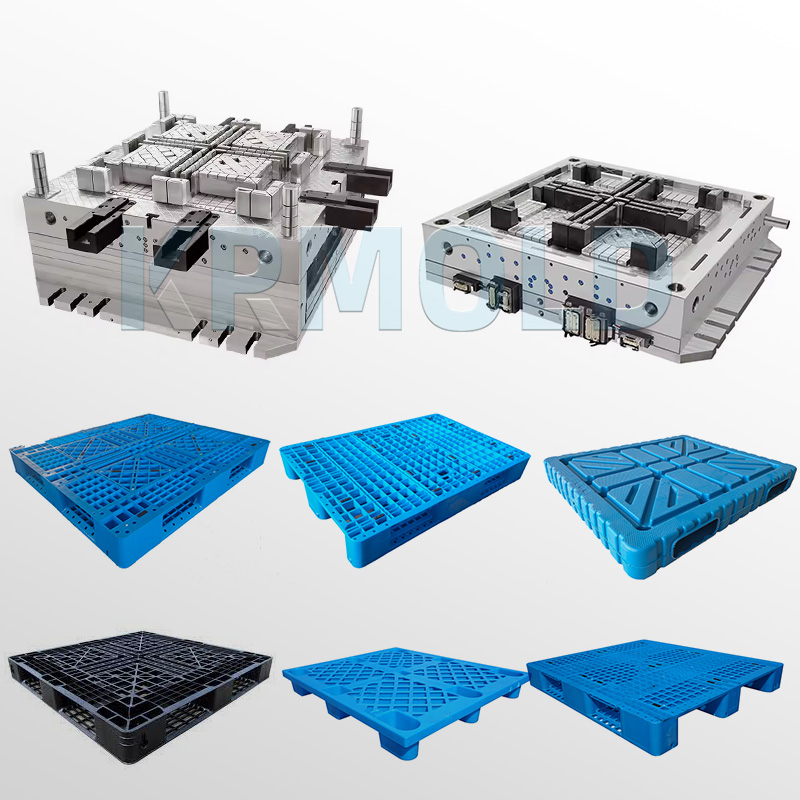

Introduction to Plastic Pallet Injection Molds

——

KRMOLD is dedicated to providing a complete range of plastic pallet injection molds, capable of producing pallets in various sizes for widespread use in everyday goods handling and product transportation in factories. KRMOLD plastic pallet injection mould not only meet market demands but also offer customized designs based on different customer application scenarios and handling conditions.

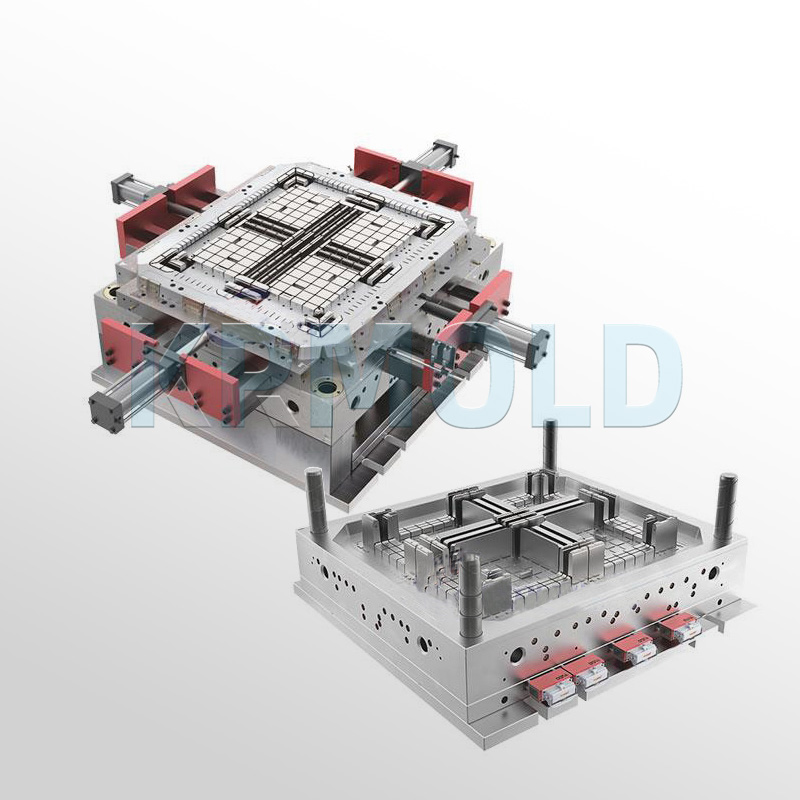

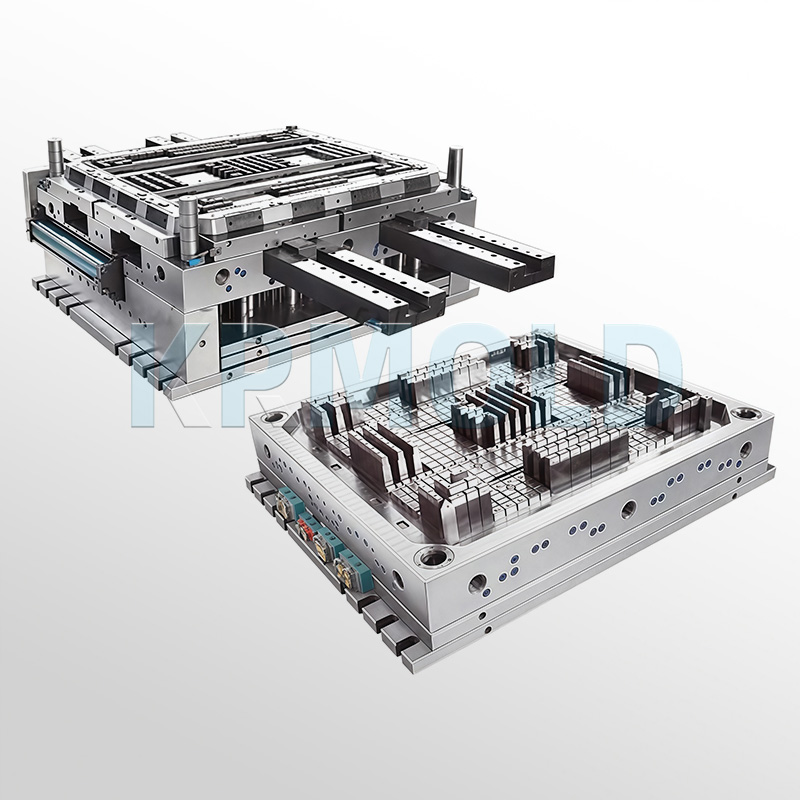

In the design process of plastic pallet injection molds, KRMOLD engineers thoroughly analyzed the characteristics of a single, straight mold with a central partition. The design integrates four sliders within a single conical mold sleeve, equally dividing the space into four sliders. The advantage of this design is that the sliders can reciprocate along the tracks, and during locking, the clamping force of the injection molding machine secures the sliders within the conical mold sleeve, preventing loosening that may occur during melt filling. This design concept not only improves mold stability but also ensures production efficiency.

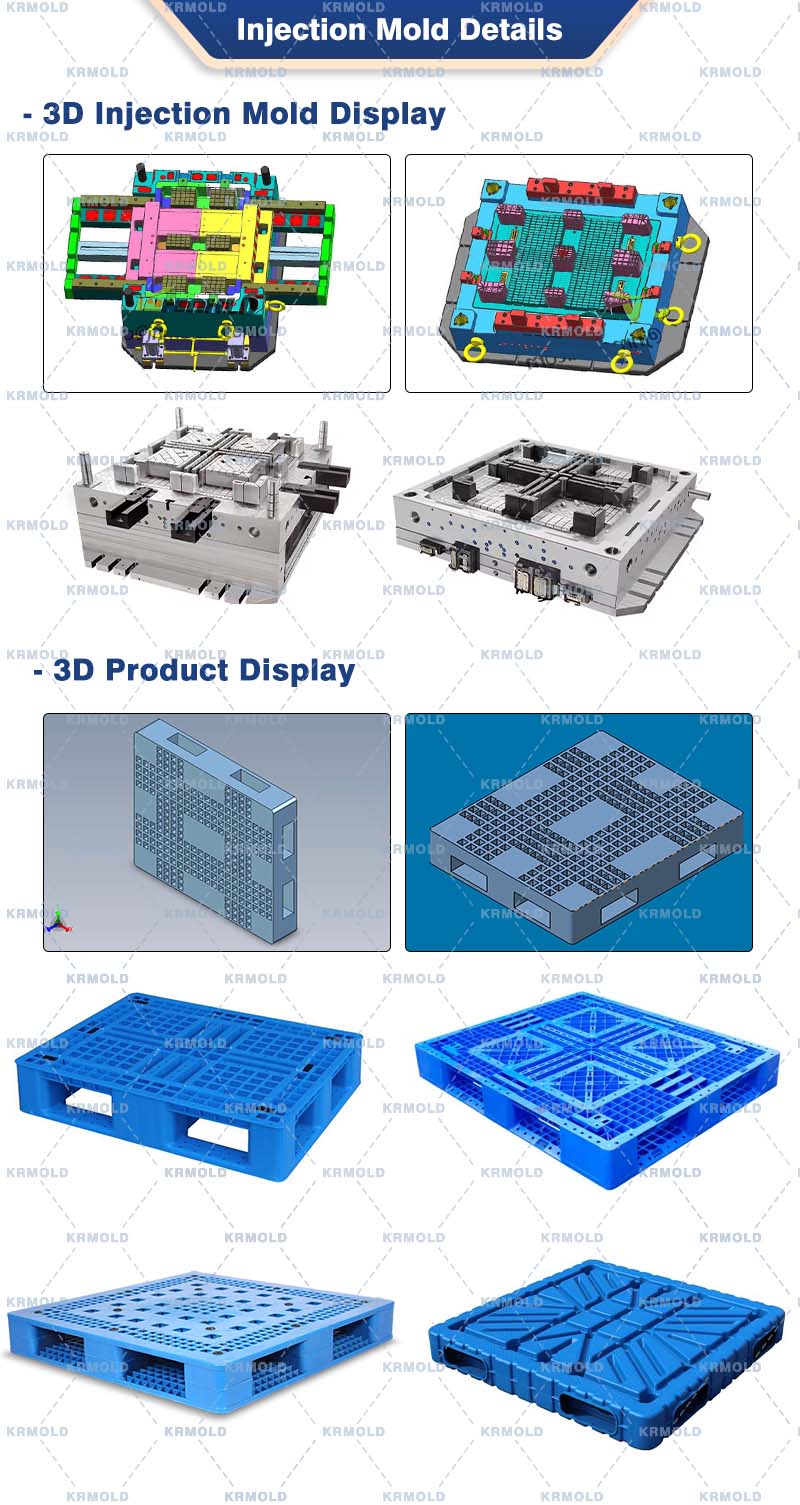

Plastic Pallet Injection Molds Specifications

——

| Mould Name | Plastic Pallet Injection Mold |

| Product Size | 1200x1200x150mm |

| Product Description | Dual-layer pallet with 4 slides |

| Mold Cavity | 1 cavity |

| Mold Size | 1800x1800x1100mm |

| Mold Main Material | 2311 |

| Mold Injection System | 16-point hot runner gate |

| Mold Ejection System | Ejector pin and ejecting block |

| Mold Cycle Time | 95 Seconds |

| Mold Running | 500K |

Plastic Pallet Injection Mould Feature

——

KRMOLD plastic pallet injection molds feature a complex structural design and a sophisticated cooling system. The professionally designed hot runner system allows for efficient high-speed injection molding of recycled materials. Precise control of the limit switches ensures a smooth and efficient ejection process.

KRMOLD plastic pallet injection mould utilize a valve-type gate hot runner system, combined with a special filtration system, enabling them to adapt to the injection molding of recycled materials. Through optimized injection molding and cooling systems, KRMOLD plastic pallet injection molds achieve near-high-speed injection molding performance, ensuring high efficiency and high quality in the production process. Simultaneously, KRMOLD plastic pallet injection mould undergo rigorous drop tests, load tests, and chemical solution tests required by all industrial pallet standards, ensuring that every pallet can withstand the test of real-world use.

Plastic Pallet Injection Mold Design for Material Selection

——

KRMOLD typically selects the following plastic materials for plastic pallet injection mould design:

-High-density polyethylene (HDPE): Due to its high shrinkage rate, the mold needs excellent venting performance.

-Polypropylene (PP): Precise temperature control zones are set up in the mold to ensure molding quality.

-Recycled plastics: These materials usually require a more robust mold structure to address material consistency issues.

Each material has different flow characteristics, shrinkage rate, and cooling performance. KRMOLD engineers fully consider these factors during plastic pallet injection molds design to ensure the quality and performance of the final product.

KRMOLD Plastic Pallet Injection Mold Customization Capabilities for Specific Applications

——

With great customizability, KRMOLD plastic pallet injection mould offer customized solutions to meet the particular requirements of several industries. KRMOLD can provide plastic pallet injection molds satisfying industry criteria whether in pharmaceuticals, food processing, or electronics.

(1) Plastic pallet injection molds for pharmaceutical and medical applications

In the pharmaceutical transportation field, KRMOLD plastic pallet injection mould can produce pallets with the following characteristics:

-Completely sealed surface: Effectively prevents external contamination and ensures safety during transportation.

-Built-in RFID tracking system: Meets regulatory requirements and facilitates logistics management.

-Integrated temperature monitoring function: Ensures stable temperature of medicines during transportation.

-Sterilization compatible: Meets the high standards of hygiene and safety requirements of the medical industry.

(2) Plastic pallet injection molds for food processing requirements

For the food processing industry, KRMOLD food-grade plastic pallet injection mould offer the following advantages:

-Antibacterial additives: Effectively inhibit bacterial growth, ensuring food safety.

-Smooth & non-porous surface: Prevents food residue and reduces cleaning difficulty.

-High-pressure washing capability: Facilitates cleaning and meets food processing hygiene standards.

-Metal detection: Ensures compliance with food safety regulations and prevents the introduction of metal foreign objects.

(3) Plastic pallet injection mould for electronic products and precision components

For precision electronic products, KRMOLD plastic pallet injection mould can produce plastic products with the following advantages:

-Static dissipation properties: Effectively protects precision components and prevents electrostatic damage.

-Precise and consistent dimensions: Facilitates automated handling and improves production efficiency.

-Smooth surface: Does not generate particles or dust, ensuring product quality.

-Flame-retardant additives: Meets safety regulations, ensuring safety during use.

Core Elements of Plastic Pallet Injection Molds Design

——

When designing plastic pallet injection mould, KRMOLD fully considers the end-use requirements of customers, including load-bearing capacity, stacking strength, environmental conditions, and handling methods. These factors help every pallet to perform admirably in a range of uses.

● Load analysis for plastic pallet injection molds

KRMOLD engineers conduct comprehensive load analysis, a crucial process in plastic pallet injection mould design. Load analysis mainly includes the following aspects:

-Static Load Capacity: The maximum weight the pallet can withstand when stationary.

-Dynamic Load Capacity: The load-bearing capacity of the pallet during movement, typically 75-80% of the static load capacity.

-Rack Load Capacity: The supporting strength of the pallet when supported only by its edges.

KRMOLD ensures plastic pallet injection molds design meets all the above requirements and guarantees the overall stability of the pallet's performance through scientifically designed and rationally arranged reinforcing ribs, material distribution, and structural support features.

● Stress distribution optimization for plastic pallet injection mould

To achieve appropriate stress distribution, KRMOLD focuses on the following aspects in plastic pallet injection molds design:

-Uniform wall thickness: Prevents warping and shrinkage marks.

-Rational reinforcing rib layout: Achieves maximum strength with minimal material usage.

-Rounded corner design: Effectively prevents stress concentration and improves mold durability.

-Balanced material flow path: Ensures consistent density within the plastic pallet injection mould, improving injection molding quality.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).