What Is Thin-Wall Container Injection Molds?

——

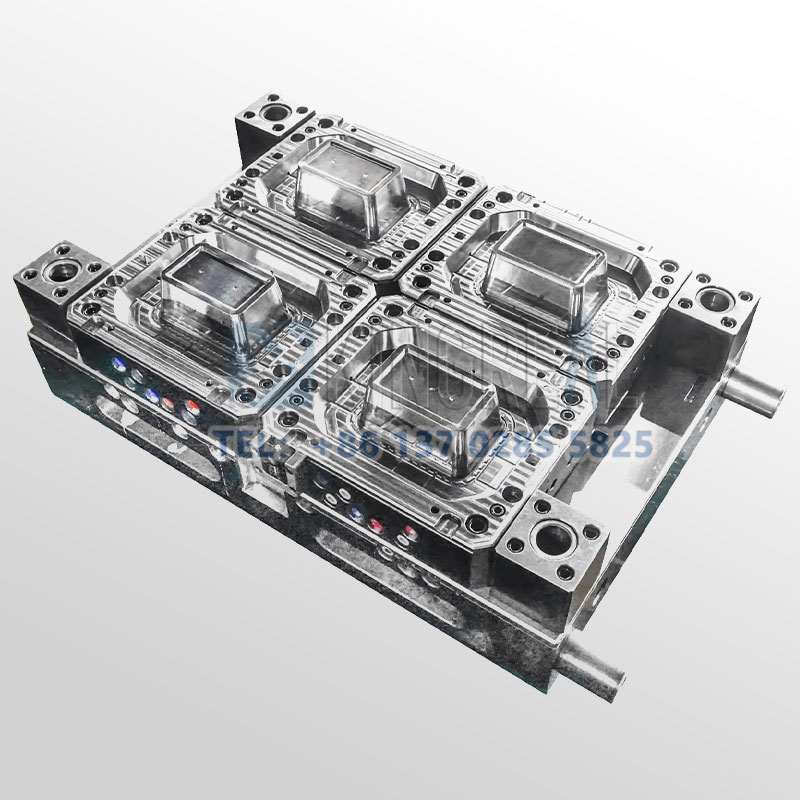

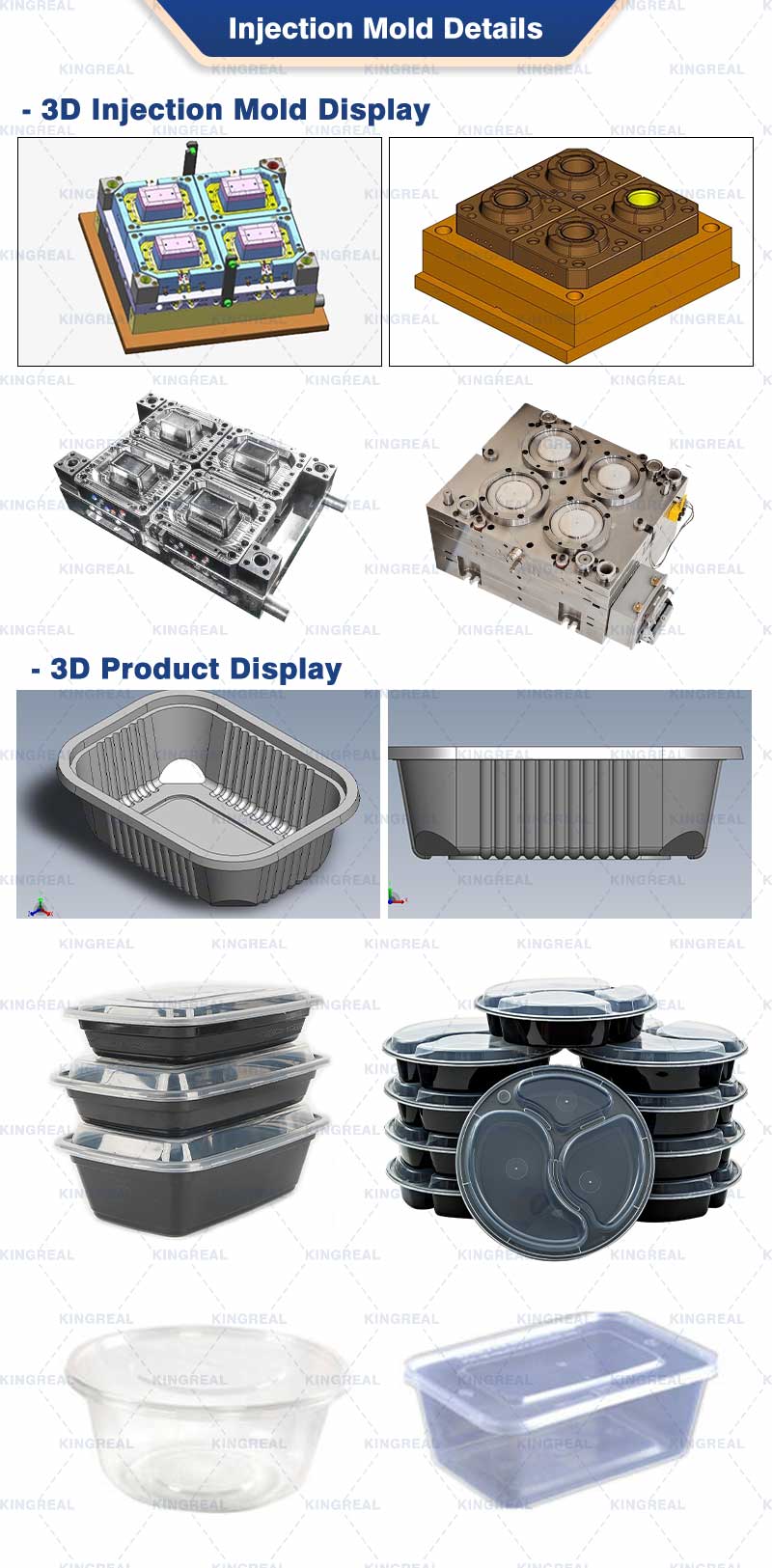

Thin-Wall Container Injection Molds are injection molding tools specially designed for the production of plastic containers with a thickness of less than 1MM, extremely thin wall thickness and a flow length ratio of more than 150. It can also be said that when the melt from the main flow channel of the mold to the furthest point of the cavity flow length (L) and container wall thickness (t) ratio. When the flow length ratio exceeds 150, it can be called thin-wall injection molding. The most typical thin-wall injection molding process products disposable fast food containers and thin-walled cell phone battery shell, wall thickness of 0.45MM and 0.25MM respectively.

Thin-walled container products in the manufacturing process will face filling difficulties, poor exhaust and deformation of the mold and other difficulties resulting in poor product quality and production output is difficult to improve, and thin-walled injection molding molds through the high-strength structure, high-efficiency runner design and accurate temperature control and other aspects of technology to help thin-walled products to complete the high-quality mass production process, to solve the food industry, the medical industry, the electronics industry, and other types of industries in the thin-walled products production and manufacturing needs. The production of thin-walled products in the food industry, the medical industry, the electronics industry and other industries in the manufacturing needs.

How To Design Injection Mold For Thin-Walled Containers?

——

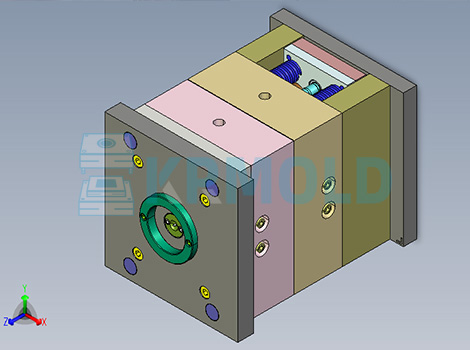

KRMOLD in the production of thin-walled containers for the production of injection molds usually need to use high-carbon chrome bearing steel SUJ2, its Rockwell hardness can reach HRC ≥ 55 steel, the original steel injection mold heat treatment in order to withstand high pressure of more than 200MPa and more than 200mm / s high-speed injection of the impact.

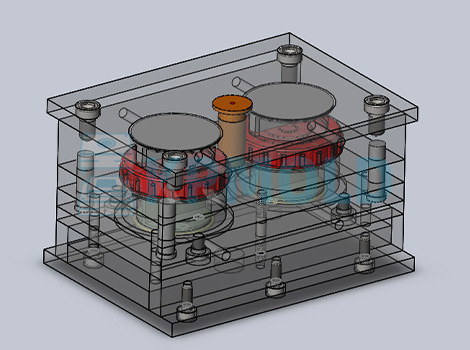

Thin-wall container injection mold adopts hot runner technology and sequence valve gate (SVG) to ensure that the melt fills the thin-wall cavity quickly and reduce material waste. Thin-wall injection molding is prone to burnout due to trapped air, so multi-stage exhaust slots need to be set up on the parting surface and at the end of filling, and the cooling system needs to evenly distribute the water circuit to avoid warping and deformation caused by residual stresses.

Thin-walled injection mold using multi-stage exhaust groove design, the main parting surface set up a primary exhaust groove and secondary exhaust groove, filling the end of the additional slider bottom of the whole circle of exhaust, annular deep tendons into the sub-bit using inserts to assist in the exhaust, to prevent the trapped gas burnt. Uniform cooling water layout is required, using a spiral water circuit with a pipe diameter of 6mm, evenly distributed 12mm from the cavity surface, and for deep cavity structure, cooling circuits are independently set up in the moving mold core, slider and other areas.

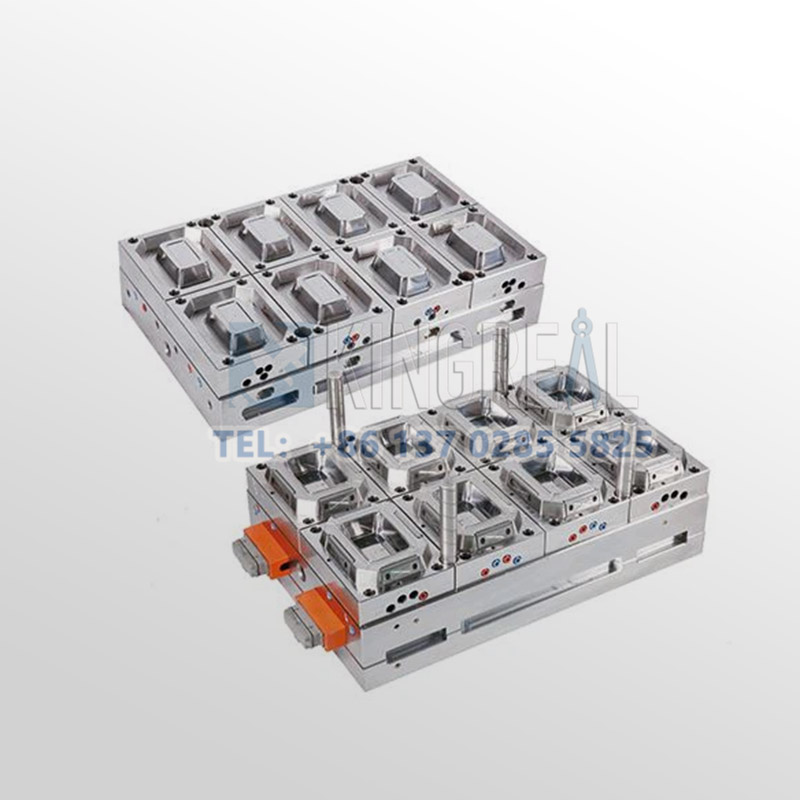

“For thin-walled deep cavities and small demolding slopes, injection molds need to be designed with a priority core pulling mechanism and a slide lateral core pulling mechanism. Adopt more ejector pins to ensure the stability of mold release to avoid the deformation of thin-walled products, which may lead to mold release difficulties."

Manufacturing For Thin Wall Packaging Molds

——

Thin-wall packaging injection mold adopts CNC processing of polished steel or carbide and other high hardness mandrels to ensure the surface finish of pre-molded parts during injection, and the mold cavity is processed by 5-axis CNC machine tool with an accuracy of ±0.005mm, which can satisfy the molding demand of thin-walled container with wall thickness of ≤1mm.

The parting surface adopts CNC milling with electric discharge machining (EDM) to ensure the sealing ≤ 0.02mm gap when closing to avoid flying edge, and multi-stage exhaust groove (depth 0.03-0.3mm) is processed at the end of the filling to realize the precise exhaust channel through CNC engraving.

KRMOLD uses high-speed CNC to process the inner hole of the hot runner plate in the injection mold, the tolerance of the hole diameter is controlled at ±0.01mm, which is suitable for the segmental filling control of Sequence Valve Gate (SVG), and the gate area adopts the micro-tool to carve the submerged gate, the angle is controlled at 30°-45°, and the CNC processed helical cooling water circuit is evenly distributed 12mm away from the surface of the cavity, combined with the beryllium copper alloy inserts to improve the local cooling efficiency to ensure the melting efficiency. Combined with beryllium copper alloy inserts to enhance the local cooling efficiency to ensure that the melt fills the thin-walled area quickly.

The four sides of the slider are processed by CNC milling with wire cutting, and the tolerance of the diagonal guide pillar hole diameter is ±0.01mm to ensure the stability of lateral core pulling, and the bottom of the slider is processed with a whole circle of exhaust grooves, with a depth of 0.3mm, to prevent thin-walled areas from being trapped in the gas burnt. The ejector hole is drilled by deep hole drilling process, and the surface of the ejector is plated with hard chrome to reduce the friction of demolding.

How To Ensure The Quality Of Thin-Walled Container Injection Mold?

——

1. In-line inspection and correction

Inspection of injection mold cavity dimensions using Coordinate Measuring Machine (CMM) and local discharge correction for thin-walled areas. Simulate the injection process through pressure test to verify the sealing and strength of the mold.

2. Optimization of test mold parameters

KRMOLD arranges the trial molding process of the injection mold in the workshop, referring to the segmented pressure control of IBM process, the first holding pressure is 80%-90% of the injection pressure to ensure that the thin-wall filling is complete. Monitor the ejection temperature to prevent the ejector pin from scratching the product.

Thin-walled container injection mold molding case

——

The automobile front bumper injection mold is made of PP+EPDM-T20 material, with thin wall thickness and high flow length ratio through internal parting surface technology and 8-point sequential valve hot runner to control the fusion mark.

Disposable lunch box injection mold made of PP material, wall thickness of only 0.45-1.2mm, the use of hot runners and copper-beryllium alloy inserts to accelerate cooling, molding cycle ≤ 5 seconds.

Electronic equipment shell injection mold production of thin-walled products wall thickness as low as 0.25mm, the use of high-flow PC or ABS materials, no shrinkage marks on the surface.

FAQ:

1.How to get a quote for custom injection molds?

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).