What Is Medical Device Housing Injection Molds?

——

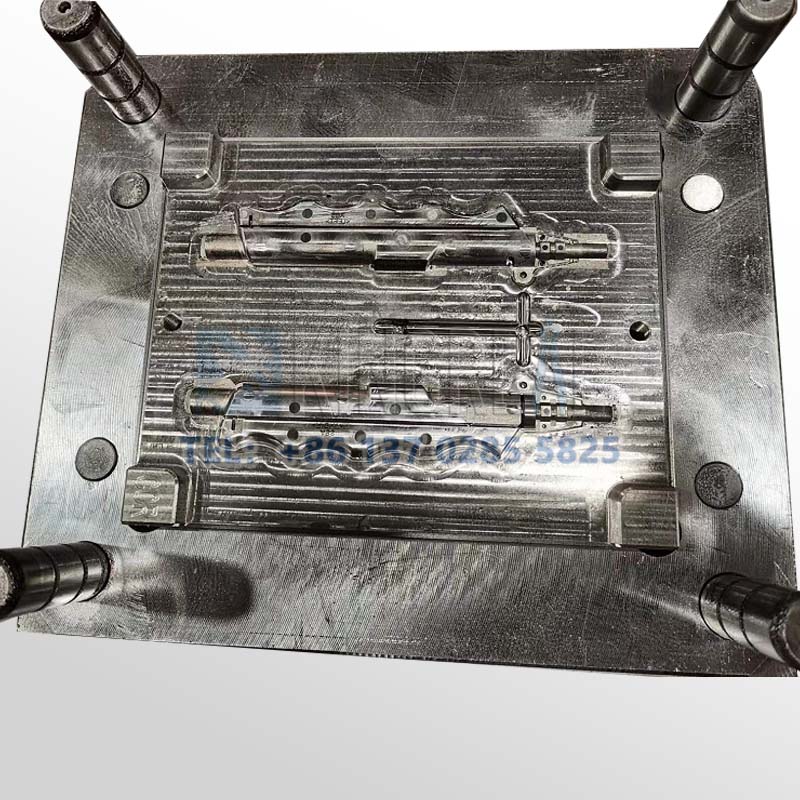

Medical Device Housing Injection Molds do not refer to a specific type of plastic product injection molds, but for the production of medical equipment plastic housing precision molds, injection molds involved in the case of diagnostic equipment housing injection molds, surgical instrument housing injection molds and medical consumables components injection molds, etc., can produce the type of plastic products Up to hundreds of kinds of plastic products can be produced, medical equipment shell injection molds for a wide range of products, KRMOLD through the analysis of medical equipment shell products for the design and production of molds, to meet the high quality of medical injection molded products of high aseptic requirements.

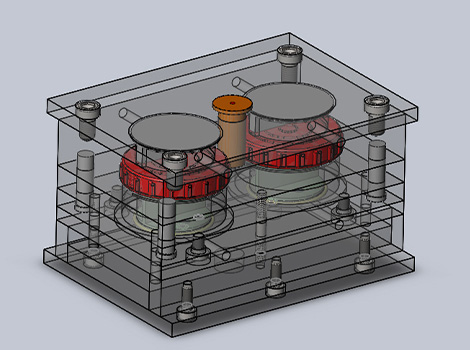

Medical enclosure injection molds are mainly composed of two parts: concave mold and convex mold. A concave mold usually includes a concave mold combination base plate, a concave mold assembly, and a concave mold combination plate, while a convex mold includes a convex mold combination base plate, a convex mold assembly, a convex mold combination plate, and a cavity cutoff assembly. Coordinated variations of these components allow injection molds to accommodate different shapes and sizes of medical housing plastic products.

What Is The Feature Of Medical Device Housing Injection Molds?

——

medical housing injection molds can quickly and accurately manufacture medical housing supplies of various shapes and specifications, such as syringe barrels, endoscopic handles, ultrasonic equipment housings and so on. Through automation and intelligent technology, efficient and large-scale production of medical outer frame injection mold products can be realized, so as to improve production efficiency and reduce costs.

The quality and performance of the mold directly affect the quality of the finished product. Medical injection molds can ensure the quality and safety of the products to meet the clinical demand for medical supplies.

Due to the coordinated changes of the convex and concave molds and auxiliary molding system of the medical injection shell molds, the medical injection molds can process a series of plastic parts with different shapes and sizes, which has a high degree of flexibility.

How To Manufacturing The Medical Device Housing Injection Molds?

——

1

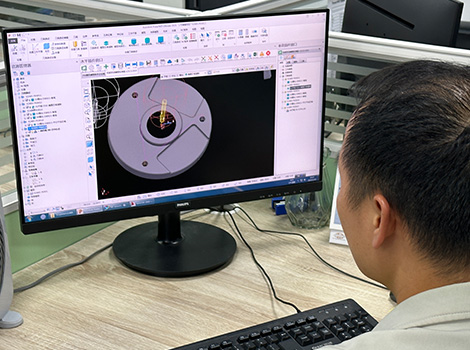

Injection mold design

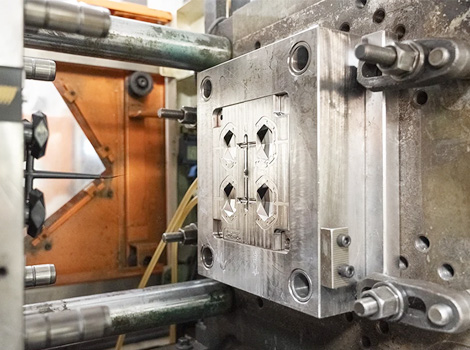

The use of CAD software for the need to produce three-dimensional modeling of medical frame plastic products, the design of injection mold cavity and type to achieve uniform heat dissipation, to prevent deformation of the shell or indentation of the core structure, to ensure the geometric accuracy of the shell. Complete the design of the cooling system of the injection mold, over the layered water circuit or nozzle structure.

2

Injection mold steel material selection

Medical plastic shell injection mold such as S136, 718 pre-hardened steel and other highly wear-resistant raw materials to meet the injection mold high-volume high-yield long-term production needs. The use of NAK80 steel mirror polishing materials for high finish requirements. Generally speaking, the selection of raw materials for injection molds needs to be decided by considering the service life of the molds and the production capacity of plastic products. If customers have special requirements, KRMOLD can also provide customized services.

3

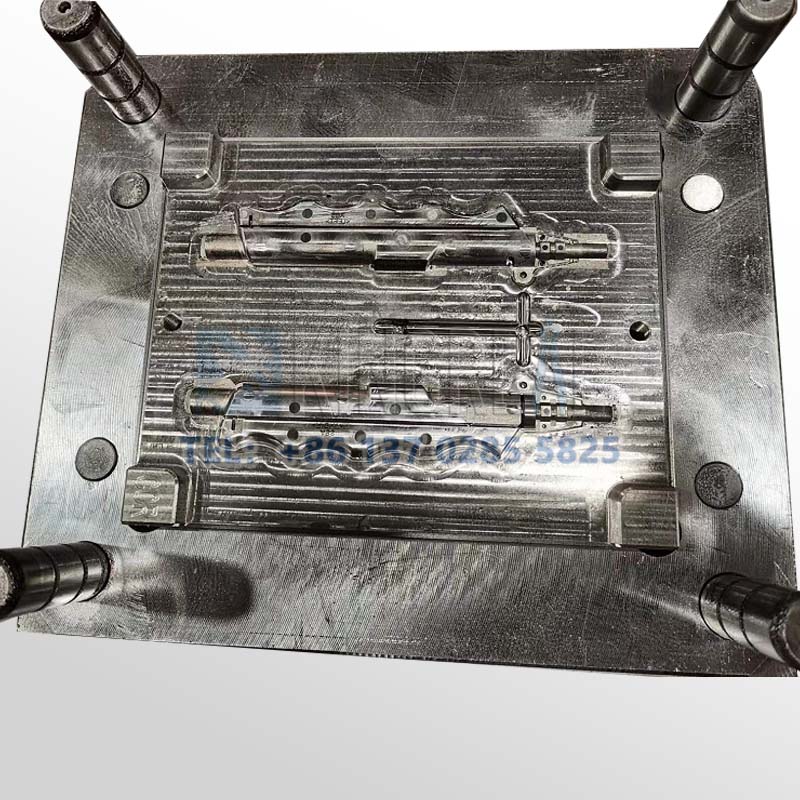

Injection Mold Manufacturing and Processing

Medical plastic frame injection molds are manufactured by CNC 5-axis milling machine for complex surfaces, and copper electrode discharge machining (EDM) for deep bone positions and precision slots. At the same time, KRMOLD is also equipped with wire cutting machines, grinding machines, drilling machines and other internationally renowned brands of processing equipment to complete the injection mold precision processing license.

4

Precise quality inspection system

After the completion of the manufacturing process of the medical plastic frame injection mold, the core accuracy of the mold will be measured by the professional inspection equipment such as secondary and tertiary yuan. At the same time, we will arrange the testing process of trial mold in the factory to ensure that the plastic parts molded by the injection mold meet the customer's production requirements.

What Services Can We Provide?

——

1.One-stop full-process service

We provide full-process service from integrating requirements, mold design and manufacturing to delivery and after-sales service.

The technical team is deeply involved in the customer's product design stage, optimizing the mold structure and designing the mold drawings through the mold flow analysis software (such as Autodesk Moldflow, UGNX). Equipped with imported CNC, Shadick wire cutting machine, mirror discharge equipment and other precision processing equipment to achieve ±0.02mm precision;

We have a large-scale intelligent workshop to support secondary processing such as silk-screen printing, welding, spraying, etc. We strictly implement the quality system of ISO13485 and IATF16949; meanwhile, we provide free transportation, regular mold maintenance and one-year warranty service.

2.Complete quality control system

There is a full chain production workshop, using Makino five-axis machining centers, Haitian injection molding machines and other well-known equipment at home and abroad to avoid delays in outgoing processing. Through the CMM coordinate measuring machine, three-dimensional inspection instrument full inspection of key dimensions, the implementation of PDCA cycle quality management. Meanwhile, we provide complete quality inspection report of injection molds.

3.Accurate delivery control to guarantee the project schedule

Through digital management, production progress monitoring from the beginning of the order, for different orders and delivery date for data monitoring, once there are factors that may be delayed, immediately arrange to speed up the production schedule, to ensure that the customer in the delivery period to complete the manufacturing of plastic injection molds.

4.Provide injection molds in the factory trial mold modification services

The production workshop is equipped with injection molding machines of famous brands at home and abroad, such as Nissei and Toshiba of Japan, etc. We provide customers with factory trial mold testing services to ensure the quality and precision of the molds. We provide inspection report after mold trial and assist customers to adjust injection parameters.

What Are The Common Materials Used For Medical Plastic Enclosures?

—

| Material | Feature | Application |

Polyvinyl chloride (PVC) | Low cost, chemical-resistant, easy to process, but some containing plasticizer DEHP may precipitate | Hemodialysis lines, respiratory masks, oxygen tubing and other non-direct contact with drugs or implanted device housings 348 |

Polycarbonate (PC) | High transparency, impact resistance, high temperature steam sterilization, in line with the high safety standards for medical devices. | Hemodialysis filters, surgical tool handles, monitor housings, etc., where high transparency and durability are required |

| Thermoplastic polyurethane elastomer (TPU) | Good flexibility, anti-hydrolysis, anti-coagulation, suitable for parts in contact with blood. | Flexible housings for medical catheters, sphygmomanometer bladders, etc. |

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).