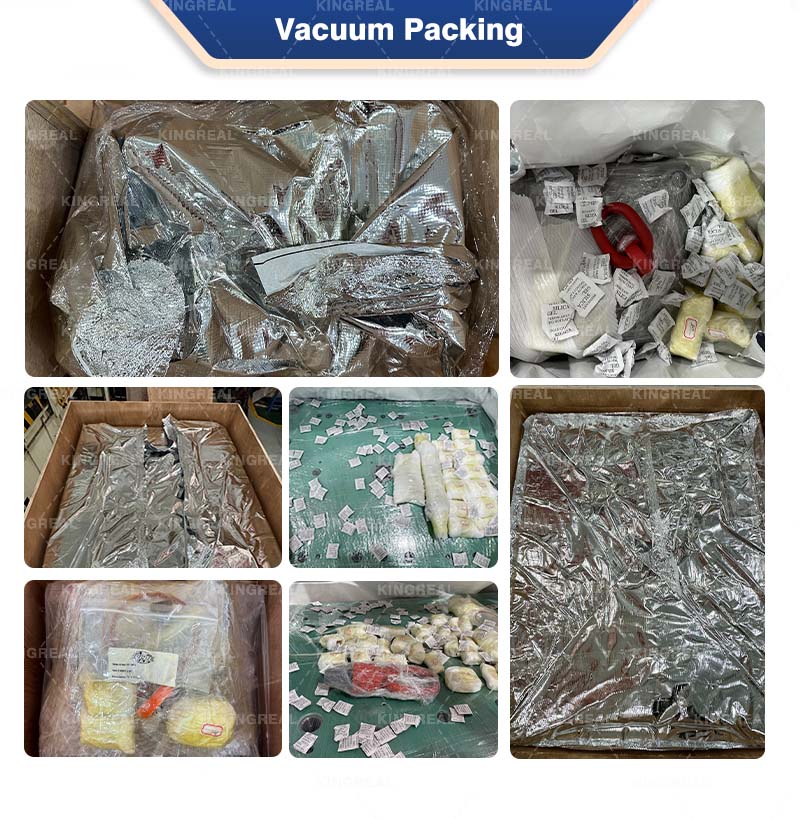

KRMOLD, as a professional injection mold supplier in China, has professional production strength, equipped with internationally renowned injection mold precision manufacturing equipment, professional technical team and production team, providing customers with a one-stop service experience for the entire process of injection mold design, production, testing, trial mold, delivery, and after-sales guidance. At the same time, customers from all over the world are welcome to visit the KRMODL injection mold factory.

“In 2025, KRMOLD will still do a good job in injection mold manufacturing for all customers!”

Why Choose KRMOLD?

——

One-stop full-process service

KRMOLD provide full-process service from integrating requirements, mold design and manufacturing to delivery and after-sales service.

The technical team is deeply involved in the customer's product design stage, optimizing the mold structure and designing the mold drawings through the mold flow analysis software (such as Autodesk Moldflow, UGNX). Equipped with imported CNC, Shadick wire cutting machine, mirror discharge equipment and other precision processing equipment to achieve ±0.02mm precision;

Complete quality control system

There is a full chain production workshop, using Makino five-axis machining centers, Haitian injection molding machines and other well-known equipment at home and abroad to avoid delays in outgoing processing.

Through the CMM coordinate measuring machine, three-dimensional inspection instrument full inspection of key dimensions, the implementation of PDCA cycle quality management. Meanwhile, we provide complete quality inspection report of injection molds.

Accurate delivery control to guarantee the project schedule

Through digital management, production progress monitoring from the beginning of the order, for different orders and delivery date for data monitoring, once there are factors that may be delayed, immediately arrange to speed up the production schedule, to ensure that the customer in the delivery period to complete the manufacturing of plastic injection molds.

"We have a large-scale intelligent workshop to support secondary processing such as silk-screen printing, welding, spraying, etc. We strictly implement the quality system of ISO13485 and IATF16949; meanwhile, we provide free transportation, regular mold maintenance and one-year warranty service."