Introduction to Waste Bin Injection Mold

——

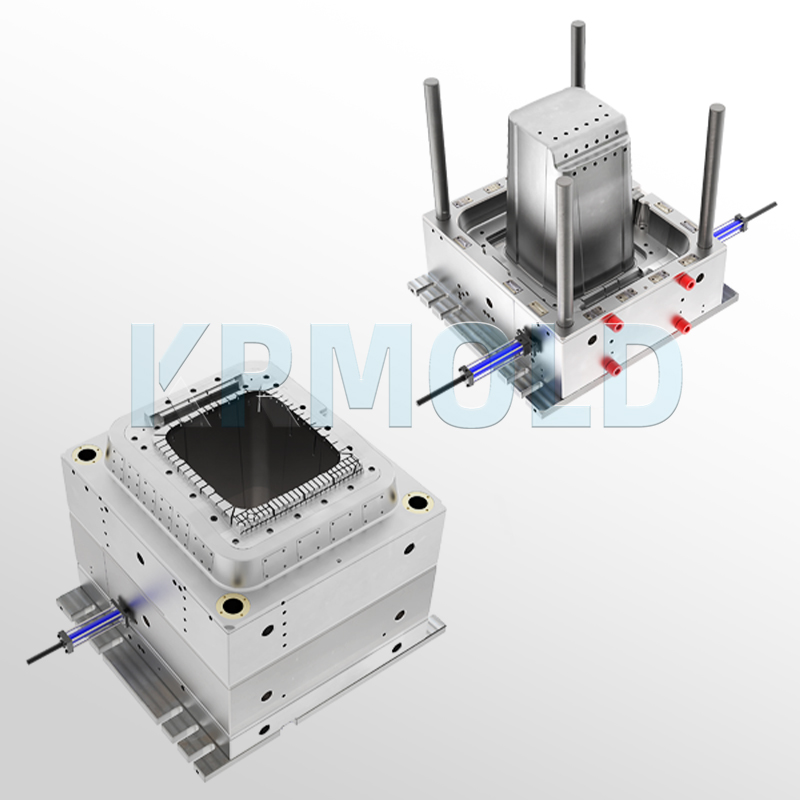

KRMOLD specializes in providing high-quality waste bin injection molds, capable of designing and manufacturing plastic trash bin injection molds for various capacities to meet specific project needs, including 32L, 45L, 60L, 80L, 120L, and 240L. KRMOLD waste bin injection molds design considers product performance and aesthetic in addition to capacity to satisfy diverse market needs for foot-operated, multi-tiered, medical, and general-purpose waste containers.

During the plastic trash bin injection mold design phase, KRMOLD engineers comprehensively analyze and optimize the waste bin injection mold structure, inlaying beryllium copper at the core tip and cavity edges. This innovative design significantly accelerates cycle times and improves production efficiency. Whatever your ideas and needs, welcome to communicate with KRMOLD to customize your plastic trash bin injection mold solution!

Features of Waste Bin Injection Mold

——

1. Short injection molding cycle and high output per unit time.

KRMOLD plastic trash bin injection molds utilize advanced CAE software for temperature distribution analysis during the molding process, particularly strengthening the cooling system design in the highest temperature areas. This optimized design effectively shortens cooling time and significantly accelerates cycle time, thereby increasing output per unit time and enabling you to achieve higher efficiency and economic benefits in the production process.

2. High Stability of the Molding System and High Yield

KRMOLD rationally designed and efficient runner system significantly improves the yield. The hot runner uses imported German heating elements to ensure uniform and stable temperature. This design reduces the number of defective products during production, fully guaranteeing that every trash can you produce is a high-quality product.

3. Uniform Wall Thickness, No Eccentricity, and Long Mold Life

KRMOLD waste bin injection molds are renowned for their high machining precision and accurate assembly. The rationally designed mold locking and guiding mechanism ensures uniform wall thickness and no eccentricity, thus extending the plastic trash bin injection mold's lifespan. This high-standard process results in trash cans that are not only aesthetically pleasing but also possess excellent practicality.

4. Suitable for injection molding of low melt index plastics, ensuring product durability.

KRMOLD waste bin injection molds are designed to balance strength and toughness, making them suitable for injection molding of low melt index plastics. This means that regardless of the pressure experienced during use, the produced trash cans possess excellent impact resistance and anti-aging properties, thus guaranteeing their long service life and stable performance.

Advantages of Plastic Trash Bin Injection Mold

——

KRMOLD is committed to providing customers with high-quality waste bin injection molds, ensuring rigorous control at every stage of production. KRMOLD plastic trash bin injection molds have the following significant advantages:

-Appearance Quality: KRMOLD waste bin injection mold manufacturing process follows strict standards, ensuring no color difference, bubbles, or cracks, guaranteeing a smooth and aesthetically pleasing finished product. -Dimensional Accuracy: All trash cans perfectly conform to customer dimensional requirements, achieving high precision. -Easy Stacking: Designed with stacking performance in mind, trash cans can be easily overlapped, facilitating storage and transportation, and improving overall transport efficiency. -Excellent Functionality: The secure installation of the wheels and lids ensures excellent functionality and user convenience in daily use. |  |

Waste Bin Injection Mold Design Considerations

——

During the design process of KRMOLD plastic trash bin injection molds, engineers fully considered the needs of different usage scenarios (such as homes, factories, and entertainment venues) to ensure that the produced trash cans can withstand stacked weight without bending or deforming. Therefore, KRMOLD emphasizes the following while creating and making plastic trash bin injection molds:

-Material Selection: Selecting high-strength materials to improve the overall durability of the plastic trash bin injection mold.

-Draft Angle Optimization: Properly adjusting the draft angle of the waste bin injection mold to facilitate subsequent demolding and reduce potential deformation problems.

-Reinforcing Rib Design: With customer approval, appropriately adding reinforcing ribs to the design not only helps with smooth demolding but also contributes to cost control.

-Rounded Corner Design: Optimizing the rounded corner design improves plastic trash bin injection mold strength and ease of demolding.

Hot Runner System for Waste Bin Injection Mold

——

The hot runner system is one of the core components of KRMOLD plastic trash bin injection molds. It uses a heating device to ensure that molten plastic particles remain in a molten state during injection. This design avoids solidification caused by cooling, ensuring uniform flow and filling of the plastic, and greatly improving the molding quality of the product. The advantages of hot runner waste bin injection molds include:

-Simple operation & high production efficiency: The simplified process improves production efficiency and reduces reliance on manpower.

-High product quality: The injection molding process avoids defects such as burrs, bubbles, and warping, ensuring the quality of the finished product.

-High durability: Hot runner plastic trash bin molds have a long service life, are easy to maintain, and can support high-intensity production tasks, helping you improve your factory's production efficiency.

More significantly, hot runner technology also helps to preserve the environment. Using a low-temperature hot runner injection molding method gets rid of cooling water flow, which saves priceless water supplies as well as lowers exhaust emissions, therefore helping to protect the environment.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).