What Is Overmolding Injection Molding?

——

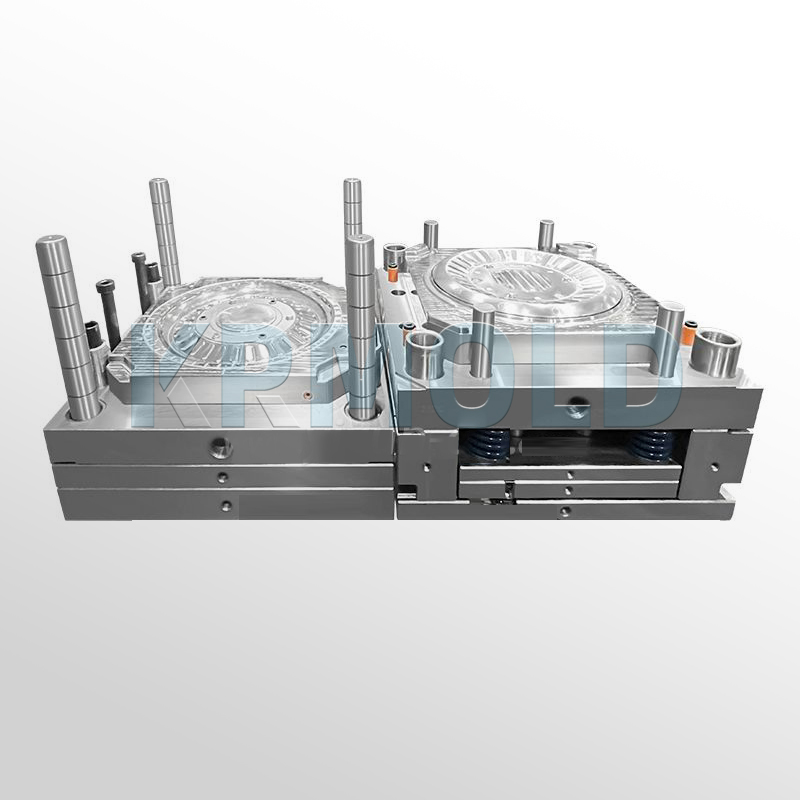

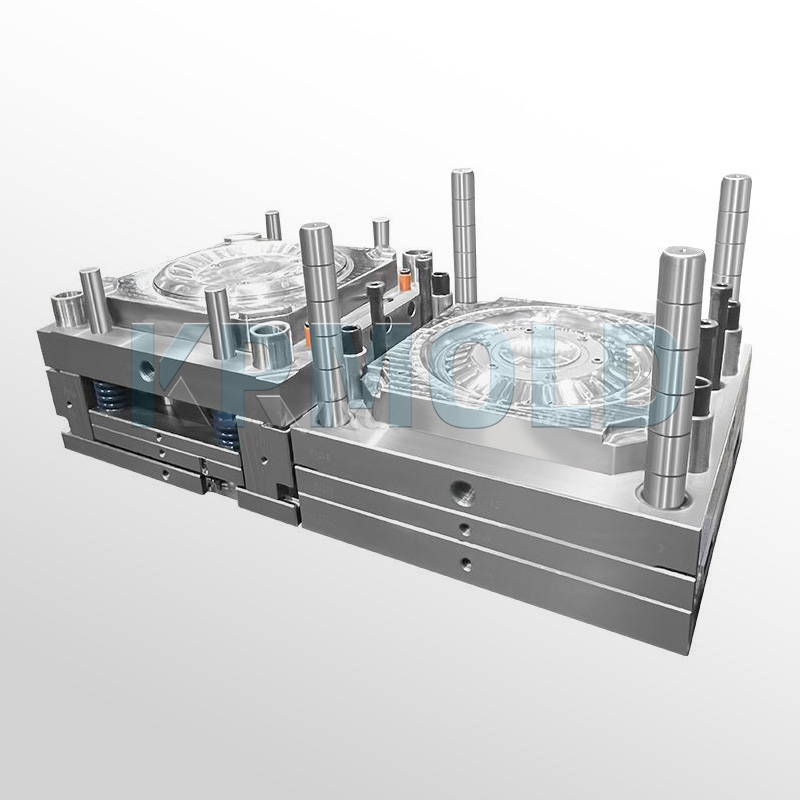

"KRMOLD, a professional injection mold manufacturer in China, is able to provide customers with customized injection molds used to inject molten material into a prepared mold and allow it to cool. During cooling, the material solidifies and takes the shape of the mold before being discharged to meet the mass production of the part product. In the field of injection mold manufacturing and innovation, KRMOLD continuously drills down into customers' actual product production needs, analyzes the structural characteristics and applications of the products, and realizes as many injection molding process production needs as possible in the manufacturing of injection molds, of which Overmolding is one of the most common injection molding processes."

The core of Overmolding in the injection molding process is the combination of different materials through two or more injection moldings. The first injection forms a base material, which is then placed into another mold and covered with a second material for a surface or specific area. Products produced through the overmolding injection molding process have the ability to enhance functional features, achieve multiple design requirements, and increase the efficiency of product production.

Overmolding injection molding process broadly refers to the process of combining different materials into a single part through multiple injection molding, which can be realized in a variety of different production forms according to the customer's production needs:

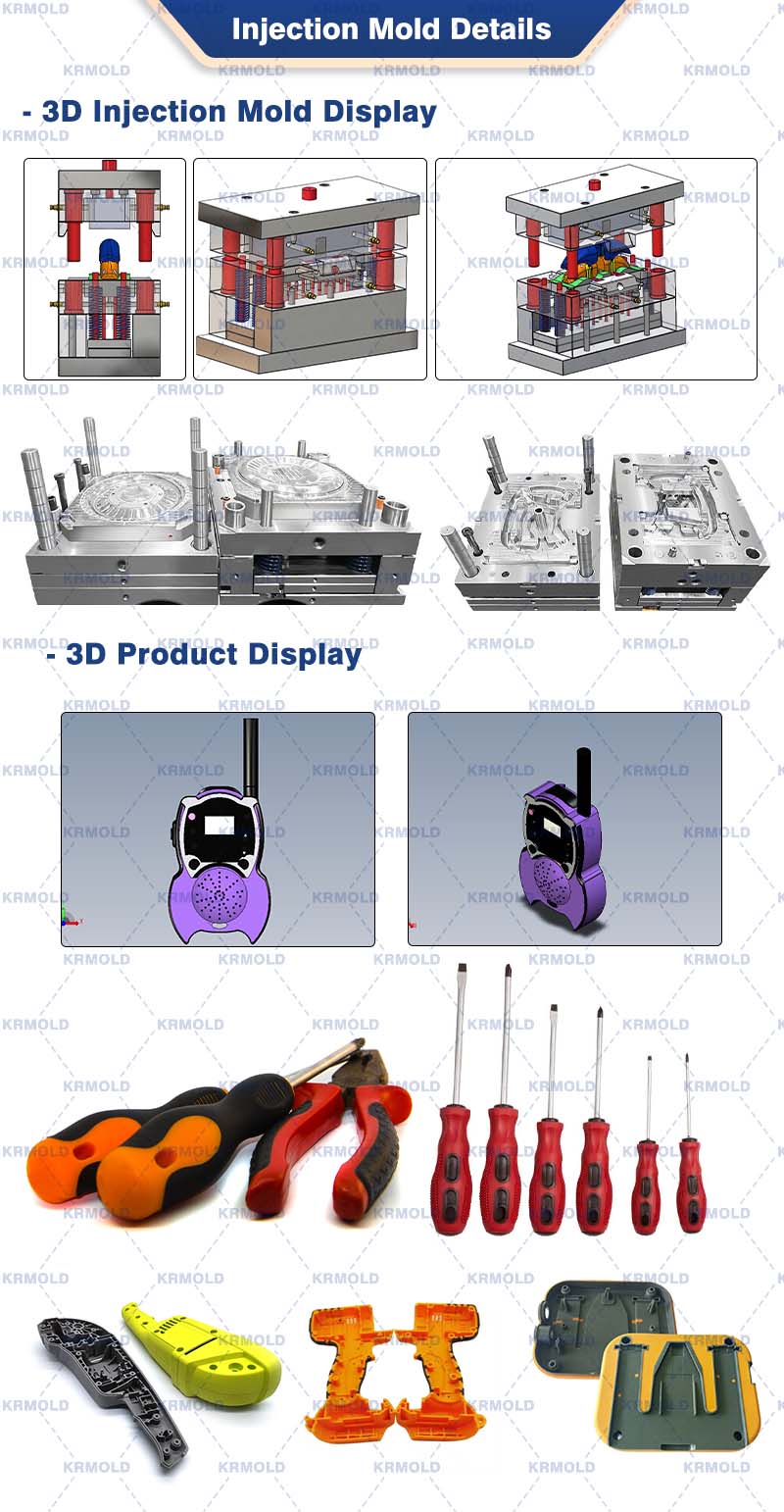

★Insert Molding: In the injection molding process if the base material is a metal part or brass part, this type of secondary molding is often referred to as insert molding, which only requires a single mold to complete the process. Insert molding requires only one mold to complete the process. After the initial molding of the substrate, it is manually or robotically placed into a second set of molds for overmolding. A common example of insert molding is a screwdriver handle, which is produced by combining a metal insert with a plastic injection mold.

★Two-Shot Molding (Two-Shot): belongs to a kind of Overmolding, need special two-color injection molding machine, in the same machine through the mold rotation to complete the two injection molding. Two-shot molding or “two-color” injection molding processes two different polymers (or two different colors of a polymer) into a final product through a single injection molding process, enabling multiple functions to be integrated into the molded product. The combination of materials may be mechanically embedded or chemically bonded. kRMOLD is a professional manufacturer of injection molds and can offer its customers services in designing and producing injection molds. KRMOLD is a professional manufacturer of injection molds and can provide customers with design and production services for injection molds that meet the requirements of the overmolding process, where two or more materials are injected into the mold in stages to form an integrated composite structure.

What is the Overmolding injection molding process?

——

Step 1: Injection of the substrate

The substrate material is injected into the injection mold cavity and cooled to form the substrate part. The substrate can be molded individually or through a previous injection.

Step 2: Transferring the substrate

If a two-color injection molding machine is used, the substrate stays in the same mold and proceeds directly to the next step. In the case of a two-cavity mold, the substrate is transferred to the second cavity by robot or manually.

Step 3: Overmolding

Overmolding materials (e.g. TPE, TPU) onto the substrate to ensure that the material is fully filled and to avoid problems such as air bubbles and poor bonding. Control the injection temperature, pressure and flow rate to prevent the overmolding material from penetrating into unwanted areas.

Step 4: Cooling and demolding

After proper cooling time, the product is demolded. Check the adhesion of the overmolding material to the substrate to ensure that there is no warping, peeling or defects.

Advantage Of Overmolding

——

1

Multi-material integration

Overmolding supports the combination of ABS, PC thermoplastic, TPE/TPR thermoplastic elastomer, silicone and other materials. For example, the combination of hard substrate and soft rubber covering can simultaneously achieve structural strength and tactile comfort, which is suitable for tool handles, smart wearable devices and other scenarios.

2

Complex structure design of injection mold

With CAD software and mold flow analysis technology, we can design high-precision molds with complex geometrical shapes to meet the needs of multi-material layered injection molding. Overmolding combined with automated injection parameter control ensures tight product tolerances, which is especially suitable for medical devices and other products that require precision. Overmolding combined with automated injection parameter control ensures tight product tolerances, especially suitable for medical devices and other fields that require high precision.

3

Improve the performance of injection molded products

Overmolding provides better performance by secondary injection molding TPE, TPU, silicone soft materials on plastic or metal hard substrates. The soft material provides better touch, increased friction, anti-slip and anti-sweat, which enhances the feel and comfort of Overmolding injection molding. In the field of sports equipment, medical tools, etc., the rubber-coated layer improves the stability of grip and avoids slipping.

4

Improve production efficiency

Overmolding injection molding process reduces assembly steps and improves production efficiency, avoiding the need for manual assembly or bonding of soft materials, Overmolding direct one-piece molding, reducing labor costs and assembly errors. Overmolding is directly molded in one piece, reducing labor costs and assembly errors. Overmolding also reduces the amount of soft materials by overmolding only critical areas compared to all-silicone or all-rubber products.

What Is Common Overmolding Material?

——

Material Application | Material Name | Characteristics |

Base Material | ABS | High rigidity, easy to process, low cost, suitable for use as a basic structural component for tool handles, electronic housings, injection molding. |

Polycarbonate | Impact-resistant, high transparency, commonly used in injection molding of parts requiring high strength. | |

Nylon | Abrasion-resistant, high-temperature resistant, suitable for injection molding of industrial parts | |

Over Material | Thermoplastic elastomer (TPE/TPR) | Soft, non-slip, shock absorbing, good compatibility with ABS/PC and other hard rubber, commonly used in tool grips, smart bracelet wristbands injection molding |

Thermoplastic polyurethane (TPU) | Highly elastic, oil resistant, suitable for automotive seals, sports equipment cover injection molding | |

Silicone | High-temperature resistant, biocompatible, used in medical equipment (e.g., surgical instrument handles) and food-grade products. |

Application Of Overmolding

——

1.Consumer Electronics Injection Molds

Through the combination of hard and soft rubber, it can take into account the structural strength and vibration damping performance, while supporting the complex geometric design. Typical cases of Overmolding injection molds include smartphone shells using hard PC substrate + TPU/silicone coating to improve the drop resistance and grip comfort.

2.Automotive industry injection molds

In the field of automotive parts manufacturing, injection molds using Overmolding molding process to help mass production of various types of automotive parts to meet the demand for lightweight, such as the instrument panel using ABS substrate + TPU covering layer, to enhance abrasion resistance and tactile sensation; door handles combined with metal inserts and TPE, to enhance the durability.

3. Medical industry injection molds

In the medical industry manufacturing field, injection molds using Overmolding molding process production, including surgical instrument handles using stainless steel inserts + medical-grade silicone covering, taking into account the sterilization performance and non-slip design and disposable infusion device valve through transparent PC + color TPE two-color molding, to achieve the function of zoning visualization.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).