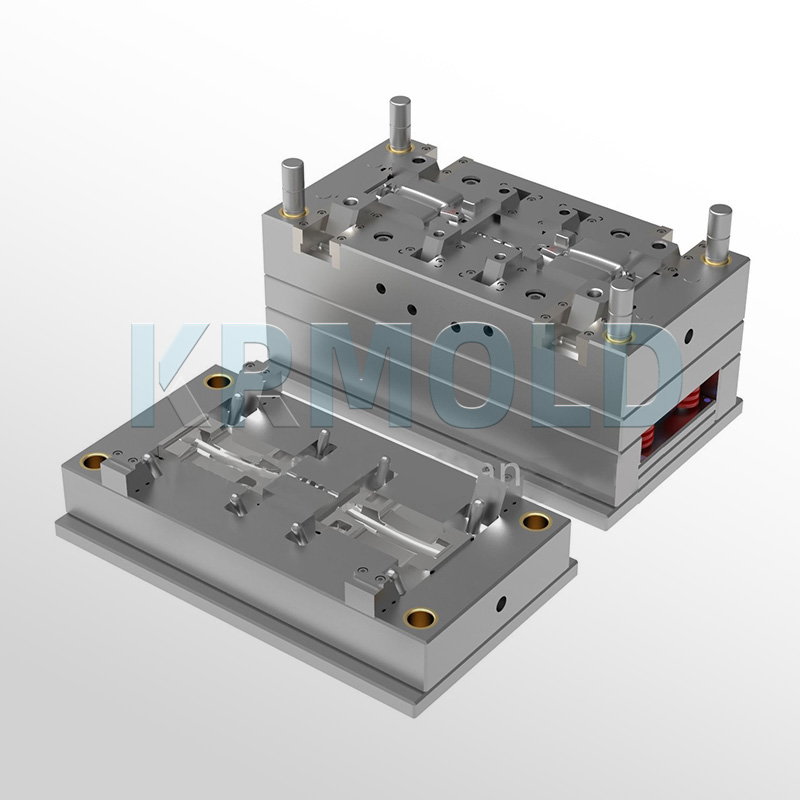

Introduction to PP/PPE Injection Molding

——

PP/PPE Injection Molding are two types of plastic materials that are often used in plastic injection molding. PP stands for polypropylene, which is a polymer made from propylene through polymerization. It is a thermoplastic synthetic resin with excellent performance and a colorless, translucent, thermoplastic, lightweight general-purpose plastic. PPE stands for polyphenylene ether, a high-performance thermoplastic plastic that is popular in the injection molding industry due to its excellent mechanical properties, chemical resistance and dimensional stability. At the same time, due to the unique combination of heat resistance, stiffness and toughness, PPE resin has become an ideal choice for a wide range of aplications in various industries.

Injection Molding Processing Conditions

——

PPE injection molding processing conditions

| Drying | Recommend drying before molding for approximately 2 - 4 hours at 100 C (212 F). PPOs have low levels of moisture absorption can typically be molded as received. |

| Melt Temperature | 240 - 320 C (464 - 608 F); higher ranges for grades with higher levels of PPO |

| Mold Temperature | 60 - 105 C (140 - 220 F) |

| Material Injection Pressure | 60 - 150 MPa |

PP injection molding processing conditions

| Drying | Not normally necessary if proper storage is used |

| Melt Temperature | 220 - 280 C (428 - 536 F); not to exceed 280 C |

| Mold Temperature | 20 - 80 C (68 - 176 F); suggested: 50 C (122 F) The crystallinity level is determined by the mold temperature. |

| Material Injection Pressure | Up to 180 MPa |

Advantages of PP/PPE Injection Molding

——

Advantages of Thin-Wall PP Container Molds

① Moisture resistance and durability

PP injection molded polypropylene materials have excellent moisture resistance, fatigue resistance and impact resistance. This means that in humid or extreme environments, PP molded products can maintain their structural stability and functionality, reduce damage caused by environmental factors, and thus extend their service life.

② Electrical insulation performance

Polypropylene is an ideal electrical insulator in Medical-Grade PP Molds, which can effectively prevent the conduction of current. This makes PP molded products suitable for electrical equipment and related applications, ensuring the safety of users during use, especially in situations where electrical isolation is required.

③ Chemical resistance

PP injection molded polypropylene has good chemical resistance to a variety of acids and alkalis. This makes it widely used in industries such as chemicals and medicine, and can be used safely in environments with contact with chemicals to reduce the risk of material corrosion.

④ High flexural strength

Due to the semi-crystalline nature of polypropylene, PP injection molded products by Food-Grade PP Molds exhibit high flexural strength. This property allows polypropylene to be made into living hinges, which can bend without breaking even under extreme movements (such as 360-degree rotation), thereby improving the flexibility and durability of the equipment.

⑤ Copolymerization with other polymers

In High-Temperature PP Molds, polypropylene can be easily copolymerized with other polymers such as polyethylene. This property enables the manufacture of more robust and durable materials in engineering applications to meet the stringent requirements and diverse needs for material performance in different fields.

Advantages of PPE injection molding

① Customization and consistency

The PPE injection molding process allows highly customized designs to accommodate a variety of sizes, shapes and functional requirements. This flexibility ensures that PPE products can meet specific safety standards and the personalized needs of users. At the same time, through injection molding technology, thousands of identical PPE units can be mass-produced, ensuring consistency in quality and performance of each product and meeting the industry's strict quality control standards.

② Adjustability function

In Automotive PP Component Molds design, adjustability is an important feature. For example, adjustable straps on helmets or respirators can adapt to the head size and shape of different users, thereby improving wearing comfort and secure fit. This design not only improves the user experience, but also enhances the protective effect, ensuring that it is not easy to fall off or create gaps during use.

③ Shorten the cycle time

Thin-Wall PP Container Molds can significantly shorten the production cycle, and the cycle time of some simple parts can be as low as 15 seconds. This efficient production method not only speeds up the time to market, but also meets the market's demand for fast delivery, helping companies gain an advantage in the competition.

④ Reduce material waste

The precision of the PPE injection molding process minimizes material waste. This efficient material use method not only reduces production costs, but also improves environmental sustainability and makes the production process more environmentally friendly. By optimizing material use, companies can actively respond to global calls for sustainable development while meeting production needs.

Features of PP/PPE

—

PP:

The heat resistance is very good. PP products by High-Temperature PP Molds can be used in high temperature environments below 100 degrees for a long time, and the temperature will not be significantly deformed when it reaches about 150 degrees. And the density of PP material is relatively small, which is 0.81-0.91g/㎝3, which is the lowest density among commonly used plastics. PP material has good mechanical properties, high heat resistance, good chemical properties, almost no water absorption, no reaction with most chemicals, pure texture, non-toxicity, and good electrical insulation.

PPE:

PPE plastic has excellent heat resistance because it can survive in high temperature environments without changing its original mechanical properties. Secondly, PPE plastic has excellent chemical resistance, acid resistance, alkali resistance and solvent resistance. In addition, PPE plastic has dimensional stability, which ensures that the shape and size of this material remain consistent under different conditions. PPE plastic is also known for its flame retardancy, which can provide higher safety in situations involving fire hazards.

Application Areas of PP/PPE Injection Molding

——

"There are many application areas for PPE injection molding and PP injection molding. For example, PPE injection molding can be used to manufacture mask frames, respirator mask shells, goggles frames and lenses, and certain ventilator components. High-Temperature PP Molds can be used to manufacture small appliances, daily necessities, toys, washing machines, cars, packaging boxes, etc."

KRMOLD has selected some for detailed introduction:

Medical industry:

① Mask frame

Injection molding processes that can be used:

(1) Insert molding

Features: Metal or other materials can be embedded during the injection molding process to enhance structural strength and durability. Suitable for complex parts that require special support to ensure the stability of the mask.

Features: Allows surface decoration during the injection molding process, such as pattern printing or color matching, to enhance the appearance and functionality of the product, suitable for medical equipment that requires beauty and easy cleaning.

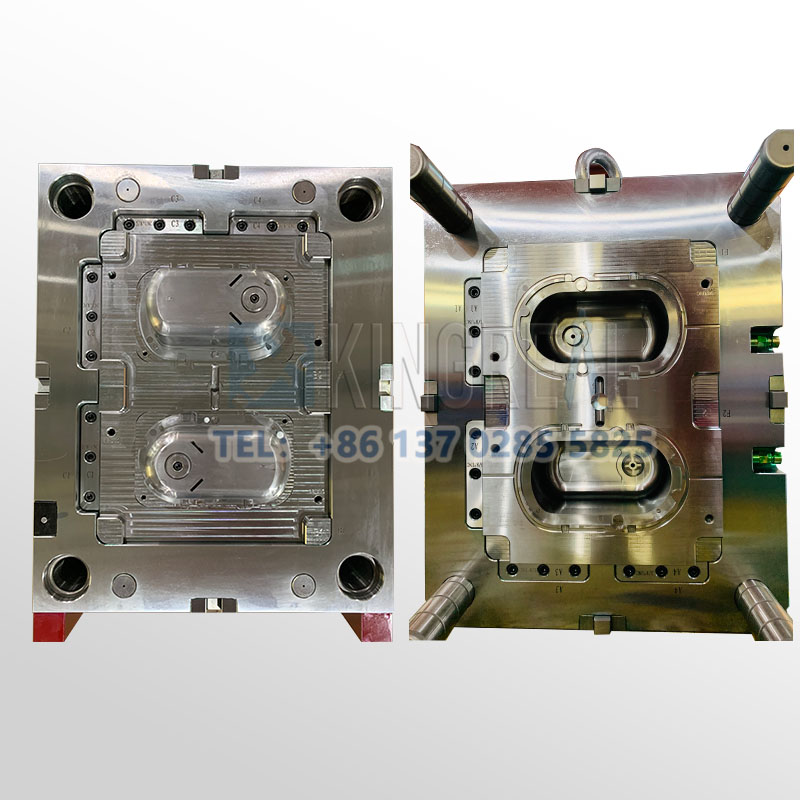

② Respirator mask shell

(1) Overmolding

Features: By wrapping plastic around other materials, it provides better sealing and protection, ensuring the safety and effectiveness of the mask shell during use.

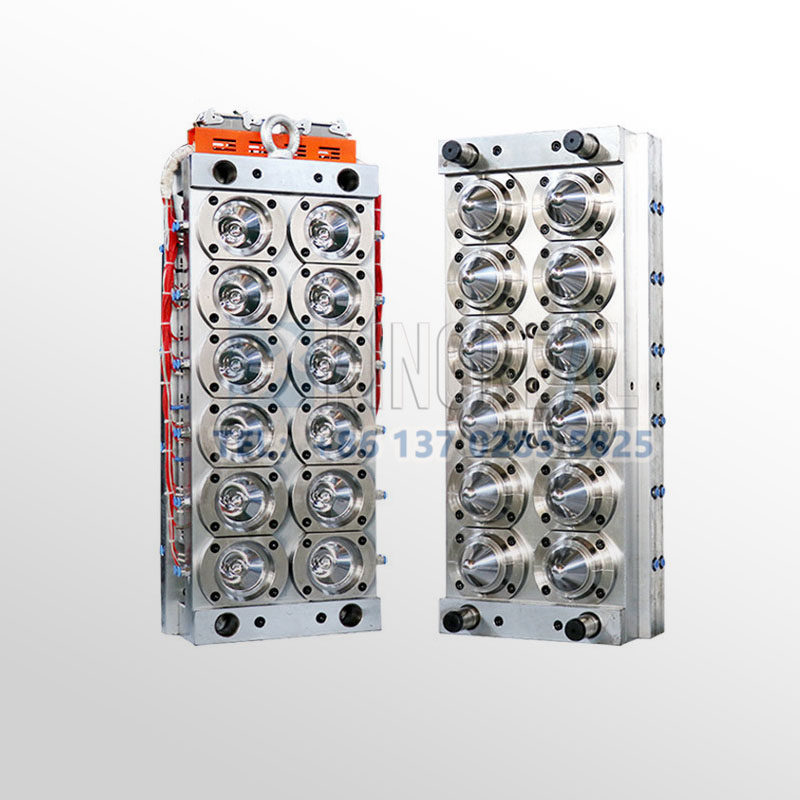

(2) Multi-cavity injection molding

Features: It can produce multiple identical shells in the same production cycle, greatly improving production efficiency, suitable for large-scale production needs, and reducing unit costs.

Home appliance industry: washing machines

Available injection molding processes:

(1) Double shot injection molding

Features: Using two different materials in the same process can produce shells with different characteristics, such as one side is soft and the other side is hard, providing better user experience and functionality.

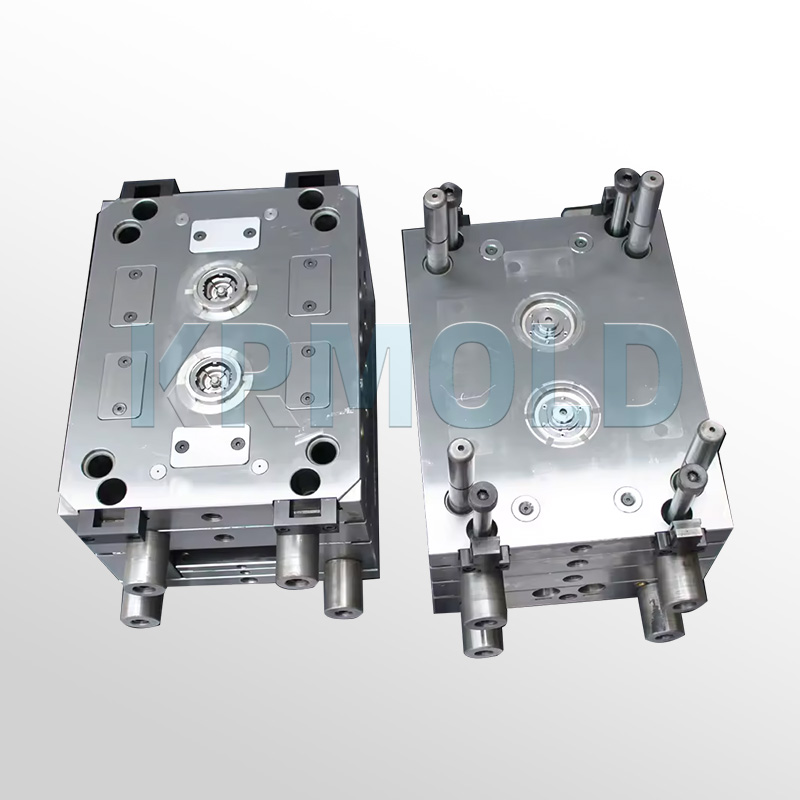

(2) Gas-assisted injection molding

Features: Using gas assistance, it can produce lighter and more stable components, reduce material usage, improve production efficiency, and reduce costs.

Automotive industry: automotive parts

Available injection molding processes:

(1) Multi cavity injection molding

Features: It is suitable for large-scale production of automotive parts. It can produce multiple parts in the same cycle, improve production efficiency, reduce production costs, and ensure the consistency of each part.

Features: It is used to produce small and precise automotive parts, such as switches and buttons, and can achieve high precision and detailed design, which is suitable for the needs of modern cars for small parts.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).