What is Silicone Rubber Molded?

——

Liquid silicone molding (LSR) is a specialized process that forms an inorganic polymer composed of silicon (Si), oxygen (O), carbon (C) and hydrogen (H). Due to its viscous nature, liquid silicone molding is easy to process, making it ideal for high-volume production and ensuring consistent part quality, thereby increasing productivity. The properties and processability of liquid silicone rubber make it an ideal material for complex part designs and demanding critical applications. LSR molding is different from traditional thermoplastic injection molding. In this process, the liquid silicone is packaged in two containers, part A and part B, and is usually mixed in a 1:1 ratio. After mixing, the material is injected into a hot mold, where it crosslinks and cures to form the desired part geometry.

This liquid silicone molding technology is suitable for precision high-volume production, and customers in many industries use this process in the final stages of prototyping to provide near-production-quality LSR parts that meet the requirements of clinical trials, testing and pilot production. Liquid silicone rubber injection molding is widely used in fields such as medical, lighting and automotive, and is an excellent solution. Compared to silicone rubber compression molds, lsr molding are safer, more precise, more environmentally friendly, and more productive with less labor.

Introduction Of LSR Material

——

"LSR stands for liquid silicone molding, an inorganic polymer formed by silicon (Si), oxygen (O), carbon (C), and hydrogen (H). The main chemical chain is called the backbone, which is formed by silicon and oxygen (called siloxane). To achieve its final properties, a catalyst is added during the curing process to form chemical bonds between the backbones, called crosslinks. Platinum and peroxide are two chemicals used in this curing process, and LSR is a platinum-cured silicone rubber. Platinum-cured silicone rubber has advantages over peroxide-cured silicone rubber, including better tensile and tear strength, clarity and consistency, and does not leave peroxide residue.

The versatile properties of LSR come from its siloxane bonds. This chain provides an inorganic backbone that does not interact with biological materials and can be combined with organic chemical groups. Siloxane bnds also help provide better mechanical properties and strength."

How Liquid Silicone Rubber Injection Molding Works?

——

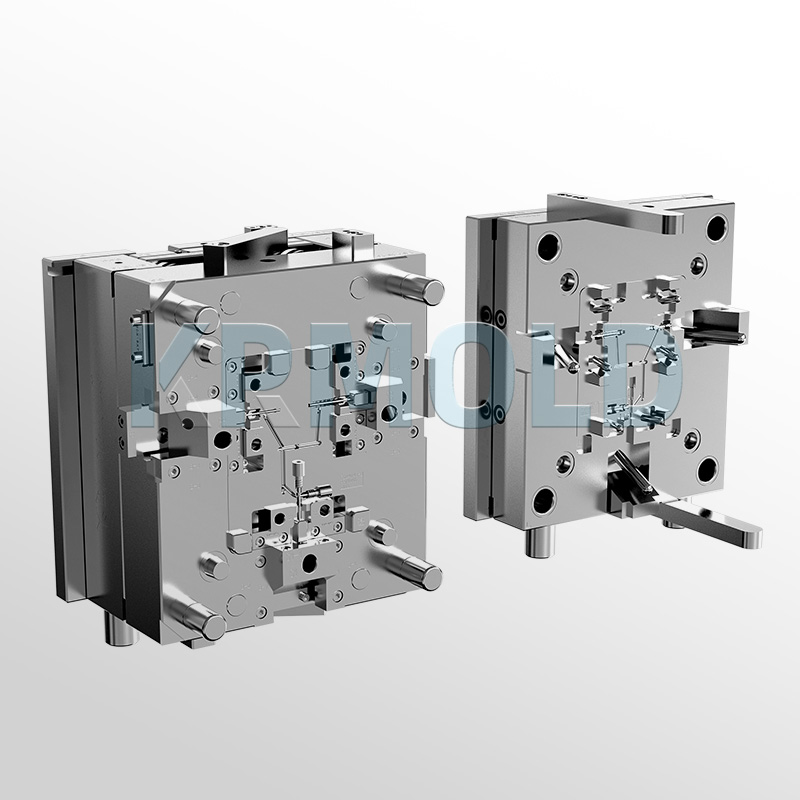

Liquid silicone molding (LSR) is flexible, workers need to manually remove parts from the liquid silicone injection molding, so ejectors are usually not built into the Silicone Rubber Molded design. Like standard aluminum tools, LSR molding tools are manufactured using CNC machining to ensure they can withstand the high-temperature molding process. After milling, the tools are hand-polished to the customer's specifications, with six standard surface finish options available.

The finished tools are loaded into advanced LSR-specific injection molding machines, which are finely tuned to accurately control the injection volume to produce consistent LSR parts. Because LSR is a thermoset polymer, its molded state is permanent and once solidified, it cannot be melted again like thermoplastics. Once production is complete, the parts (or initial samples) are boxed and shipped quickly.

Advantages of Liquid Silicone Molding

——

1. Fast Curing

A significant advantage of lsr molding is its fast curing speed. Compared with traditional colloid materials, LSR parts can be fully cured in seconds, while colloid materials usually take several minutes. This fast curing feature not only improves production efficiency, but also significantly shortens delivery time, allowing companies to respond more flexibly to changes in demand in the fierce market competition. Fast curing means that higher output can be achieved during the production process, reducing the idle time of the equipment, thereby improving overall production efficiency.

2. Complex Shape Molding Capability

Liquid silicone molding has the characteristics of low viscosity, making it very suitable for molding components with thin walls or small features. Due to its strong fluidity, LSR is able to easily fill fine details in the liquid silicone rubber injection molding. This ability allows designers to create complex part shapes, including undercut structures, without having to worry about mold trapping problems that may occur with traditional molds. When removing parts, lsr molding does not require demolding, so it can significantly reduce the complexity and time cost of the production process. This flexibility makes Silicone Rubber Molded an ideal choice for many high-precision applications, especially in industries such as medical, electronics, and automotive.

3. Diverse hardness options

liquid silicone molding can provide a range of hardness options based on demand, ranging from 5 to 90 durometers to meet the needs of different applications. Users can mix LSR materials of different hardness to match the desired color and characteristics based on specific usage scenarios and performance requirements.

4. Advantages of overmolding

Liquid silicone rubber injection molding is also well suited for overmolding processes. In this process, manufacturers can insert a substrate into an overmolding cavity and then inject LSR into the cavity to form a second layer of material. Certain grades of LSR materials have superior bonding properties and can firmly bond to specific substrates (such as plastics and metals), eliminating the preparation operations required in other overmolding processes. This property makes LSR an ideal choice for a variety of material combinations, enabling more complex structures and excellent performance.

5. Superior temperature stability and chemical resistance

Devices made of liquid silicone molding have superior temperature stability and can maintain stable performance in high or low temperature environments. The material can withstand harsh environments from low to high temperatures, making it ideal for use in harsh industrial applications.

Features Of Liquid Silicone Injection Molding

——

√High tear strength

√UV resistance

√Biocompatibility

√Low compression set

√Excellent chemical resistance

Applications Of Liquid Silicone Rubber Molding

——

"Liquid silicone rubber injection molding (LSR) are widely used in multiple industries, including automotive, medical, home appliances, packaging, and more. These applications are usually manufactured through different injection molding processes, each of which has its own unique advantages."

1

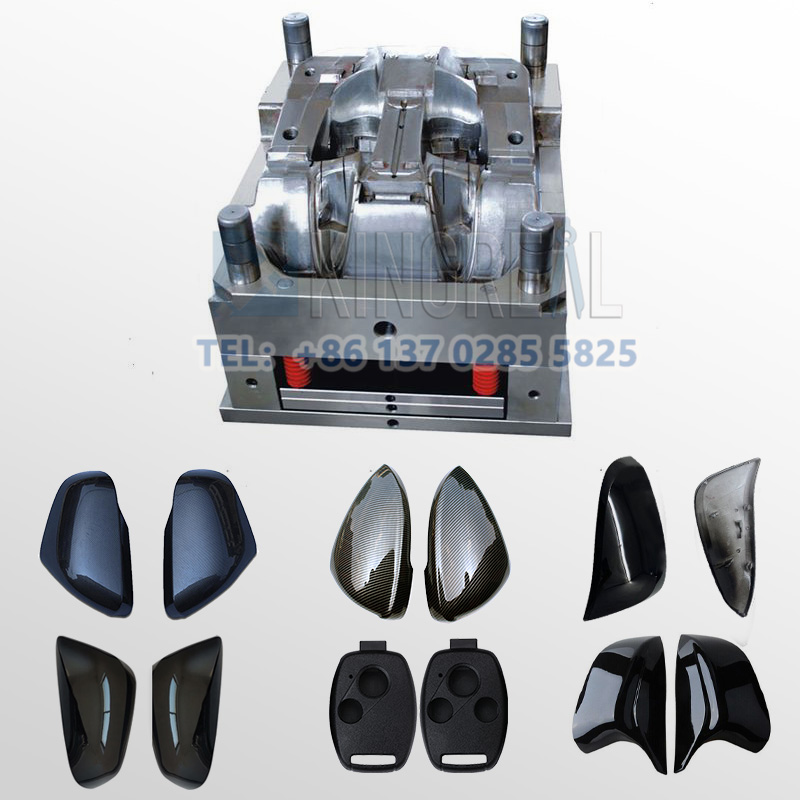

Automotive Industry

Applications:

- Liquid silicone rubber molding are used in the automotive industry to manufacture seals, gaskets, soft-touch buttons, and dashboard components.

Injection molding process: Overmolding

- Process description: In this process, a substrate (such as plastic or metal) is first injected into a mold to form a bottom component. Then, liquid silicone is injected into the Silicone Rubber Molded to form a second layer of material covering the substrate.

- Benefits: This process can achieve a combination of multiple materials to improve the functionality and appearance of the component. By combining soft silicone with a hard substrate, it can provide better feel and non-slip properties while reducing assembly time.

2

LED Lenses and Optics

Applications:

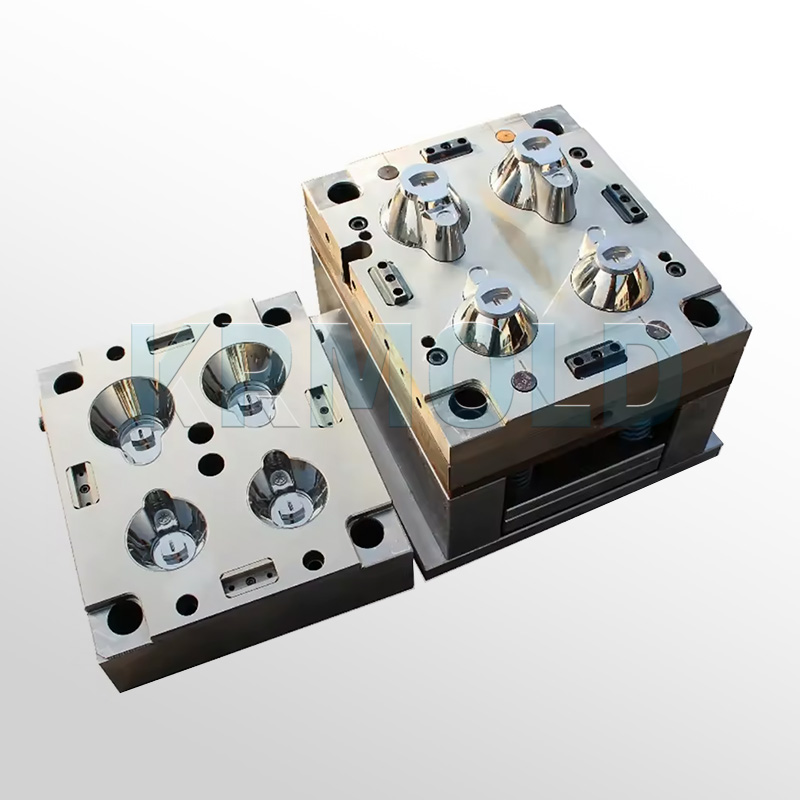

- Liquid silicone rubber molding are used to manufacture lenses, lampshades, and other optical components for LED lamps.

Injection Molding Process: IMD Injection Molding

- Process Description: This process combines injection molding and printing technologies, where the injection molding is performed inside the mold, while the pattern or image is printed onto the product surface during the molding process.

- Benefits: This process enables high-precision optical properties, ensuring the clarity and light transmittance of optical components. The IMD process can also reduce subsequent decoration steps, reducing costs and time.

3

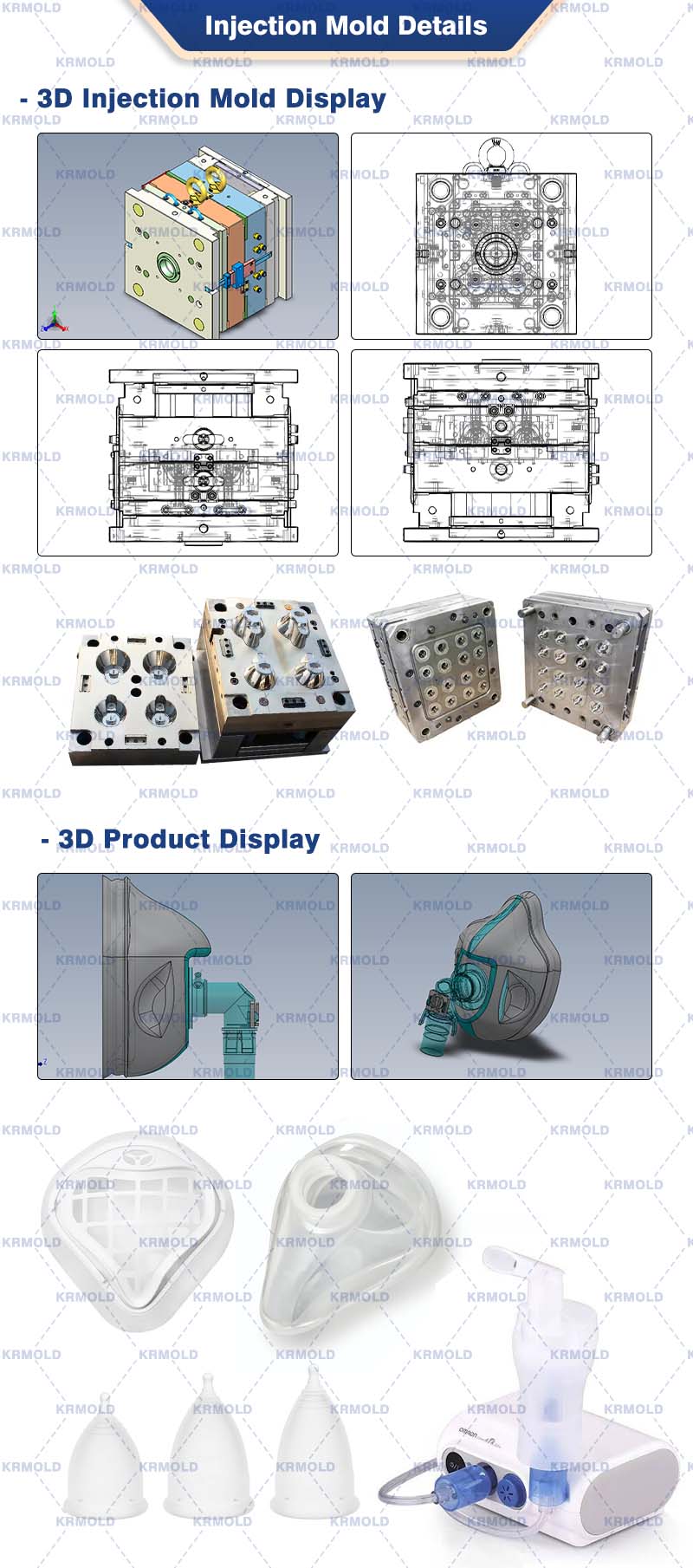

Medical

Applications:

- In the medical industry, lsr molding are used to manufacture medical devices and patient interface components, such as catheters, syringes, and handles for surgical instruments.

Injection Molding Process: Micro Molding

- Process Description: This process focuses on manufacturing extremely small, high-precision parts. Liquid silicone is injected through micro molds to form complex geometric shapes.

- Benefits: Micro injection molding technology allows the manufacture of extremely small and complex parts with high precision and consistency, suitable for the strict requirements of medical devices, ensuring safety and performance.

4

Home appliances

Application:

- Liquid silicone injection molding are used to manufacture soft-touch buttons, handles and other components in home appliances.

Injection molding process: Double Shot Molding

- Process description: This process forms a composite part by injecting two different materials into the same mold.

- Benefits: Double shot molding technology enables seamless combination of different materials, providing better touch and enhanced functionality. It can also reduce assembly time and reduce production costs.

Why Choose KRMOLD?

——

1

One-stop service

KRMOLD provides a comprehensive one-stop service, covering all aspects from preliminary design to final production. KRMOLD's team works closely with customers at the start-up stage of the project to ensure that every design detail meets customer needs and expectations. Through this integrated process, customers can save time and costs while ensuring quality control of the product at all stages.

2

Quality assurance

During the mold manufacturing process, KRMOLD always adheres to high standards of quality assurance. The mold components used by KRMOLD are all from well-known domestic and foreign brands, which are known for their excellent quality and reliability. The use of high-quality materials not only improves the durability and stability of the mold, but also ensures the accuracy and consistency of the final product.

3

Mold trial production and modification service

KRMOLD is well aware that accurate mold design is crucial to the quality of the final product. Therefore, KRMOLD provides trial mold modification services. After the mold is produced, KRMOLD will first conduct a trial mold to ensure that its parameters meet the predetermined requirements. If any non-compliance is found, KRMOLD will quickly re-modify it. In addition, KRMOLD is equipped with multiple high-precision quality inspection equipment for strict testing to ensure that each mold meets industry standards.

4

Rich experience

KRMOLD has a professional team with nearly 20 years of experience, and team members have accumulated rich knowledge and skills in the field of mold manufacturing. KRMOLD is committed to providing fast-response services to promptly resolve any problems that customers may encounter during the project advancement process. Whether it is design consultation, technical support or production progress tracking, KRMOLD's team will provide you with efficient and professional services.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).