KRMOLD is committed to providing complete custom plastic injection mold manufacturing solutions for customers across various industries. KRMOLD serves not only traditional industries such as automotive, medical, consumer electronics, and home appliances, but also provides agricultural machinery injection molds, marine equipment injection molds, and agricultural machinery injection molds. Whether it's complex aviation equipment injection mold or marine equipment injection mold, or durable agricultural machinery injection mold, KRMOLD will meet customers' diverse mold needs through exquisite craftsmanship and extensive industry experience.

-What can KRMOLD Custom Plastic Injection Mold Do?

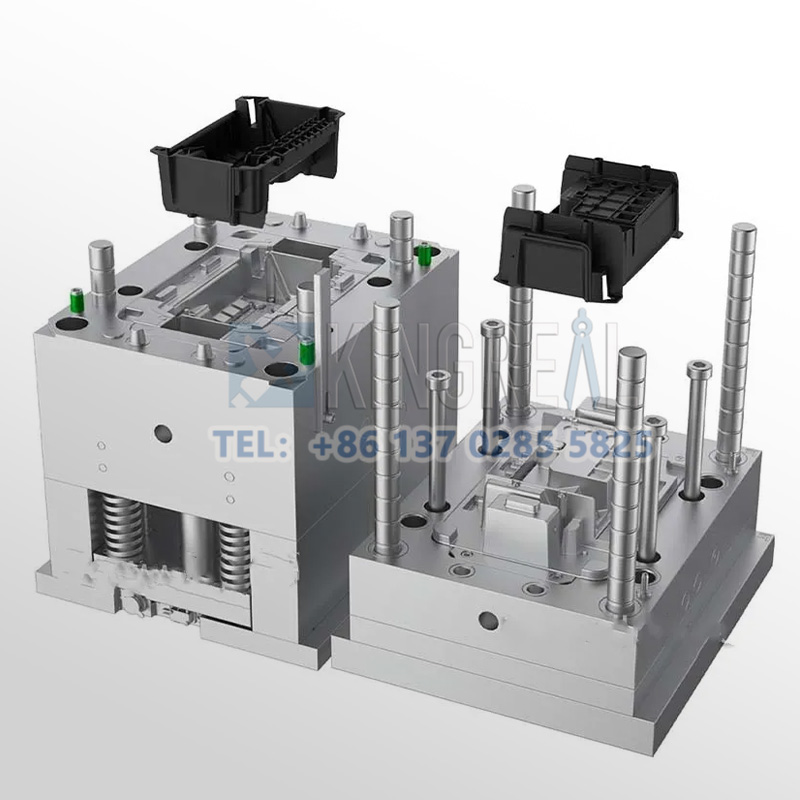

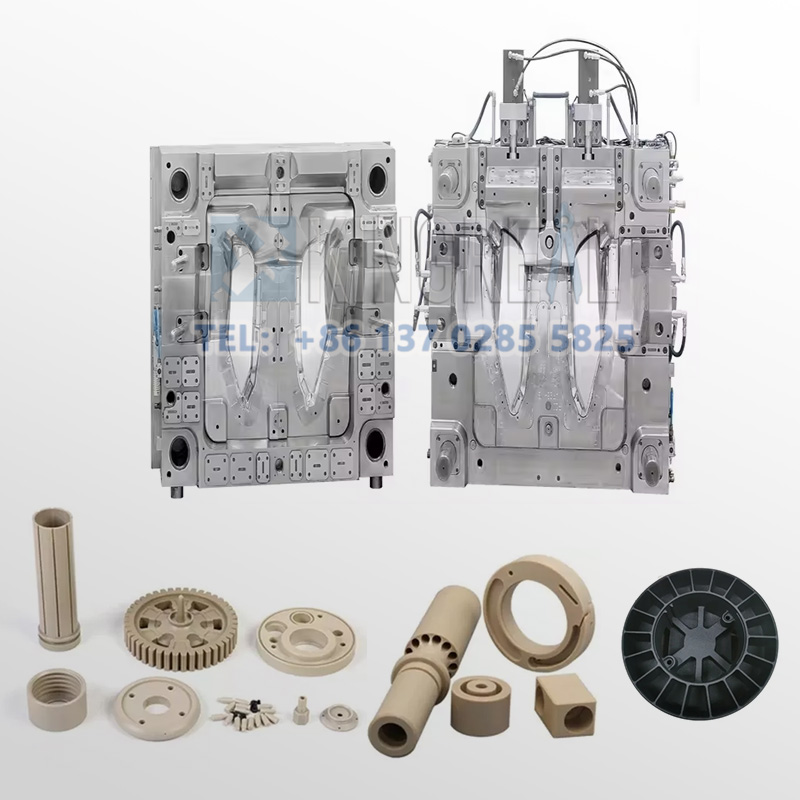

KRMOLD custom plastic injection molds encompass multiple processing stages, including modeling and analysis, mold design, CNC precision machining, EDM, wire EDM, and polishing. A series of precise processes ensure that each agricultural machinery injection mold accurately meets the customer's technical requirements. When designing aviation equipment injection molds, KRMOLD places particular emphasis on analyzing the customer's actual production needs. Every requirement is carefully evaluated, including the product application area, production environment, output, and precision requirements. Through in-depth needs analysis, KRMOLD can design and produce custom plastic injection molds that meet the customer's specific characteristics, ensuring their efficiency and reliability in actual production. Especially in the aerospace, marine, and agricultural machinery manufacturing sectors, custom plastic injection molds not only need to withstand extreme environments but also possess high reliability and complex functions. To meet these stringent requirements, KRMOLD custom plastic injection molds offer the following significant advantages:

| 1. High-strength and high-temperature resistant agricultural machinery injection mold | Aviation equipment injection molds often withstand extreme loads, therefore the selected materials must possess high strength and rigidity while being able to withstand high-temperature environments. KRMOLD typically uses aerospace-grade alloy materials in the production of aviation equipment injection molds to ensure the safety of the custom plastic injection molds used in high-value products such as aircraft. In marine equipment injection molds, these custom plastic injection molds must withstand the severe test of salt spray corrosion. KRMOLD ensures that the marine equipment injection molds can be used for extended periods in marine environments without losing functionality by selecting corrosion-resistant alloy materials or employing surface coating treatments. Agricultural machinery injection molds also need to be resistant to chemical corrosion, and the materials must comply with environmental regulations to ensure that no harmful substances are released when in contact with soil or crops. |

| 2. Aviation equipment injection molds with complex structural designs | The design of aviation equipment injection molds requires micron-level precision, which often necessitates the use of multi-curved surfaces and microporous heat dissipation designs in the mold cavity structure. To achieve this goal, KRMOLD integrates advanced technologies from electrical discharge machining (EDM) and five-axis numerical control (CNC) machine tools. These processing methods not only improve aviation equipment injection mold precision but also lay the foundation for manufacturing complex structures. In agricultural machinery injection mold development, KRMOLD focuses on the perfect combination of functionality and durability. For example, agricultural machinery injection molds must not only effectively transfer seeds but also possess a wear-resistant structure. Marine equipment injection molds utilize laser fused deposition modeling (FDM) technology. This innovative manufacturing method integrates conformal cooling channels, shortening the cooling cycle by more than 30%, thereby reducing the risk of deformation and improving marine equipment injection mold maintenance efficiency. |

| 3. Improving aviation equipment injection mold lifespan | Aviation equipment injection molds face high-frequency stress cycles; therefore, employing special heat treatment processes to enhance their fatigue resistance is crucial. KRMOLD aims to provide the highest quality products while ensuring a mold lifespan exceeding 1 million cycles. In agricultural machinery injection mold design, due to frequent exposure to abrasive particle environments, KRMOLD typically employs surface hardening treatments, such as nitriding coatings, to extend agricultural machinery injection mold lifespan, thereby ensuring a return on investment for customers. |

-KRMOLD Custom Plastic Injection Mold Solutions

KRMOLD provides custom plastic injection mold solutions to meet every meticulous production need.

● Complete and precise agricultural machinery injection mold manufacturing solutions:Based on the customer's budget and requirements, KRMOLD designers will propose a comprehensive agricultural machinery injection mold manufacturing solution. KRMOLD emphasizes the speed of agricultural machinery injection mold manufacturing to respond to rapid market changes, while providing necessary technical support and maintenance services, as well as customization of special accessories.

● Capacity assessment and delivery planning: For each customer's specific application, KRMOLD engineers will conduct a detailed capacity assessment of the aviation equipment injection mold to ensure on-time sample delivery and shipment. This planning allows customers to better manage production and market launch.

● Design for manufacturability analysis and design team: KRMOLD has an independent industrial design team that ensures successful marine equipment injection mold creation and reduces uncertainties in subsequent development processes through early-stage Design for Manufacturability analysis and interactive discussions.

● Continuous R&D and improvement: KRMOLD is committed to continuous improvement in mold R&D and design. Through continuous learning and innovation, KRMOLD enhances its technical capabilities and service quality to adapt to the ever-changing needs of customers.

-Ready to Get Your Custom Plastic Injection Mold?

If you are looking for high-quality custom plastic injection molds, whether for aerospace, marine, agricultural, or other fields, KRMOLD is the ideal choice. KRMOLD professional team will handle the design, manufacturing, trial molding, and debugging, ultimately delivering the custom plastic injection mold to your designated location. Tell KRMOLD your needs, and we look forward to working with you!