Full Solution For Agricultural Machinery Injection Mold

——

As a professional manufacturer of injection molds, KRMOLD is proud to help customers in the agricultural equipment industry to solve their injection molding needs. KRMOLD has a professional injection mold design team, production team, quality inspection team, and injection mold precision manufacturing equipment and injection molding machines to provide customers with professional technical support and production guarantee to help customers solve their KRMOLD provides complete production solutions in the design of injection molds to meet the production needs of agricultural machinery, regardless of the form, function, output, and life span of the parts.

Agricultural machinery parts are exposed to harsh outdoor conditions, frequent use, and agrochemical exposure, so high quality design and precise, seamless production of agricultural machinery parts is a major concern for customers in the agricultural sector. KRMOLD expert technical team analyzes and optimizes the injection mold manufacturing process, always selecting the ideal material and manufacturing process for the customer's customized parts. KRMOLD always selects the ideal material and manufacturing process for customized parts to produce injection molds for agricultural machinery, and ensures the best performance through strict quality tests and final inspections.

In common agricultural machinery and equipment, such as tractors, cultivators, seeders, combine harvesters, irrigation equipment, etc., a large number of parts are needed to meet the manufacturing and long service life of the machinery and equipment, so in the injection mold manufacturing, KRMOLD will not only provide an injection mold, but also evaluate the actual use of scenarios through the selection of raw materials for the injection molds and processing design to meet the needs of customers seeking low cost and quick turnaround. KRMOLD also evaluates the actual usage scenarios by selecting the raw materials and processing design of the injection molds to meet the needs of our customers who are looking for low cost and quick turnaround time.

Agricultural Machinery Injection Mold is made by melting and injecting ABS, PP, PA66 and other raw materials commonly used for agricultural machinery parts into the mold cavities, and then cooling and molding them to obtain agricultural machinery parts with specific shapes, sizes and functions, which are suitable for agricultural machinery with high requirements for durability, complex structures and environmental resistance. Agricultural Machinery Injection Mold is widely used in the manufacture of shells, gears, connectors and other parts of agricultural machinery.

Feature Of Agriculture Plastic Injection Mold

——

Agriculture Plastic Injection Mold common application cases include tractor, harvester, planter and other equipment plastic shell injection molding, agricultural machinery instrument panel, control panel, connectors, shrouds, brackets products injection molding, so what are the characteristics of Agriculture Plastic Injection Mold? What are the characteristics of Agricultural Plastic Injection Mold?

1. Long service life of the mold, high durability: agricultural machinery parts usually need to withstand harsh environments such as high temperatures, moisture and corrosion, Agricultural Injection Mould is generally made of high-strength steel, wear-resistant and corrosion-resistant.

2. High injection molding accuracy requirements: Agricultural machinery parts need to accurately match the mechanical equipment, so the Agricultural Machinery Injection Mould is more accurate to ensure that the injection molded products have the consistency and good assembly.

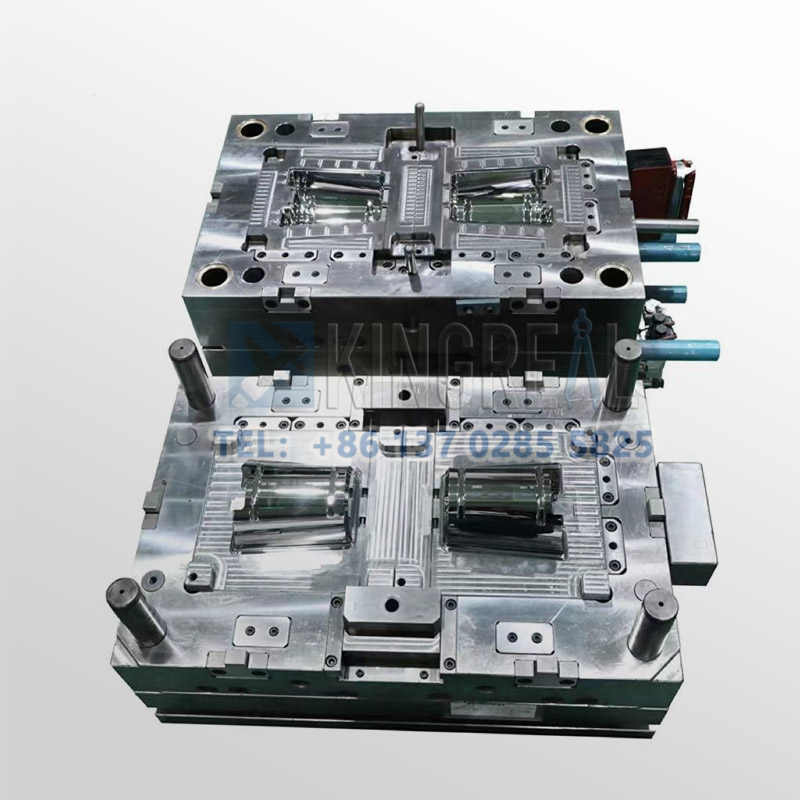

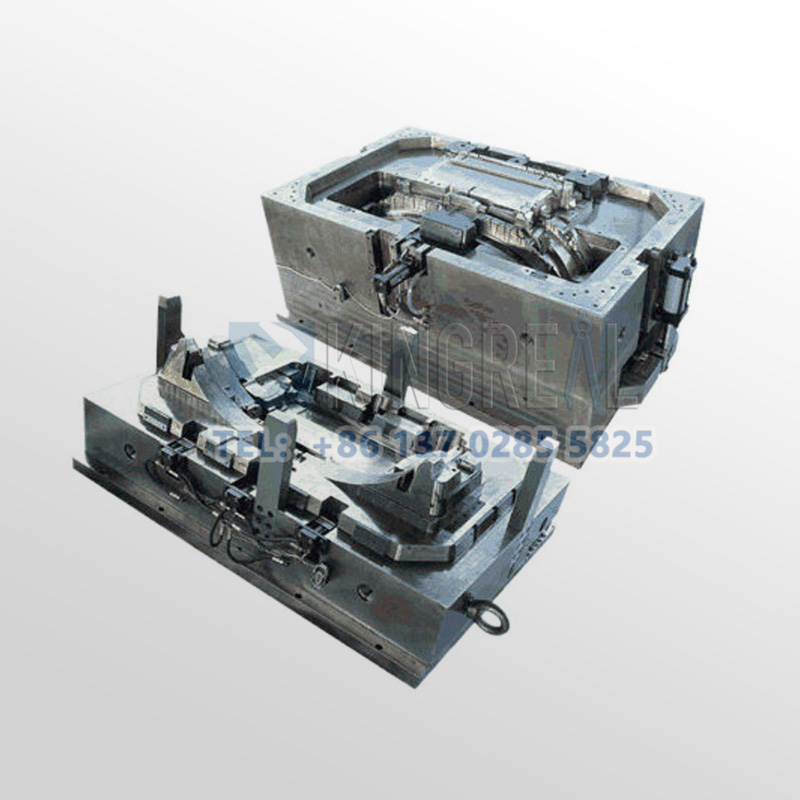

3. Complex structure of agricultural machinery injection mold: some agricultural machinery parts are large, in the design and manufacture of injection molds may involve multi-cavity, slider, inserts and other structural design, in order to meet the complex shape of the molding needs.

4. Multi-cavity injection molding, efficient production: injection molding is suitable for mass production, reducing production costs and improving efficiency.

How To Choose Raw Materials For Agricultural Machinery Injection Molding?

——

Agricultural machinery injection molding using PP as a raw material has chemical resistance, acid and alkali resistance, good impact resistance and other advantages. Common examples of finished products include agricultural machinery shells, shrouds, storage boxes, fenders, instrument panels

2. ABS (Acrylonitrile Butadiene Styrene)

Agricultural machinery injection molding using ABS as a raw material to produce parts required for agricultural manufacturing has a good surface finish, easy to paint and spray, low temperature resistance and other characteristics, commonly used in injection molding production control panels, internal structure of agricultural machinery, handles, instrument housings

3. PA (nylon)

Agricultural machinery injection molding using PA as a raw material for the production of agricultural manufacturing of parts and components required with high mechanical strength, high load-bearing capacity, good chemical resistance, oil and alkali resistance, etc., commonly used in injection molding production of gears, bearing housings, transmission parts, wear-resistant sheaths, etc.

4. POM (paraformaldehyde)

Agricultural machinery injection molding using POM as a raw material for the production of agricultural manufacturing of parts and components required can be POM is used as a raw material for agricultural machinery injection molding to produce parts required for agricultural manufacturing, which can achieve ultra-high impact resistance and good transparency, and is suitable for parts with high strength requirements. Common injection molded products include transparent covers, lampshades, instrument panel housings, protective screens, etc.

Manufacturing Process Of Agricultural Machinery Injection Mold

——

Understand the function, size, and tolerance requirements of agricultural machinery parts, determine the plastic material, evaluate the production lot of the part, and decide the service life of the mold before manufacturing the injection mold.

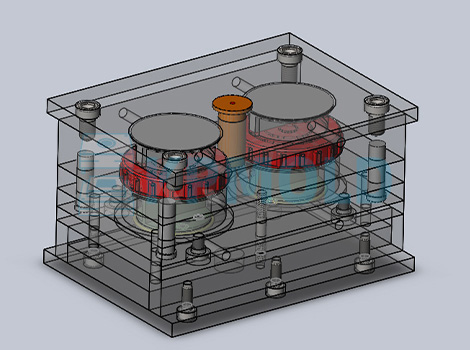

SolidWorks Front CAD design software is used to design the injection mold model according to the customer's needs, and Moldflow and other software are used to simulate the flow path.

The mold steel is made of raw materials such as P20, H13, S136, etc., and the mold cavities are rough machined with CNC milling machine to ensure the basic shape, and at the same time, the EDM, wire cutting, heat treatment and finishing are carried out. Manufacturing process.

After the completion of the agricultural machinery injection mold manufacturing in the factory assembly test mold quality testing process, assembly of moving mold, fixed mold, slider, ejector and other parts, in the injection molding machine for the quality of molding and the fit of the quality testing

FAQ:

1. How to ensure the dimensional accuracy of the mold and product consistency?

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software.

Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage.

Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

2. Molds are easy to wear or short life, how to improve?

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

3. Why is the cost of mold opening higher?

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).