Specification Of Surgical Instrument Injection Molds

——

| Mould Material | SKD61,DAC55,Dievar |

| Mold Surface Processing | Titanium plated or nitrided |

| Mould Size | 50×50×30mm |

| Mold Tolerance | ±0.02mm |

| Mold Cavity | Single/Multi |

| Mould Runner | Hot Runner/Cold Runner |

| Mold Life | 50K Shot |

| Product Material | PC+S316 |

| Insert Material | Stainless steel/titanium alloy |

Why Need To Choose Scalpel Handle Molds?

——

Meet the requirements of medical grade materials and complex structures

Surgical instruments require the use of bio-compatible materials such as LCP, PEEK, etc. These materials have the characteristics of high temperature resistance and chemical corrosion resistance, resulting in processing difficulties. While traditional cutting processes are inefficient and costly, injection molds enable efficient and precise molding of complex structures such as thin-walled, micro-perforated, and spiral channels.

Through Insert Molding (Insert Molding) platinum tungsten alloy spring ring and stainless steel conductive terminal metal parts and plastic combination, to avoid secondary assembly contamination, and improve the sealing.

Guaranteeing the sterility of medical instruments

Surgical Instrument Injection Molds are manufactured and injection molded in ISO 7 clean room to avoid particle contamination and ensure the surface finish of the instruments to meet the requirements of surgical sterility.

KRMOLD takes the final sterilization of the instruments into consideration in the design of the molds to ensure that the material will not be deformed or degraded after sterilization.

Advantage Of Scalpel Handle Molds

——

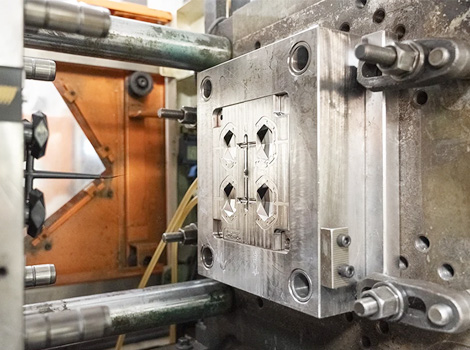

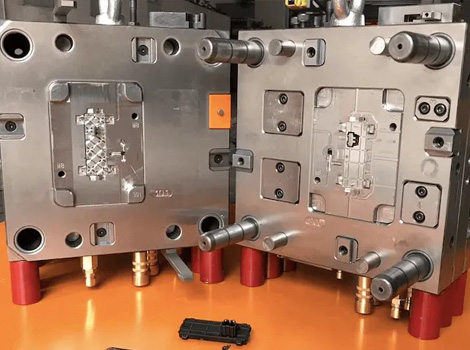

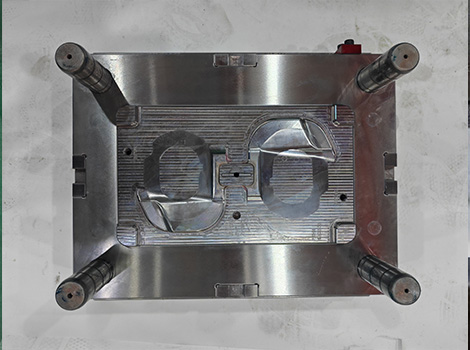

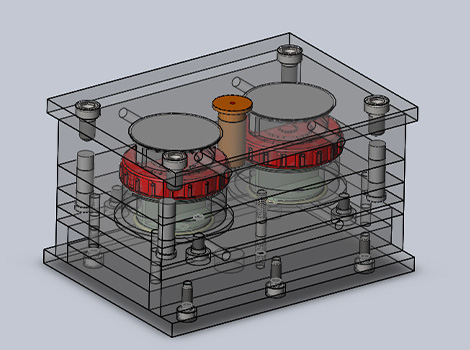

“Injection Mold design for Precision tools for the production of plastic products by injecting molten plastic at high pressure into the mold cavities, cooling and curing to form finished products of specific shapes and sizes.Surgical instrument injection molds consist of a moving mold and a fixed mold, which, when closed, form a pouring Surgical instrument injection molds consist of a moving mold and a fixed mold, which, when closed, form a pouring system and a cavity. The molten plastic is injected into the mold through the nozzle of the injection molding machine, cooled and cured, then the mold is opened and demolded to obtain a Scalpel Handle plastic product that conforms to the shape of the cavity.”

Surgical Instrument Injection Molds have a design tolerance of up to ±0.02mm, which is suitable for complex geometric features of precision instruments such as endoscope components and interventional catheters, such as micropores, thin walls, spiral channels, and other product component models.

Surgical Instrument Injection Molds can adopt multi-cavity mold design, and a single injection molding can mold 4-8 products, and the mass production efficiency is increased by 3-5 times. Using high-performance steels such as Dievar and Anco-T, the life span is 200,000-500,000 molds, and the maintenance cost is reduced by 30%.

Surgical Instrument Injection Molds are equipped with integrated sensors to monitor mold temperature and pressure in real time, combined with AI to optimize molding parameters, with a yield target of ≥99.5%. Through standardized mold frames, different products can be quickly adapted to reduce development costs by 30%.

Manufacturing Of Surgical Instrument Injection Molds

——

Our advantage

Surgical Instrument Injection Molds mold design needs to comply with the ISO1348 quality management system to ensure traceability and production consistency. The sterilization compatibility and bio-compatibility of the instrument need to be considered during the mold design phase.

Injection molds use high-strength, corrosion-resistant mold steels such as SKD61 and Dievar as raw materials to adapt to raw materials such as LCP and PEEK of surgical instrument products. The cavity and core are processed by CNC machining centers with a tolerance control of ±0.02mm, which is suitable for precision structures such as micropores (diameter ≤0.5mm). EDM spark machines are used to form complex textures or deep grooves, with a surface accuracy of mirror level.

After the initial processing and manufacturing of Surgical Instrument Injection Molds, they will be assembled and tested in the assembly workshop. The original injection molds will be tested by precision testing tools such as 2D and 3D. The mold trial process will be carried out in the factory. The mold will be installed in the injection molding machine for the production and testing of plastic parts, and the unqualified parts will be modified and debugged.

"Other processing equipment includes wire cutting machines, milling machines, grinders and polishing machines to perform tight manufacturing processes for injection molds."

Why Choose Us?

—

1.One-stop full-process service

We provide full-process service from integrating requirements, mold design and manufacturing to delivery and after-sales service.

The technical team is deeply involved in the customer's product design stage, optimizing the mold structure and designing the mold drawings through the mold flow analysis software (such as Autodesk Moldflow, UGNX). Equipped with imported CNC, Shadick wire cutting machine, mirror discharge equipment and other precision processing equipment to achieve ±0.02mm precision;

We have a large-scale intelligent workshop to support secondary processing such as silk-screen printing, welding, spraying, etc. We strictly implement the quality system of ISO13485 and IATF16949; meanwhile, we provide free transportation, regular mold maintenance and one-year warranty service.

2.Complete quality control system

There is a full chain production workshop, using Makino five-axis machining centers, Haitian injection molding machines and other well-known equipment at home and abroad to avoid delays in outgoing processing. Through the CMM coordinate measuring machine, three-dimensional inspection instrument full inspection of key dimensions, the implementation of PDCA cycle quality management. Meanwhile, we provide complete quality inspection report of injection molds.

3.Accurate delivery control to guarantee the project schedule

Through digital management, production progress monitoring from the beginning of the order, for different orders and delivery date for data monitoring, once there are factors that may be delayed, immediately arrange to speed up the production schedule, to ensure that the customer in the delivery period to complete the manufacturing of plastic injection molds.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).