Introduction of TPU/TPE Injection Molding

——

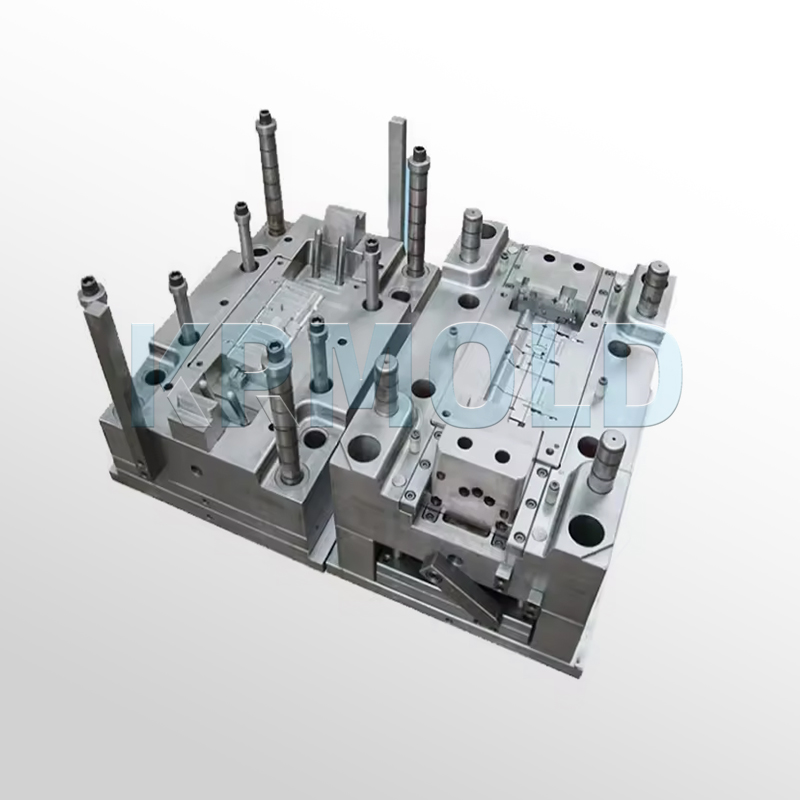

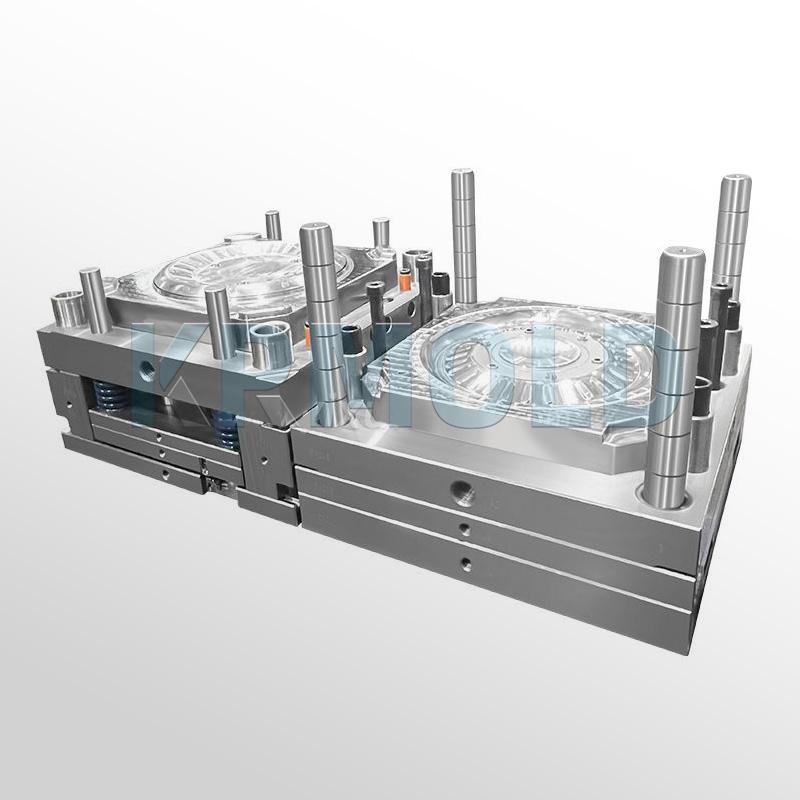

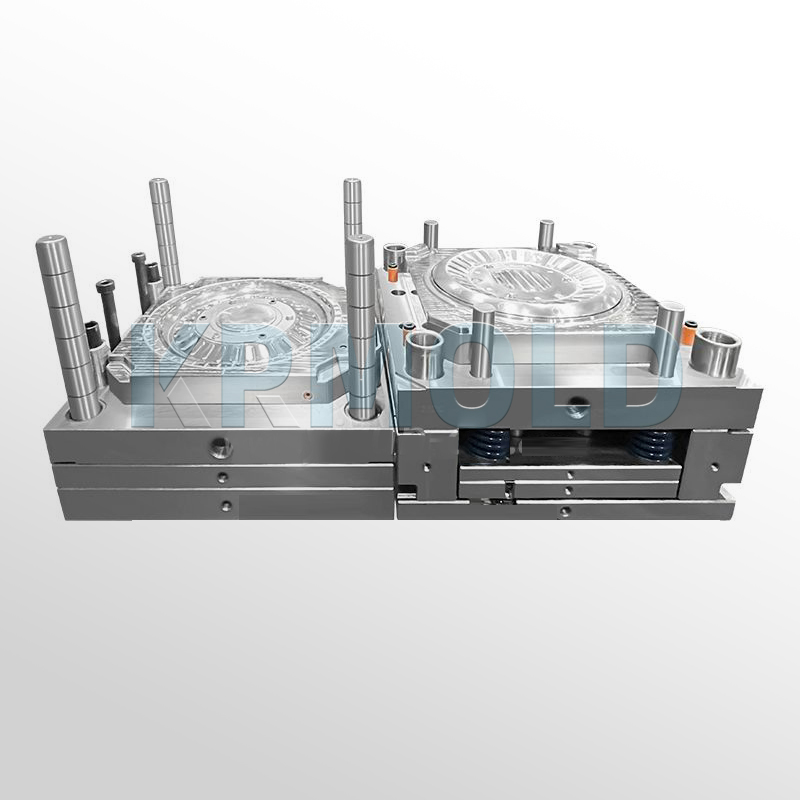

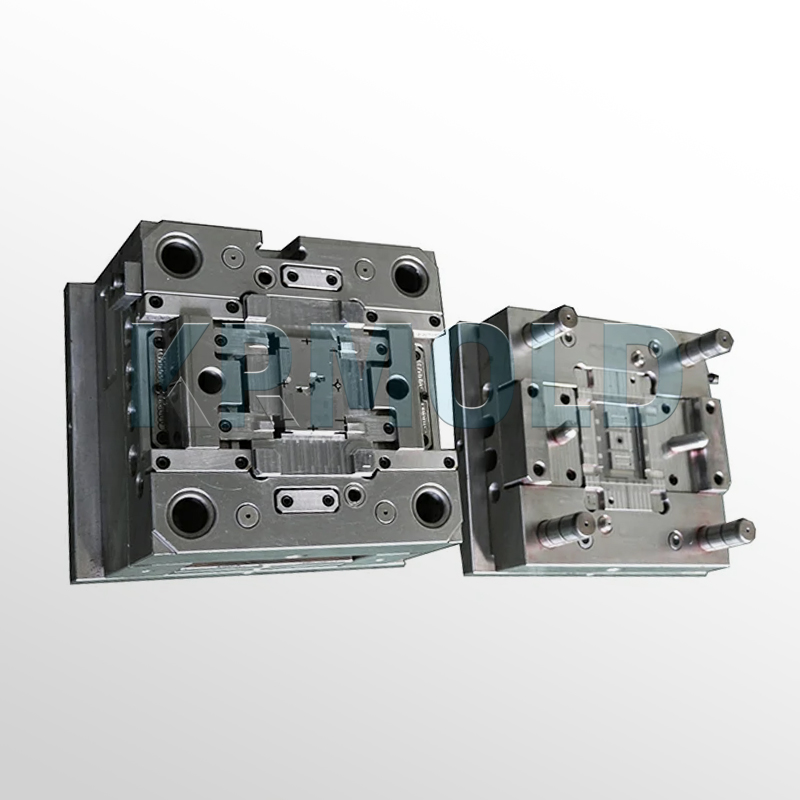

TPE injection molding is a versatile manufacturing technology. Its full name is Thermoplastic Elastomer. It is a mixture of plastic and rubber that combines the flexibility of rubber with the strength and processability of plastic. It involves injecting molten TPE material into the TPE Elastomer Molds cavity under high pressure and allowing it to cool and solidify to form the desired product. Its lower melting point makes it easier to Sports Equipment Grip Molds, which is ideal for products that require a soft touch, such as grips or seals.

TPU injection molding stands for thermoplastic urethane, which is a versatile and durable material. In TPU Flexible Molds, TPU is highly praised for its ability to withstand harsh conditions, making it a favorite in the automotive and sporting goods industries.

Injection Molding Process

——

TPU Injection Molding Process

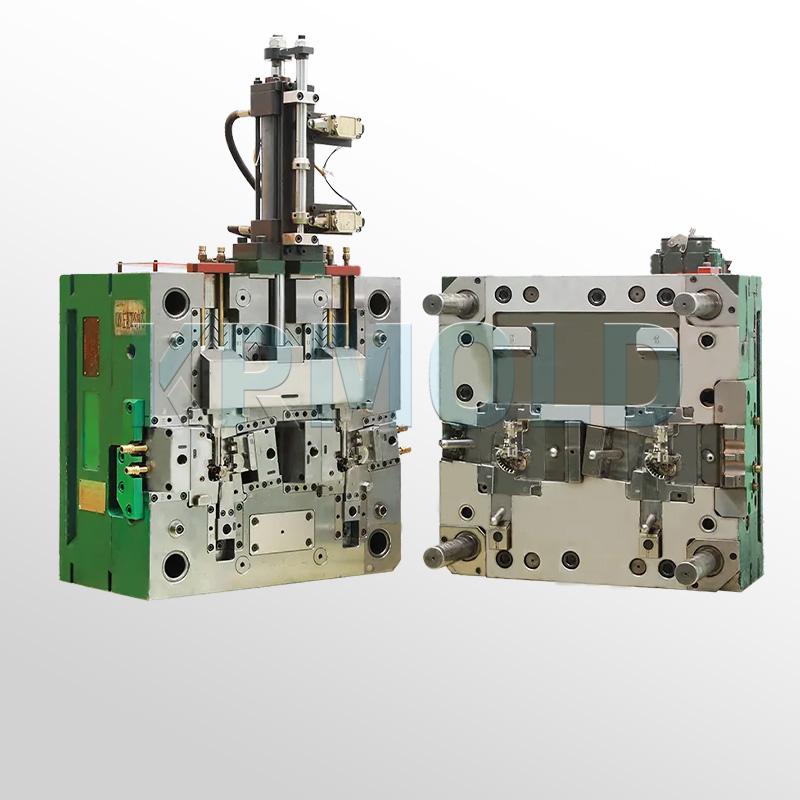

| Process | TPU injection molding requires higher temperatures than TPE, generally between 180°C and 220°C. The process involves heating the TPU Flexible Molds to a liquid state and then injecting it into the TPU Flexible Molds under high pressure. |

| Cooling Time | TPU Flexible Molds have a fast cooling time, which helps reduce production time and improve efficiency. The cooling time is generally between 10 and 30 seconds, depending on the size and thickness of the product. |

| Equipment Requirements | Use an injection molding machine that can accurately control temperature and high pressure to ensure product quality. |

TPE Injection Molding Process

| Process | TPE Elastomer Molds tends to be more flexible and can be performed at lower temperatures, generally between 160°C and 200°C. TPE can be molded using a variety of techniques, including conventional injection molding and multi-layer injection molding. |

| Cooling Time | TPE Elastomer Molds also have a fast cooling time, generally between 5 and 15 seconds, which helps save production time. |

| Equipment Requirements | Injection molding machines with adjustable temperature and injection speed settings are required to accommodate the characteristics of Medical Soft-Touch Molds. |

TPU Flexible Molds vs TPE Elastomer Molds

——

“When you are considering whether to use TPU injection molding or TPE injection molding, KRMOLD recommends that you think about the following aspects:"

◆Physical properties: TPU is generally superior to TPE in tensile strength and wear resistance. However, TPE has excellent flexibility and a softer feel.

◆Chemical resistance: TPU is generally more resistant to oil, grease and other chemicals than TPE.

◆Availability: TPE is easier to mold due to its lower melting point, but unlike TPU, it may not be suitable for high-temperature applications.

◆Cost-effectiveness: TPE is generally more economical, making it a practical choice for large or cost-sensitive projects.

You need to combine the above characteristics of TPU and TPE and choose the corresponding Sports Equipment Grip Molds according to the finished product you need to produce.

Characteristics of TPU Flexible Molds and TPE Elastomer Molds

——

Characteristics of TPE injection molding process

● Flexibility

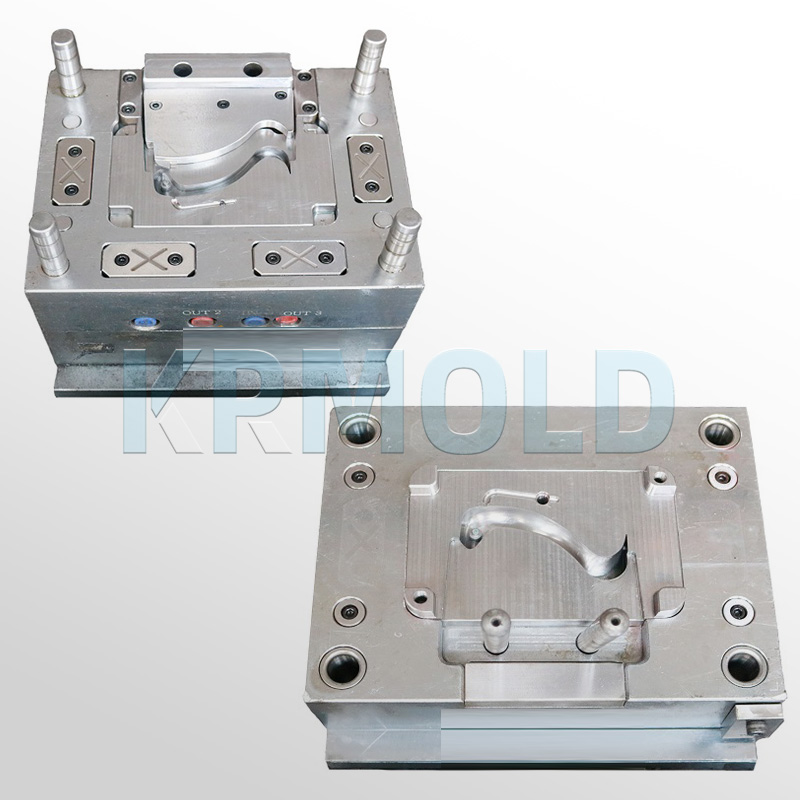

The TPE injection molding process has unparalleled design flexibility and is ideal for manufacturing products with complex shapes. Unlike other materials, TPE can easily adapt to Sports Equipment Grip Molds design, allowing manufacturers to produce innovative and customized products. This flexibility opens up endless possibilities for designers, allowing them to turn their creative visions into reality without compromising product functionality.

● Overmolding

TPEs are highly compatible with other materials, making overmolding a viable option. Overmolding involves adding a layer of TPE to an existing material or component, creating a seamlessly integrated product.

This technique not only improves aesthetics, but also enhances the durability and functionality of a product. Overmolding eliminates additional assembly steps, simplifies the production process and reduces overall manufacturing costs.

● Wide hardness range

TPE materials have a wide range of hardness, from very soft to relatively hard. This wide hardness range enables manufacturers to tailor the properties of the material to the specific requirements of each product.

For example, applications that require high flexibility can use softer TPEs, while harder TPEs are suitable for applications that require structural integrity. This versatility allows TPE injection molding to meet different industries and applications.

TPU injection molding process

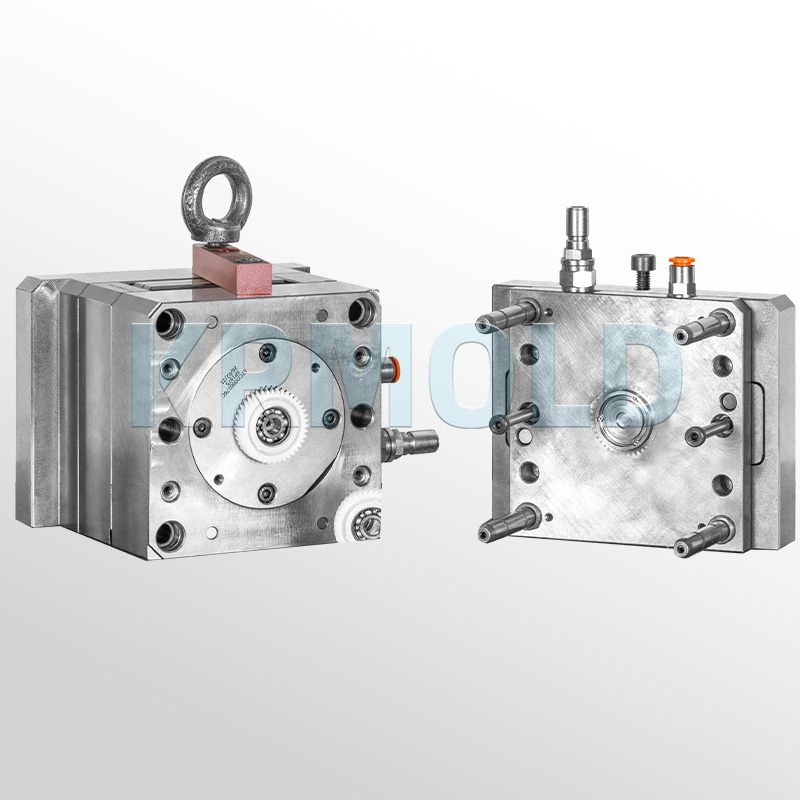

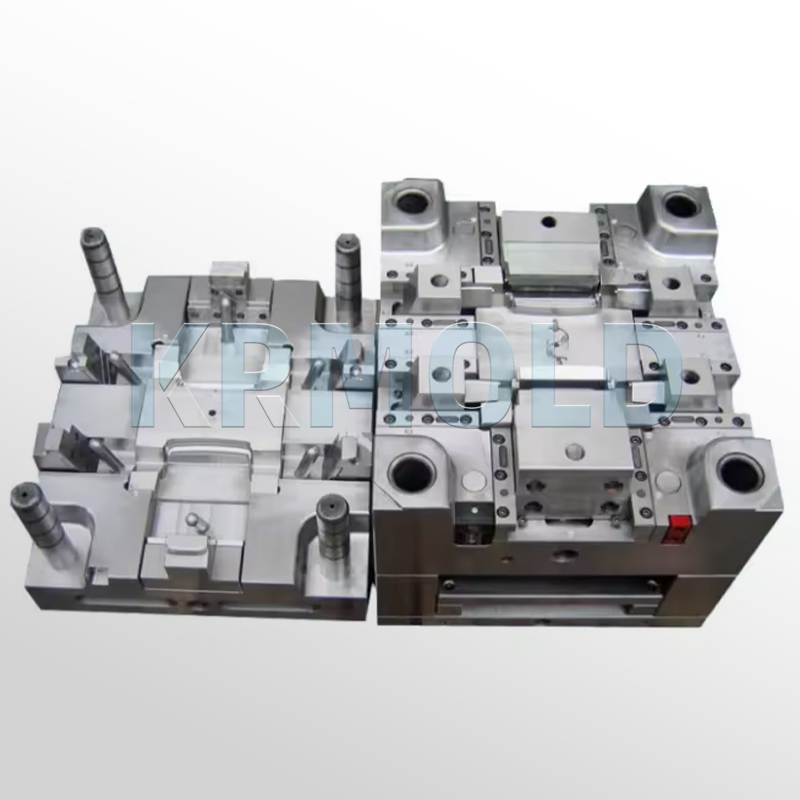

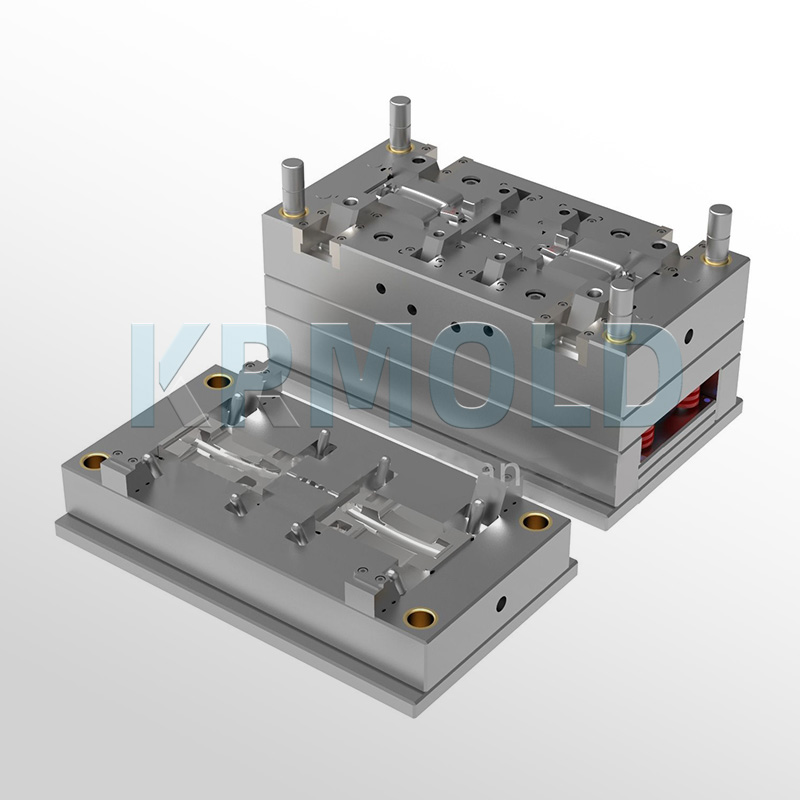

● High precision. Whether you want to capture the complexity of a complex design or ensure that every product in a batch of products is exactly the same, Waterproof Seal Molds can do it. This precision is a testament to Sports Equipment Grip Molds's adaptability, allowing it to be molded into both simple and complex shapes without compromising detail.

But it's not just about looks. TPU is known for its durability. Its mechanical properties, especially its hardness, ensure that products made from it can withstand the rigors of daily use. This resilience is particularly beneficial in industries where products are constantly worn out.

●Durable. The durability and versatility of Waterproof Seal Molds often saves customers a lot of money. Products made from TPU tend to last longer than similar products, ensuring that replacements are rare.

Applications of TPU/TPE Injection Molding

——

TPU Flexible Molds

TPU injection molding has a wide range of uses. The most common are made into automotive parts, consumer electronics protective covers, medical devices, and industrial parts.

Medical Devices

Due to its high-performance properties, thermoplastic polyurethane (TPU) is widely known as an ideal material for medical and healthcare applications.

Its excellent mechanical properties and resistance to oils, greases and chemicals make TPU injection molding useful in the production of a wide range of medical devices, such as diagnostic and artificial respiration equipment, medical mattresses and medical device cables.

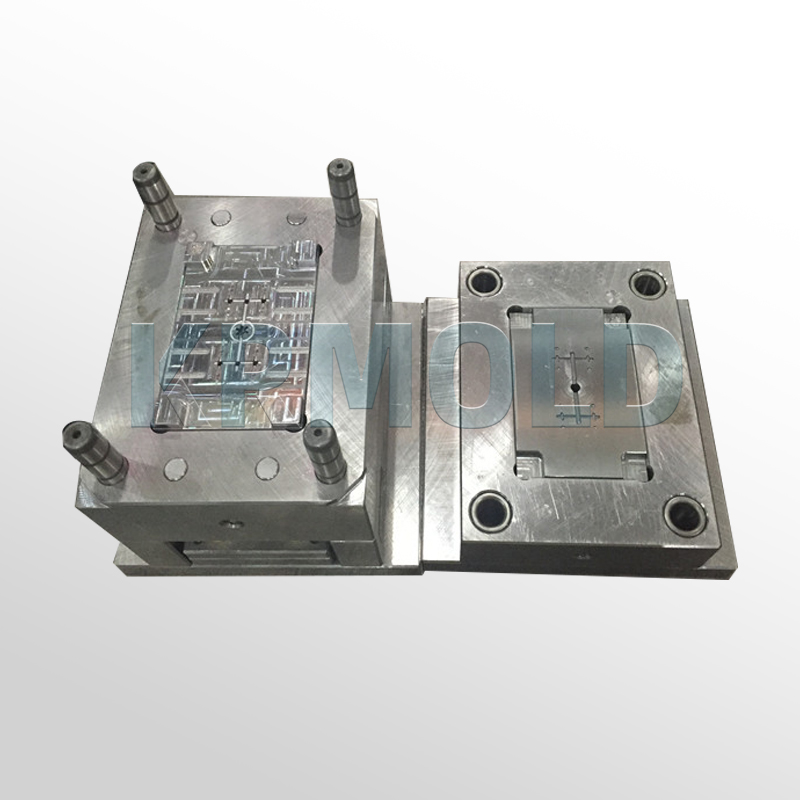

Injection molding processes that can be used:

Features: Insert molding allows components made of metal or other materials to be embedded in plastic parts, and is particularly suitable for medical devices that require enhanced strength and functionality, such as sensors or connectors.

2. Overmolding

Features: Overmolding can combine TPU with other materials to make the handle or contact area of medical devices more comfortable, while achieving non-slip and durability. Suitable for the handheld part of medical devices.

TPE Elastomer Molds

The most common application areas for TPE injection molding are adhesives, coatings and sealants, consumer goods, and industry and construction.

Consumer goods

Consumer goods often come into contact with the body and are often used in hygienic applications, so they need to be very safe. TPE injection molding complies with many regulatory standards, including FDA, which encourages their use in the consumer goods industry.

They are used to manufacture many everyday products and plastic compounds, from baby toys to plastic handles to packaging materials.

Available injection molding processes:

Features: The IMD injection molding process can directly integrate decorative layers or labels into the surface of consumer products during the injection molding process, which is suitable for products that require brand logos or patterns, such as toys or household items.

Features: Gas-assisted injection molding can reduce the filling pressure of the Waterproof Seal Molds, which is suitable for the production of large-volume, thin-walled consumer products, maintaining lightness and strength, such as the shell of packaging materials.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

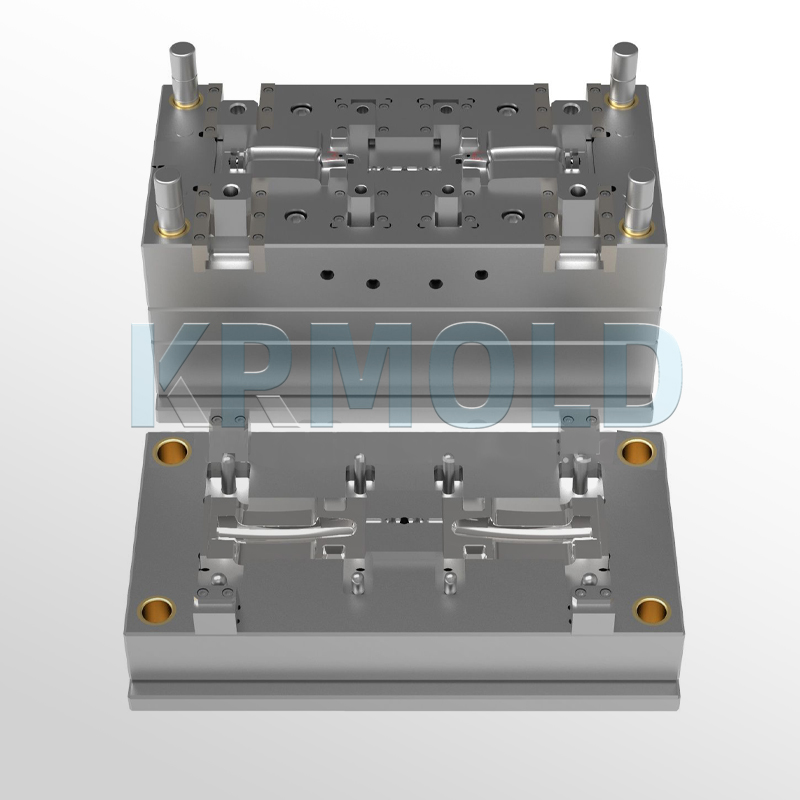

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).