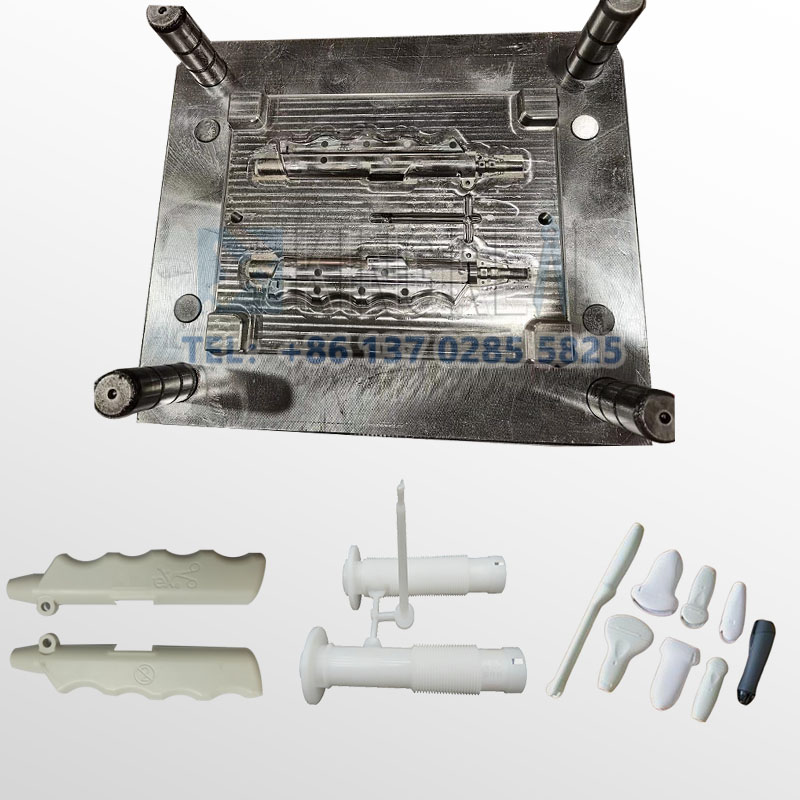

"KRMOLD medical injection molds are capable of producing a variety of complex and precise medical plastic products, making them essential tools in medical device manufacturing. With KRMOLD medical injection molds, customers can efficiently produce a wide range of medical devices, including disposable syringes, plastic test tubes, cell culture dishes, culture flasks, dispensers, pipette tips, atomizer cans, and respirators."

KRMOLD boasts strong R&D capabilities and a comprehensive service team, along with over 100 sets of processing equipment. KRMOLD has established strong partnerships with numerous renowned medical device manufacturers both domestically and internationally. In recent years, through in-depth R&D and technological advancements, KRMOLD surgical instrument injection molds boast not only high quality and precision, but also boast high transparency, a dent-free surface, and high precision, further enhancing the performance and safety of medical devices.

1/ Complete Medical Injection Mold Customization Solutions

KRMOLD offers complete medical injection mold solutions, encompassing the entire process from mold creation, design, production, and mold testing. KRMOLD medical device housing injection mold customization services ensure that every step meets the customer's specific needs.

(1)Centrifuge tube injection mold making

KRMOLD will organize a new disposable medical syringe injection mold workshop for in-depth discussions with the client to determine the new surgical instrument injection mold requirements and acceptance criteria. During this phase, KRMOLD staff will provide comprehensive recommendations based on their experience with other clients in medical injection mold projects, taking into account the client's specific project requirements and national medical industry standards.

The KRMOLD team will conduct thorough pre-project preparation, including requirements communication, solution development, mold design for manufacturability (DFM), and mold flow analysis. By efficiently and accurately understanding client needs, KRMOLD is able to provide a corresponding solution. Furthermore, KRMOLD experienced sales team and responsive service mechanism ensure prompt medical device housing injection mold optimization and solutions, ensuring a smooth project progress.

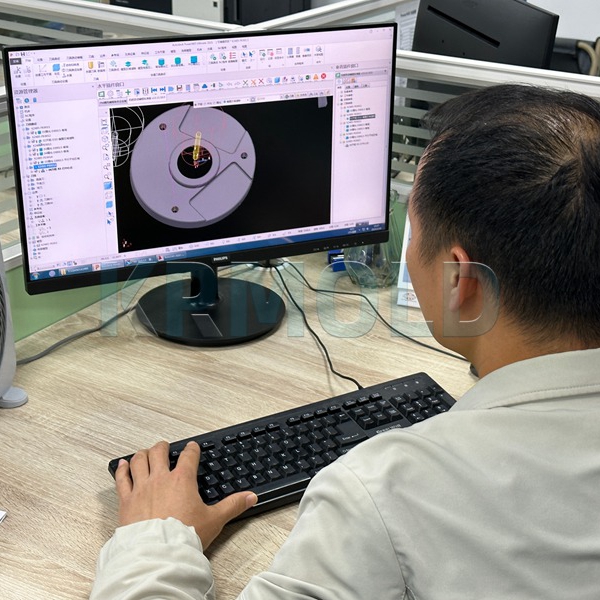

(2)Centrifuge tube injection mold design

Once the requirements are confirmed, KRMOLD will immediately begin disposable medical syringe injection mold design. KRMOLD design team possesses extensive product structure expertise, combining R&D and production expertise to ensure the design meets both product and surgical instrument injection mold requirements. During the design phase, KRMOLD will work closely with the client, and will not proceed until the client approves the design proposal. Through this collaborative effort, KRMOLD is able to significantly improve medical device housing injection mold development progress and injection molding yield, thereby reducing mold development time and costs. Customers enjoy high efficiency and affordable pricing, ensuring every customer can truly experience KRMOLD expertise and service.

(3)Centrifuge tube injection mold manufacturing

During the disposable medical supplies injection mold manufacturing process, KRMOLD pays close attention to every detail and promptly addresses any issues, ensuring that samples meet production standards. KRMOLD has its own manufacturing workshop and technical team, eliminating the need to work with multiple factories. This ensures high coordination across all processes, ensuring efficiency and quality.

KRMOLD utilizes advanced processing equipment and precision manufacturing processes during medical device housing injection mold manufacturing, ensuring that each medical injection mold meets the highest industry standards for quality and performance. KRMOLD technical team rigorously controls every step of the manufacturing process according to the design drawings to ensure a flawless final product.

(4)Surgical instrument injection mold testing

After disposable medical syringe injection mold completion, KRMOLD staff conducts comprehensive testing to ensure centrifuge tube injection mold performance and quality. Testing includes visual inspection, dimensional inspection, surgical instrument injection mold structure inspection, injection molding performance inspection, material and heat treatment inspection, and cooling and heating system inspection. Through these rigorous testing processes, KRMOLD ensures that every medical device housing injection mold meets established standards, ensuring that customers receive safe and reliable products.

2/Advantages of Medical Injection Mold

1

Efficient production for centrifuge tube injection mold

Surgical instrument injection molds enable the rapid and accurate manufacture of various shapes and specifications of medical devices, such as syringes, infusion sets, and blood collection devices. Through the application of automation and intelligent technologies, KRMOLD disposable medical syringe injection molds enable efficient, large-scale production, improving production efficiency and reducing costs. KRMOLD surgical instrument injection molds can produce large quantities of qualified medical devices in the shortest possible time, significantly shortening the time to market.

2

Quality assurance for surgical instrument injection mold

KRMOLD pays attention to every detail to ensure that disposable medical syringe injection molds deliver high standards of product quality and safety, meeting the stringent clinical demands for medical devices. KRMOLD medical device housing injection molds undergo rigorous testing and verification to ensure that every part meets industry standards. Whether in material selection or process control, KRMOLD prioritizes quality to ensure patient safety.

3

Flexibility for medical device housing injection mold

Due to the coordinated changes in the disposable medical supplies injection mold's male and female dies and auxiliary molding systems, medical injection molds can produce a wide range of parts in various shapes and sizes, offering high flexibility. This flexibility enables KRMOLD to provide customers with personalized product solutions that meet diverse market demands. Whether it's large-scale production or small-batch customization, KRMOLD can efficiently handle it.

4

Cost-effectiveness for surgical instrument injection mold

KRMOLD disposable medical supplies injection molds not only offer efficient production capabilities, but also reduce production costs while ensuring high product quality. Through optimized design and production processes, KRMOLD reduces material waste and production time, enabling customers to enjoy high-quality products while achieving a more competitive cost advantage.

KRMOLD is committed to providing customers with the best medical injection mold solutions. Whether it's a disposable medical device or a complex medical device, KRMOLD disposable medical syringe injection molds can meet your diverse needs. Contact KRMOLD today to explore the endless possibilities of medical injection molds!