"Packaging injection molds can be used to manufacture various transport containers, industrial packaging, cosmetics, household chemicals, and different types of bottle caps. These cosmetic container injection molds are not only ideal for product packaging but also represent an efficient, safe, and environmentally friendly production method. KRMOLD meets all the stringent requirements and standards for packaging materials. KRMOLD specializes in custom packaging injection molds, enabling the production of food packaging injection molds that meet the stringent requirements and industry standards for various packaging materials. The KRMOLD team is ready to engage in in-depth discussions with customers to assist in the development or improvement of packaging solutions to meet the ever-changing needs of the market."

Types of KRMOLD Packaging Injection Mold

KRMOLD is committed to providing customized packaging injection mold solutions based on the specific project needs of its clients. Below are some of the main packaging mold types offered by KRMOLD:

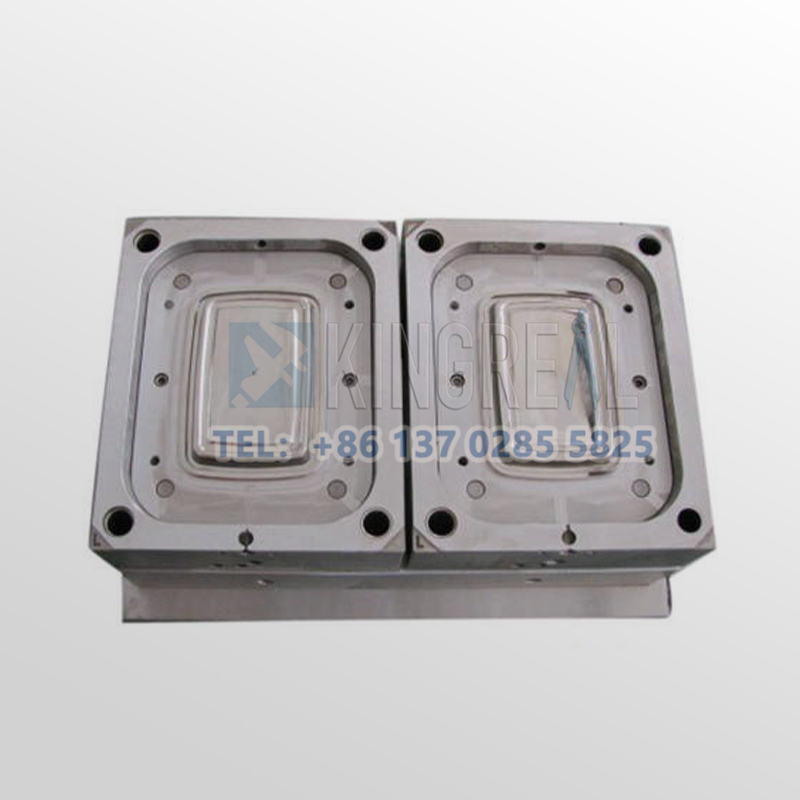

Thin-wall container injection mold: KRMOLD thin-wall container injection molds are specifically designed for producing plastic containers with a wall thickness of less than 1 mm. These thin-wall container injection molds are commonly used to manufacture products such as disposable fast food boxes and thin-walled mobile phone battery cases. Thin-walled containers not only significantly reduce material usage and lower production costs but also maintain good strength and rigidity.

Cosmetic container injection mold: KRMOLD cosmetic container injection molds are designed to produce high-precision and high-surface-quality container components, such as cosmetic bottles, caps, cans, pump heads, and lipstick tubes. KRMOLD understands the cosmetic industry's dual requirements for aesthetics and practicality, therefore, it pays close attention to detail in cosmetic container injection mold design to ensure the perfect presentation of each component.

Food packaging injection mold: KRMOLD designs and manufactures plastic molds for food packaging, focusing on achieving high-speed production and hygiene safety. KRMOLD's food packaging molds meet food contact standards, ensuring the safety and stability of products when in contact with food. Through optimized design, KRMOLD's molds effectively reduce the risk of contamination during production.

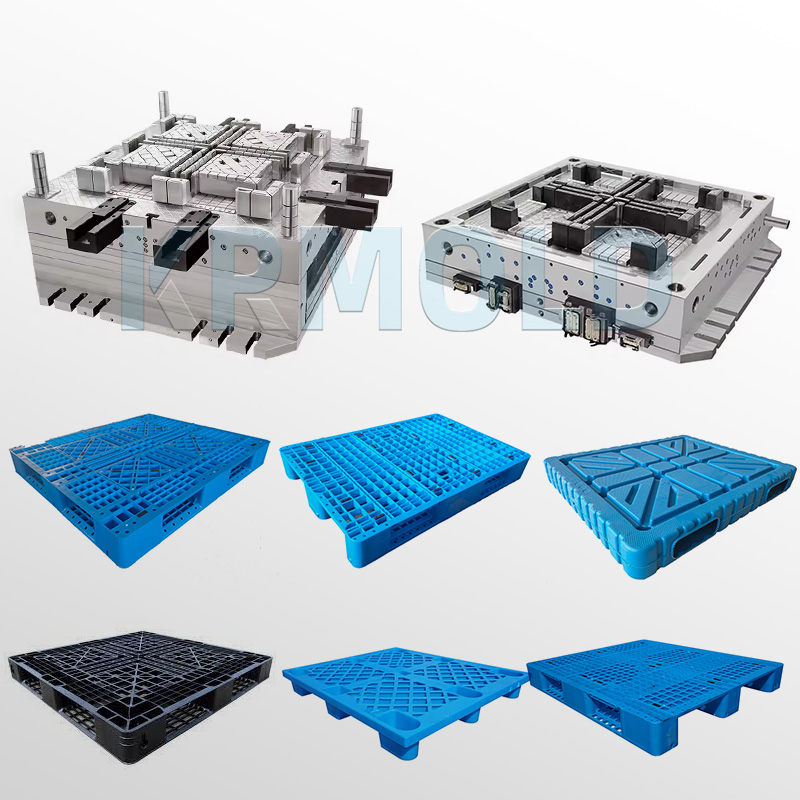

Logistic packaging injection mold: For the logistics and warehousing industries, KRMOLD logistic packaging injection molds are designed for producing efficient plastic packaging products. These logistic packaging injection molds optimize logistics processes and reduce transportation costs while ensuring product safety. By increasing packaging density and space utilization, KRMOLD logistic packaging injection molds not only improve product transportation safety but also significantly enhance logistics efficiency.

What Services Does KRMOLD Provide for Packaging Injection Mold?

KRMOLD services cover a wide range of areas to meet the diverse needs of customers in the cosmetic container injection mold industry:

-Mold-related accessories: Providing customized food packaging injection mold accessories to offer comprehensive support for customers' production needs.

-Product assembly services: Professional assembly services ensure that thin-wall container injection molds undergo thorough inspection before use to achieve optimal performance.

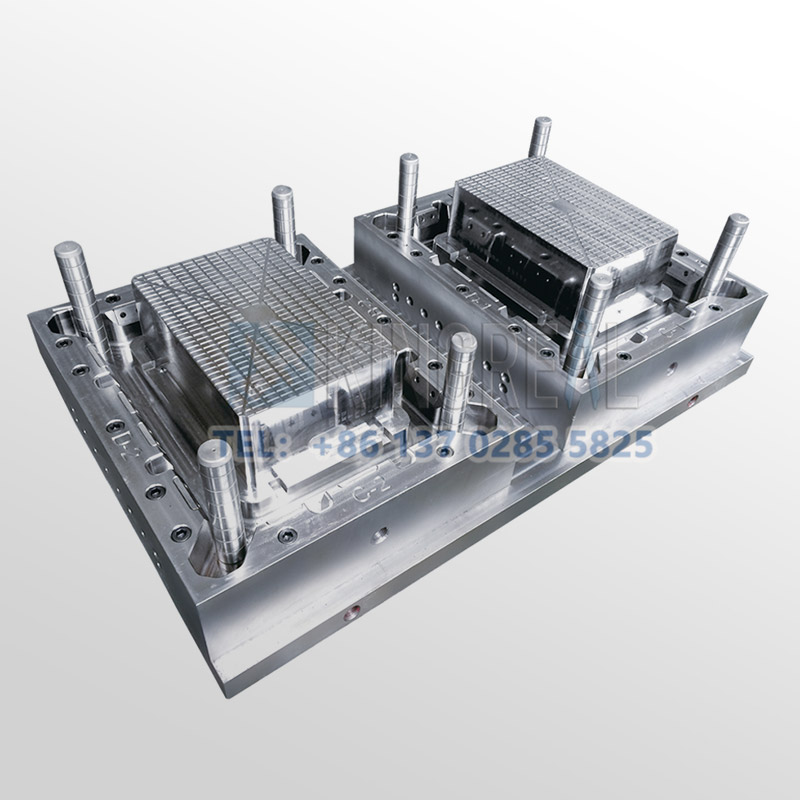

-Injection mold development and design: Innovative designs based on customer needs to ensure efficient logistic packaging injection mold operation.

-Product appearance and structural design: Focusing on the aesthetics and functionality of products to enhance their market competitiveness.

-Precision multi-cavity development and design: Providing precision plastic pallet injection mold solutions for high-volume production needs to improve production efficiency.

-Precision mold component machining: Providing high-precision cosmetic container injection mold machining services to ensure the quality and stability of mold components.

-Mold machining and manufacturing: A complete food packaging injection mold manufacturing process covering every stage from design to production, ensuring product quality and delivery time.

Personalized Packaging Injection Mold Solutions

KRMOLD focuses on providing tailored thin-wall container injection mold solutions for customers in different fields. These logistic packaging injection molds not only optimize space utilization and improve labor efficiency but also effectively reduce production costs. KRMOLD cosmetic container injection molds offer superior component protection while prioritizing sustainability, providing customers with long-lasting packaging solutions. Whether used in the food, cosmetics, or logistics industries, KRMOLD molds maximize production efficiency and economic benefits.

●Why Choose KRMOLD Packaging Injection Molds?

| Increased Part Density: KRMOLD plastic pallet injection molds can produce various pallet types and innovatively allow each pallet to hold more items, reducing shipping frequency and effectively lowering transportation costs. | Reduced Freight and Logistics Costs: KRMOLD logistic packaging injection molds, with their higher packaging density and optimized space utilization, significantly reduce the number of trucks required, further saving on freight and logistics costs. |

| Reusability: KRMOLD food packaging injection molds are reusable, continuously producing high-precision plastic products and reducing long-term material costs. | Suitable for High-Volume Production: For customers requiring large-scale production, KRMOLD thin-wall container injection molds are a cost-effective solution, efficiently producing large quantities of plastic products and ensuring their production capacity. |

| Suitable for complex shapes: For products requiring complex shapes, KRMOLD cosmetic container injection molds can be customized to create plastic products that better meet the needs of customer projects, providing customers with greater flexibility and creativity. |