Full Solution For Marine Equipment Injection Molds

——

Marine Equipment Injection Molds are injection molding tools specially used for the manufacture of ships, marine engineering equipment and underwater equipment components, injection molded parts and components need to adapt to the marine environment of high corrosion, high humidity, salt spray erosion and other extreme conditions, while Plastic Components for Marine needs to meet the needs of the At the same time, Plastic Components for Marine needs to meet the demand for high-precision molding of complex structural parts of various marine engineering components.

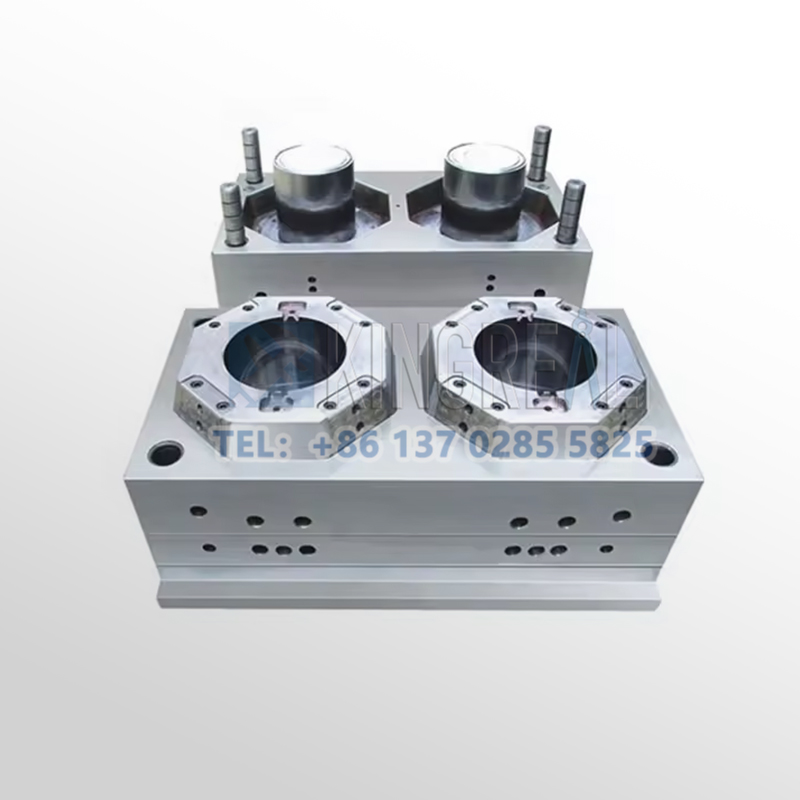

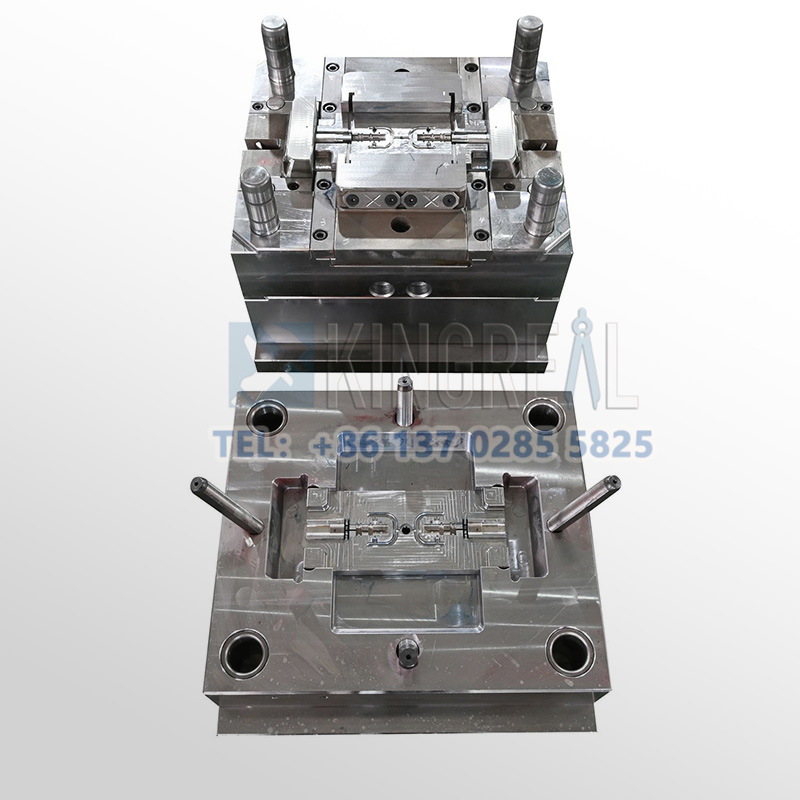

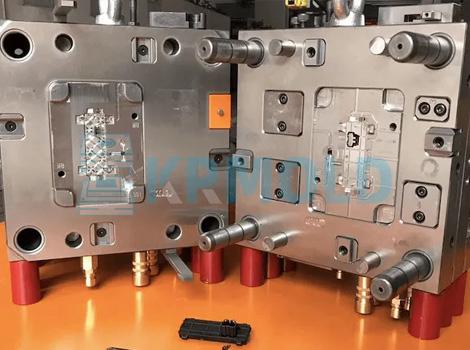

KRMOLD, as an injection mold manufacturer, has nearly 20 years of rich project experience in the field of injection mold design, innovation and manufacturing, and has helped customers in various industries to realize the customized design needs of injection molds, including the automotive industry, the medical industry, the consumer electronics industry, as well as the aerospace and marine industry. In the marine industry, due to the harshness of the marine environment, such as salt spray, microorganisms and seawater corrosion, the injection mold materials and molded parts are very demanding, KRMOLD usually uses anti-corrosion coatings or corrosion-resistant materials on the surface of the injection molds for the production of marine industry components, and to meet the specific needs of the components, KRMOLD will design customized designs for the injection molds. KRMOLD designs customized injection molding solutions for specific parts.

By choosing KRMOLD as a supplier of injection molds, you can obtain a number of services, including analysis of the product requirements of the parts (function, production volume, shape, etc.), 3D model design of the injection molds, CNC machining of the injection molds (including roughing, precision machining, and wire-cutting machines, etc.), factory trial testing and debugging modifications of the injection molds, and other services, to produce injection molds that meet the needs of the products and obtain long-term production benefits for the customers. We can provide customers with injection mold tools that can meet their production needs and gain long-term production benefits.

Feature Of Injection Molds for Marine Equipment

——

Marine injection molds are made of stainless steel 316L, titanium alloy or glass fiber reinforced plastic, the mold surface will also be treated with nickel plating or PTFE coating to enhance the corrosion resistance. In addition, injection molding materials (such as nylon PA66, PEEK) itself with chemical corrosion resistance, suitable for fuel system components or underwater equipment shell.

Marine components require precise geometry and surface finish. Injection molds for the marine industry ensure sealing by reducing air holes through high-pressure injection and vacuum-assisted technology. For complex curved surfaces, carbon fiber/epoxy resin molds can accurately replicate bionic structures to reduce water resistance.

Marine industrial injection molds are designed to withstand the high humidity, high pressure and temperature fluctuations of the marine environment. For example, FRP molds control thermal shrinkage through a layered gluing process to avoid deformation caused by temperature changes. In addition, large hull molds adopt modular design, which is convenient for demolding and maintenance.

Common Marine Equipment Injection Mold Molding Process

——

Gas-Assisted Injection Molding

Marine industrial injection molding adopts Gas-Assisted Injection Molding process to inject inert gas (e.g. nitrogen) at the pressure holding stage to form a hollow structure, which reduces the amount of material used (weight reduction of 15-30%) and improves the impact resistance, especially suitable for large hull parts. Injection molds for the marine industry are commonly used for marine corrosion resistant pipe fittings, where gas pressure is used to control wall thickness uniformity and avoid stress concentration, and gas passage accelerates cooling and shortens molding cycle time.

2K Molding for Marine Industry 2K Molding is a molding process that integrates two different materials or colors on the same product by means of double injection or two-color molds, which improves the functionality and appearance quality. Combining soft and hard materials (e.g. TPU and PA) co-injected in the same mold to achieve functional integration. Common injection molded products include waterproof cable glands, marine handles, buttons and sealing gaskets

Injection Molding Materials Commonly Used in Marine Equipment

—

| Material | Feature | Application |

| PPS (polyphenylene sulfide) | High temperature resistance, chemical resistance, dimensional stability | Waterproof electronic housings, cable connectors. |

| High strength, abrasion and corrosion resistance | Deep-sea equipment, sensor housings | |

| PA (nylon, GF-reinforced) | High strength impact resistance, hydrolysis resistance | Ship's mechanical parts, gears |

| PC (polycarbonate) | High transparency, impact resistance | Radar covers, navigation light covers |

| PP (polypropylene) | Lightweight, weather-resistant | Buoyage and rescue equipment |

| TPU (thermoplastic polyurethane) | Soft, non-slip, abrasion-resistant | Seals, waterproof handles |

"KRMOLD injection molds for the marine manufacturing industry are designed to be material-compatible with different types of plastic raw materials, ensuring the accuracy and longevity of injection-molded parts.

About KRMOLD. KRMOLD focuses on the field of precision mold design and production, with a manufacturing team of 200+ professional technicians, a technical R&D team of 30+ engineers, and a full-cycle service team covering pre-sales consultation to after-sales maintenance, providing full-process services ranging from mold design, precision processing to injection molding.

KRMOLD Mold is equipped with international first-class equipment such as CNC machining centers, Japan Makino precision spark machine, Japan Shadick wire cutting machine, Japan Toshiba injection molding machine and other domestic and international famous brands of production equipment, to achieve ± 0.002mm processing accuracy, to meet the needs of a variety of high-precision plastic injection molds. As a long-term mold supplier for Ford, Mercedes-Benz, BMW and other Fortune 500 companies, Kingreal Mold has delivered more than 500 sets of automotive lighting molds, interior parts molds and other cooperative projects, Kingreal Mold produces injection molds for the automotive industry, medical industry, furniture industry, consumer electronics industry and so on."

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).