Full Solution For Food Packaging Injection Molds

——

Plastic Food Packaging has the characteristics of diverse material selection, functional design and environmental innovation, and has become an indispensable packaging product in the food industry. Injection molding is the core manufacturing process of Plastic Food Packaging. It melts various plastic raw materials such as PP, PET, PLA through an injection molding machine and injects them into the inner cavity of the injection mold for cooling and shaping to form packaging products that meet food safety standards. Common food packaging injection molding products include plastic bottles, sealed boxes, canned containers, etc.

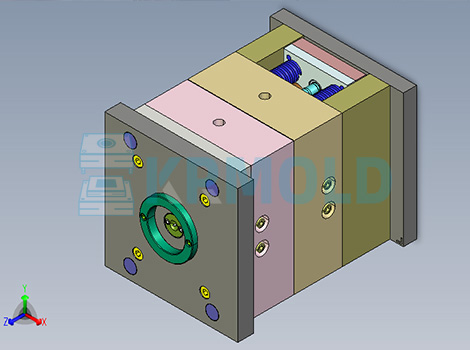

KRMOLD is a professional injection mold manufacturer in China that is committed to providing customers with complete injection mold production solutions. It designs injection molds according to the product characteristics, needs and output required by different industries. Among them, Food Packaging Injection Molds are designed to meet the mass production needs of customers in the food industry for various packaging products. It has the following characteristics:

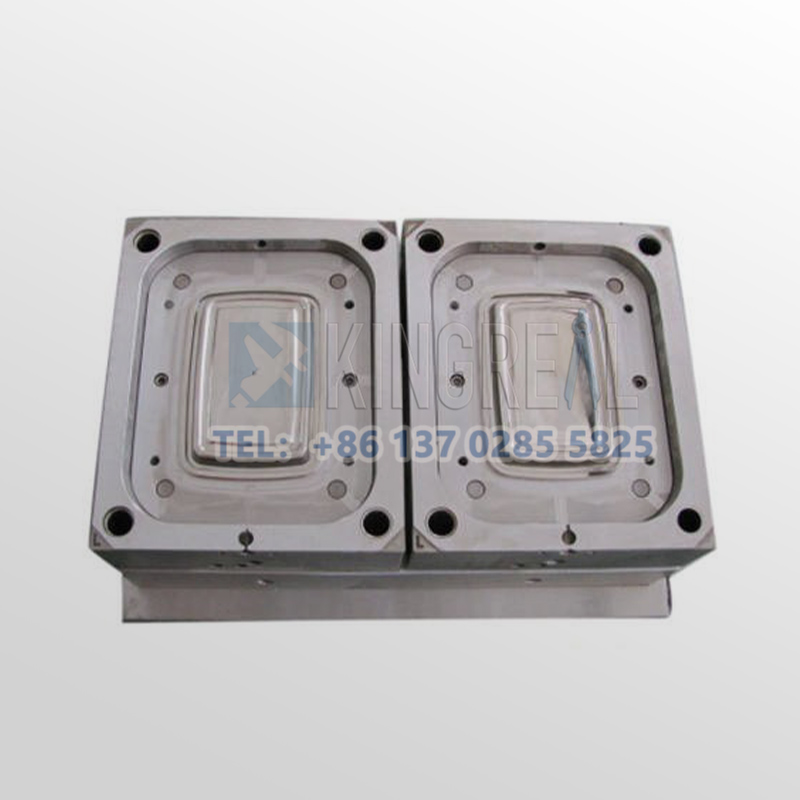

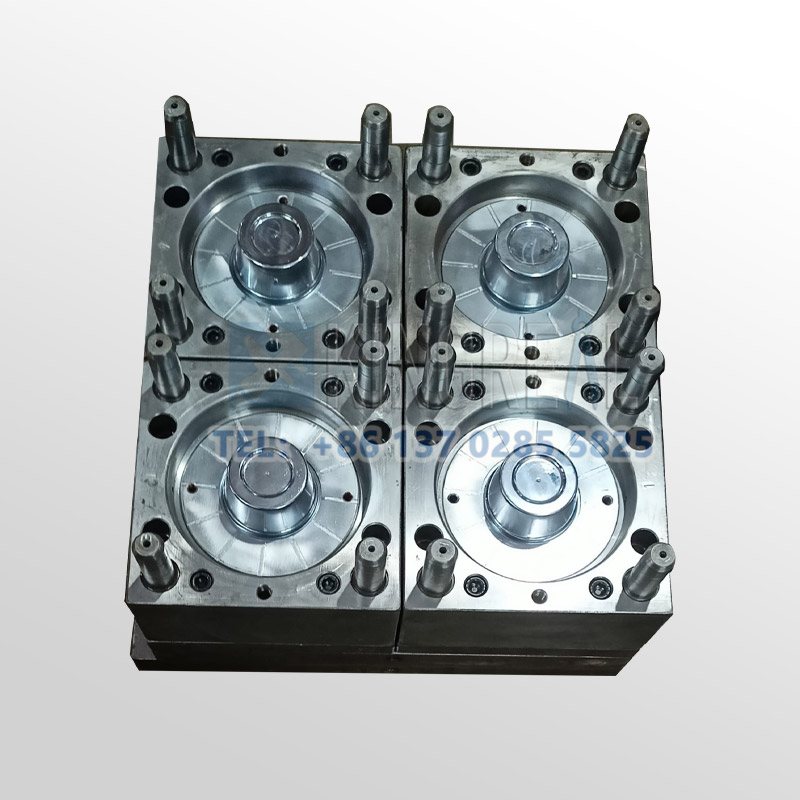

1. High precision and consistency: The design of food outer packaging molds needs to ensure that the size, sealing and appearance of food packaging products meet the food contact material specifications, such as the bottle mouth thread design of food packaging products and the raw material meltability.

2. Material adaptability: Packaging Injection Molding supports food-grade plastics (such as PP, PET, PLA, etc.), especially for biodegradable materials, precise temperature control is required to avoid thermal decomposition.

3. Functional structure: Food Packaging Injection Molds integrate thin walls (less than 0.2mm), leak-proof grooves, buckles and other designs to meet the needs of sealing, portability, etc.

Injection Mold Manufacturing Process

——

“How to ensure that the injection mold design and manufacturing can meet the characteristics of food packaging products injection molding production needs?”

KRMOLD gives priority to stainless steel (such as S136) or aluminum alloy as the raw material for injection molds to ensure corrosion resistance and compliance with FDA standards. Meanwhile, for degradable plastics (e.g. PLA), copper alloy with better thermal conductivity or 3D-printed cooling inserts are used to accurately control temperature and avoid thermal decomposition of materials.

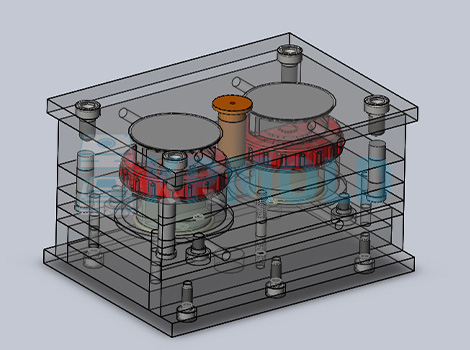

KRMOLD designs the injection molds for packaging products with sliding molding base to achieve dynamic adjustment of mold size, which is suitable for the production of different sizes of packaging containers. The sliding connection between the positioning plate and the groove, together with the bolt fixation, can quickly adjust the spacing between the molding cavities and reduce the frequency of mold replacement. For thin-walled containers for food packaging, KRMOLD adopts air ejector or in-mold folding technology to complete the design of the injection mold, avoiding the breakage caused by ejection sticking.

KRMOLD adopts CNC milling machine, EDM and other precision machining equipments of international famous brands to manufacture food packaging injection molds, to ensure the surface finish of the cavity (Ra≤0.8μm), and to avoid the residual contamination of the melt. At the same time, we are equipped with secondary and tertiary precision testing devices to ensure the precision of injection molds.

KRMOLD Services For Customers

——

“What will you get if you choose KRMOLD as a supplier of injection molds for food packaging products? KRMOLD not only produces injection molds but also focuses on providing a series of services to customers, helping them to obtain long-term production benefits through high-quality and well-matched injection molds.”

1

Design and co-development

KRMOLD customizes the design of high-precision injection molds according to customers' needs (such as food packaging product samples or 3D drawings) by using professional design software to solve all kinds of complex structural molding problems.KRMOLD adopts advanced software to predict the injection defects, optimize the mold design and process parameters, reduce the development risk and shorten the cycle time.

2

CNC precision machining service

KRMOLD has complete injection mold manufacturing equipment and professional production team to ensure high quality production of food packaging injection molds. For example, KRMOLD is equipped with Japanese CNC machine, spark machine, wire cutter and milling machine and other well-known injection mold processing equipment. injection mold processing equipment.

3

Complete mold quality inspection service

KRMOLD will carry out a complete quality inspection system after completing the manufacturing process of the injection molds, including the food packaging injection molds using the secondary and tertiary yuan tester for precision testing and recording, as well as in the factory to complete the assembly of the trial mold process, the injection molds will be installed on the injection molding machine for the production of the production accuracy testing.

4

Realize large-scale and efficient production

KRMOLD can provide multi-cavity mold design to help food packaging injection molds to achieve a single injection can be synchronized production of multiple containers, significantly improving efficiency. The common food packaging multi-cavity injection mold 12-cavity PET bottle mold, can achieve a single injection synchronous production of 12 PET bottle products.

"KRMOLD supports the whole process of technical support and after-sales service, through regular maintenance and problem tracing mechanism, to solve the abnormalities in the use of food packaging injection molds in a timely manner. KRMOLD also provides value-added services such as spraying, silk-screen printing and assembly to realize one-stop delivery."

FAQ:

1.How to get a quote for custom injection molds?

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

2. How long does it take to get a quote for an injection mold?

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

3. What is the lead time for injection molds?

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).