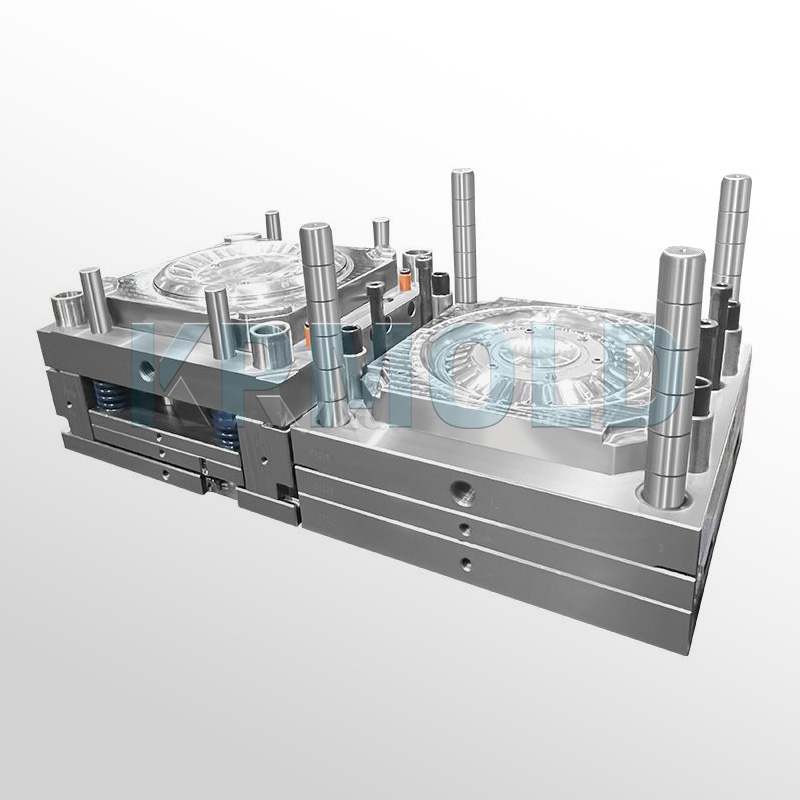

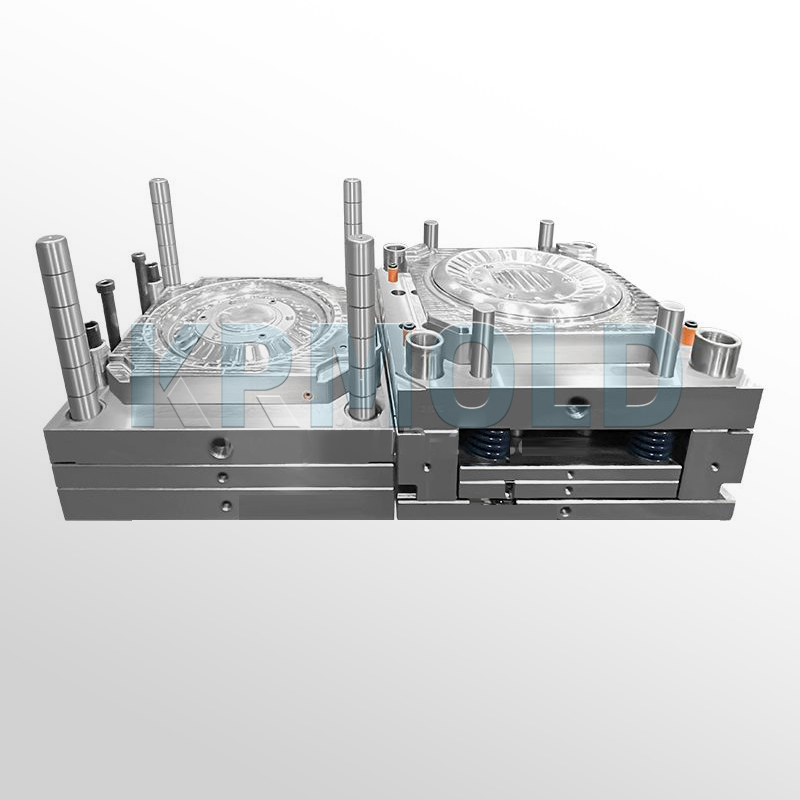

What Is PC Injection Molding?

——

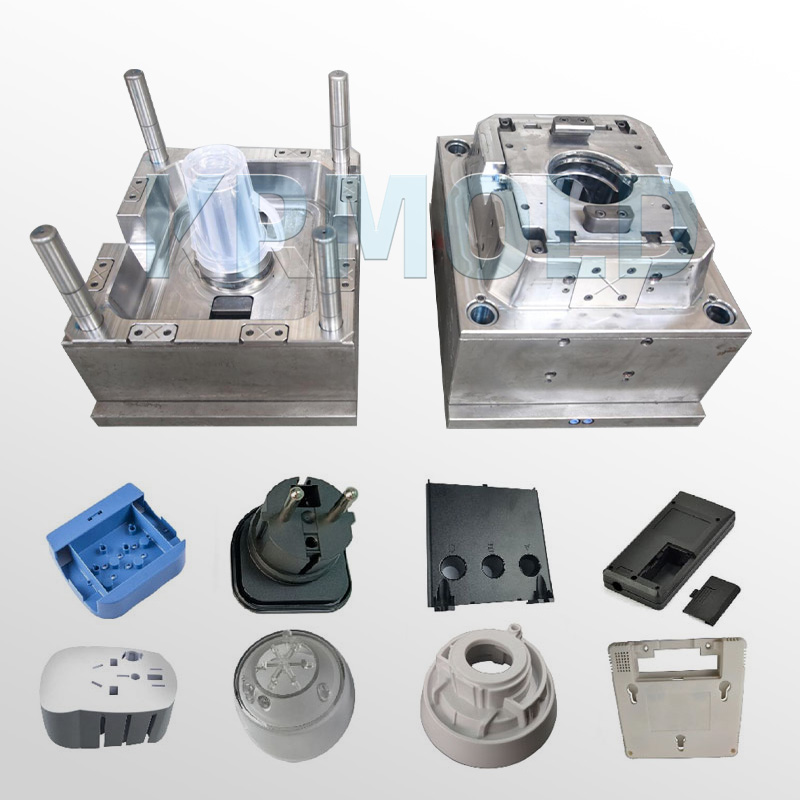

PC injection molding refers to Polycarbonate injection molding. PC is one of the plastic materials used in injection molds. It is widely used in the automotive industry, medical industry, home appliance industry, packaging industry and other fields for its high strength, rigidity, impact resistance and heat resistance.

Polycarbonate comes in many types or grades. Common grades of polycarbonate include medical grade polycarbonate, food grade polycarbonate and general grade polycarbonate. And a major advantage of using optical-grade PC molds is that polycarbonate has excellent optical properties and most light can pass through. Even when colored, this amorphous plastic can maintain its durability and strength. Sometimes, polycarbonate is used instead of other materials because PC can maintain its physical properties over a wider temperature range.

Benefits Of Impact-Resistant PC Housing Molds

——

① Fast cycle

PC injection molding is much faster than other processing methods, such as vacuum forming and machining. Faster production cycles mean that Impact-Resistant PC Housing Molds can produce more parts in the same amount of time. This not only reduces the cost of each part, but also improves overall production efficiency, allowing companies to meet market demand more quickly.

② Avoid surface defects

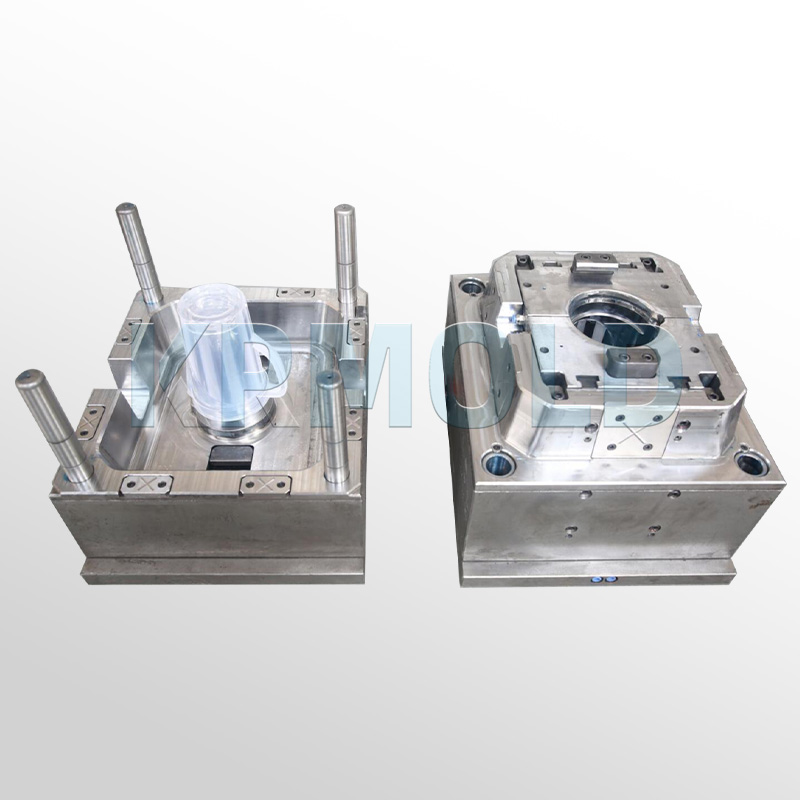

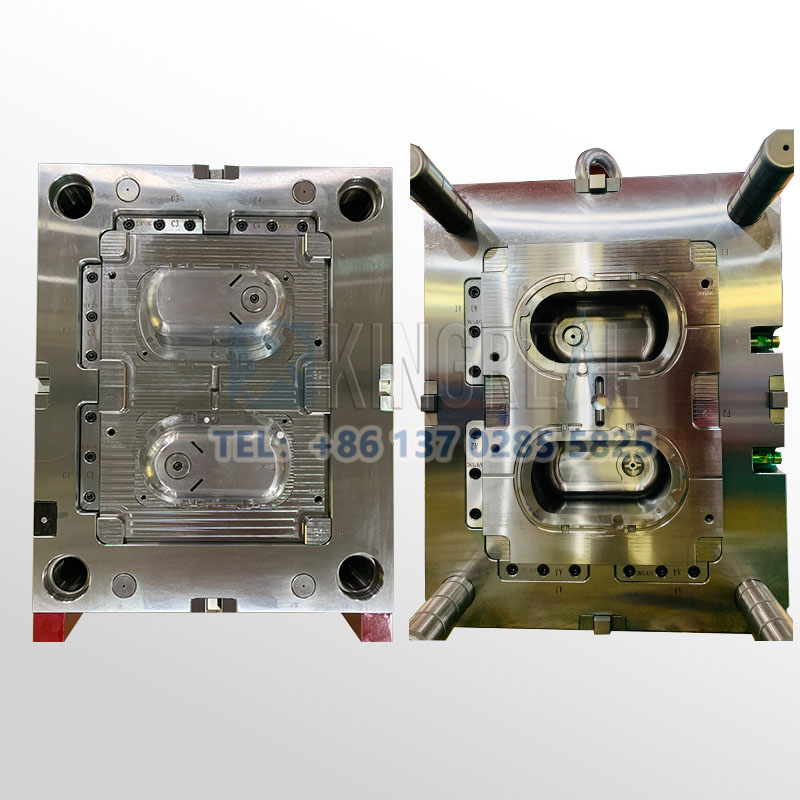

The surface smoothness of polycarbonate materials is very important for certain applications that require high transparency, such as car headlights. During the PC Injection Molding process, the surface quality of the part is directly affected by the smoothness of the Bulletproof Glass Injection Molds. If the High-Performance Plastic Molds are finely polished to achieve a mirror effect, this smooth property will also be transferred to the molded part. This can effectively reduce surface defects and make the final product more perfect.

③ Can adapt to a variety of part sizes

A big advantage of PC Injection Molding technology is that it can produce parts of various sizes. Almost any size of Transparent PC Molds can be designed as needed, so that parts of various sizes can be customized to meet the needs of different industries. This flexibility makes the manufacturing process more efficient and can respond quickly to market changes.

④ Achieve excellent part-to-part repeatability

PC injection molding uses precision-machined Impact-Resistant PC Housing Molds, which ensures that the parts produced have high consistency in size and quality. Although there may be some slight changes in the size of the part, these changes are generally kept within acceptable ranges. By using statistical process control, these changes can be effectively prevented from being amplified by machine wear, process instability or material differences. This repeatability is especially important for parts that require high precision, such as lenses.

⑤ Produce products with different designs and shapes

As long as the proper design principles (called DFM, design for manufacturing) are followed, Bulletproof Glass Injection Molds can be used to produce parts of various styles and shapes. This includes using technologies such as overmolding and insert molding to manufacture parts made of a combination of multiple materials. This diversity allows designers to achieve more complex and innovative product designs to meet the needs of different users.

Applications Of Optical-Grade PC Molds

——

The market demand for PC Injection Molding is very large, and the products produced by it are widely used in various industries. The following are some key application examples listed by KRMOLD:

Medical Industry

(1) Syringes: Polycarbonate has excellent corrosion and heat resistance and can withstand radiation, ethylene oxide or steam autoclave sterilization. These properties make it an ideal material for medical devices that require high-temperature sterilization.

Optional plastic injection molding process:

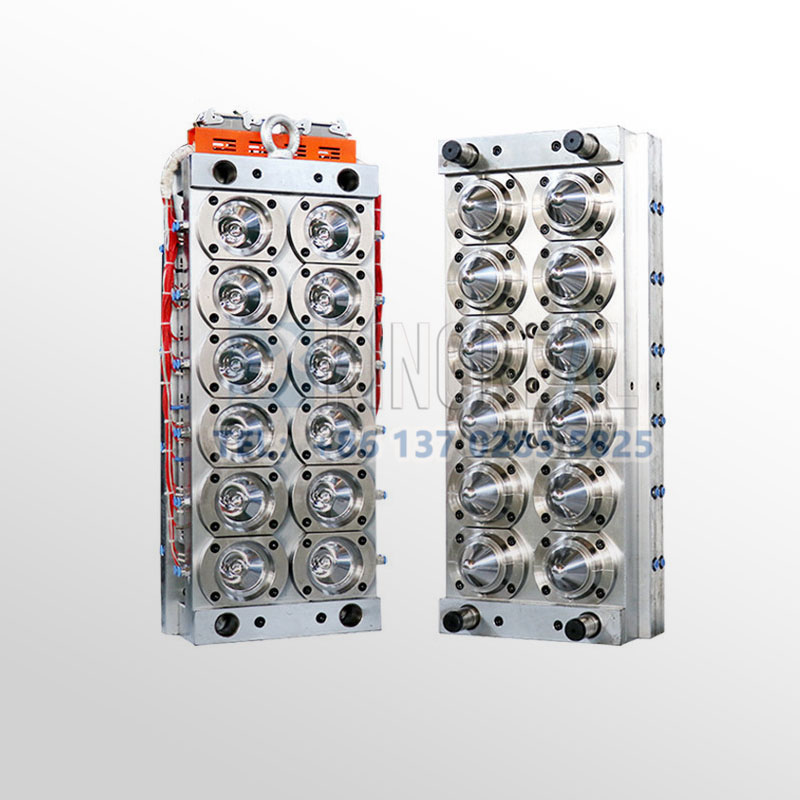

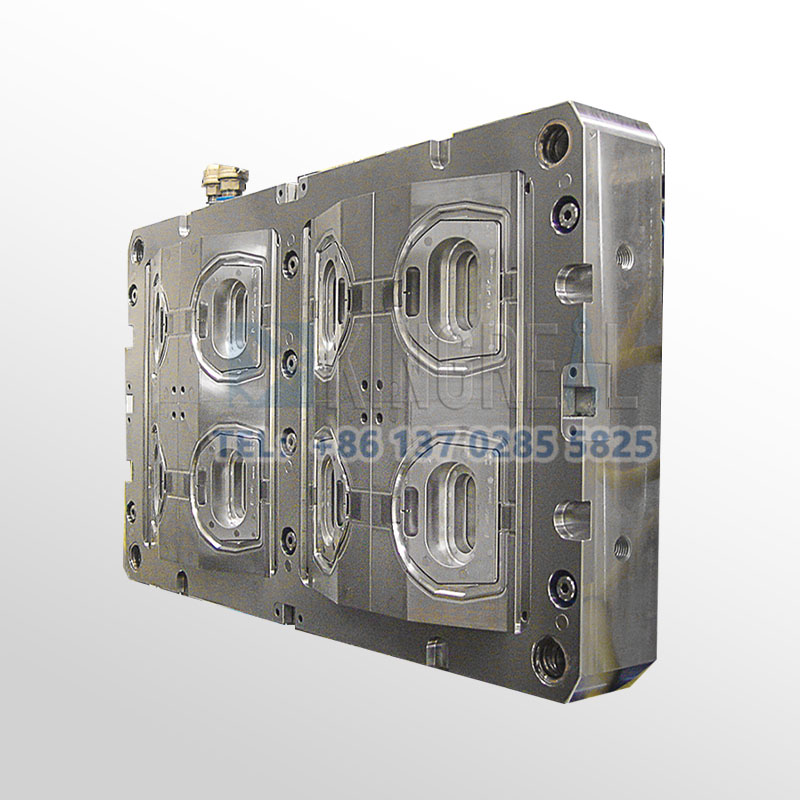

① Multi cavity injection molding

Multi cavity injection molding allows multiple medical syringes to be produced simultaneously in the same injection molding cycle, which is very effective in the production of syringes. By using multi cavity injection molding, manufacturers can significantly improve production efficiency and reduce the cost of each syringe. This process is particularly suitable for large-scale production, ensuring the consistency of quality and performance of each syringe, meeting the high standards required by the medical industry.

Micro molding is an injection molding process used to produce small and precise parts, which is suitable for manufacturing small components of syringes. This process can achieve extremely high dimensional accuracy and surface finish, ensuring the consistency of the various parts of the syringe in terms of function and appearance.

The micro molding is particularly suitable for the production of components such as needles and pistons of small syringes, which can meet the high standards and high precision requirements of the medical industry, while improving production efficiency and reducing production costs.

(2) Glasses and lenses: Polycarbonate is often used in eyeglass lenses because of its good optical clarity and UV resistance. After adding UV stabilizers, polycarbonate lenses can effectively resist harmful UV light and protect eye health.

Optional plastic injection molding process:

Overmolding is an injection molding process that combines two different materials together. In the production of glasses and lenses, overmolding can be used to add a layer of soft material, such as thermoplastic rubber (TPR), to polycarbonate lenses to provide better comfort and non-slip properties. This process allows manufacturers to combine multiple materials in the same production process, enhancing the functionality and appearance of glasses.

Through overmolding, manufacturers can form a soft coating on the edge or frame of the lens to improve wearing comfort while increasing the durability and impact resistance of the frame. This process is particularly suitable for the production of sports glasses and children's glasses.

The double shot molding allows two different polymer materials to be used in the same Two-Shot Injection Molds for injection molding. This process is particularly suitable for the production of glasses and lenses, and can achieve a perfect combination of different materials. For example, polycarbonate can be used as the main material for the lens, while another soft material can be injected into the frame part to provide better comfort and grip.

The advantage of the double shot molding is that it can complete complex designs in one step, reducing the need for subsequent assembly. This process ensures a good combination of materials, enhances the overall functionality and aesthetics of the glasses, and makes them more in line with user needs.

Automotive industry

Car headlights: Polycarbonate is widely used in car headlights due to its toughness, high and low temperature resistance, UV resistance and transparency. In addition, its excellent impact resistance enables it to effectively resist the impact of road debris and ensure driving safety.

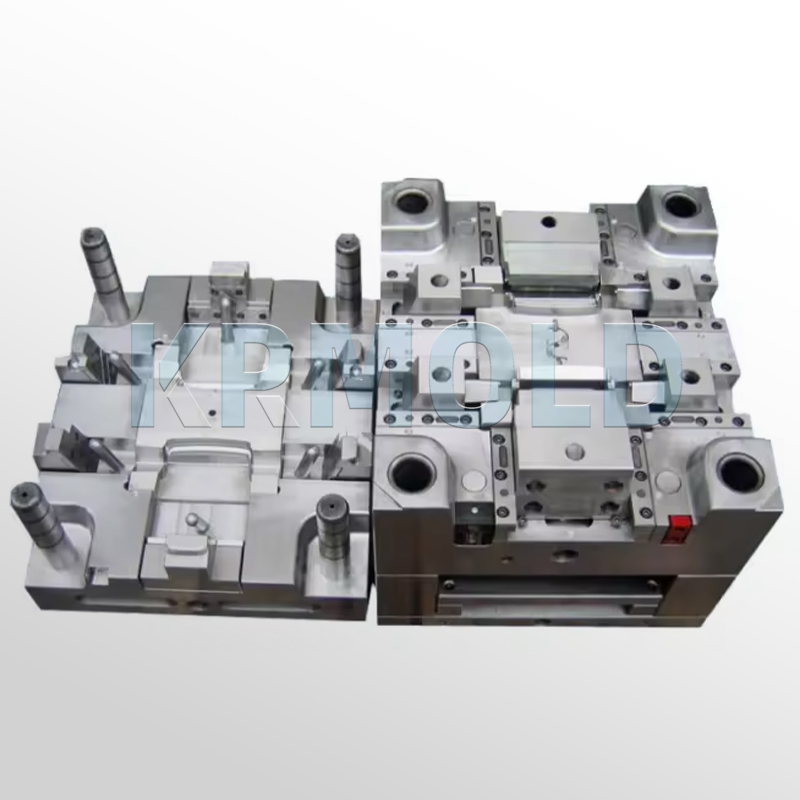

Gas-assisted molding is a process that reduces material usage and improves the quality of finished products by introducing gas during the gas-assisted molding. In the manufacture of car headlights, this process can effectively reduce the weight of plastic parts while maintaining the strength and rigidity of the parts. Gas injection can form cavities during the gas-assisted molding, reduce material filling, and thus optimize manufacturing costs.

This process is particularly suitable for the production of complex-shaped car headlight housings, which can achieve better surface finish and reduce the risk of deformation. At the same time, it can also improve production efficiency, shorten cooling time, and further enhance overall production capacity.

In-mold decorating Injection Mold is a process that embeds decorative film into the molding process, which is very suitable for the manufacture of automotive headlights. By embedding the film of the pattern or logo into the plastic during the In-mold decorating Injection Mold, high-quality surface effects and wear resistance can be achieved. This process can provide a wealth of appearance design options while protecting the film pattern from external influences.

The IMD Injection Molding makes the automotive headlights not only have good functionality, but also improve the visual effect, meet the aesthetic requirements of modern automotive design, and enhance consumer appeal.

Properties of Polycarbonate

——

| Property | Value |

| Density (g/cm³) | 1.2 – 1.22 |

| Shrinkage Rate (%) | 0.4 – 0.7 |

| Tensile Strength at Yield (MPa) | 55 – 75 |

| Elongation at Break (%) | 80-150 |

| Flexural Modulus (GPa) | 2.2-2.4 |

| Flexural Strength (MPa) | 75-100 |

| Drying Temperature (°C) | 80-100 |

| Drying Time (hrs) | 2-4 |

| Melt Temperature (°C) | 220-260 |

| Mold Temperature (°C) | 70-100 |

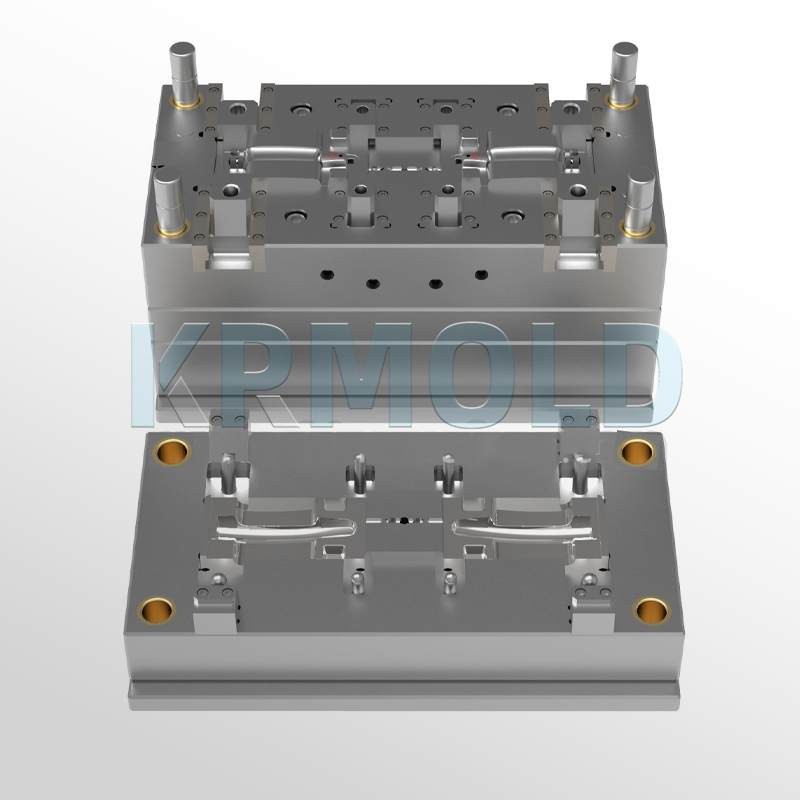

Process Of PC Injection Molding

——

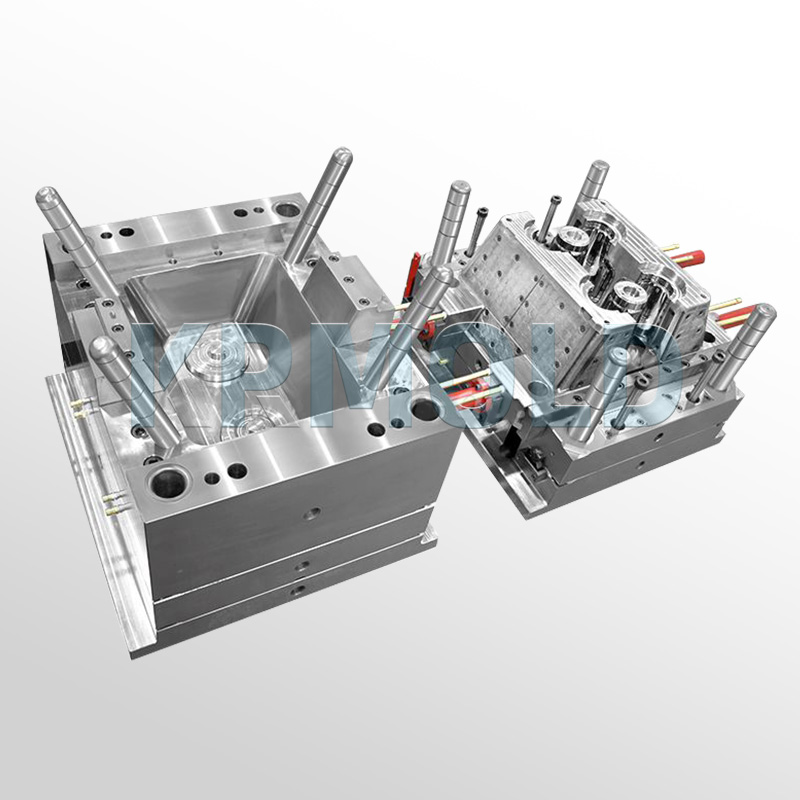

1. Filling stage

During the filling stage, polycarbonate pellets are heated to a molten state and then injected into the Optical-Grade PC Molds through the nozzle of the injection molding machine. The key to this stage is to ensure that the molten material can quickly and evenly fill every corner of the Impact-Resistant PC Housing Molds. Control of filling speed and pressure is critical to prevent bubbles and defects. If the filling is uneven, it may cause defects on the product surface, which will affect the quality of the final product.

2. Switching stage

The switching stage refers to the stage when the PC injection molding machine's control system switches to peak pressure after a short delay after filling is completed. During this stage, the system maintains a certain pressure to ensure that the polycarbonate is evenly distributed and fills the High-Performance Plastic Molds. This process requires extremely precise control to avoid voids or incomplete filling due to insufficient pressure.

3. Pressure stage

During the pressure stage, the PC injection molding machine continues to apply pressure to ensure that the material remains in the Transparent PC Molds during cooling and solidification. The purpose of this stage is to offset the shrinkage that may occur in polycarbonate during cooling. By maintaining appropriate pressure, product deformation can be reduced and the dimensional accuracy and consistency of parts can be improved.

4. Cooling stage

The cooling stage is the last step of the PC injection molding process. During this stage, the polycarbonate gradually cools and solidifies in the High-Performance Plastic Molds to form the final product. The length of cooling time directly affects the physical properties and appearance of the product. If the cooling is uneven, it may cause uneven distribution of internal stress in the product, which may cause rupture or deformation in subsequent use. Therefore, properly designing the cooling system and time is the key to ensure product quality.

Process Conditions For PC Injection Molding

——

| Drying | Different grades of PC absorb moisture, so pre-drying is very important. Drying at 100 – 120 degrees Celsius (or 212 – 248 degrees Fahrenheit) for 3 to 4 hours is recommended. The moisture content must be kept below 0.02% before the process begins. |

| Melting point | 260 – 340 degrees Celsius (or 500 – 644 degrees Fahrenheit); low MFR PC grades require higher temperatures and vice versa |

| Mold temperature | 70 – 120 degrees Celsius (or 158 – 248 degrees Fahrenheit); low MFR PC grades require higher temperatures and vice versa. |

| Plastic injection molding pressure | Keep the pressure as high as possible to achieve rapid molding. |

| Injection speed | When using small size or side gate, a slower injection speed should be used; for other gate types, a higher speed should be used. |

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

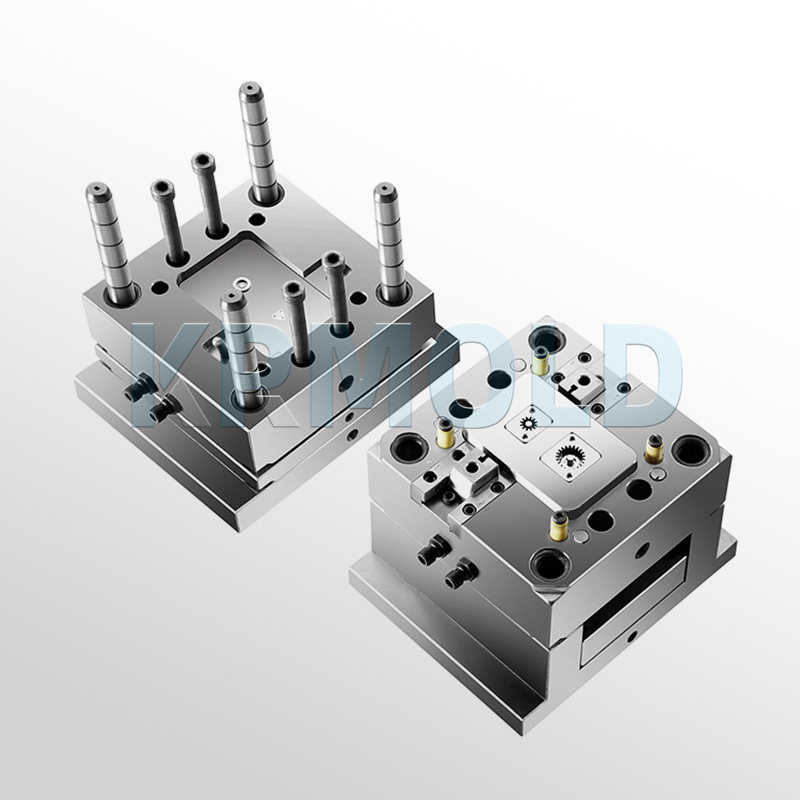

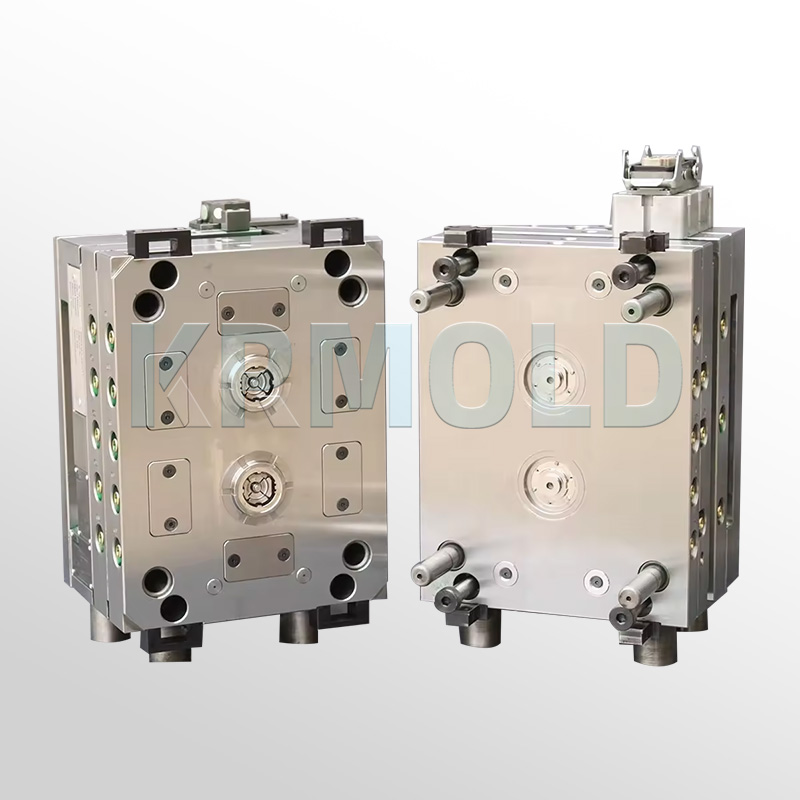

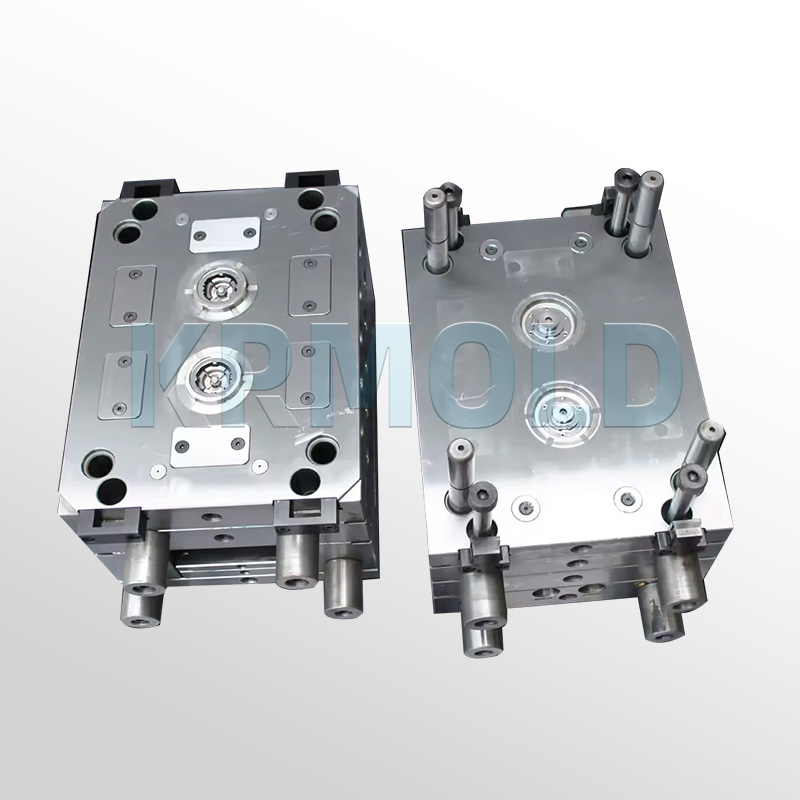

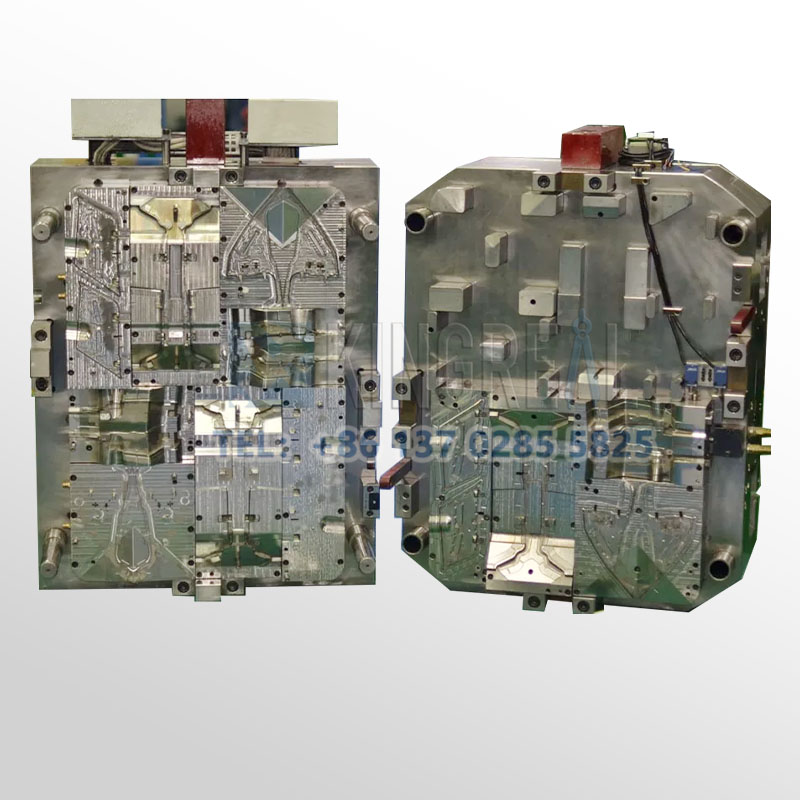

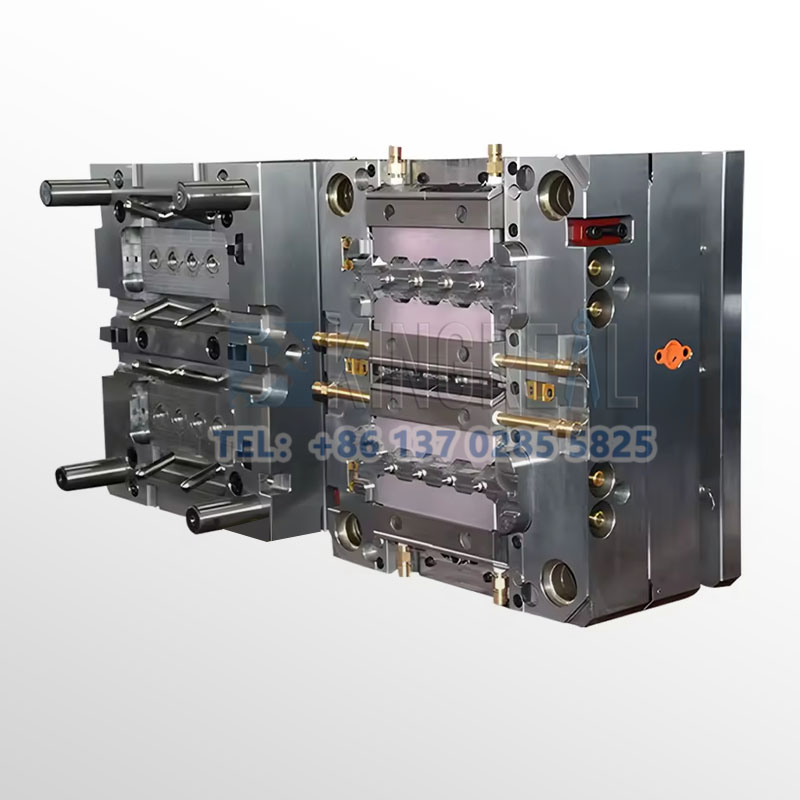

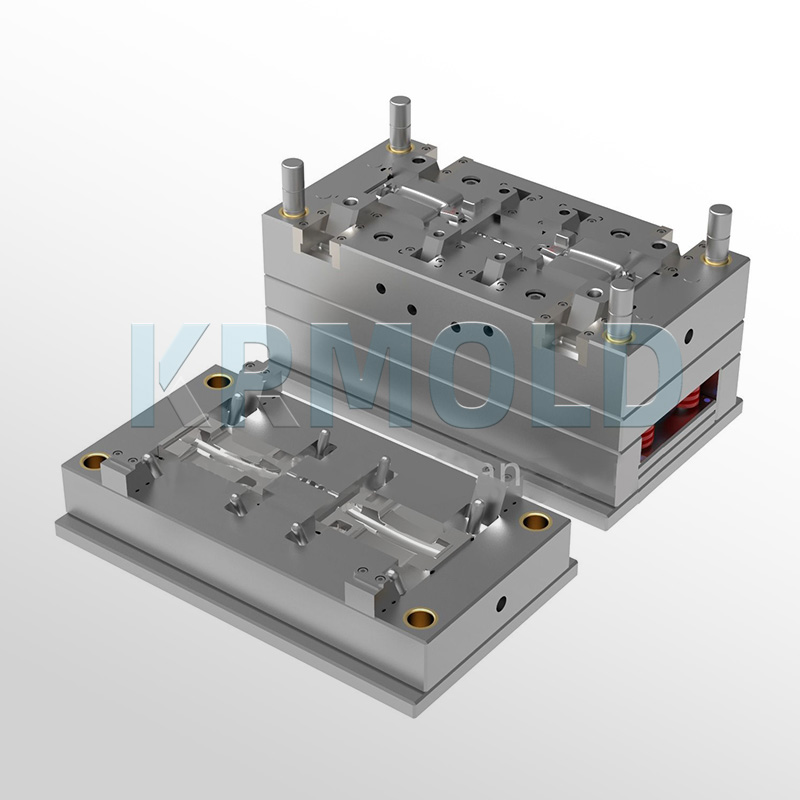

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).