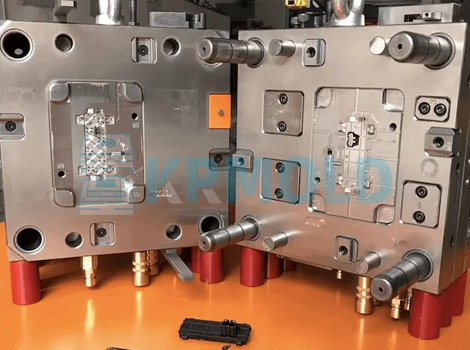

Full Solution For Logistic Packaging Injection Mold

——

KRMOLD Logistic Packaging Injection Mold is an injection molding tool specially designed for the production of plastic packaging products for logistics transportation and warehousing, which can help customers in the logistics and transportation industry to quickly produce logistics packaging products in bulk.Logistics Pallets Injection Mold produces logistics packaging products that meet customers' production requirements through the process of melting and high-pressure injection of the required raw materials into the mold cavity for filling, cooling and demolding. Logistics Pallets Injection Mold produces logistics packaging products in line with customer's production requirements through the injection process of melting and high-pressure injection of the required raw materials into the mold cavity for filling, cooling and demolding, therefore, the precision, functionality and life span of the injection mold have a direct relationship with the precision and yield of the finished logistics packaging products.

KRMOLD is a professional plastic injection mold manufacturer in China, dedicated to providing customers with complete injection mold design and production solutions, so far there are abundant injection mold design cases in different industries, such as automotive industry, medical industry, consumer electronics industry and household industry. In the field of logistics and packaging industry, KRMOLD has customized the design and innovation of injection molds for logistics and packaging products with the characteristics of high strength, stackable and reusable, etc. Combined with the customer's actual production needs, KRMOLD has made new innovations on the structure of the molds, the materials, and the adaptability of the process.

Typical Cases Of Logistics Packaging Injection Molds

——

1

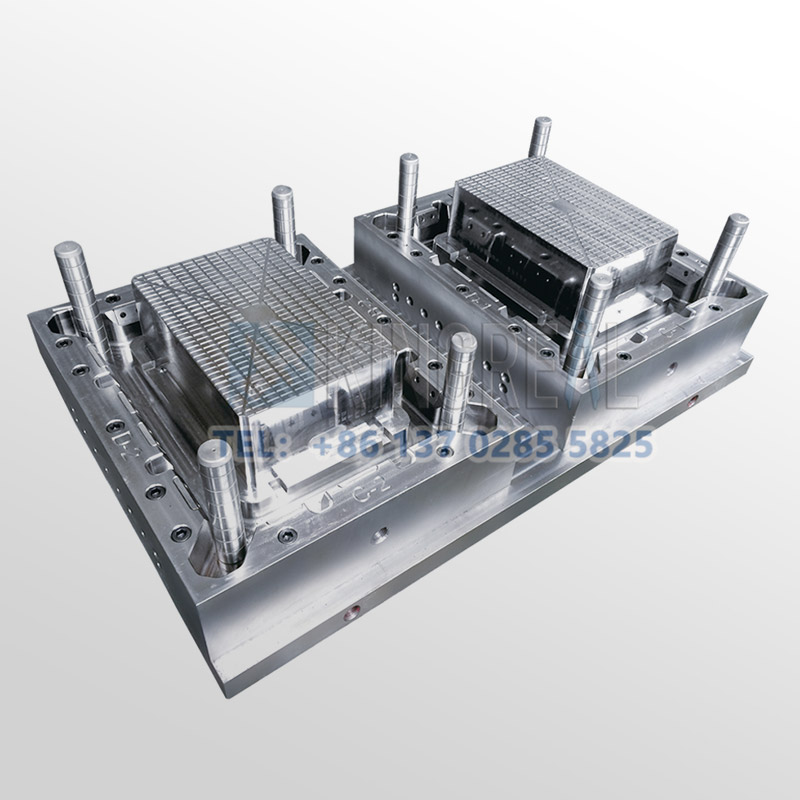

Folding crate injection molds

Foldable crate injection mold is used to produce foldable crates for e-commerce sorting, auto parts transportation and fresh food distribution. Generally speaking, folding crate wall thickness of 1.5-3mm, using PP/PE as raw materials, with lightweight and impact resistance characteristics. Folding crate injection mold in the design of the movable hinge structure, support for more than 100,000 times folding, saving 70% of the storage space. Mould cavity surface anti-slip texture design, to help stacking folding crate stability.

2

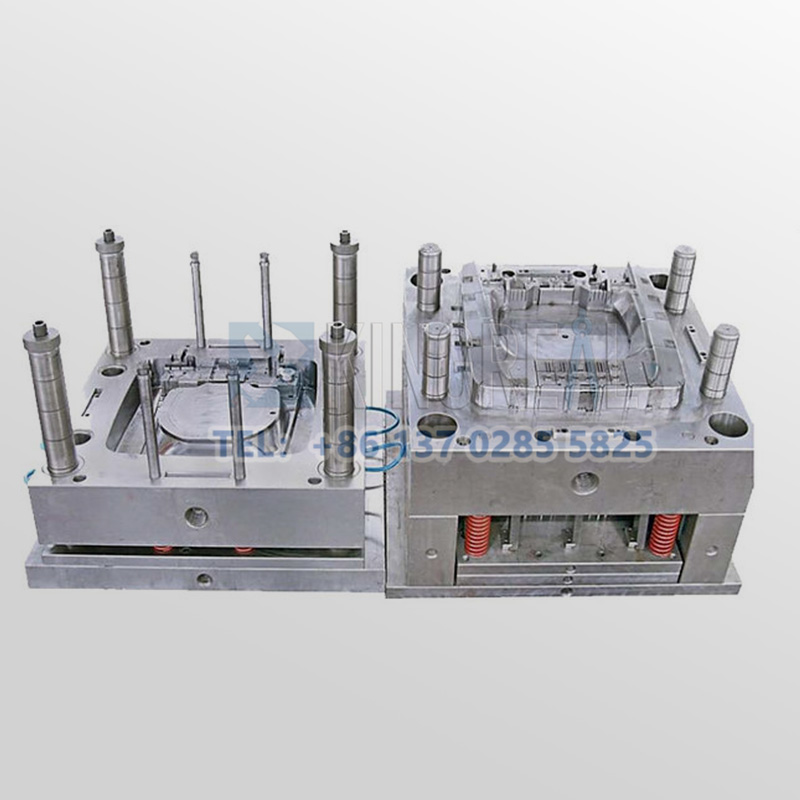

Standardized pallet injection molds

Standardized pallet injection mold for the production of plastic pallets for automated warehousing and cross-border logistics products, load capacity of up to 1.5-2 tons, the bottom of the integrated honeycomb reinforcement. Standardized pallet injection molds have built-in non-slip grooves to prevent cargo from sliding. RFID chip slot can be embedded to support logistics tracking.

3

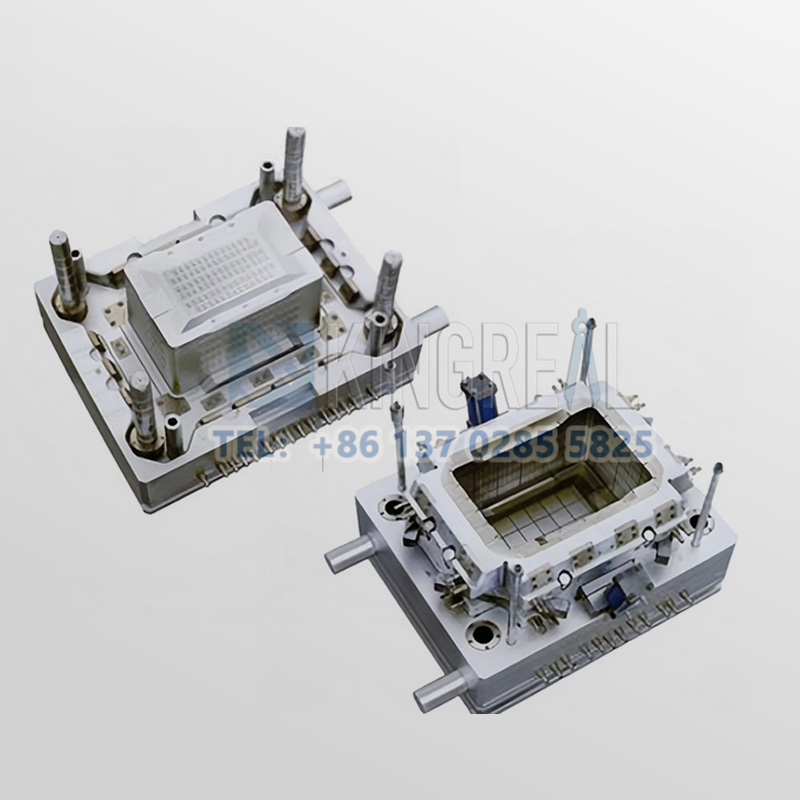

Shockproof liner injection molds

Used in the production of precision instruments, medical equipment and electronic products for packaging logistics needs. The anti-vibration liner injection mold adopts multi-cavity mold design to achieve one out of many batch mass production, while ensuring the consistency of the cushioning structure. It can be customized to fit the shape of the product.

4

Cold chain logistics box injection molds

It is used to produce cold chain logistics box for pharmaceutical cold chain and fresh food transportation. Cold chain logistics box injection mold with integrated sealing groove structure ensures airtightness of the lid, and adopts HDPE+glass fiber reinforced material, which is resistant to low-temperature brittleness.

Logistics Packaging Products Injection Mold Features

——

1

Meet the structural design requirements of different logistics packaging products

KRMOLD logistics packaging product molds are equipped with slider and tilt top mechanism to realize complex movable structure and meet the foldable and nestable structure requirements of logistics packaging products. Injection molds meet the lightweight requirements of logistics packaging products through gas-assisted injection molding (GAIM) or micro-foaming process (MuCell).

2

Meet the material requirements of different logistics packaging products

Logistics packaging injection molds can be adapted to high impact materials and environmentally friendly materials injection molding production needs, common logistics packaging product cases PP + EPDM (automotive parts box injection mold), UV-modified PE (outdoor crate injection mold).

3

Injection mold to achieve a variety of functional requirements

Logistics packaging product molds reserved QR code / RFID insert slot to meet the digital needs of the supply chain. At the same time, we provide integrated molding of clips and locks, with mold precision of ±0.02mm to ensure smooth opening and closing.

4

Innovative injection mold production process

Logistics packaging products injection mold through the hot runner system design to achieve the reduction of waste, improve the production efficiency of multi-cavity molds, while the use of 3D printing copper alloy waterway to help shorten the cooling time by 30%.

Logistics Packaging Injection Mold Production Process

——

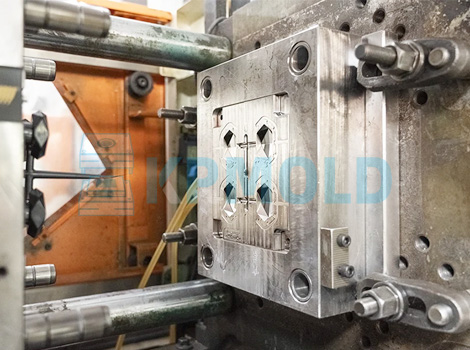

1.Multi-cavity injection molding technology

Logistics packaging injection mold to achieve multi-cavity injection molding technology, “one mold, multi-cavity” design (such as a mold 8 cavities or 128 cavities), a single injection output of a number of logistics packaging products, the efficiency can be up to the traditional single-cavity molds 5-8 times, to reduce the occupancy of equipment and waste (such as the use of hot runner system), the cost per unit of product reduction of more than 30%. H-type or radial runner layout is adopted in the design of the injection mold to ensure that the melt reaches all cavities at the same time and the pressure is uniform. The diameter of the main runner decreases step by step, and the cold material well is set at the end to avoid uneven filling.

2. Gas Assisted Injection Molding Technology (GAIM)

Logistics packaging injection mold to meet the gas-assisted molding technology, in the thick-walled area of the logistics packaging products injected with nitrogen to form a hollow structure, weight reduction of 20% -40%, while enhancing the rigidity of the gas to maintain pressure to compensate for plastic shrinkage, reduce surface defects. The design of the injection mold is 2-3 times of the wall thickness of the cross-section of the gas channel, the corner of the arc transition, combined with the reinforcement as a sub-gas channel to enhance the efficiency of the shrinkage compensation, the use of high-temperature sealing ring, the gas needle gap <0.02mm, to prevent backflow of molten material.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).