What Is Micro Injection Molding?

——

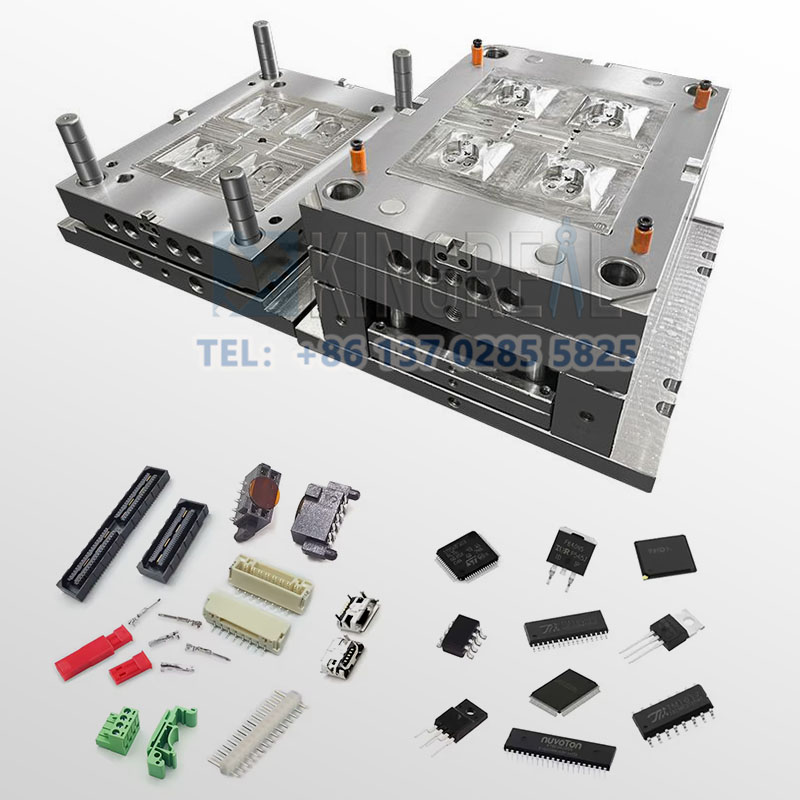

With the rapid development of high technology and precision technology, there is a rapidly growing demand for Micro Injection Molding products in the medical equipment, automotive industry, and consumer electronics industry. The main characteristics of Micro Injection Molding products are small size, special shape, and complex functional areas. Generally speaking, the size is in the order of a few microns to a few centimeters, the aspect ratio is between 1 and 100, and the individual functional areas require high strength, high finish, high transparency, and so on.

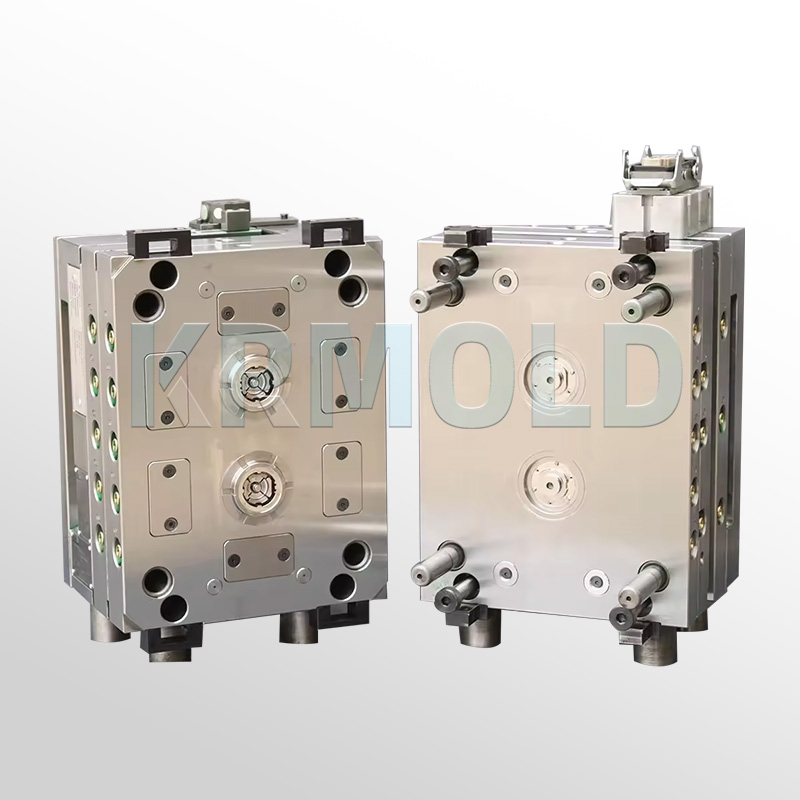

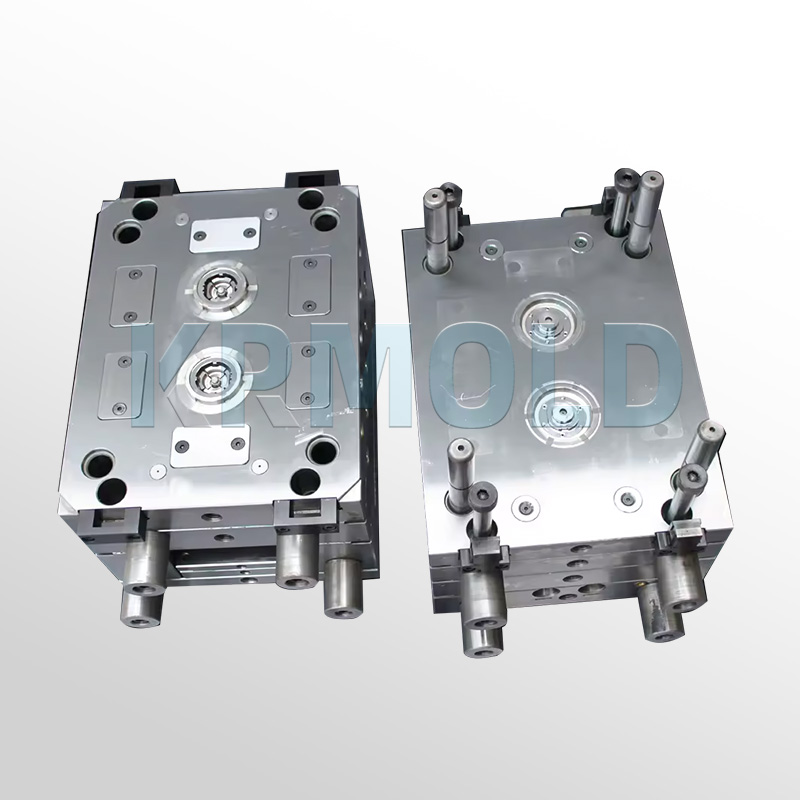

Micro Injection Molding is a highly specialized plastic manufacturing process focusing on the production of very small-sized, high-precision micro-plastic parts, which is also an extremely high challenge for the design and manufacture of injection molds.

1. In order to ensure that the mold can be filled correctly, high injection speed and high injection pressure are required, the material temperature should be as high as possible within the permissible range of the melt temperature, and the wall temperature of the injection mold should be controlled at the high end.

2. In the micro-injection molding process micro to ensure that a sufficiently large injection volume needs to be used in the injection mold design of large runners and large gates, which can ensure that the polymer in the flow of the process of reliable control and switching to avoid material degradation.

3. Injection molds require special split heating and cooling systems in order to dynamically control the mold temperature.

4. In order to control the production process as well as to handle and package the micro-injection molded products efficiently, the injection molds should have improved mold sensors, high-precision mold guides, mold evacuation systems, integrated runner collectors and manipulators for product removal, automatic gate removal systems,

5. Injection mold cleaning systems activated at each cycle, etc., which are essential for the correct production and collection of micro-injection molded products. These equipment are essential for the proper production and collection of micro-injection molded products.

How To Manufacturing The Micro Injection Mold?

——

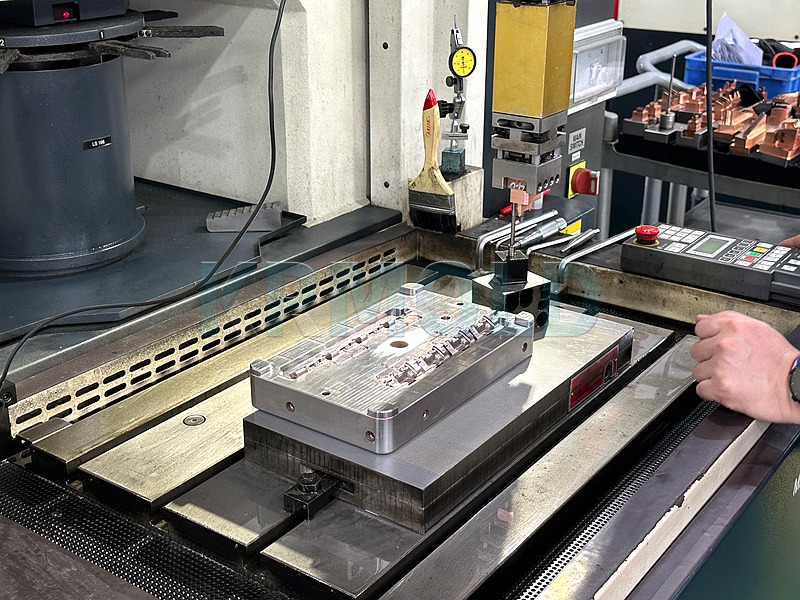

KRMOLD as a professional injection mold manufacturer, is committed to helping customers to solve a variety of production needs, which micro to help the demand for micro-injection molding process, KRMOLD in the injection mold processing design also has new innovations. For example, the processing of micro-injection molding molds can use the traditional processing methods, materials, various CNC precision machining methods and electric discharge machining (EDM).

However, as the size of the mold inserts and cavities of micro-injection molding products is reduced, some of the technology in the field of microelectronics has been used in the manufacture of micro-injection mold inserts and cavities. Typically, KRMOLD uses LIGA technology in combination with micro-precision machining processes such as injection mold micro-cutting, ultra-precision machining, laser machining and micro-EDM technology.

What Is Advantage Of Micro Injection Molding?

——

1.Ultra-precision Injection Molding Manufacturing

Micro Injection Molding injection molding process is suitable for the production of high-precision plastic parts at the micron or even nanometer level, which can achieve very small tolerances.

2.High Material Utilization of Injection Molding

Due to the small size of the part, the amount of injection molding material needed is less, reducing waste and improving cost-effectiveness. Applicable to expensive or high-performance polymers, such as PEEK, LCP, etc..

3. Injection molds meet complex geometries

Micro-injection molds are designed to produce precision structures such as micro-runners, micro-holes and micro-gears. It is suitable for medical devices, electronic products, optical components and other high-demand fields.

4.Efficient automated production

The micro-injection molding process has a short production cycle, which enables mass production and improves production efficiency. Compatible with automated assembly and robot operation.

5. Ensure the consistency of micro-injection molded parts

The micro-injection molding process ensures the consistency and repeatability of each part due to the use of precision molds and high-precision control systems. Suitable for industries with strict quality control requirements, such as the medical and electronics fields.

Application Of Micro Injection Molding

——

Due to the extremely high requirements for precision and biocompatibility of medical devices, injection molds designed and manufactured using Micro Injection Molding production process plays an important role in the field of medical industry parts production. Common micro injection mold cases:

Micro surgical instrument injection molds (such as micro forceps, catheter connectors, stents)

Drug delivery system injection molds (such as insulin delivery device micro-components)

Microfluidic chip injection mold (for rapid diagnosis and biochemical analysis)

Micro implantable device injection molds (such as hearing devices, neurostimulators shells)

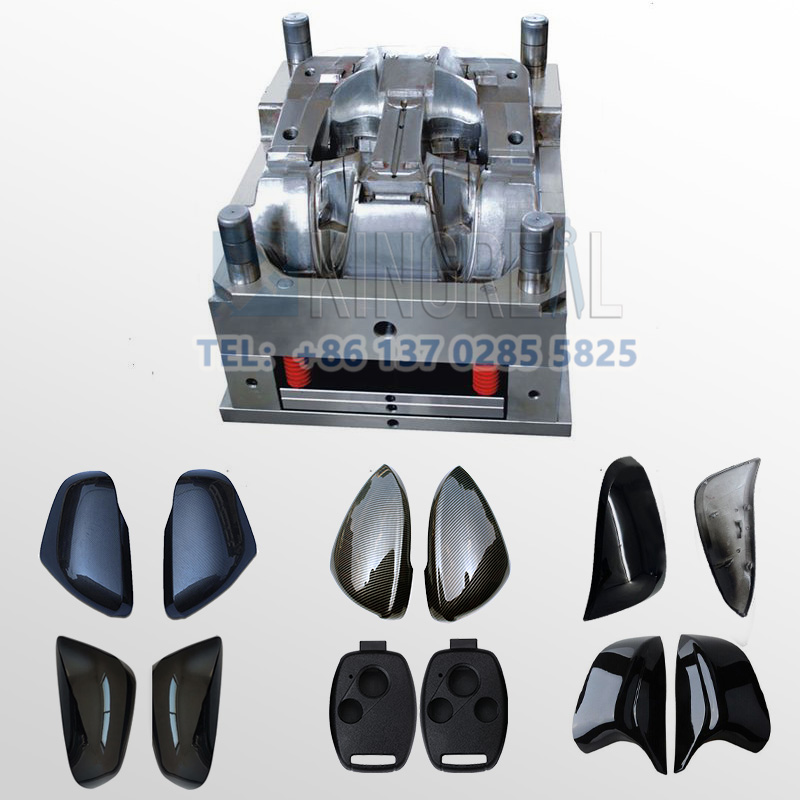

Automotive injection molds with micro injection molding process are mainly used for sensor housings, fuel tanks, and other medical devices. Automotive injection molds are mainly used for sensor housings, fuel injection system micro-valves and electronic control unit connectors. The trend of automobile lightweight and intelligence prompts the demand for higher reliability of micro-injection molded parts under complex working conditions. Common micro-injection mold cases:

Micro gear injection mold (precision drive system)

Fuel nozzle parts injection mold (high-precision injection control components)

Micro-sensor components injection mold (tire pressure monitoring, radar sensors)

micro-injection molding process in the consumer electronics industry has a wider range of applications, covering micro-connectors, optical lenses, sensor housings and micro-motor components. The consumer electronics industry has a wider range of applications in the field of micro-injection molding process. The electronics industry on the demand for miniaturization and functional integration to promote the application of micro-injection molding technology.

Typical cases of consumer electronics injection molds

* Mobile phone camera lens injection mold: using PMMA material through the micro-injection molding, a mold four-cavity design to achieve efficient mass production, the surface roughness needs to reach the nanometer level to meet the optical properties.

*Fiber optic connector injection mold: 0.25mm diameter precision interface, through the hot runner system to reduce the scrap rate, the material used is high temperature resistant LCP.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).