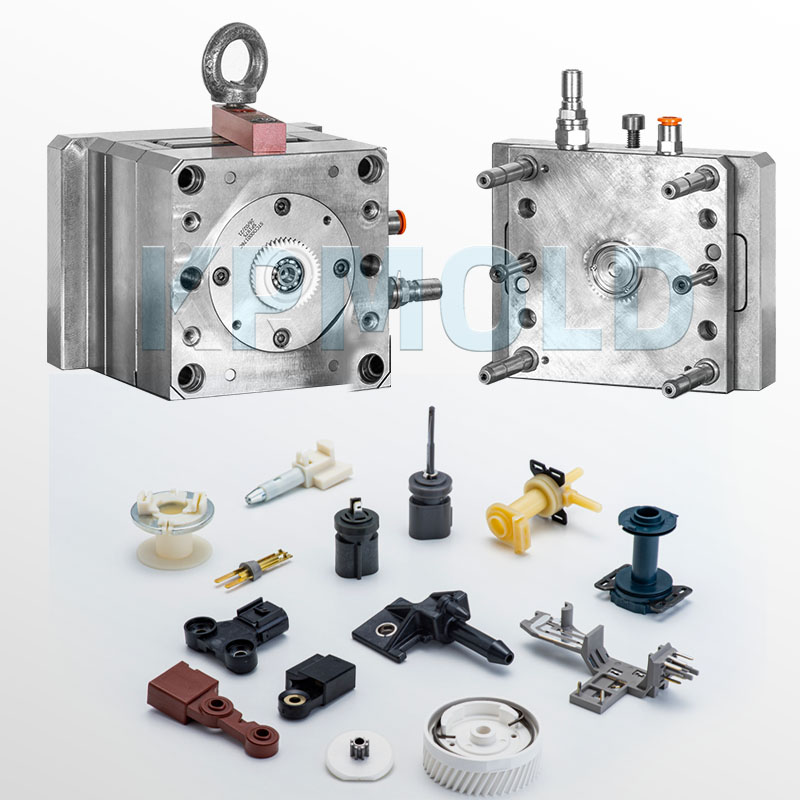

What Is Insert Molding?

——

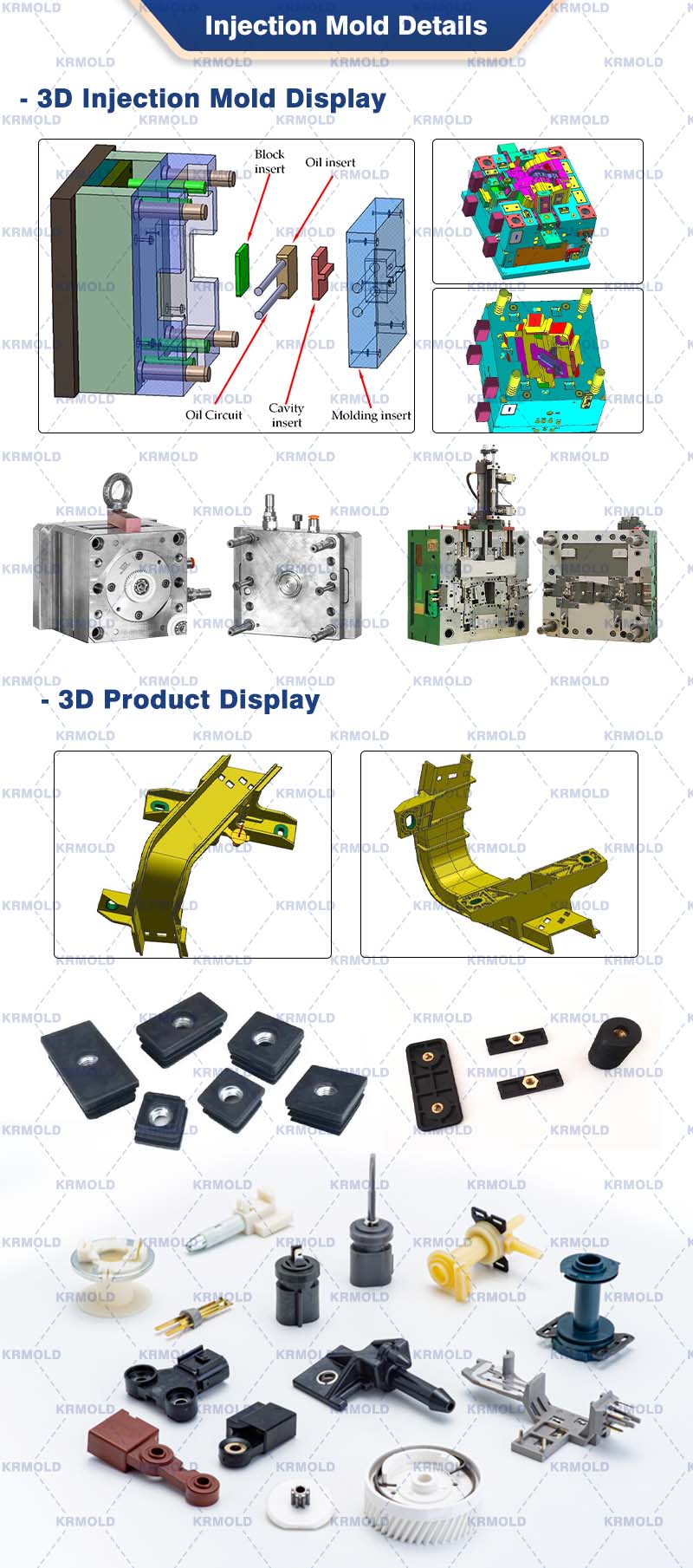

“KRMOLD is a professional injection mold manufacturer, can provide customers with complete injection mold design, manufacturing and after-sales service.KRMOLD has nearly 20 years of experience in injection molding projects, is committed to providing customers with a complete production solution, and seek long-term injection molding product production benefits.KRMOLD injection molds can achieve a variety of different injection molding processes, including Insert Molding helps customers in many industries to solve their production needs."

Insert Molding is an injection molding process in which metal or other prefabricated parts (inserts) are placed into a mold and then encapsulated in plastic, typically used in marine equipment, aerospace, automotive, electrical and electronic, and medical industries.”

Insert Molding is a process that combines a metal or other material insert, pre-fixed in an injection mold, with plastic. During the injection molding process, the plastic is injected and molded around the insert, and after the mold is opened, the insert is encapsulated by the cooled and cured plastic, resulting in products with inserts such as threads and electrodes. The Insert Molding process can improve the strength, abrasion resistance, electrical conductivity, heat resistance or water resistance of products by combining the properties of different materials (such as the ease of molding plastics and the rigidity of metals), and is widely used in the injection molding of parts and components in the fields of marine equipment, aerospace, automobiles, and electrical and electronic appliances.

Advantage Of Injection Molding

——

1.Material synergy and performance breakthroughs

Injection Molding through the plastic of easy molding, elasticity and metal of rigidity, high strength and heat resistance complement each other to achieve the complex structure of integrated molding, precision electronic shell injection mold using Injection Molding production process to take into account the lightweight and performance enhancement. Combining plastic insulation and metal conductivity to meet the basic functions of electrical products.

2.Improve injection molding production efficiency

Injection Molding using Injection Molding process can eliminate welding / riveting and other secondary processing, shorten the assembly cycle, reduce labor and equipment investment. At the same time, vertical injection molding machine and robot, the whole line of devices linked to achieve insert positioning, injection and inspection of the whole process of automation, improve efficiency and yield, for customers to improve long-term production efficiency.

3.Mold design innovation

injection molding insert materials covering metal, glass, fiber, engineering plastics, etc., to support cross-industry applications, through mold optimization and insert pre-processing, to achieve miniaturization, thin-walled and biomimetic structure, breakthroughs in the traditional design limitations.

4.High-precision injection molding effect

Molten plastic and inserts are tightly wrapped, the gap control precision reaches micron level, which significantly improves vibration resistance and sealing, and adopts parting surface avoidance, slanting pin compression and gradient cooling design, avoiding burr and internal stress concentration, to ensure the molding stability of complex inserts.

5. Improve the quality of injection molding products

The preheating of inserts and injection pressure are coordinated to reduce the risk of deformation caused by differences in the coefficient of thermal expansion, and the integrated IoT sensors monitor the mold temperature and positioning status of inserts in real time, and combine with Moldflow simulation to predict the problem of punching deviation and reduce the rate of defective products.

Insert Molding Process

——

1. insert pretreatment

injection molding the first step is to remove the insert oil, oxidation layer, and through sandblasting, plating or chemical treatment to enhance the bonding force with the plastic. In the new energy vehicle battery connector injection molding money needs to be pre-silver plating of copper inserts inside the product to enhance the conductivity and corrosion resistance. For the difference between the coefficient of thermal expansion of metal inserts and plastic, the inserts need to be preheated to reduce the deformation or cracking caused by internal stress after molding.

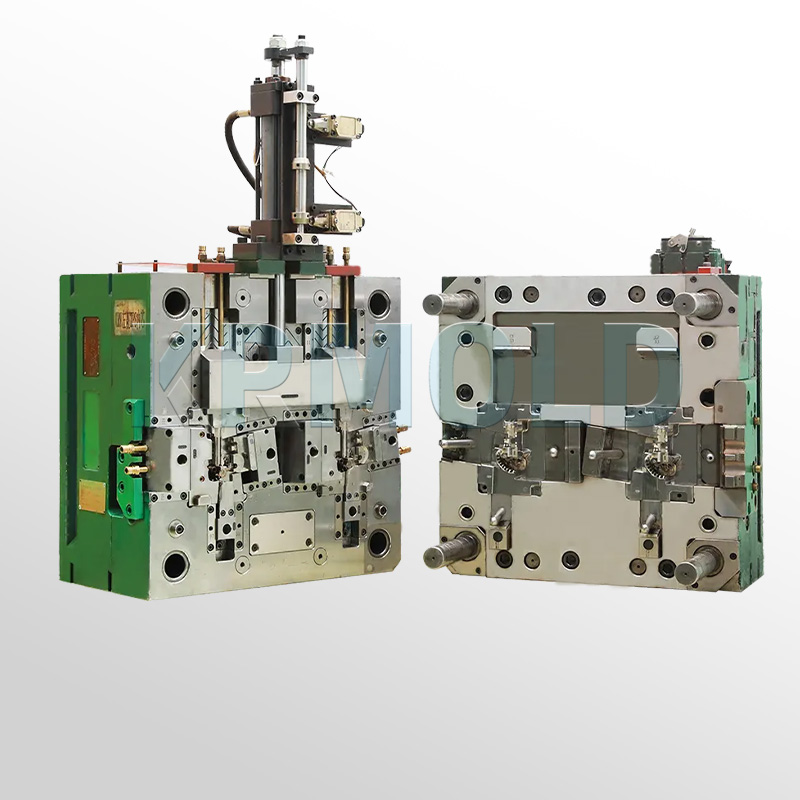

2. Installation of injection mold

The inserts are oriented by vibration table, and the robot (EOAT) with vision system grabs the inserts and accurately places them in the injection mold cavities with the help of vacuum adsorption or mechanical grippers. Vertical injection molding machine because the mold face up, easier to achieve fully automated insert placement, a common case is the automotive sensor housing injection mold production process.

3. Plastic injection

After the injection mold is installed, high pressure injection ensures that the melt fully fills the gaps between the inserts and reduces air pockets. The melt temperature needs to be precisely matched to the material properties and the mold temperature is controlled by a mold temperature controller to reduce shrinkage. Generally speaking, liquid crystal polymers or PEEK polyether ether ether ketone are preferred, combining high temperature resistance with low shrinkage, which is suitable for precision electronic components.

4. Cooling and curing

The injection molding machine uses a gradient cooling system to accelerate curing and shorten cycle times. Some materials (e.g. epoxy resin) need to be heated twice for curing to enhance the mechanical properties.

5. Demolding and Ejection

The layout of the thimble needs to be avoided in the area of the inserts to prevent the inserts from being strained during ejection. For thin-walled injection mold products, pneumatic ejector or flexible ejector bar is used to reduce the risk of deformation. The automation system synchronizes the release of the mold and the recovery of the insert.

6. Quality inspection of injection molded parts

Laser cutting or ultrasonic vibration removes the overflow material to ensure the surface finish of the exposed part of the inserts, and at the same time, pressure/temperature sensors are integrated in the mold to provide real-time feedback on the deviation of injection parameters. Electrical conductivity test and sealing test for injection molded products.

Application Of Insert Molding

——

1.Automotive Injection Molding Mould

Battery management system, high-voltage power distribution unit and inverter components of new energy vehicles are combined with insulating plastics such as copper rows and other metal inserts through insert injection molding technology to effectively isolate the risk of high-voltage short-circuit and optimize the layout space at the same time. Automotive electrical connectors through brass or copper metal inserts and PBT, PA and other engineering plastics combined to achieve high conductivity and corrosion resistance.

2.Consumer Electronics Injection Molding Mould

Mobile phone antenna module adopts metal inserts and liquid crystal polymer injection molding, taking into account the thin and light weight and high-frequency signal transmission ability; Type-C interface connector integrates conductive terminals through the insert technology to improve mechanical strength and electrical stability.

3. Medical device injection molds

Surgical knife handles, orthopedic implants through titanium alloy inserts and PEEK biocompatible plastics, taking into account the rigidity, sterilization resistance and ergonomic design; dental instruments in the metal probe and plastic seals integrated molding to enhance the accuracy of the operation. Insulin pens, inhalers, etc. through the insert molding integration of metal valves and plastic shell, to ensure sealing and durability; medical catheters through the stainless steel guide wire inserts to enhance bending resistance

4. Aerospace injection molding molds

Aircraft seat skeleton, luggage latch using aluminum alloy inserts combined with PPS reinforced plastics, to meet the requirements of the high strength to weight ratio and corrosion resistance; sensor shell through the insert technology to achieve extreme temperature stability performance. Sensor housings are stabilized by insert technology for extreme temperatures. Aircraft connectors are made of gold-plated copper inserts combined with PEI high-temperature-resistant plastics to ensure the reliability of signal transmission; fasteners use insert molding to reduce the number of assembly steps and improve structural consistency.

Insert Molding Injection Mold Design Feature

——

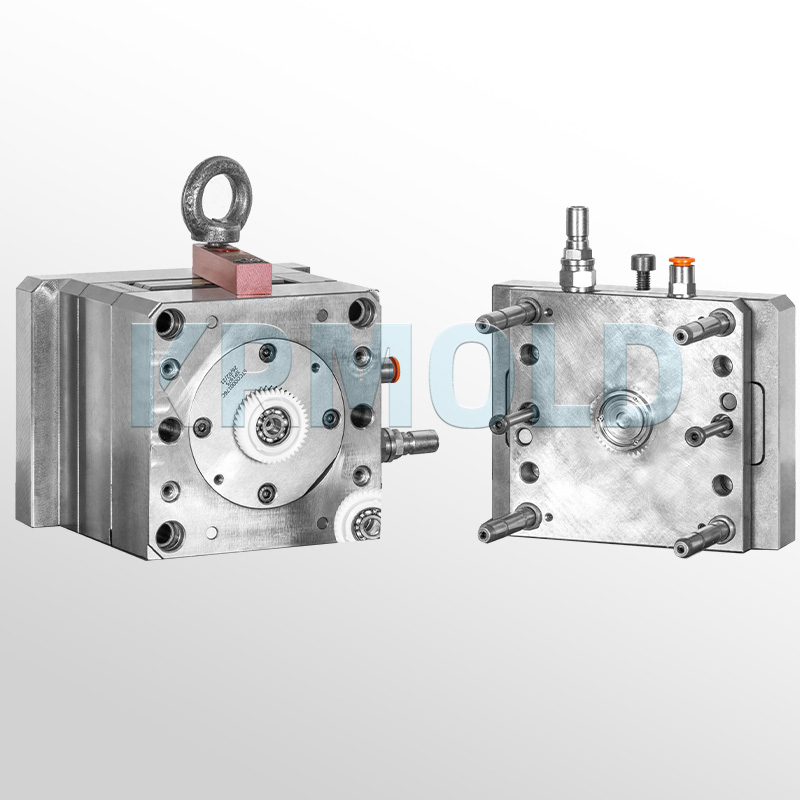

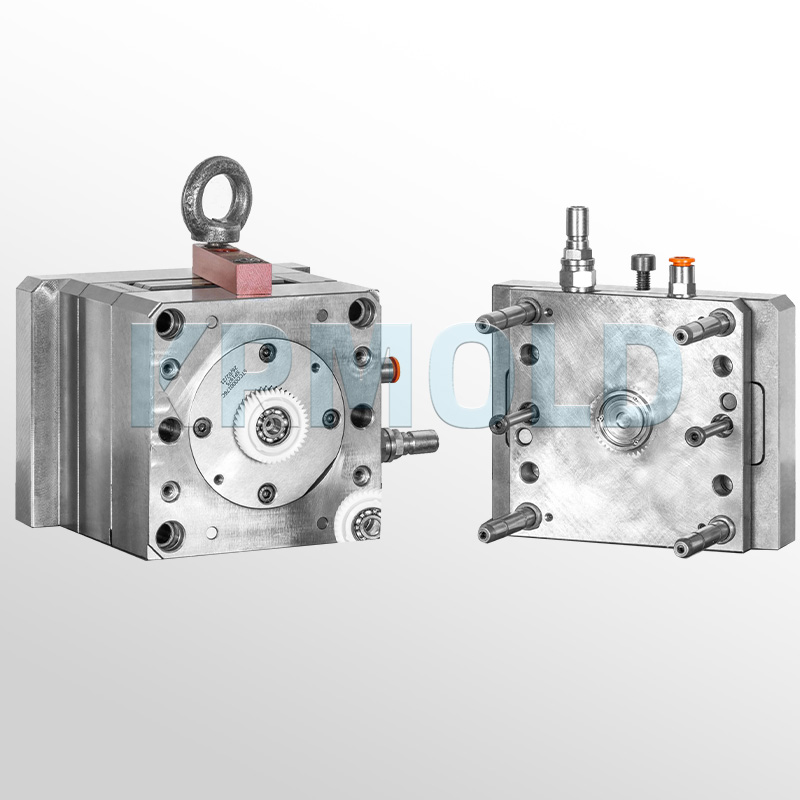

1. Ensure the correct positioning of inserts

Before injection molding, you need to use mechanical clamping, magnetic suction, vacuum adsorption, pin positioning and other ways to fix the inserts, to ensure that they will not move during the injection process, and the design of non-slip structure to enhance the bonding force of the plastic. Generally speaking, KRMOLD suggests customers to use robots to automate the placement of inserts in order to improve accuracy and reduce human error, which is suitable for mass production. Design appropriate insert guidance system to ensure precise robot alignment and reduce pick and place time.

2. Injection mold port design

The insert injection mold design adopts a balanced runner design to ensure uniform filling of plastic and avoid air bubbles and fusion marks. Increase the exhaust slot in the mold to avoid air retention resulting in bubbles, black spots or fusion marks, set up vacuum-assisted exhaust for precision insert injection molding, improve the filling effect. Adopt cooling waterway around the insert to ensure uniform cooling and avoid thermal stress.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).