KRMOLD is equipped with milling machines, grinders, drilling machines and other machining equipment to complete the rough machining, finishing and surface treatment of injection molds.

1. Generally speaking, in the initial molding stage of the mold material, the milling machine quickly removes the blank excess through the milling process to form the basic outline of the mold cavity and parting surface. The milling machine is used to cooperate with CNC processing equipment to further process various complex geometric structures such as special-shaped flow channels and multi-steps on the injection mold, with an accuracy of up to ±0.02mm, to meet the needs of high-precision molds

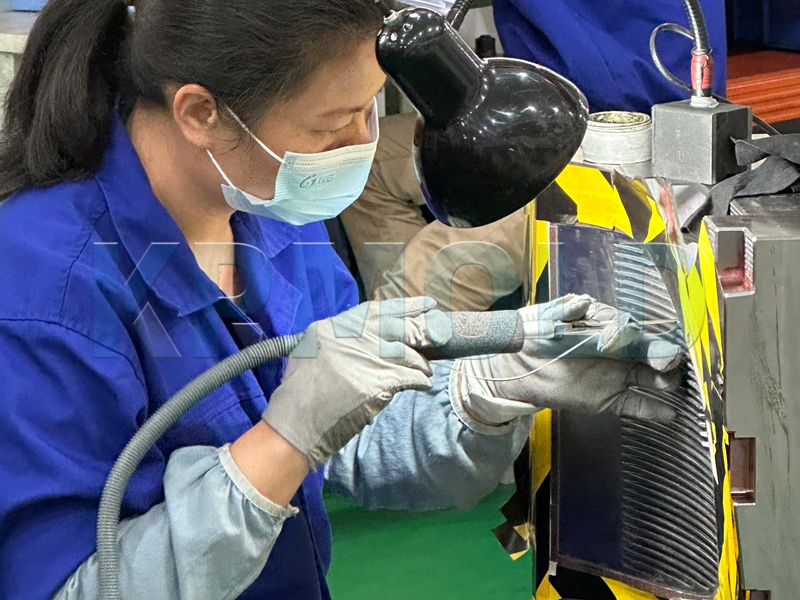

2. After the mold is heat treated, the grinder performs high-precision grinding on the mold surface such as the slider matching surface and ejector pin hole to eliminate heat treatment deformation and ensure dimensional accuracy.

3. The drilling machine is a supporting equipment for the basic processing and auxiliary processes of the injection mold. In the mold blank cutting stage, the drilling machine is used to process auxiliary structures such as positioning holes and screw holes to provide a benchmark for subsequent processing. In the mold assembly link, the drilling machine processes ejector pin holes, cooling water channel connection holes, etc. to ensure the matching accuracy of parts.