Full Solution For Cosmetic Container Injection Molds

——

The injection molding process is the most common production method for Cosmetic Container products. Different raw materials (e.g. PP, PETG, ABS) are melted and injected into the mold cavities, which are then cooled and cured to produce container parts products (e.g. bottle caps, cans, pump heads, lipstick tubes, etc.) with high precision and surface quality. With the enhancement of the pursuit of uniqueness, design and functionality of cosmetic packaging products, the design and manufacturing requirements of injection molds, as the core process of producing cosmetic packaging products, have been increasing.

1. Injection molds need to support complex shapes and multi-material combinations (e.g., co-injection of transparent and colored layers) to meet the production needs of cosmetic packaging products. KRMOLD adopts 3D modeling and precision CNC machining technology (CNC) to achieve micron-level accuracy for cosmetic packaging injection molds.

2. Cosmetic packaging injection molds need to reserve space for embedding sensors (e.g. chip slots) and ensure that the injection process does not affect the performance of electronic components, and the mold material needs to be resistant to high temperatures and corrosion in order to be suitable for the smart coating process.

3. Cosmetic packaging injection mold by using mirror polishing technology to reduce the surface defects of cosmetic packaging products, to optimize the slope of the mold to avoid material residues; the development of multi-layer co-injection molds to achieve the combination of barrier layer and functional layer.

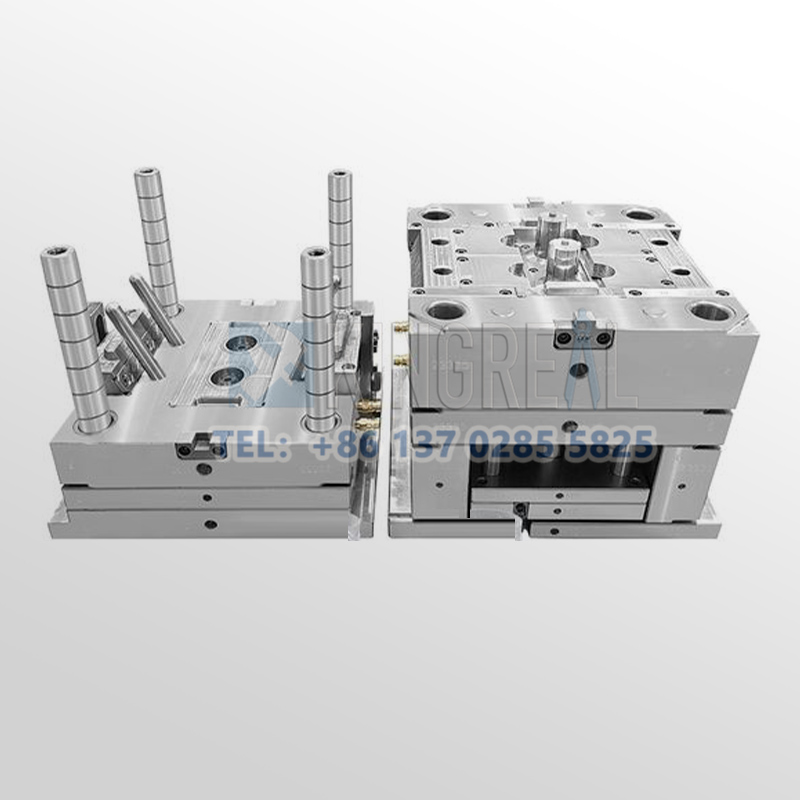

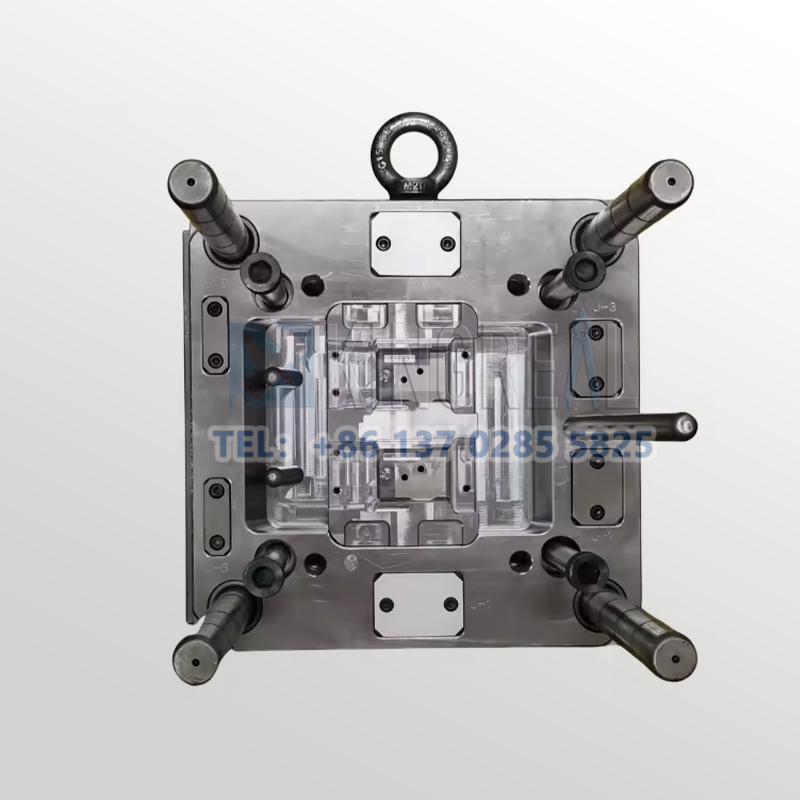

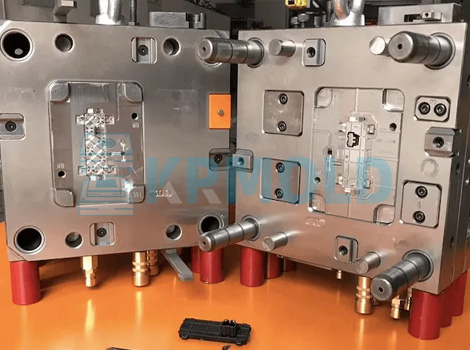

Component Of Cosmetic Container Injection Molds

——

1. Mold core and cavity: Cosmetic packaging injection molds are made of high hardness steel (such as S136, NAK80), and the surface is mirror-polished (Ra ≤ 0.01μm) to ensure the glossiness of the products. 2;

2. Pouring system: the mold adopts hot runner design (to reduce cold material) and needle-valve type glue feeding (to avoid fusion line) to ensure the material is evenly filled;

3. Cooling system: the injection mold shortens the cooling time and prevents deformation by optimizing the waterway layout (follower waterway);

4. demolding mechanism: the injection mold adopts the structure of inclined top, slider, pneumatic ejector, etc., which is suitable for the demand of complex concave or threaded demolding.

Advantage Of Cosmetic Container Injection Molds

——

Cosmetic packaging requires high precision in surface texture (e.g. embossed logo) and sealing structure (e.g. pump head threads), and KRMOLD injection molds need to be processed with CNC machine tools (CNC) and EDM technology to achieve an accuracy of ±0.02mm in the injection mold to ensure the consistency and functionality of the cosmetic products. Packaging products consistency and functionality.

KRMOLD injection molds are designed to meet the complex structure of cosmetic packaging products such as shaped bottle mouths and curved bottle bodies. KRMOLD adopts the follow shape cooling water circuit to optimize the cooling efficiency and reduce the risk of deformation. For example, the skin care can body mold achieves efficient mass production through 1-out-of-32-cavity multi-cavity mold design, which improves the production efficiency of the product.

KRMOLD applies AI algorithms to optimize injection parameters (e.g. pressure, temperature) in real time, increasing the injection molding yield to 98.5%; meanwhile, it adopts IoT sensors to monitor the mold wear data and reduces the downtime by more than 20% with predictive maintenance.

Common Injection Molding Processes

——

“KRMOLD injection molds for cosmetic packaging products can be designed according to the customer's actual production requirements, such as output, inserts and laminating, etc. to achieve different injection molding processes.”

Insert Molding is a process in which prefabricated inserts such as metal, glass, and fiber are placed in a mold, and plastic is molded to cover the inserts to form an integrated product. It has the advantage of combining the moldability of plastics with the rigidity of metals to create complex structures, as well as reducing the number of secondary assembly steps and improving sealing and reliability.

Common examples are injection molds for pump head components, smart packaging molds and decorative structural molds.

Two-shot molding injection molding injects plastics of different colors or materials into the same mold through two injections to form packaging parts with gradient, soft-hard combination, and other effects. The combination of hard and soft plastic enhances functionality and reduces the need for spraying, which is in line with the trend toward environmental protection. Common cases of gradient bottle body injection mold, soft and hard plastic combination injection molds.

Commonly used materials cosmetic packaging injection molding raw materials

——

1. PP/PE: low cost, good chemical resistance, suitable for non-transparent parts such as bottle caps and pump heads.

2. PET/PETG: high transparency and recyclability, used for transparent bottle body (two-step method required: injection molding tube embryo + blow molding).

3.ABS/AS: balancing toughness and surface gloss, suitable for embossed logo decorated can bodies.

Bio-based materials (PLA/PHA): environmental trends, molds need to be adapted to low-temperature molding and corrosion-resistant steel.

FAQ:

1.How to get a quote for custom injection molds?

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

2. How long does it take to get a quote for an injection mold?

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

3. What is the lead time for injection molds?

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

4. How to ensure the dimensional accuracy of the mold and product consistency?

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software.

Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage.

Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).