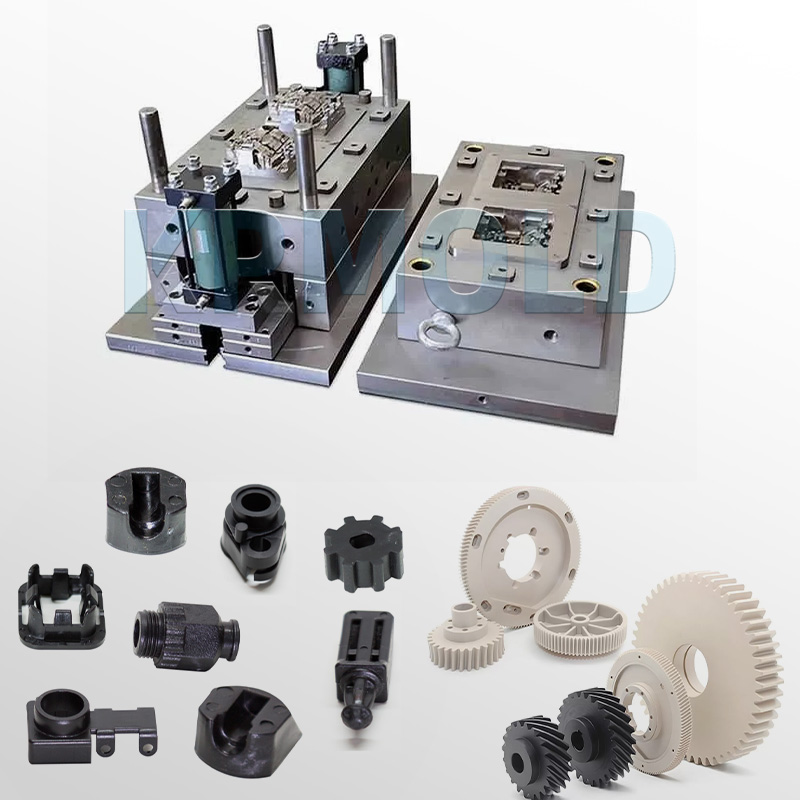

KRMOLD, a professional plastic injection mold manufacturer, is committed to providing customers with high-quality plastic injection molds covering multiple application areas. KRMOLD plastic injection molds are tailored to different customer needs and product characteristics, ensuring that each plastic injection mold performs optimally in its specific industry. Below are some of the featured plastic injection molds offered by KRMOLD in various fields:

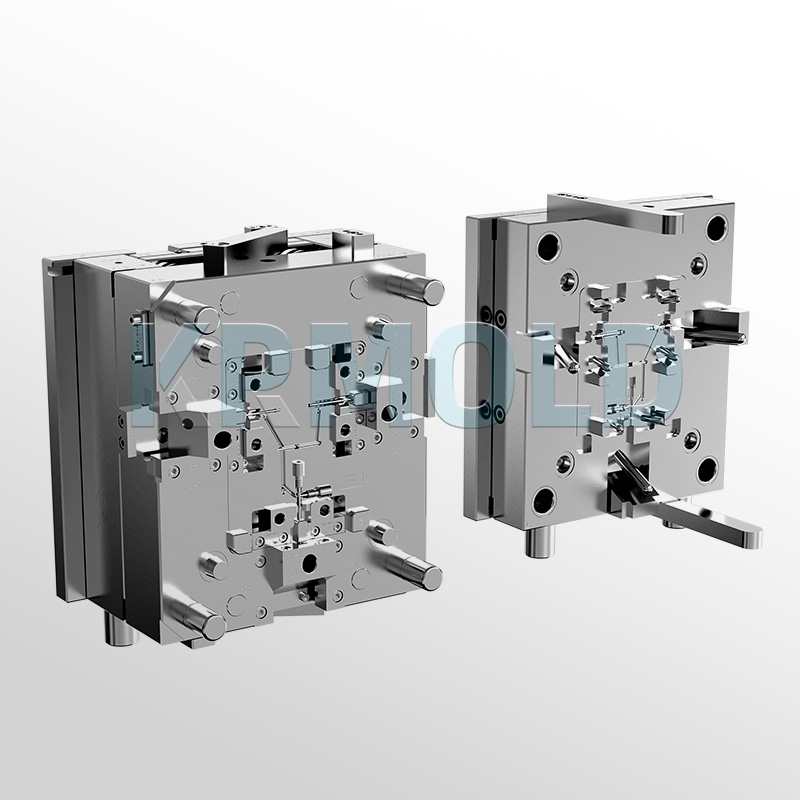

| Automotive Industry | Automotive Lighting Injection Mold, Auto Rearview Mirror Injection Mold, Car Bumper Injection Mold, Auto Engine Cover Injection Mold, Car Center Console Frame Injection Mold, Automotive Wheel Arch Liner Injection Mold, Gearbox Housing Injection Mold... |

| Medical Industry | Surgical Instrument Injection Mold, Medical Device Housing Injection Mold, Disposable Medical Supplies Injection Mold, Centrifuge Tube Injection Mold... |

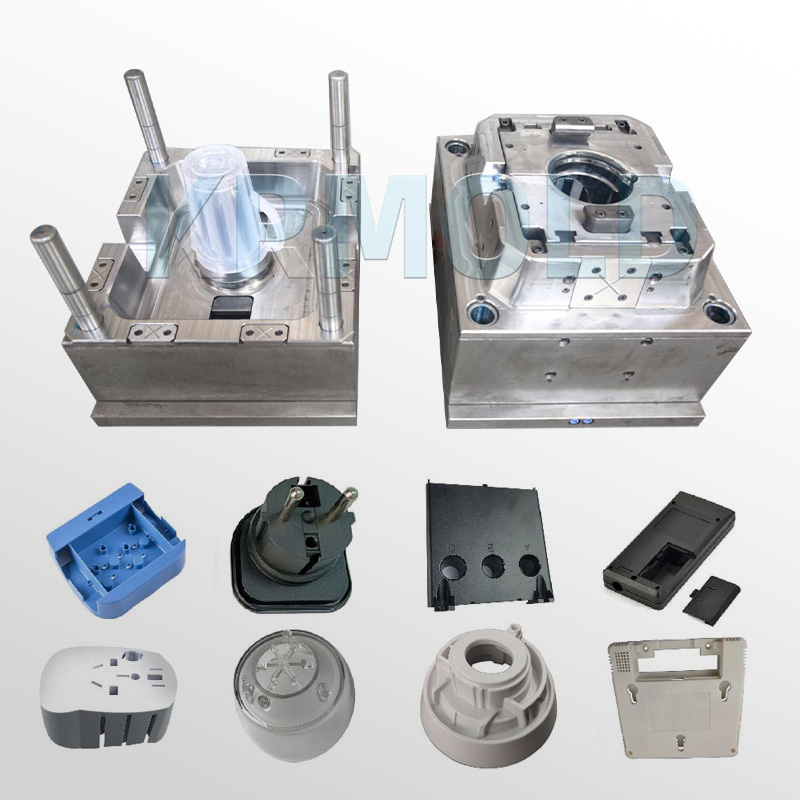

| Consumer Electronics Industry | Smart Device Housing Injection Mold, Electronic Housing Injection Mold, Electronic Component Injection Mold... |

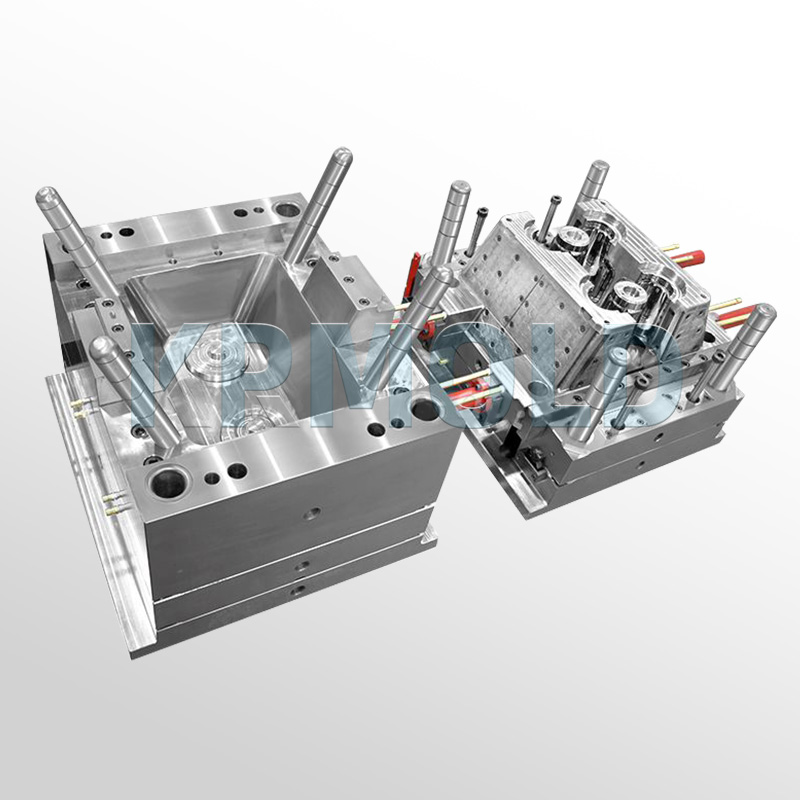

| Home Appliance Industry | Washing Machine Plastic Mold, Plastic Plug Socket Injection Mold, Household Appliance Shell Injection Mold, Plastic Chair Injection Mold... |

| Packaging Industry | Plastic Bottle Cap Injection Mold, Plastic Pallet Injection Mold, Waste Bin Injection Mold... |

Material Selection for Plastic Injection Molds

----------------------------------------------------

KRMOLD understands that excellent plastic injection molds rely on suitable materials. KRMOLD offers customers a wide range of material options to meet the needs of different applications. These materials include:

-Acrylic (PMMA): A high-transparency optical material suitable for products requiring good visual effects.

-Acrylonitrile-butadiene-styrene (ABS): A high-performance engineering plastic widely used in various injection-molded parts.

-Nylon (PA): A wear-resistant and heat-resistant specialty material widely used in automobiles and electronic equipment.

-Polycarbonate (PC): A high-impact, transparent material commonly used in electronic products requiring high strength.

-Polyethylene (PE): The most widely used general-purpose plastic with good chemical stability.

-Polystyrene (PS): A cost-effective everyday material suitable for mass production.

-Polypropylene (PP): A lightweight, chemically resistant material widely used in various consumer products.

-Polyoxymethylene (POM): The first choice for precision mechanical parts, possessing excellent mechanical properties.

-Thermoplastic elastomers (TPE): Rubber alternatives, offering more flexible application options.

-Thermoplastic polyurethane (TPU): A high-performance elastomer with excellent wear resistance and tear resistance.

In addition, ABS, silicone, PEI, and PEEK are also commonly used options in KRMOLD plastic injection mold design and production, meeting the diverse needs of different customers.

At KRMOLD, we are committed to providing our customers with the highest quality plastic injection mold solutions. If you need more information about KRMOLD plastic injection molds or have any specific requirements, please feel free to contact us!