What Is Gas-Assisted Molding?

——

Gas-Assisted Molding is a technology used to make injection molded products, through the injection mold tool for mass production.The principle of Gas-Assisted Molding is to produce a hollow cross-section inside the injection molded part by using high pressure gas, using the gas to build up pressure, reducing the residual internal stress of the product, eliminating the surface shrinkage marks of the product, reducing the material, widely used in thick and thin walled composite plastic parts which are difficult to process, reducing the number of parts in the assembly structure, helping to shrink the mold, assembly line and labor requirements, saving the production cost of injection pressure is small.

It is widely used for thick and thin-walled composite plastic parts which are difficult to process, reducing the number of parts in the assembly sructure, helping to reduce the mold, assembly line and labor demand, and saving production costs by requiring small injection pressure. Gas-assisted injection molding produces hollow, can reduce the weight, save materials, and shorten the molding cycle of plastic parts out of the mold residual stress is small, warping deformation is small, good dimensional stability.

How Can Injection Molds Be Designed To Meet The Gas-Assisted Molding process?

——

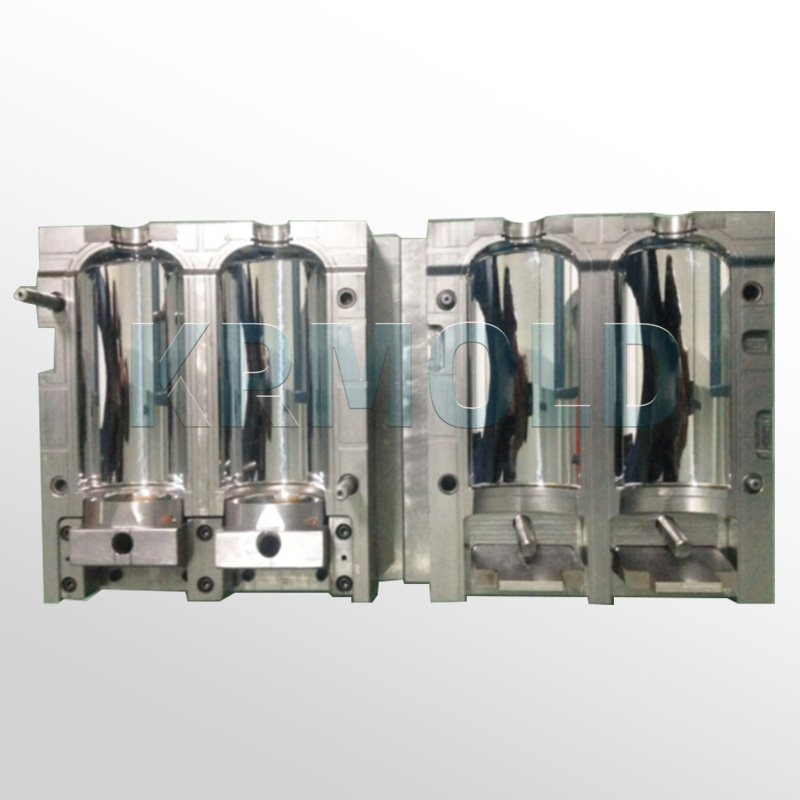

The gas channel is a part of the injection mold that guides the high-pressure gas into the plastic melt and makes it flow along the set path, which is very important for the accuracy of the Gas-Assisted Injection Molding process.KRMOLD usually considers to make a gas channel for the thicker wall area of the plastic molded product when designing the injection mold.

Generally speaking, the gas from the special injection port into the plastic melt to fill the end of the main flow channel, the product wall thickness of the larger areas and reinforcement or reinforcement of the internal rib, in the injection mold for the independent injection port and gate integrated type.

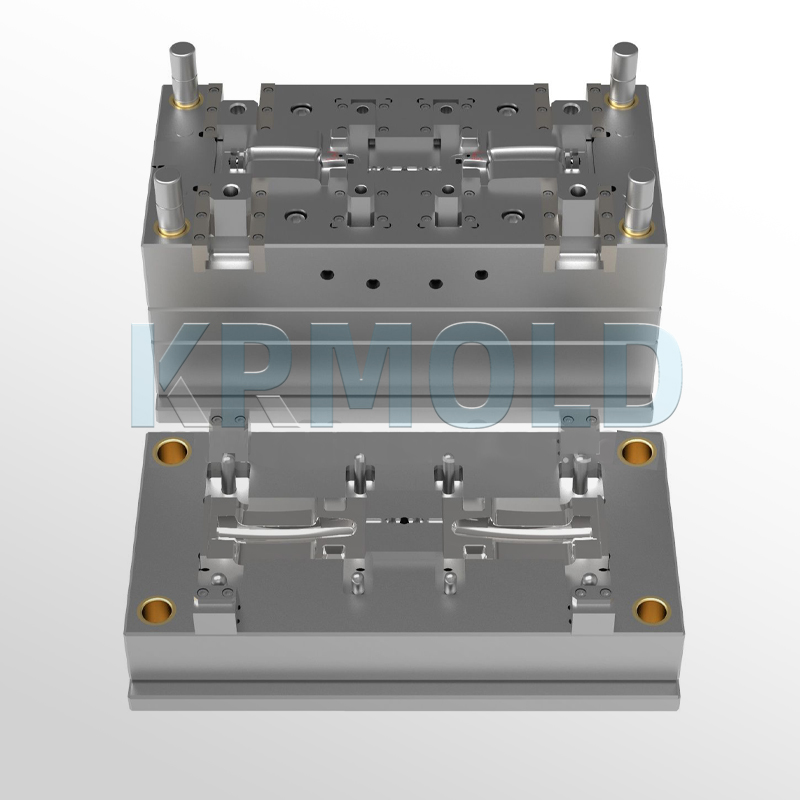

injection molds usually use multi-point gates to allow the plastic to fill the cavity evenly. Avoid gates that are too small to prevent the flow of melt from being impeded, resulting in gas not being able to enter. Generally speaking, hot runners are chosen for Gas-Assisted Molding to control the melt flow and improve the filling uniformity.

"When designing injection molds, KRMOLD usually considers making gas paths in the thicker areas of the molded product, so that the gas can form a hollow structure inside, and the pressure needs to be distributed uniformly to avoid gas intrusion into the surface of the cavity, which can cause surface defects. It is also necessary to avoid dead corners to ensure that the gas can be discharged smoothly to prevent stagnant gas from causing molding defects."

Advantage Of Gas-Assisted Molding

——

During gas assisted injection molding, high pressure gas creates hollow channels inside the product, thus reducing the amount of plastic used.

While conventional injection molding requires filling the entire cavity, gas-assisted injection molding can accomplish the same product structure with less plastic.

Applicable to thick-walled parts, to avoid material accumulation, while reducing the weight, greatly reducing the use of raw materials to equalize the production cost.

The gas assisted injection molding process ensures uniform pressure of the internal gas and uniform stress on the plastic melt, thus reducing shrinkage and deformation problems caused by cooling shrinkage. It is suitable for products with uneven wall thickness, especially reinforcing bars, handrails, tubular structures, etc., to avoid surface defects caused by uneven shrinkage.

Due to the flow characteristics of the gas, gas assisted injection molding allows the plastic melt to fill more complex structures, especially parts with reinforcement, thick walls or cavities. Hollow structures can be manufactured to make products lighter, such as handrails, tubular parts, appliance housings, etc.

"In conventional injection molding, multiple melt streams converge to form fusion lines, which affects appearance and strength. Gas-assisted injection molding has a balanced internal flow pressure, which can reduce the fusion marks and make the product surface smoother and more beautiful."

Application Of Gas-Assisted Molding

——

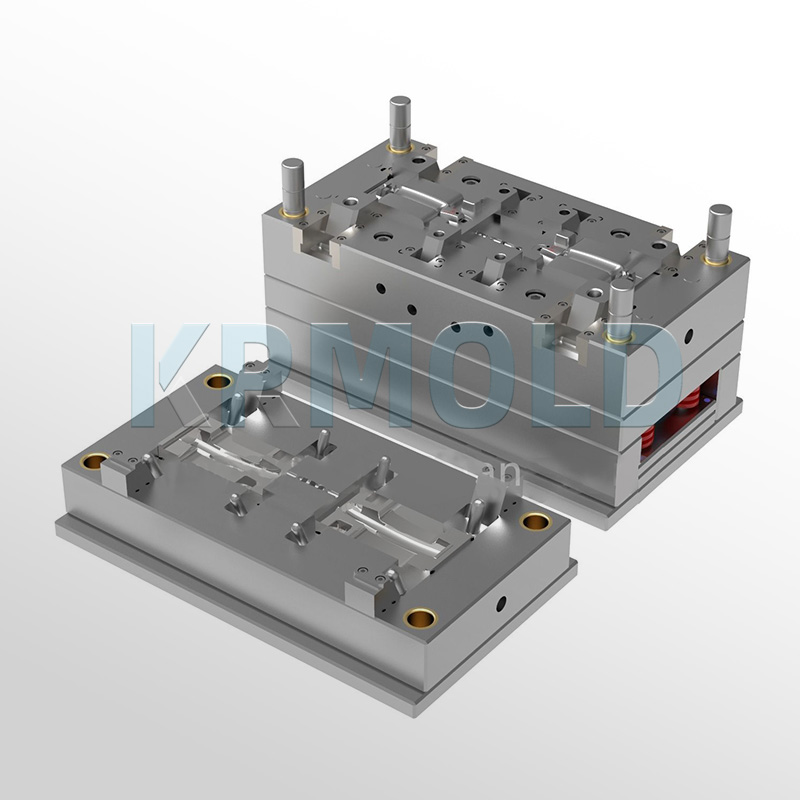

*Door handle injection mold: wall thickness of the product is reduced from 3.6mm to 2.5mm by gas-assisted injection molding process control, saving 35% of material and reducing assembly parts from 17 to 8.

*Instrument panel injection mold: gas-assisted injection molding integrated reinforcement and snap structure, residual stress reduction of 50%, qualified rate increased to 95%.

2.Home appliance injection molds

TV shell injection mold: using gas-assisted injection molding process to compress the cooling time of injection molding from 60 seconds to 42 seconds, wall thickness uniformity increased by 40%.

Refrigerator door plate injection mold: the use of gas-assisted injection molding process to ensure that the marble texture without shrinkage marks, mold life extended by 30%.

In plastic chairs, bicycle frames, fitness equipment handles and other injection molds, the use of gas-assisted technology can produce lighter and stronger plastic products.

FAQ:

1.How to get a quote for custom injection molds?

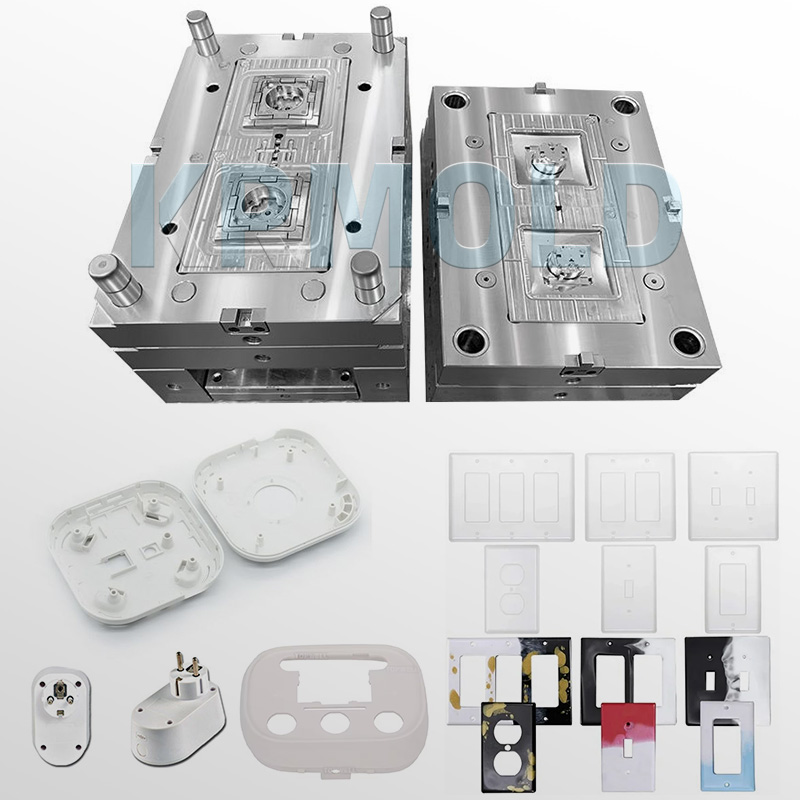

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

2. How long does it take to get a quote for an injection mold?

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

3. What is the lead time for injection molds?

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).