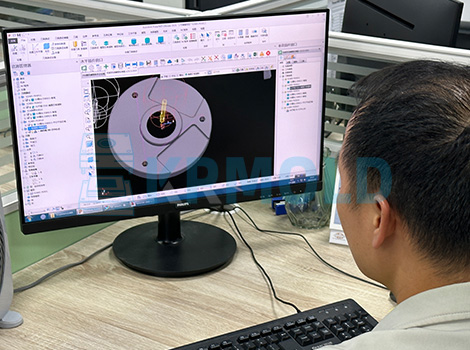

Mould Design

——

"20 years of professional experience, transparent collaboration throughout the process"

KRMOLD has nearly 20 years of experience in injection mold design. The team consists of more than 30 senior engineers. The team uses CAD/CAM collaborative design system to design injection molds throughout the process, and realizes real-time sharing of 3D models and mold flow analysis data.

◆Precise demand matching: KRMOLD synchronizes design progress with customers through weekly video conferences, opens design document permissions, and ensures zero deviation between technical solutions and needs.

◆Risk pre-management: The technical team uses Moldex3D mold flow analysis technology to predict and avoid potential defects such as shrinkage and warping 15 days in advance, and provides 3 sets of optimization solutions.

◆Intellectual property protection: KRMOLD uses blockchain evidence storage system, and design drawings and communication records are encrypted and traceable throughout the process.

So far, KRMOLD has completed design solutions with a first version success rate of 95% for more than 200 international brands in the fields of medical devices, automotive electronics, etc. ISO9001 quality control nodes are embedded in the design stage, supporting synchronous verification by third-party authoritative institutions, and providing free structural optimization consultation during the mold life cycle to assist customers in responding to product iteration needs.

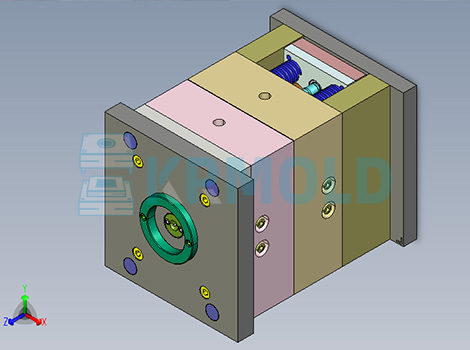

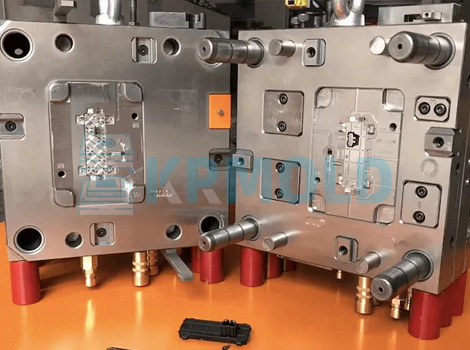

Mould Manufacturing

——

"Precision manufacturing system with full traceability"

KRMOLD has a complete injection mold manufacturing workshop, covering the entire process from mold design, manufacturing, testing, assembly, mold trial to shipment. Key process equipment is equipped with IoT data acquisition terminals to achieve real-time monitoring of equipment status and processing parameters. Each process performs ISO8062 full-size inspection, key dimensions use 3D scanning to compare original CAD data, raw material batches are locked through the ERP system, and a complete production progress monitoring system ensures delivery date.

"Transparency in traceability of injection mold manufacturing equipment"

Japan Makino five-axis CNC (serial number can be checked online) ±2μm processing accuracy | Japan Makino EDGE3 model EDM mirror processing Ra0.1μm | Hexagon three-coordinate measuring machine (Annual calibration certificate of the Metrology Institute)

*Remote monitoring system: open the camera permissions of designated machines, customers can view the processing progress in real time (support bilingual operation log export in Chinese and English)

*Sustainable manufacturing commitment: adopt Makino MACO energy-saving CNC system, unit mold energy consumption is reduced by 27% (carbon footprint report can be used for ESG audit)

*After-sales quick response: provide 48-hour on-site maintenance service during the warranty period, and provide free mold maintenance intelligent reminder system.

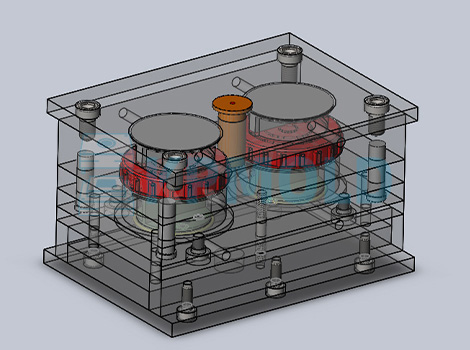

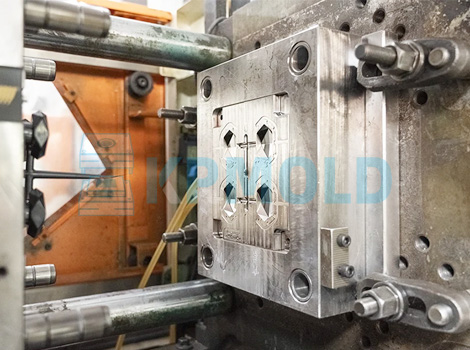

Mold Trial Service

——

KRMOLD is equipped with professional injection molding machines (Japan Toshiba EC350S) in the factory workshop to provide injection mold trial services and adjust mold parameters according to the results. Through the full-process standardized mold trial system and intelligent process closed-loop management, it provides customers with quantifiable, traceable and reproducible mold trial solutions, helping to achieve dual guarantees of mold performance and mass production stability. After the injection mold is produced, it is assembled, installed and injection molded in the factory. For problematic injection molded products, the position of the ejector pin is adjusted to reduce product deformation, or the cooling system is optimized to shorten the molding cycle.

In order to ensure the quality of injection molds, KRMOLD has established a complete quality inspection system, including precise three-dimensional and two-dimensional mold quality inspection equipment and a quality inspection team specifically responsible for controlling the precision of injection molds, and insists on providing customers with high-quality and high-precision injection mold products.

Injection Molding Service

——

“KRMOLD can provide a variety of different injection mold molding process services, and equip different injection mold process production processes according to the characteristics of the plastic products that customers need to mold, production volume and other requirements.”

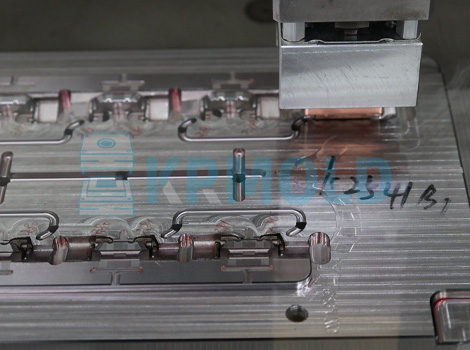

Insert Molding is a process in which the insert is pre-fixed in the appropriate position in the injection mold, and then the plastic is injected for molding. After the mold is opened, the insert is tightly buried in the plastic by the cooled and solidified plastic to obtain a product with inserts such as threads and electrodes. The positioning of the insert in the mold needs to be achieved through a positioning boss or a floating positioning pin.

Overmolding is an injection molding technology in which one material is molded over another material to form a single part. This process involves multiple injection molding steps, each of which adds a new layer of material to the previously molded component. Overmolding provides flexibility for designing products with different physical, tactile and functional properties, usually combining rigid and flexible materials.

Multi Cavity Injection Molding

KRMOLD provides multi-cavity injection molding molds, multi-cavity injection molding can make multiple parts simultaneously in one mold. The design of the mold ensures uniform flow and quality of all parts. Important components include mold base, runners, gates, and injection system. They work together to make precise products.

"The positioning boss of the injection mold needs to cooperate with the plane of the insert. For threaded inserts, the floating positioning pin is supported by a spring to accommodate dimensional errors, and the shoulder diameter is larger than the insert diameter to prevent overflow."