What Is IMD Injection Molding?

——

The IMD process, known as In-Mold Decoration, is a decorative technology that combines beautifully printed films with plastic resins in injection molds. Through this process, the surface of a plastic product is given a beautifully printed texture and strong protection against abrasion and scratches.

IMD Injection Molding meets the injection molding needs of components in a wide range of industries, including automotive interiors, electronics, home appliances, and medical devices, to create decorative panels with intricate patterns and colorful accents that add a distinctive appeal to products. IMD Injection Molding uses a hardened, transparent film to protect the decorative layer. This film is made of high-performance materials such as polycarbonate (PC) or polyester (PET), which combine high transparency with excellent abrasion resistance. By applying a hardener or UV curing, the film is bonded to the plastic substrate, ensuring a long-lasting decorative effect.

In order to meet the IMD Injection Molding process, the core requirements of IMD injection molds revolve around product precision, thermal management and surface protection, and injection molds need to be designed with comprehensive consideration of film characteristics, plastic substrate properties and process parameters.

What Is The IMD Injection Molding Processing?

——

1. Film Design and Printing: Before IMD Injection Molding starts, it is necessary to adopt CAD to design the pattern, realize high-precision printing through screen printing or UV ink, and complete the 72-hour curing test to ensure that the adhesion is ≥5N/cm.

2. Positioning and Thermoforming: After the film is cut and punched with positioning holes, it will be adapted to the complex 3D surfaces through thermoforming technology.

3. In-mold injection: Place the molded film into the injection mold, inject the plastic raw material at 80-120℃ mold temperature, and control the filling speed and pressure through multi-stage injection parameters to prevent film rupture.

4. Post-processing: After the injection is completed, the mold is cooled and demolded to remove burrs, and sprayed with a protective coating to enhance abrasion resistance.

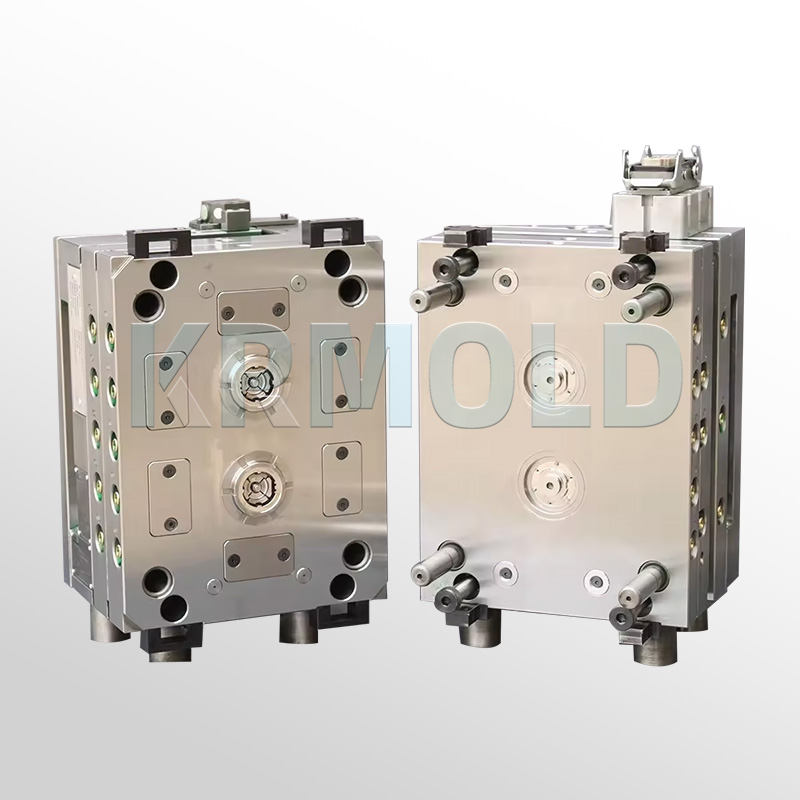

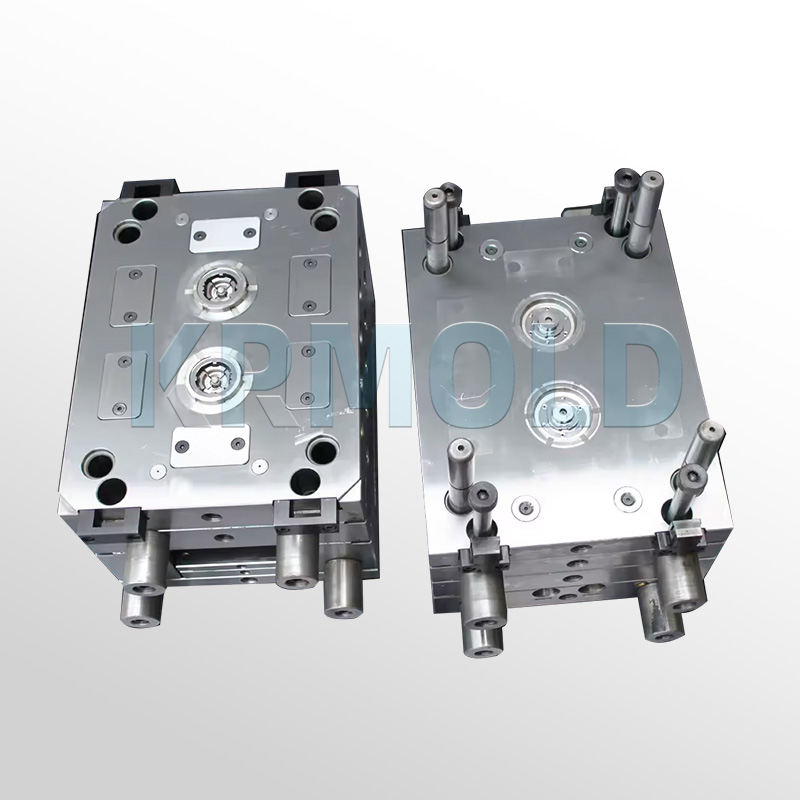

What Is Design Feature Of IMD Injection Mold?

——

1. Enhance the shrinkage rate of injection mold

In IMD process, the heat shrinkage rate of plastic substrate and surface PET film are different, the film wrapped around the plastic substrate will limit its shrinkage, if the design is based on the conventional shrinkage rate will lead to finished product dimensional deviation or even film cracking. The shrinkage rate of normal injection molds is usually 0.5%, but IMD molds need to be adjusted to about 0.3% (depending on the actual situation).

KRMODLD needs to optimize the cavity size of the mold through CAE simulation when producing injection molds, and correct the mold according to the actual shrinkage rate after the mold trial.

2. Precision positioning of injection molds

In order to meet the IMD injection molding requirements, injection molds need to be designed with high-precision positioning holes to ensure that the film does not shift when the mold is closed, and some of the molds use vacuum adsorption or mechanical clamping devices to fix the film to prevent displacement caused by injection pressure.

In the IMD process, the size of the film needs to be slightly smaller than the final product size (about 0.1-0.2mm) to avoid white leakage or rupture of the edges during the injection molding process.

3. Injection mold runner design

When designing the mold for IMD injection molding process, the mold runners need to ensure that the molten plastic fills all cavities uniformly to avoid local overheating or underfilling of the film due to differences in flow paths. Priority should be given to the use of submerged gates or sprue gates to minimize the visible traces of the gate on the surface of the film. The location of the gate should avoid the film pattern area to prevent damage to the ink layer.

4. Multi-Circuit Cooling Channels for Injection Molds

Injection molds need to be equipped with multi-circuit cooling channels to ensure that the temperature difference between each area is ≤5℃, to avoid film deformation or uneven shrinkage due to uneven cooling, and some of the molds are integrated with a heating plate to preheat the film and improve its ductility to adapt to complex 3D structures.

5. injection mold release design

injection mold in the design of the ejection system needs to be parallel to the film surface contact, to avoid the ejector pin scratching the decorative layer, complex curved surface products can be used pneumatic demolding or segmented ejection mechanism. The surface of the mold cavity should be polished to mirror level, usually KRMOLD has special polishing tools and professional operators to polish the surface of the mold cavity to mirror level, and chrome plating or nitriding treatment to reduce friction resistance and extend the life of the mold.

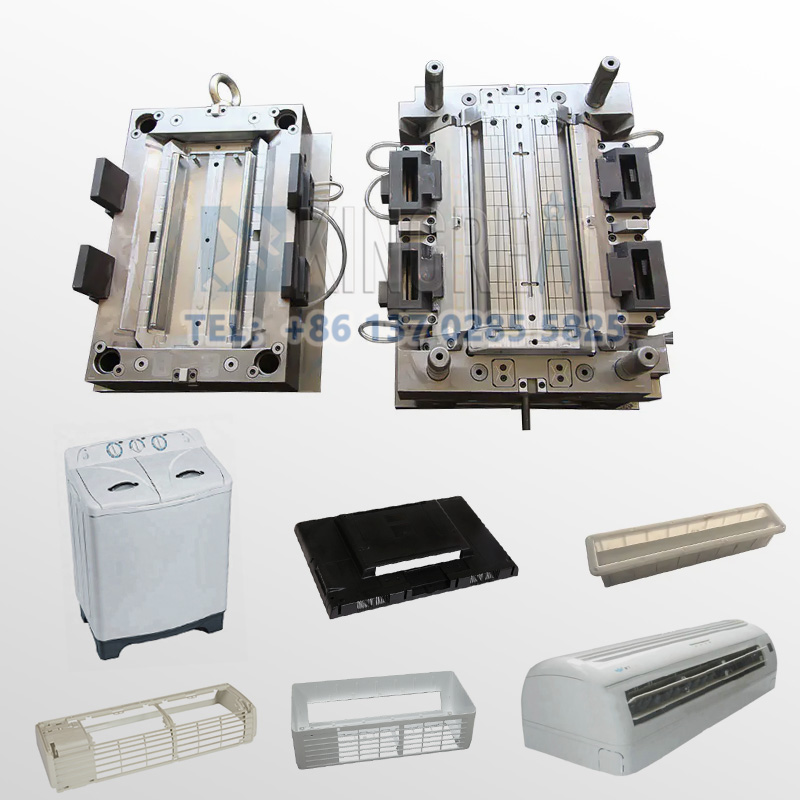

What Is Application Of IMD Injection Molding?

——

Home Appliance Industry Injection Mold

IMD injection molding process plays a significant role in enhancing the appearance of home appliance products texture and functionality. Through the injection mold for IMD injection molding production of panels, shells and other parts of the home appliance industry can show a three-dimensional pattern, not only wear-resistant, scratch-resistant, but also has a chemical resistance, thus improving the durability and aesthetics of the product.

Typical cases include:

*High-end refrigerator panel: IMD thermal transfer process to achieve marble texture, cost 30% lower than traditional spraying, surface hardness of 3H.

*Microwave oven control panel: integrated backlight buttons through IMD injection molding, life expectancy up to 1 million presses, support for wet hand operation.

*Washing machine touch screen: injection molding using hardened PET film, detergent corrosion resistance, the pattern will not fade permanently.

Electronic consumer industry injection mold

Early electronic consumer industry, IMD process is widely used in cell phones, tablet PCs, e-book readers and other devices shell and key manufacturing. Consumer electronics industry injection molds using IMD injection molding process not only enriches the product color and pattern options, but also maintains the product's lightweight and durable characteristics. At the same time, IMD process also promotes the development of personalization of electronic products to meet the diverse needs of the market.

Typical cases include:

*Mobile phone center frame and lens: IMD process is used to achieve frosted light transmission effect, with a light transmission rate of ≥90%, as well as anti-fingerprint residue and support for 5G signal penetration.

*Smart watch dial: injection mold embedded in touch sensor, surface hardness of 3H or more, scratch resistance improved by 5 times.

*Headphone shell: injection mold through gradient color diaphragm and UV curing technology to achieve high-resolution patterns, yield rate of more than 95%

Automotive Manufacturing Industry Injection Mold

The automotive industry is another important application area of IMD injection molding process. IMD injection molding process plays an important role in the manufacture of interior parts such as instrument panel, air conditioning panel and interior panel. It not only beautifies the appearance of the interior, but also enhances its durability and scratch resistance. For customers in the automotive industry, IMD injection molding improves the competitiveness of their products while reducing costs. In addition, the process helps to recycle the interior parts in an environmentally friendly way, which is in line with the pursuit of sustainable development in the automotive industry.

Typical Cases

*Automotive touch panel injection mold: embedded heating function, temperature resistance range -30℃~120℃, response time <0.1 seconds.

*Automotive grille injection mold: adopts self-repairing coating, scratches disappear automatically within 24 hours, integrated LED dynamic light and radar sensor.

*Automotive dashboard injection mold: IMD process replaces traditional spray paint, reducing cost by 15% and increasing chemical resistance by 50%.

FAQ: How to ensure the dimensional accuracy of the mold and product consistency?

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software.

Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage.

Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).