What is Two-Shot Injection Molding?

——

Two-shot injection molding, also known as 2k injection molding or double shot injection molding, is a technique that combines two different materials or colors into a single plastic part. This procedure combines two materials using specialized two-shot injection molding equipment to produce premium plastic parts with several characteristics. 2k injection molding has the benefit of fusing the benefits of various materials into one part, therefore improving functionality as well as aesthetics.

What is Working Process of Two-Shot Injection Molding?

——

2k injection molding is performed on specialized machines equipped with two or more injection units. The key to this process lies in precise control of the injection units and clever mold design to ensure multiple injections. The typical process is as follows:

-First shot: The first material is injected into the mold to form the base layer.

-Mold rotation or translation: After the first shot is completed, the mold is rotated or translated to align the new injection material with the new cavity.

-Second shot: The second material is injected and chemically or mechanically bonds with the first layer, ultimately forming the complete part.

What is Design Features of Two-Shot Injection Molding?

——

1) Product design for 2k injection molding

The design of two-color injection molded products is often complex because their structure consists of two different materials. Therefore, material compatibility has to be thoroughly taken into account during design and the material ratio and join approach have to be optimized depending on the intended use and operating conditions of the product.

2) Material selection for two-shot injection molding

Choosing the right materials is essential in 2k injection molding. Usually different colored polymers, the choice has to guarantee good strength and endurance as well as perfect mixing. Correct material selection and tight control of two-shot injection molding parameters can dramatically increase the performance of two-color injection molded goods.

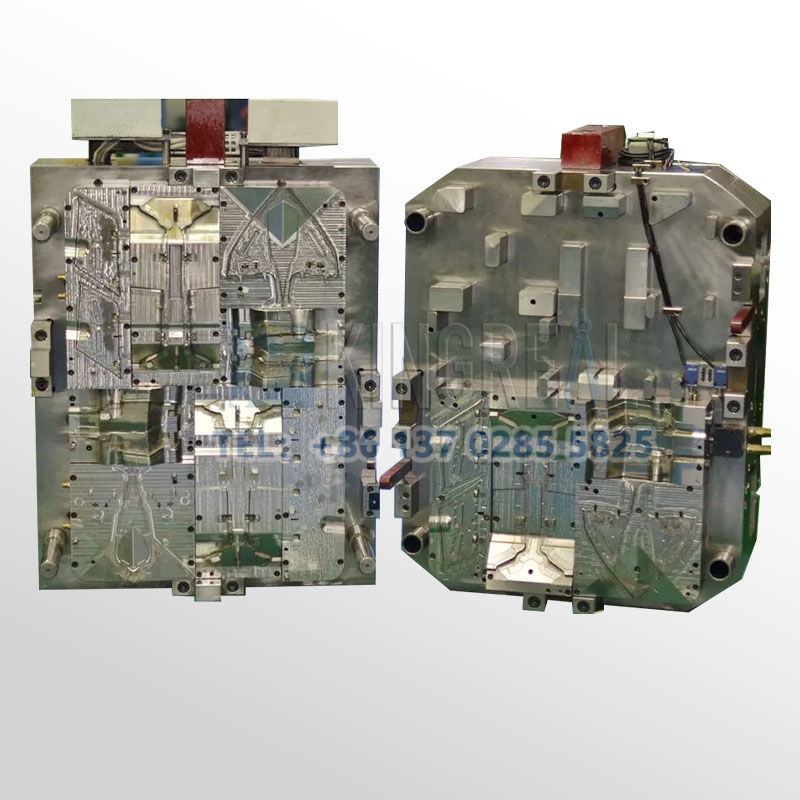

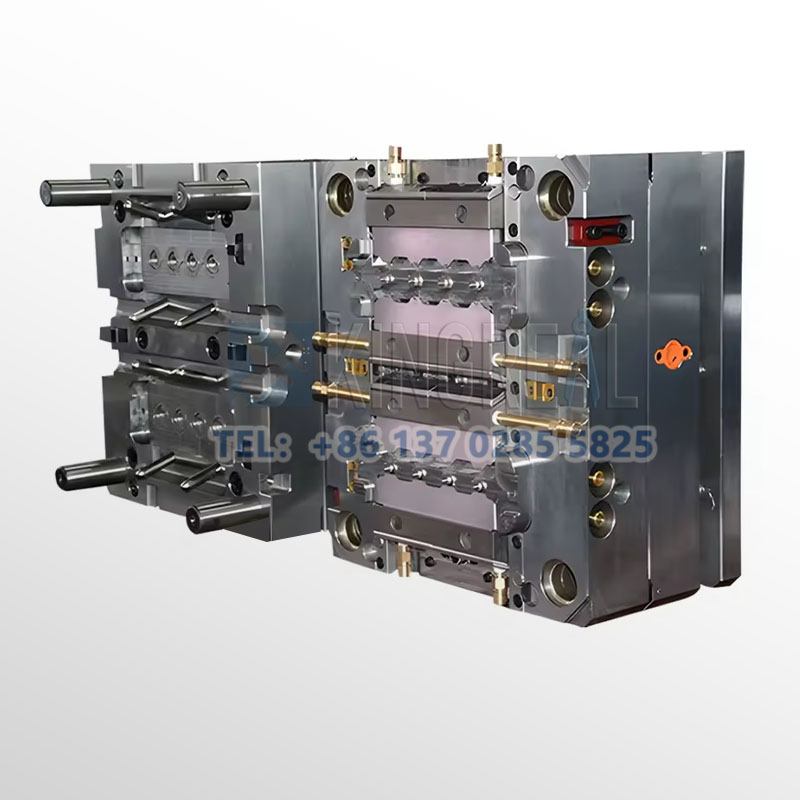

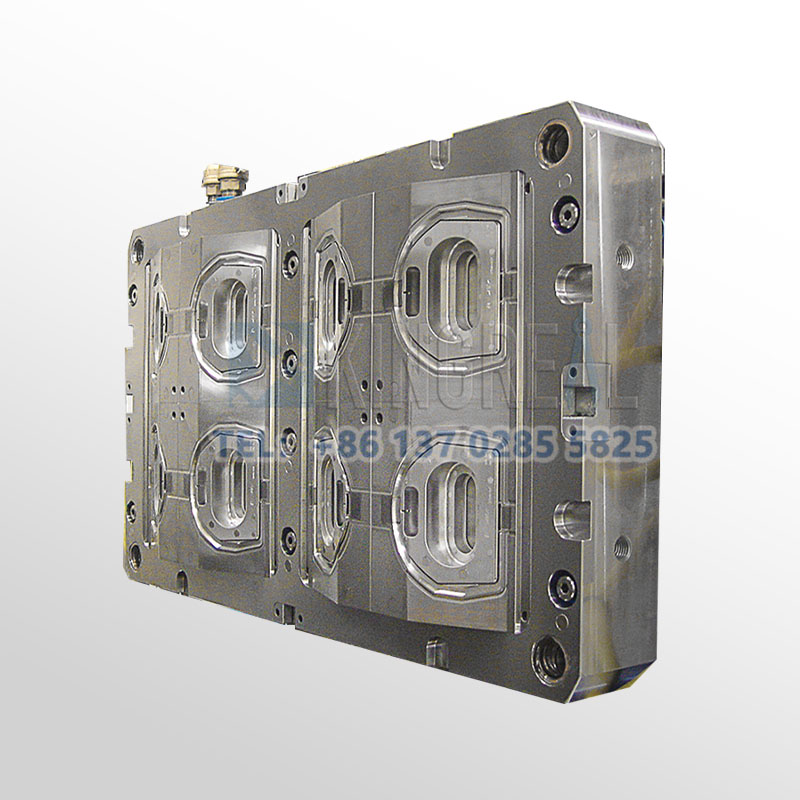

3) Mold design for 2k injection molding

The design of two-color injection molds is unique. To guarantee a tight fit between the grooves and recesses of the two injection molds, the mold structure need be carefully considered. Moreover, the demolding apparatus's design is important since demolding is often needed following the second shot. Appropriate design of several injection techniques and demolding situations—including hydraulic demolding and vertical rotational injection molding machines—is necessary.

What are the Advantages of 2K Injection Molding?

——

1) Improving aesthetics for 2k injection molding

2K injection molding technology enables the production of two-color products in a single production process, enhancing the product's visual appeal. Designers find it simpler to include logos, graphics, and other elements to improve the distinctive character of goods.

2) Increased efficiency for two-shot injection molding

Manufacturers may save considerable labor and time since a lot of the process is automated. This boosted efficiency simplifies the manufacturing process.

3) Expanded design options for 2k injection molding

Two-shot injection molding is a perfect way to produce metal molds and translucent plastic goods at a reasonable price since it provides a broad range of design possibilities. This flexibility enables designers more liberty to better meet market needs.

4) Reduced post-processing for 2k injection molding

The two-shot injection molding technique's holistic character removes many post-processing stages, therefore saving needless energy, time, and expense. This not only improves product precision but also speeds the production process.

5) Perfect parts for 2k injection molding

Conventional manufacturing processes usually need distinct production of various components followed by assembly, therefore consuming resources and elevating expenses. Two-shot injection molding, however, greatly lowers the component count needed, therefore lowering costs, saving time and energy, and eliminating possible material differences.

6) Shorter cycle time for 2k injection molding

Two-shot injection molding removes the need for extra processes, therefore shortening production cycles and increasing general efficiency.

What are the Applications of Two-shot Injection Molding?

——

Two-shot injection molding is often used to produce intricate parts with a variety of design features, hence it is a preferred option across several sectors including:

-2k injection molding in automotive: Used to produce instrument panel components, climate control knobs, and soft-touch interior trim.

-2k injection molding in medical: Create devices with ergonomic handles and integrated seals.

-2k injection molding in consumer electronics: Provide stylish and functional housings for remote controls, mobile phones, and wearables.

-2k injection molding in household tools and appliances: Enhance the safety and operating comfort of power tools and kitchen appliances.

FAQ About 2K Injection Molding

——

Q1: What materials can be used for two-shot injection molding?

A1: Usual two-shot injection molding materials are ABS/PC, PP/TPE, and PA/TPU. These materials need good compatibility and resistance to fusion all through the molding process.

Q2: When planning a two-shot injection molding, what factors have to be taken into account?

A2: The design calls for careful thought of the flow and fusing characteristics of the two materials so that they can properly combine. Moreover, the mold has to be made in two parts, each for injecting a different plastic color.

Q3: During two-color injection molding, which quality control elements should be emphasized?

A3: KRMOLD has to make certain that the injection volumes of both colors are equal and that no bubbles or faults are introduced during the 2k injection molding. Moreover, to guarantee the quality of the finished product, factors including mold temperature, pressure, and injection velocity must be closely observed.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).