What is PEEK/PEI Injection Mould?

——

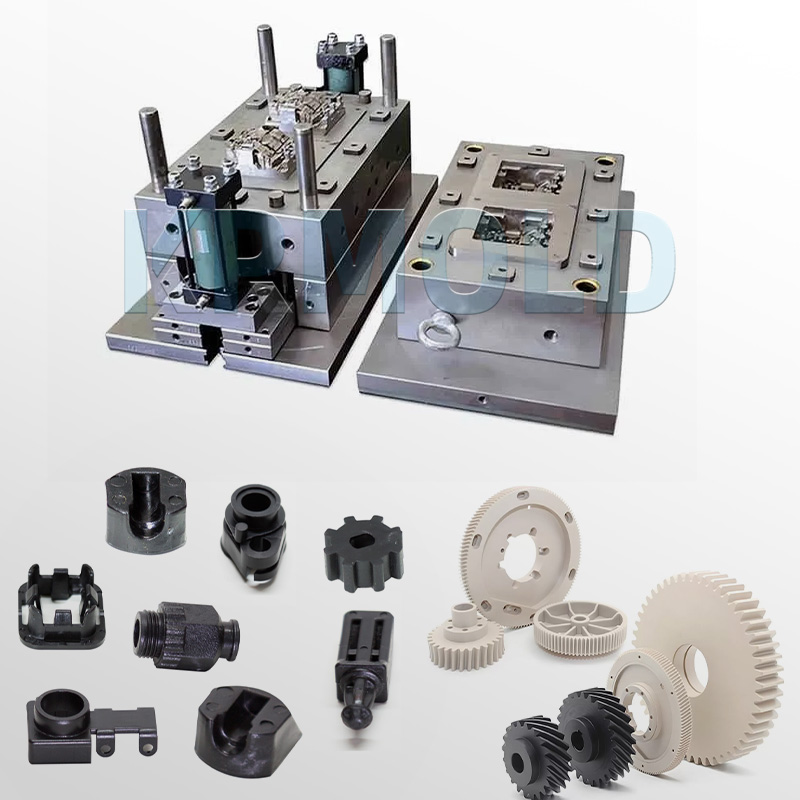

PEEK injection molding is a complex manufacturing process that involves injecting molten polyetheretherketone (PEEK) material into a pre-designed PEEK High-Temperature Molds cavity. This versatile thermoplastic polymer has excellent properties, including high temperature resistance, chemical inertness, mechanical strength and electrical insulation. As a result, PEEK has become the material of choice for applications that require peak performance under the harshest conditions. And it also meets FDA food contact requirements and can be sterilized for medical applications.

PEI injection molding is used to produce plastic parts that withstand high temperatures and harsh environments. Polyetherimide (PEI) is a high-performance engineering thermoplastic that also has excellent dielectric strength for reliable electrical insulation. PEI Precision Component Molds is mainly used for specific types of challenging applications. KRMOLD can provide you with PEEK/PEI Injection Mould to meet your needs. You can choose according to the characteristics of the finished product to be produced and combined with your actual production situation.

PEI vs. PEEK

—

| Property | PEI | PEEK |

| Heat Resistance | Up to 200℃ | Up to 250℃ |

| Cost Efficiency | Moderate | High |

| Chemical Resistance | Strong | Excellent |

"PEEK offers greater chemical resistance and thermal performance, while PEI strikes a balance between cost and high-end performance, making it an ideal choice for most applications."

Advantages of PEEK/PEI Injection Mould

——

Advantages of PEI Precision Component Molds

1

Creep Resistance

PEI has good creep resistance (a measure of deformation under static load) when exposed to higher temperatures. In addition to excellent dimensional stability, PEI has a uniform coefficient of thermal expansion, resulting in more predictable dimensional changes when heated.

2

Sterilizable

Due to its high temperature resistance, injection molded PEI can be sterilized in a steam autoclave. Additionally, PEI resists gamma radiation, which is also used to sterilize medical devices and surgical tools.

3

Environmental Resistance

PEI has good ultraviolet (UV) resistance, but its UV resistance can be enhanced by adding UV stabilizers. PEI is resistant to sunlight, heat, and water, making it ideal for outdoor applications such as building-mounted electric meters.

4

Dielectric Strength

PEI has the highest dielectric strength of all plastics, making it an excellent insulator for applications such as electrical enclosures and capacitors. By definition, dielectric strength is the maximum voltage required to produce dielectric breakdown of a material. Once dielectric breakdown is reached, the material becomes conductive rather than insulating.

Advantages of PEEK High-Temperature Molds

1

Excellent Mechanical Properties

PEEK injection molding produces components with excellent mechanical strength, making it a material that can withstand heavy loads and pressures without compromising performance.

Its high tensile and compressive strengths make it an excellent choice for applications that require reliable and durable parts under extreme operating conditions. Aerospace Specialty Plastic Molds's ability to maintain structural integrity under pressure ensures long-lasting, reliable performance.

2

High Temperature Resistance

The outstanding feature of Medical Implant Molds is its excellent tolerance to high temperature environments. Unlike many other plastics, Medical Implant Molds can thrive in extreme heat without losing physical properties. This characteristic makes it a material of choice for the aerospace, automotive, and oil and gas industries, where components often encounter high temperatures during operation.

PEEK High-Temperature Molds' heat resistance allows it to maintain mechanical integrity and dimensional stability even under challenging thermal conditions.

3

Chemical Inertness

One of the most important advantages of PEEK High-Temperature Molds is its high tolerance to a wide range of chemicals, acids, and solvents. This property makes PEEK a valuable choice for critical applications in the chemical processing and pharmaceutical industries, which are often exposed to corrosive substances.

Medical Implant Molds' ability to resist chemical corrosion ensures the longevity and reliability of parts in corrosive chemical environments where traditional materials may fail.

4

Lightweight Alternative

Despite its strong mechanical properties, Aerospace Specialty Plastic Molds are surprisingly light compared to traditional metal parts. This property gives it a competitive advantage, especially in industries seeking to reduce weight to improve efficiency and fuel economy. PEEK injection molded parts help reduce weight in aerospace, automotive and other applications, making them a valuable choice for modern design and engineering.

Key Elements to Successful PEEK/PEI Injection Mould

——

PEEK injection molding :

①Material selection: Select the appropriate PEEK material grade based on specific application requirements, considering factors such as mechanical properties, high temperature resistance, chemical resistance, wear resistance, and regulatory compliance.

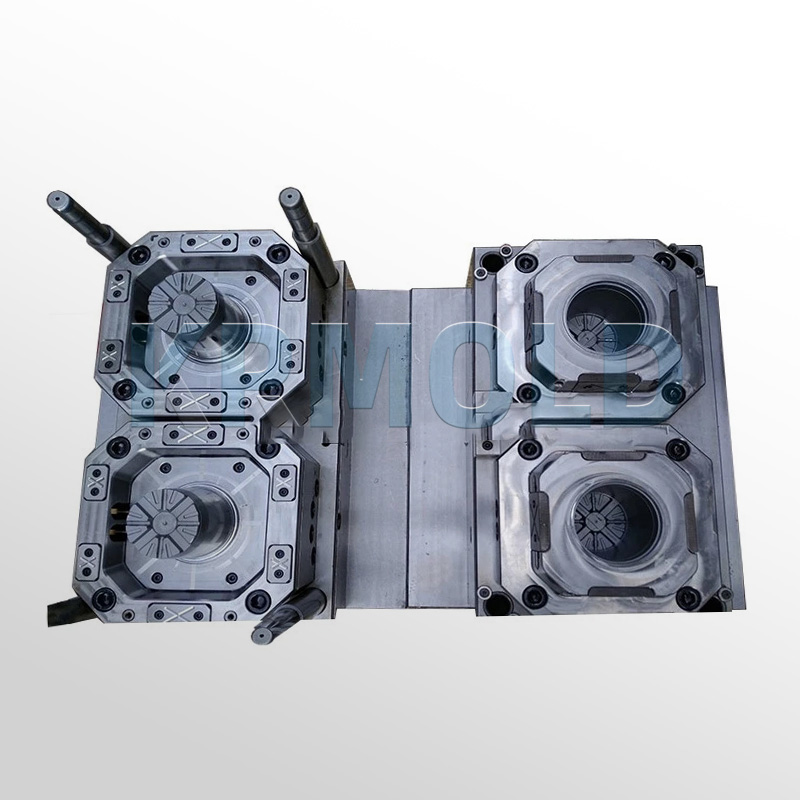

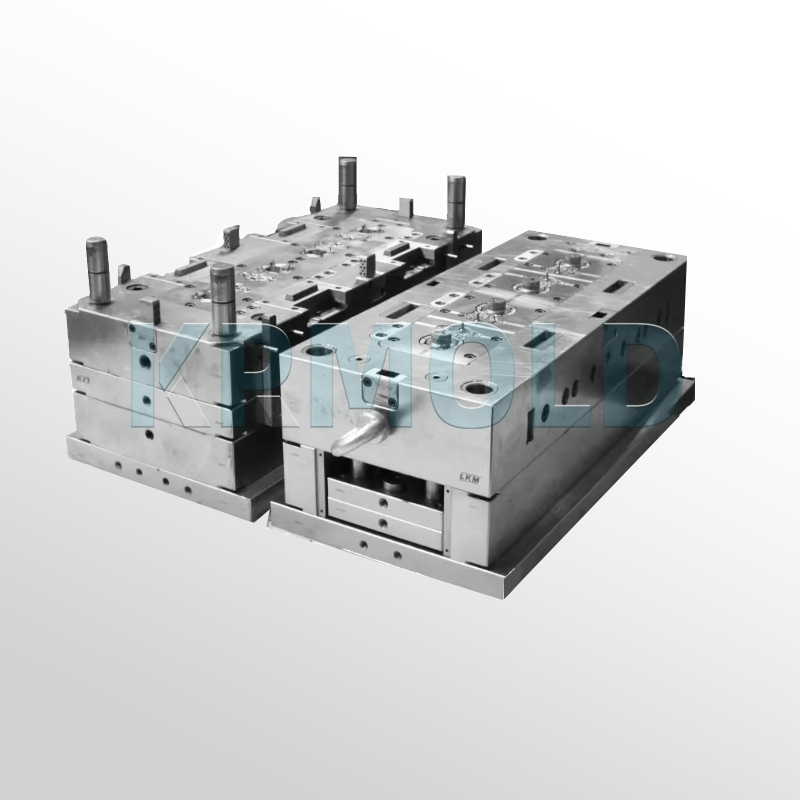

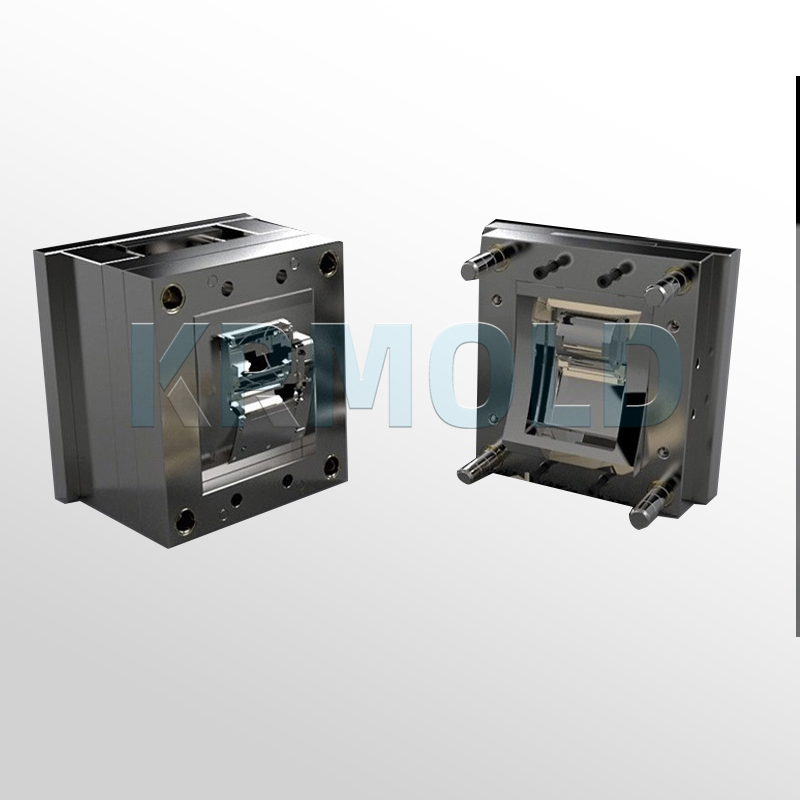

②Mold design: Accurately design the Medical Implant Molds to accommodate the part geometry, gating, venting, and cooling requirements required for PEEK injection molding. Consider features such as draft angles, parting lines, and venting channels to facilitate demolding and minimize defects.

③Tooling: Manufacture Medical Implant Molds tools using high-quality materials and precision machining techniques to achieve tight tolerances, smooth surface finish, and durability. Verify mold component accuracy through thorough inspection and verification.

④Injection process optimization: Optimize process parameters such as barrel temperature, injection pressure, injection speed, cooling time, and holding pressure to achieve consistent part quality, minimize cycle time, and prevent defects such as warpage, sink marks, or surface blemishes.

⑤Injection unit: Ensure the injection unit is properly calibrated and equipped with a precision metering and mixing system to accurately dispense PEEK material into the Aerospace Specialty Plastic Molds cavity. Pay attention to screw design, back pressure control, and screw/barrel alignment to prevent material degradation and ensure uniform melt quality.

PEI injection molding:

① Mold temperature: 150-200°C (302-392°F). Keep the mold temperature within this range for good part filling and ejection.

② Mold material: Steel or aluminum. Select the PEI Precision Component Molds material based on the specific requirements of the part and the PEI material.

③ Mold design: PEI injection molding can produce complex shapes and designs, but the PEI Precision Component Molds design should be done for the specific part and material.

④ Ventilation: Good ventilation is important to ensure proper filling and ejection. There needs to be vents to exhaust air and gas during injection.

⑤ Cooling system: Make sure the cooling system is designed to properly cool and solidify the part.

⑥ Material selection: You should choose the PEI material based on the needs of the part. You need to consider its temperature, what chemicals it is exposed to, and how strong it needs to be.

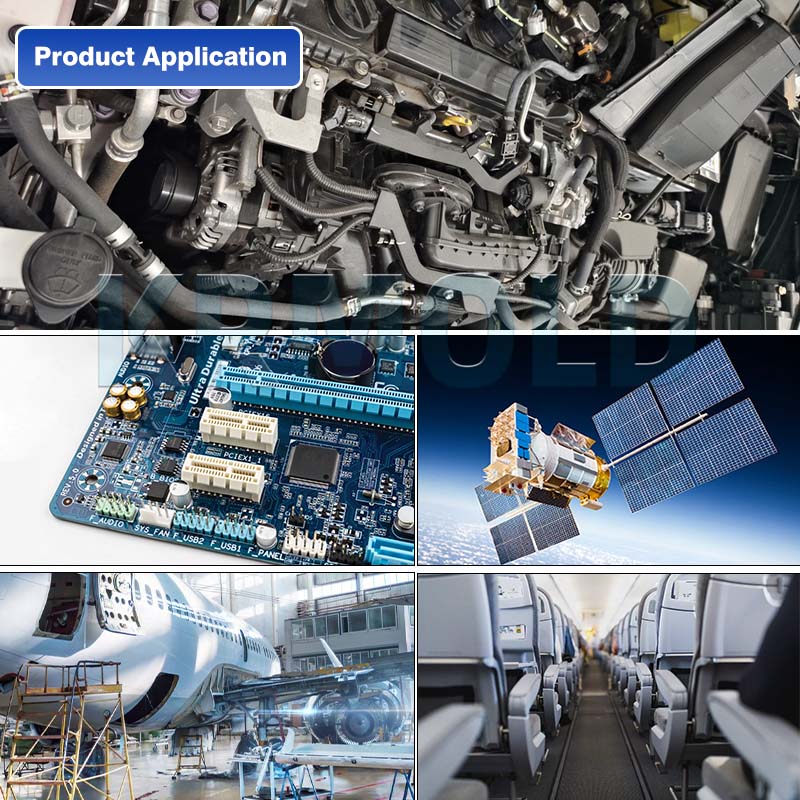

Applications of PEEK/PEI Injection Mould

——

PEEK High-Temperature Molds

Medical devices: surgical instruments, implants and diagnostic equipment components.

Aerospace: components that require a high strength-to-weight ratio and high temperature resistance.

Automobile: engine components, transmission components and other under-the-hood applications.

Electronic products: connectors, insulators and high-performance electrical components.

Among them, engine components, transmission components and other under-the-hood applications of automobiles can use Overmolding.

It has the following characteristics:

Enhanced performance: Overmolding can improve the strength and stiffness of components and is suitable for applications that withstand high temperatures and high loads.

Complex shapes: It is possible to manufacture components with complex shapes, which are suitable for demanding applications such as automotive engines and transmission components.

Material saving: By optimizing material distribution, waste is reduced and material utilization is improved.

Good surface quality: Overmolding can provide better surface quality and reduce the need for post-processing.

PEI Precision Component Molds

Electronics: PEI's excellent electrical insulation properties and chemical resistance make it suitable for electronic applications that require high electrical performance and stability, such as electrical insulation components, connectors, switches and circuit boards.

Consumer goods: PEI injection molding is used for consumer goods such as household appliances, toys and sports equipment.

Optical equipment: PEI High-Temperature Molds’ temperature stability and mechanical strength make it suitable for optical instruments and military applications, including structural components, protective covers and optical instruments.

Energy: PEI injection molding is used for energy industry components, including wind turbine components, solar panel components and nuclear reactor components.

Among them, household appliances can use micro molding. It has the following characteristics:

High precision and miniaturization: Micro injection molding technology is able to manufacture extremely small parts, usually in the range of a few millimeters to a few centimeters, which is suitable for small components in household appliances.

Complex geometry: This technology can achieve complex designs and subtle details to meet the high requirements of functionality and aesthetics for household appliances.

High material utilization: Micro injection molding can effectively reduce material waste, maximize the use of PEI resin and reduce costs.

Excellent mechanical properties: PEI material itself has excellent mechanical properties, high temperature resistance and chemical resistance, suitable for high-performance components of household appliances.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).