What is Flame-Retardant ABS Molds?

——

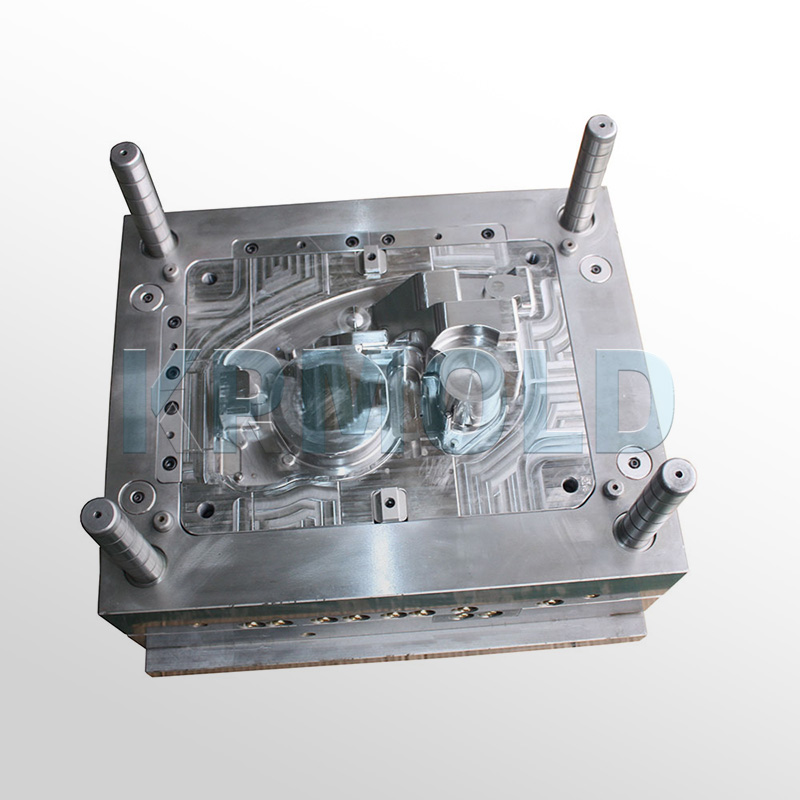

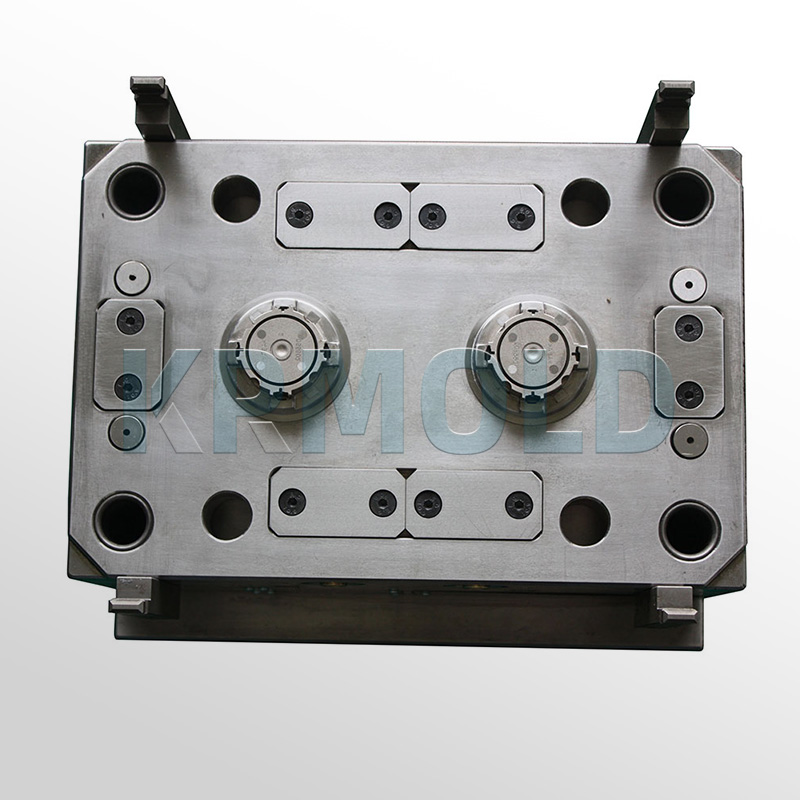

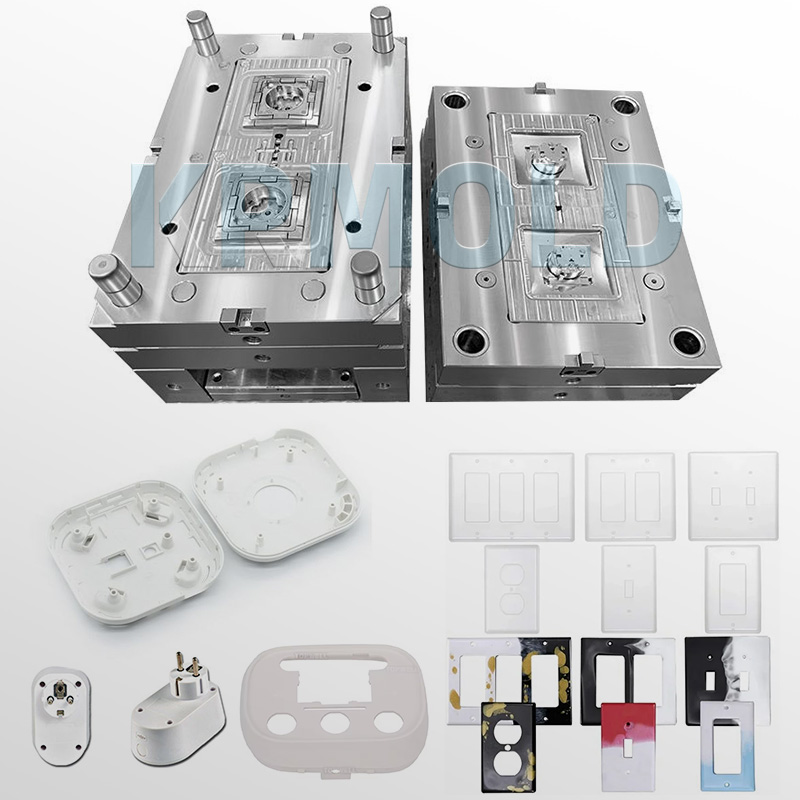

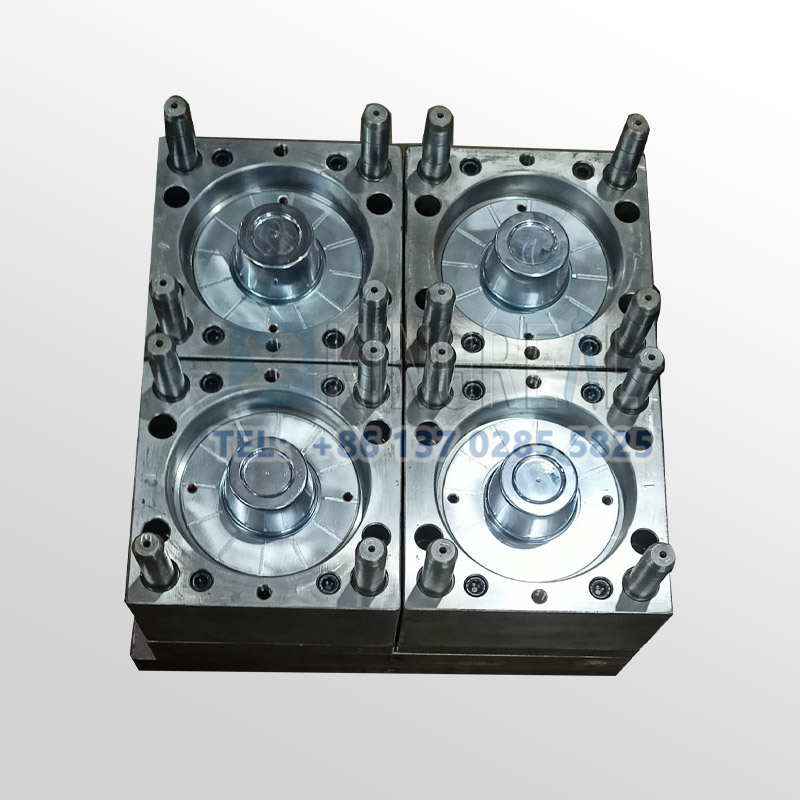

The ABS Injection Molding process is the same as most other thermoplastics. Resin pellets are first fed into a hopper, where they are melted and injected into the High-Gloss ABS Housing Molds using high pressure, and then removed after cooling to manufacture parts needed in various fields. This simple and efficient process makes it very suitable for mass production and produces little waste. Thermoplastics like ABS can withstand such temperature changes without being destroyed, which is why they are popular in many manufacturing processes.

ABS Electronic Housing Molds is widely used in many fields such as medical, automotive, consumer electronics, and home furnishings because of its characteristics such as stability under load, high impact strength and dimensional stability, high tensile strength, and recyclability.

Advantages Of ABS Appliance Component Injection Molds

——

(1) Improve product consistency

ABS injection molding process is capable of producing complex parts suitable for many complex application scenarios. This capability is usually not available in other injection molding processes. By combining advanced technology and a controlled injection molding process, High-Gloss ABS Housing Molds can ensure the repeated production of molded parts with the same shape and high quality. In addition, this ABS material can maintain its characteristics and performance even after experiencing extreme temperature changes.

(2) Wide range of applications

ABS Appliance Component Injection Molds are able to handle ABS resins of various sizes and exhibit excellent integration capabilities. This flexibility enables it to produce different components for multiple industries, including automotive, electronics, home appliances, and toys, to meet a variety of needs. This wide range of applicability makes Flame-Retardant ABS Molds the first choice for many manufacturers.

(3) Impact resistance

ABS material has excellent impact resistance and can withstand large external forces without breaking easily. This feature makes products produced using ABS Electronic Housing Molds perform well when subjected to collisions or impacts, and is particularly suitable for applications requiring high durability, such as automotive parts and electronic housings.

(4) Chemical corrosion resistance

ABS Appliance Component Molds have good resistance to a variety of chemicals. This makes components made of ABS materials less susceptible to damage when exposed to chemicals, making them suitable for use in chemical, medical and laboratory fields. This chemical corrosion resistance ensures the durability and reliability of the product in harsh environments.

(5) Excellent wear resistance

ABS materials themselves have excellent wear resistance, which enables parts produced by High-Gloss ABS Housing Molds to effectively resist wear during long-term use. This feature is particularly important in applications that require frequent friction or contact, such as mechanical parts and sports equipment, which can extend the service life of the product and reduce maintenance costs.

ABS Injection Molding Manufacturing Process

——

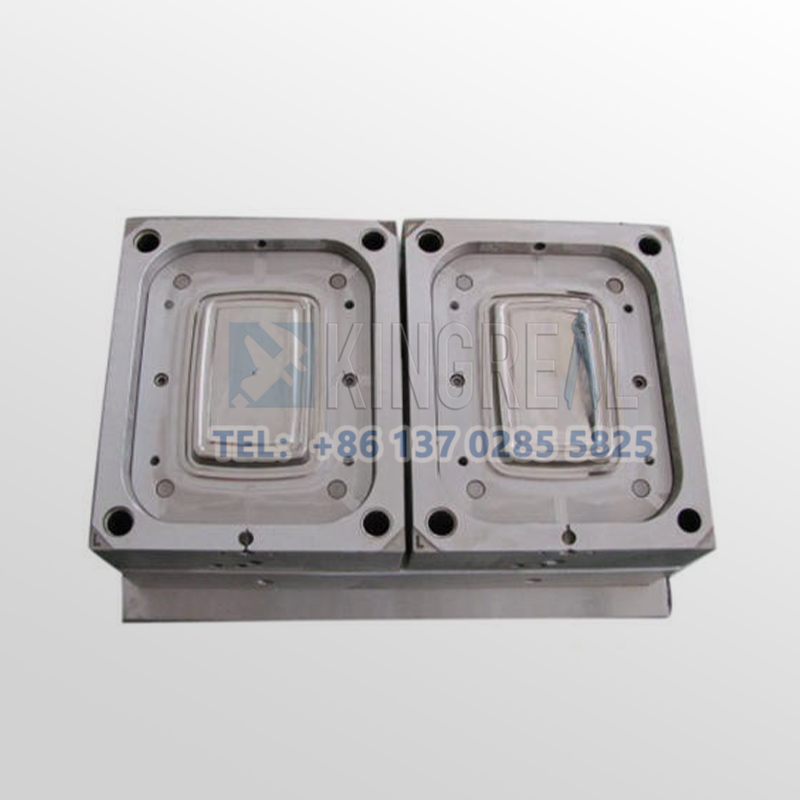

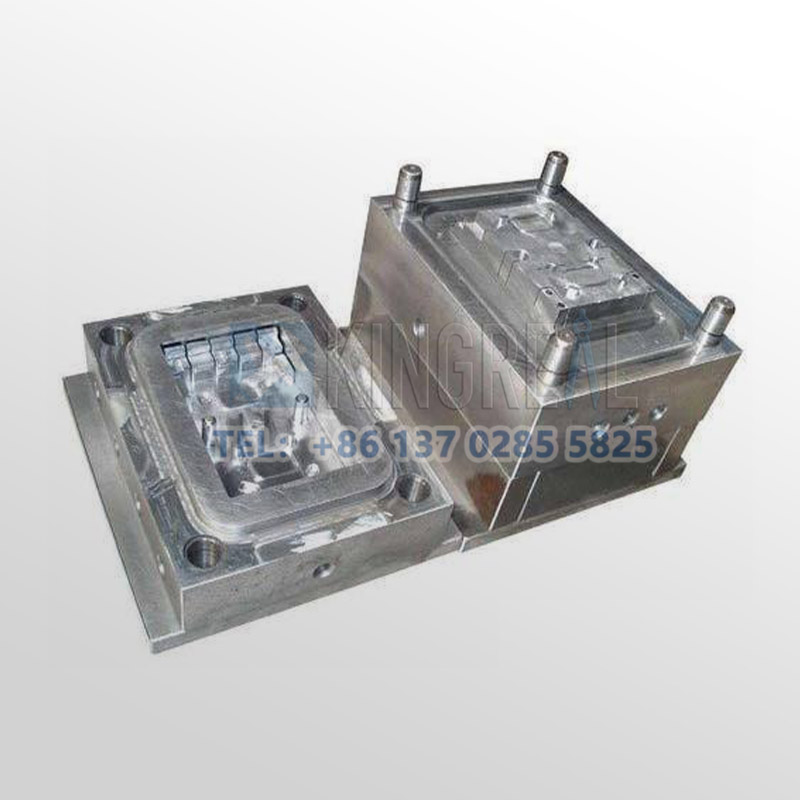

The manufacturing process of ABS injection molding begins with the preparation of ABS plastic pellets. These pellets are first heated and melted into a moldable fluid state, and then the molten ABS plastic is injected into the cavity of the ABS Appliance Component Injection Molds by high pressure. After the Flame-Retardant ABS Molds is filled, the plastic begins to solidify almost immediately to form the desired shape. Next, the part in the ABS Appliance Component Molds gradually cools to a solidified state, ensuring that it remains precisely in the designed shape of the ABS Electronic Housing Molds.

Once the ABS plastic is completely cooled, the ABS Appliance Component Injection Molds is opened and the molded part is removed by an ejection device. At this point, the manufacturing process is complete and the High-Gloss ABS Housing Molds parts are reset to prepare for the next ABS injection molding. The entire process is efficient and repeatable, making ABS injection molding an ideal choice for producing high-quality plastic parts. This process not only improves production efficiency, but also ensures product consistency and precision, and is suitable for a variety of industrial applications.

Applications Of ABS Electronic Housing Molds

——

"ABS injection molding is a manufacturing process widely used in many industries, especially in the medical, automotive, home appliance, consumer electronics and packaging industries. The following are specific finished product examples in various industries, including their characteristics and application countries."

Features: ABS material's impact resistance and chemical corrosion resistance make it very suitable for medical equipment housings, such as ultrasound machines, electrocardiographs, etc. The housing not only protects the internal electronic components, but also needs to withstand certain impacts and chemical cleaning.

Application countries: Developed countries such as the United States, Germany, and Japan.

Features: ABS injection molded syringes have excellent strength and transparency, making it easy for medical personnel to observe the injection process. Its sealing also ensures the safety and effectiveness of the drug.

Application countries: Emerging markets such as India, Brazil, and South Africa.

Features: ABS material can be used in pharmaceutical packaging containers in the pharmaceutical industry, providing good sealing and chemical resistance to ensure that the drug is not affected by the external environment.

Application countries: China, Canada, Australia, etc.

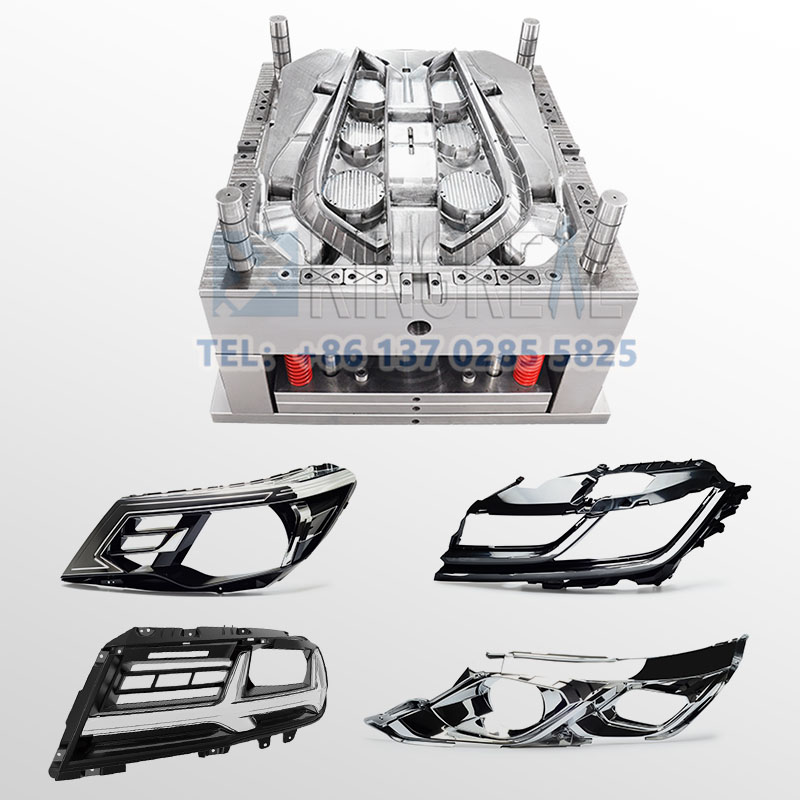

Features: ABS plastic is often used in the manufacture of automotive dashboards due to its excellent impact resistance and heat resistance. Dashboards can be designed into complex shapes and subjected to a variety of surface treatments to enhance aesthetics.

Application countries: Germany, Japan, South Korea and other automotive manufacturing powerhouses.

Features: ABS material is used for headlight housings. It has good transparency and weather resistance, can resist ultraviolet rays and other environmental factors, and ensure the service life of the headlights.

Application countries: The United States, the United Kingdom, France and other countries.

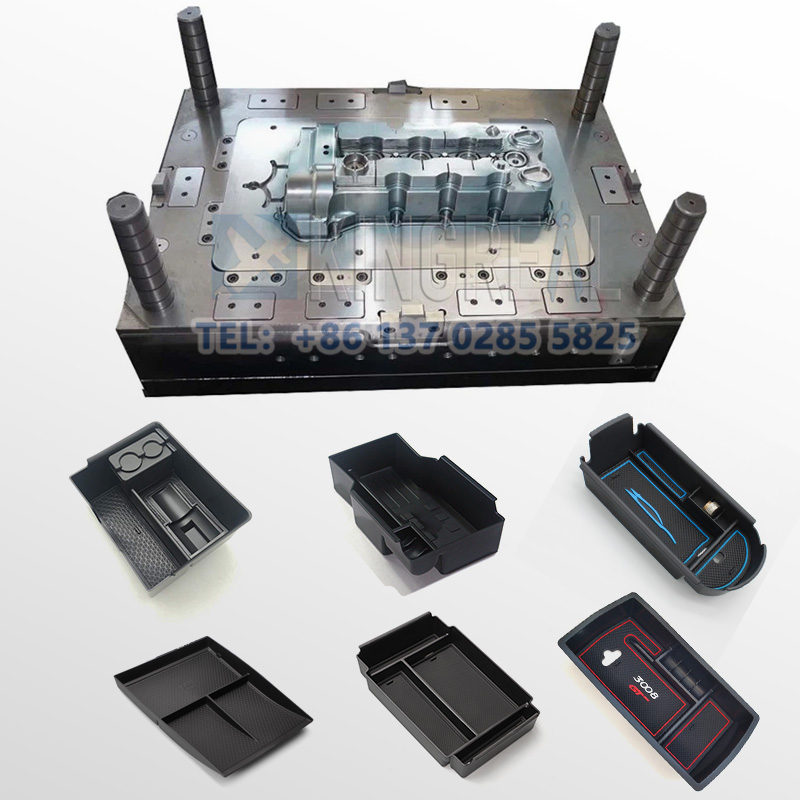

Features: ABS injection molding is used to manufacture automotive interior components, such as door handles, control panels, etc. These components must not only be beautiful, but also wear-resistant and impact-resistant.

Application countries: Italy, India, Brazil and other countries.

3. Home Appliance Injection Mould

Features: ABS material is the first choice for the housings of many home appliances, such as washing machines, refrigerators, etc. Its excellent impact resistance and high temperature resistance ensure the safety and durability of the housing.

Application countries: Japan, the United States, Germany, etc.

Features: Many kitchen appliances such as blenders and food processors are made of ABS injection molding because they are lightweight and easy to clean. Their high temperature resistance also makes them suitable for contact with food.

Application countries: China, Canada, Australia, etc.

Features: ABS injection molding is widely used in the manufacture of small household appliances such as electric kettles and electric irons because of their good insulation and heat resistance, ensuring product safety.

Application countries: Emerging markets such as India, Brazil, and South Africa.

4. Consumer Electronics Injection Mould

Features: ABS plastic is often used in the manufacture of mobile phone casings because of its lightness and strength, and can withstand the impact and scratches in daily use.

Application countries: The United States, China, South Korea, and other technologically developed countries.

Features: ABS material is used in TV casings, providing good impact resistance and beautiful design, which can adapt to various home styles.

Application countries: Japan, Germany, the United Kingdom, etc.

Features: The shell of many audio equipment is made of ABS injection molding. Due to its excellent acoustic properties and durability, it ensures the stability of the product during use.

Application countries: Italy, France, Canada, etc.

Features: The chemical resistance and excellent sealing properties of ABS materials make it an ideal choice for food packaging containers, which can effectively protect food from contamination.

Application countries: The United States, European countries, etc.

Features: ABS injection molded cosmetic packaging containers have good transparency and design freedom, which can attract consumers and enhance brand image.

Application countries: Japan, South Korea, France, etc.

Features: ABS materials are used in the packaging of electronic products, providing good protection and antistatic properties, ensuring the safety of products during transportation.

Application countries: Emerging markets such as China, India, and Brazil

FAQ About Flame-Retardant ABS Molds:

(1)Q: What is the melting temperature of ABS plastic material?

A: The melting point of ABS plastic ranges from 210 to 240 degrees Fahrenheit. This thermoplastic polymer is generally preferred because it has a relatively low melting point and is suitable for ABS injection molding and many other injection molding processes.

(2)Q: Why is the melting point of ABS so important to understand plastic injection molding?

A: Understanding the melting point of ABS plastic is essential to ensure the structural integrity of molded parts during the ABS injection molding process. This ensures that the plastic melt properly fills the ABS Appliance Component Injection Molds and achieves the desired mechanical properties without damage.

(3)Q: Does the temperature range of different plastic materials have an impact on the ABS injection molding process?

A: The temperature range of different types of plastics will affect the temperature setting of the High-Gloss ABS Housing Molds and the selection of machine parameters. Different types of plastics have specific temperature ranges that should be maintained to achieve successful ABS injection molding and retain the characteristics of the plastic.

(4)Q: What aspects of the melting of plastic materials should be paid attention to during ABS injection molding?

A: When melting ABS plastic material, you need to pay attention to correctly setting the temperature and machine parameters of the ABS Appliance Component Molds, which will reduce the possibility of defects. Specific control of the melting point of the plastic helps to increase its viscosity, thereby achieving better fluidity and the finish of the final product.

(5)Q: What is the importance of ABS's characteristics for different applications?

A: For example, ABS's strength, toughness and heat distortion temperature grades make it suitable for many applications from the automotive industry to the electronics industry. In addition, its low melting point makes it easy to process through ABS injection molding, meeting the needs of different fields.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

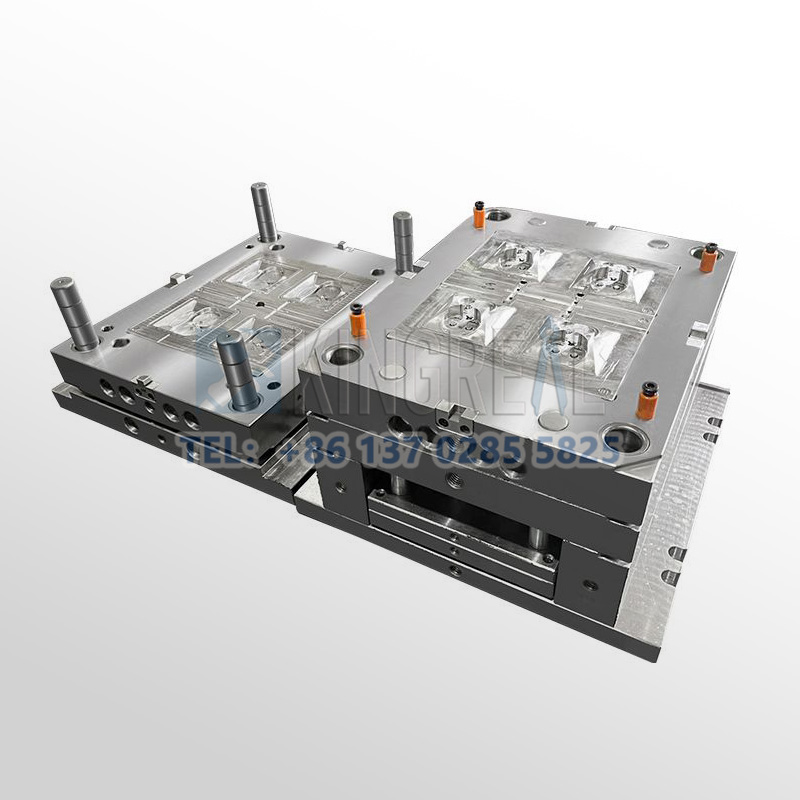

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).