Description of Aerospace Plastic Injection Mold

——

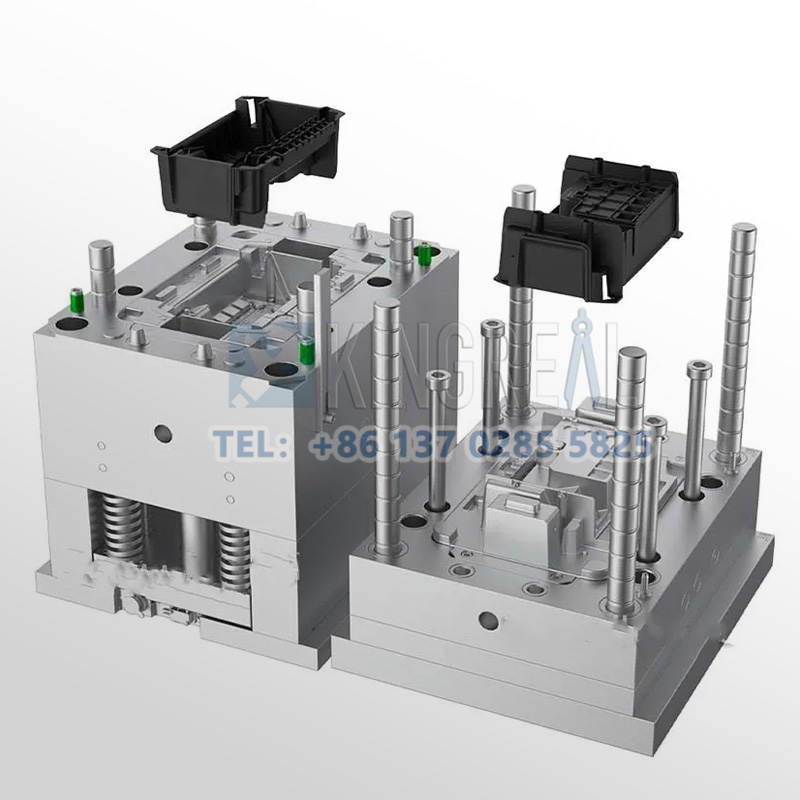

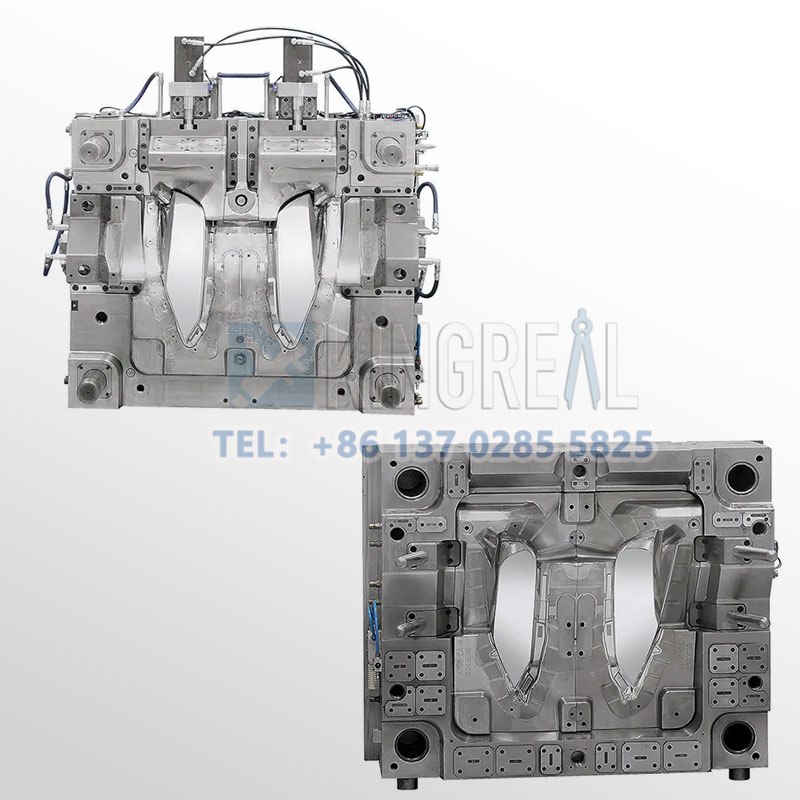

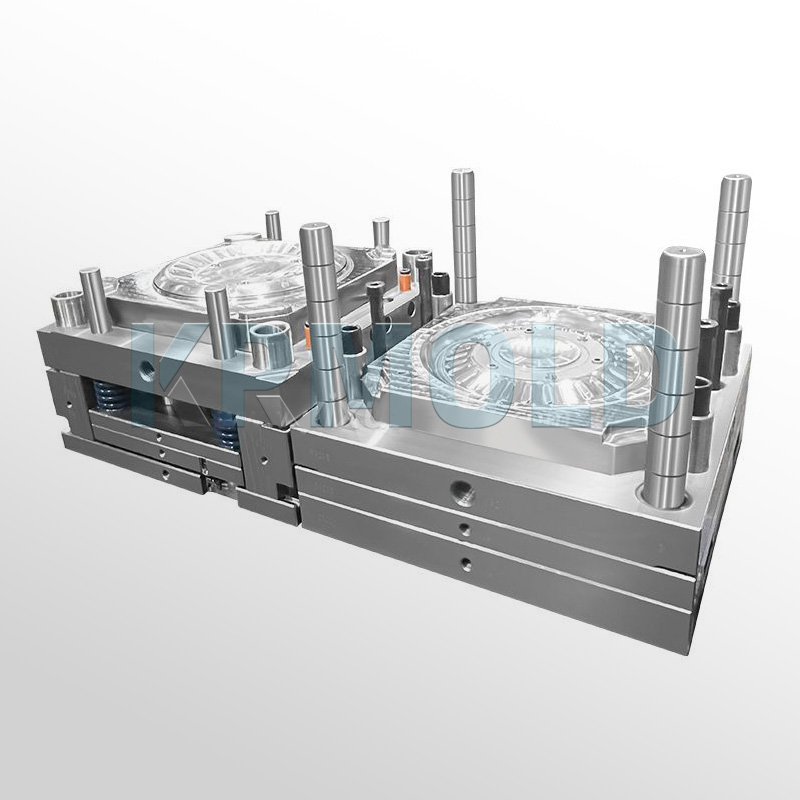

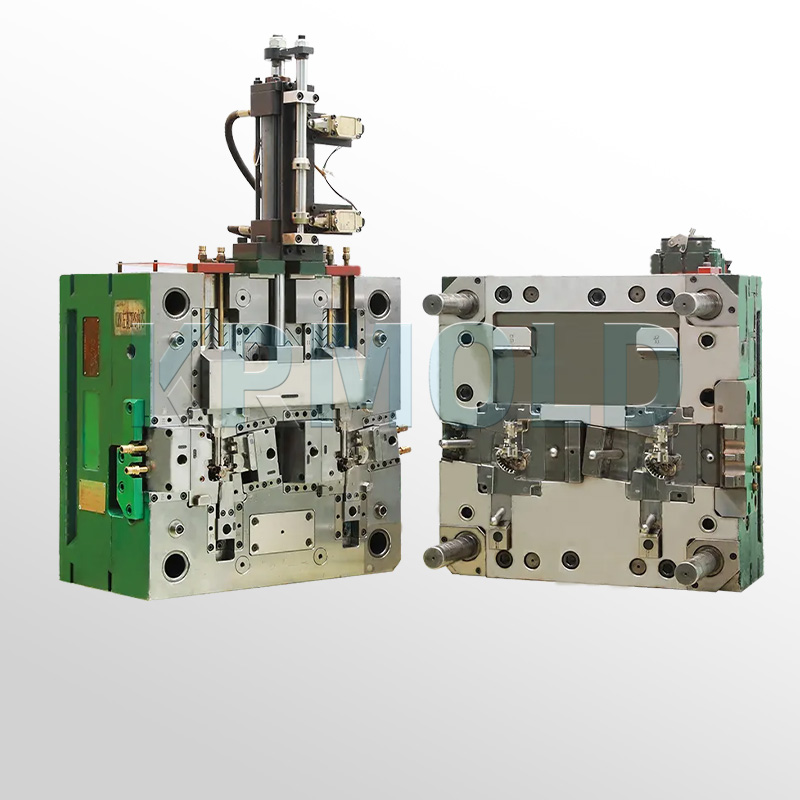

KRMOLD aerospace plastic injection molds are designed specifically for aircraft applications, capable of producing a variety of injection molded parts such as window frames, plastic turbine blades, and nose radomes. Besides improving cost-effectiveness and comfort, these exact injection molded parts help to boost aircraft performance and safety. Meeting the more demanding performance and safety criteria of the aviation sector, KRMOLD aerospace injection molds can manufacture complex, dimensionally accurate parts in a small, lightweight package.

Give your drawings to KRMOLD, and our engineers will give you a customized aerospace plastic injection mold design based on your exact production demands.

Advantages of Aerospace Plastic Injection Mold

——

1)Multiple materials for aerospace injection mold

A range of materials can be used to create aerospace injection molds. By injection molding, KRMOLD engineers can access a wide range of materials to meet the diverse needs of the aerospace industry for parts and prototypes. Commonly used materials include ABS, HDPE, and PP, which provide more flexibility and adaptability in the manufacture of aircraft elements. Moreover, the remarkable strength of these polymers guarantees that finished components in challenging situations will last and reliable.

2)Precision aerospace injection molds for aerospace parts

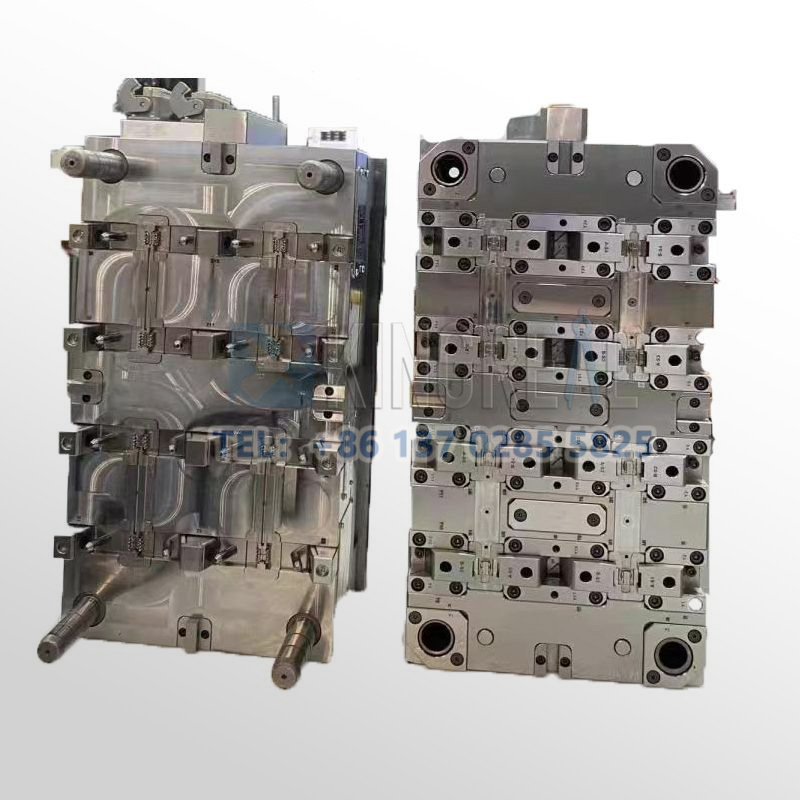

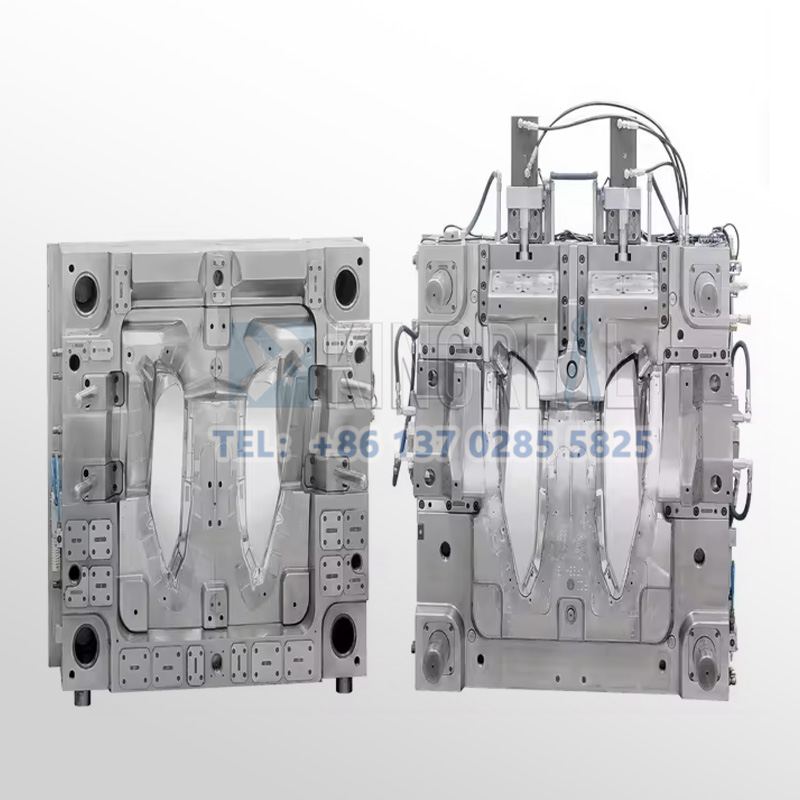

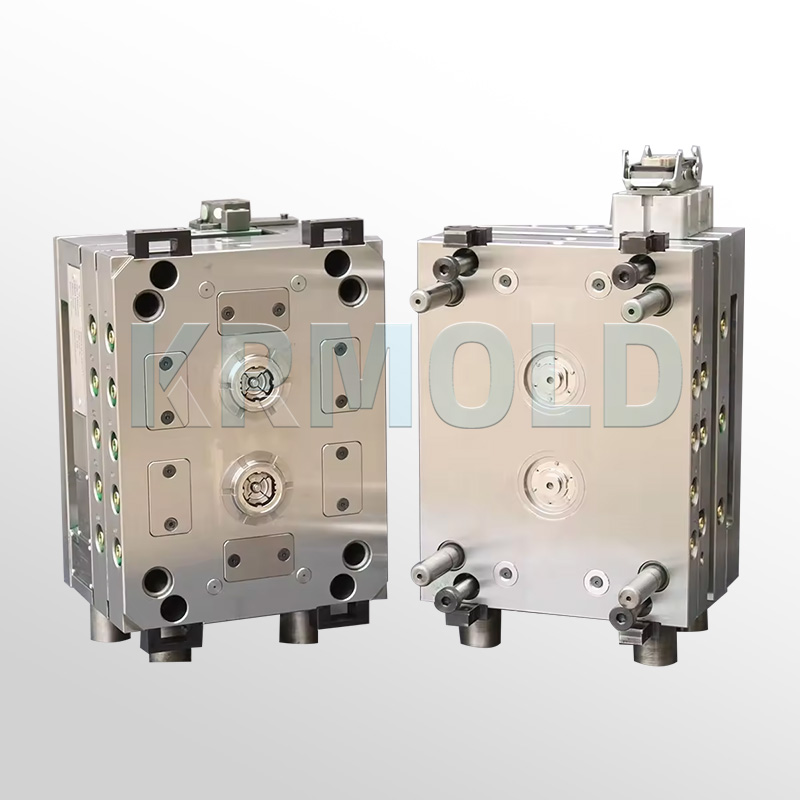

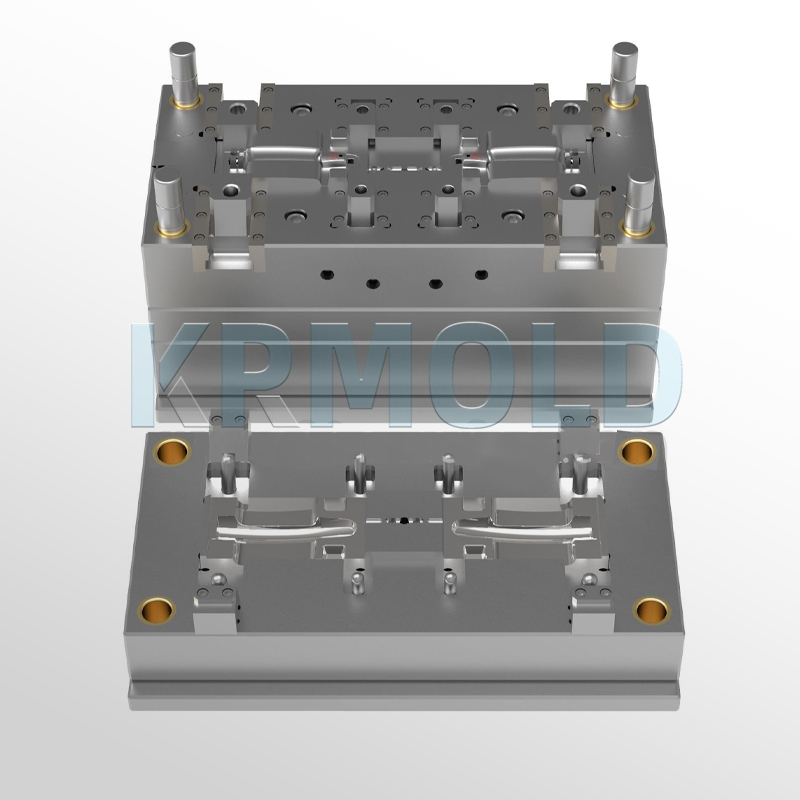

Parts made to exacting tolerances by KRMOLD aerospace plastic injection molds guarantee perfect matches with other parts and accurate shape and size. The accuracy simplifies following machining operations and raises production efficiency. Moreover, plastic injection molding technology guarantees uniform quality and appearance of aircraft components. High repeatability and very low defect rates throughout manufacturing characterize these components, so guaranteeing that every one of them matches design specifications and keeps high quality.

3)Flexible aerospace plastic injection mold design

KRMOLD can quickly respond to diverse customer component design requirements and provide customized aerospace injection mold designs. Whether basic or complicated, KRMOLD provides aerospace injection molds ready to quickly and effectively make entire components appropriate for the aviation industry. KRMOLD aerospace plastic injection molds also allow for customized surface finishes for finished components and assemblies. Along with improving the look of the part, this improves its lifespan and adds extra usefulness.

Aerospace Plastic Injection Mold Material Selection

——

| Material | Tensile Strength (MPa) | Flexural Modulus (GPa) | Maximum Operating Temperature (°C) | Density (g/cm³) | Key Functions |

| PEEK (Polyetheretherketone) | 90-110 | 3.6-4.0 | 260 | 1.30-1.32 | High strength, chemical and heat resistance, excellent wear resistance |

| Polyimide | 100-160 | 4.0-5.5 | 315 | 1.43-1.47 | Excellent thermal stability and electrical insulation |

| PPS (Polyphenylene Sulfide) | 90-110 | 3.0-4.0 | 200 | 1.35-1.40 | Chemical resistance, dimensional stability under heat |

| Glass Fiber Reinforced Polymer (GFRP) | 120-150 | 7.0-10.0 | 180 | 1.50-2.00 | High strength-to-weight ratio and excellent corrosion resistance |

| Carbon Fiber Reinforced Polymer (CFRP) | 500-1000 | 50-100 | 250 | 1.55-1.60 | Excellent stiffness and outstanding fatigue resistance |

| Nylon (Polyamide) | 75-85 | 2.6-3.3 | 120 | 1.12-1.15 | High wear resistance and good fatigue strength |

| Polytetrafluoroethylene (PTFE) | 20-30 | 0.5-0.7 | 260 | 2.20-2.30 | Low friction, chemical inertness, and excellent high-temperature performance |

| Polycarbonate (PC) | 60-70 | 2.1-2.4 | 135 | 1.20-1.22 | High impact resistance, flame retardancy, and optical clarity |

Common Aerospace Injection Molding Processes

——

Overmolding combines two different materials to form a single component. It is suitable for aerospace parts requiring a strong core and a soft outer layer, such as aerospace latches. |  |

Adding metal and plastic compounds to improve the mechanical strength of a component calls for insert injection molding. Particularly suited for electrical parts in aerospace systems is this. This insert injection molding guarantees dependability and great strength. |  |

Micro injection molding is a technology used for extremely small components and is widely used in aerospace applications such as miniature gears, sensors, and bearings. These miniature components require extremely high precision and are suitable for use under extreme conditions. |  |

Gas-assisted injection molding Gas-assisted injection molding reduces material usage and minimizes warpage and shrinkage by injecting nitrogen after the plastic is injected. In aerospace uses, this technology produces high-density, thin-walled buildings that guarantee the aerodynamic characteristics of the aircraft. |  |

Liquid silicone rubber injection molding Commonly found in aerospace components, liquid silicone rubber (LSR) injection molding process is ideal for making components with great thermal stability and flexibility, demanding seals and low and high temperature resistance. |  |

Applications of Aerospace Injection Molding

——

1) Aerospace injection mold for electronic equipment housings

Aircraft electronic component housings need great insulation qualities, high strength, and corrosion resistance to safeguard the inner electrical components. KRMOLD aerospace injection molds let designs and production of housings satisfy criteria, therefore guaranteeing surface quality and dimensional correctness.

2) Aerospace plastic injection mold for interior trim

Aircraft interior trim elements including floor panels, seat armrests, window frames, and luggage compartment racks are sometimes produced utilizing aerospace plastic injection molds. These parts need to be lightweight, flame-retardant, as well as aesthetically pleasing and comfortable. In this sector, KRMOLD offers expert aerospace plastic injection mold design and production services.

3) Aerospace injection mold for transparent parts

Aircraft absolutely need transparent components like windscreens, canopies, and windows. High strength, impact resistance, and great clarity are their needs. KRMOLD aerospace plastic injection molds can meet these special criteria, so guaranteeing that the optical and mechanical qualities of clear components are unaffected.

4) Aerospace injection mold for micro injection molded parts

Micro injection molded parts are widely used in the aerospace industry, such as micro gears and sensor components. These parts require extremely high precision and quality. KRMOLD utilizes advanced technology and equipment to produce micro injection molds that meet aerospace standards.

5) Aerospace plastic injection mold for other parts

Many aircraft components—including radar radomes, pitot tubes, and plastic turbine blades—are also made using the aerospace plastic injection molding technique. Using KRMOLD vast aerospace sector expertise, KRMOLD offers tailored aerospace plastic injection mold production for these intricate injection molded components, therefore guaranteeing quality and component performance.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).