What Is Double Shot Molding?

——

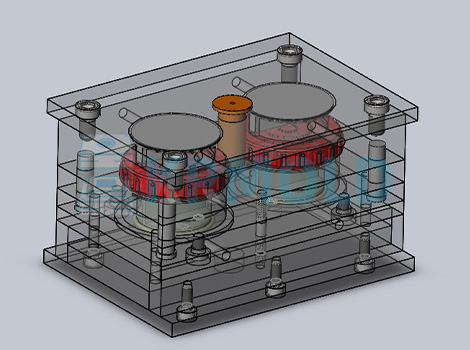

Double Shot Injection Molding technology, also known as 2K injection molding technology, is a process for manufacturing plastic products by mixing and injecting two plastic materials. At its core lies the use of one mold component to shape the form and the welding of the molding work within the mold. The molding principle is that two different plastic materials are plasticized and molded, and then precisely welded and installed in the mold to achieve the effect of two shot injection molding.

Two shot molding products are designed to meet the diverse needs of product structure and appearance. Molding methods include two shot molding, mixed-color molding, two-material sandwich, liner trim molding, and core-drawing two-color molds. KRMOLD, as a professional manufacturer of injection mold products in China, is committed to meeting customers' different production needs in the design and production of injection molds, and realizing different injection molding processes through the design of molds.

Double Shot Molding Design Feature

——

The structural design of two shot injection molded products is more complex compared to ordinary plastic products. Since the product is injection molded from two different materials, it has unique characteristics, which is fundamentally different from single material injection molded products. In the process of structural design, the compatibility of the two materials should be fully considered, and the material mixing ratio and connection method should be optimized with the function of the product and the usage environment.

In the two shot injection molding technology, it is crucial to select the right two materials. Usually, these two materials will be plastics of different colors, which not only enhances the strength and durability of the finished injection molded product, but also promotes its smooth fusion molding. The performance and quality of two shot injection molded products can be further optimized through careful selection of materials and reasonable control of injection parameters.

The mold design in two shot color injection molding also has its uniqueness. The molding part requires special consideration of the design of the two injection molds' concave and convex grooves to ensure that they can be closely matched. In addition, the design of the mold release mechanism is also critical, as it is often necessary to perform the release operation after the second injection. Different injection methods and demolding scenarios, such as demolding with vertical rotary injectors and demolding with hydraulics, require careful differentiation and design.

"At the same time, it is also necessary to conduct a detailed analysis of the complexity of the process and the use of strength to ensure that the two-color injection molded products can meet the relevant material standards and performance requirements."

Advantage Of Double Shot Molding

——

1.Improve the mechanical properties of injection molded products

Products manufactured using two shot injection molding exhibit excellent mechanical properties. During the molding process, different layers of the product form a molecular bond, giving a good choice of materials. This bonding is usually stronger than conventional molding and assembly, and even stronger than overmolding and insert molding.

2. Improve the aesthetics of injection molded products

Products made in the double shot molding process can look great while still retaining their desired structural properties. In this process, load-bearing structural components can be molded in the first step, while final touches can be added in the second step using more attractive materials.

3. Improved product ergonomics

The double shot injection molding process allows for the perfect manufacture of ergonomically designed products. Structural plastics can be easily covered or added on with materials that are more suitable for the human-machine interface. Soft rubber material is more suitable for human hands as it provides better grip and softer touch.

4. Reduced production time

The decisive advantage of two-color injection molding is the saving of production time. Since several grades can be added in the process, secondary assembly of the item is usually not required. What would have been a complete second step in the manufacturing process of conventional injection molding can now be accomplished in one combined molding process.

5. Improved Production Efficiency

This is where double shot injection molding really makes a difference. Two-color injection molding allows production lines to make more complex products in fewer production steps than ever before. Consider the traditional injection molding process: if a product consists of two different materials, it must be molded separately in two different molds, followed by a manual assembly step. In two shot injection molding, the two components are not only molded in one mold setup, but also fused together without any assembly.

6. Improved injection molding precision

Two shot injection molding offers very precise manufacturing compared to conventional molding and assembly, and even to modern processes such as insert molding. Since semi-finished products do not need to be removed from the mold between steps, there is no chance of material misalignment. If thermal effects are properly controlled through good product design, the end result can truly be as precise as the mold itself.

Key Points Of Two Shot Injection Mold Design

——

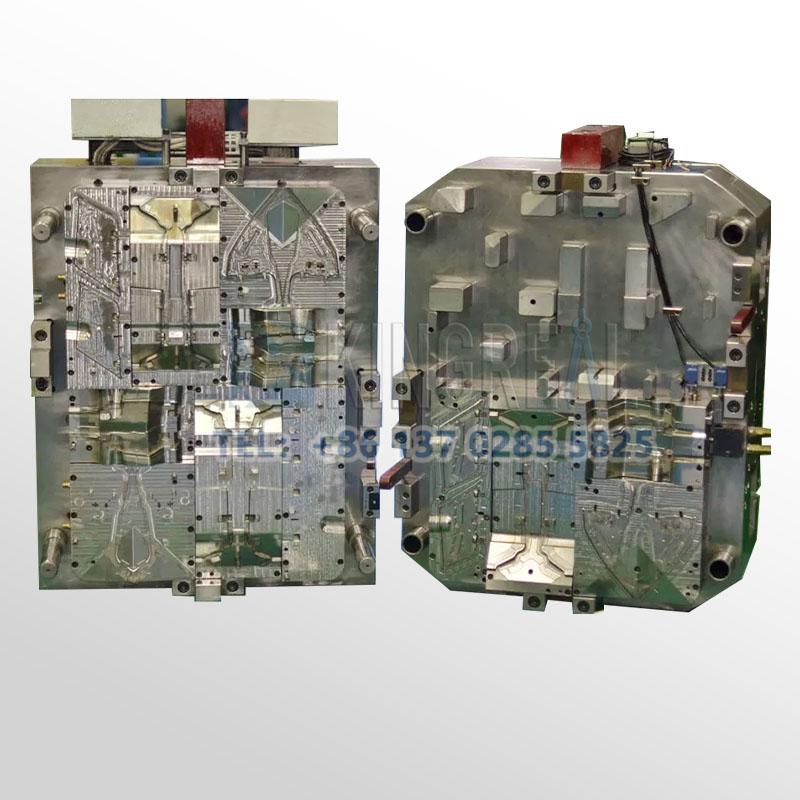

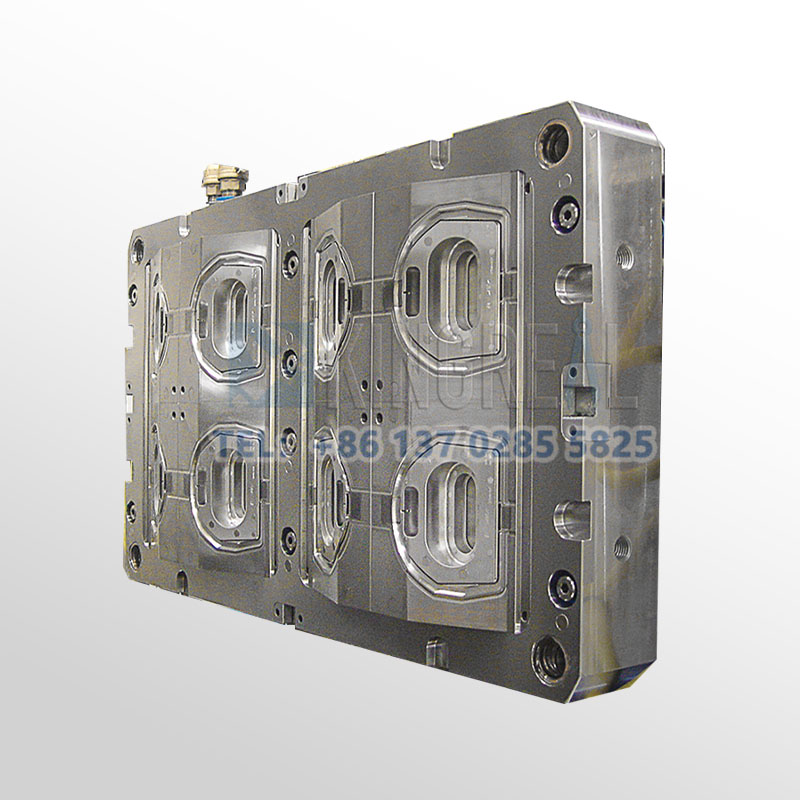

1. Molding part

The molding part of two shot injection mold is basically the same as the general injection mold, the difference is that we should consider the two positions of the injection mold convex mold is consistent, and the concave mold should be well matched with the two convex molds. Generally, the molded parts are smaller.

2. demolding mechanism

As the two-color plastic parts can only be demolded after the second injection, so the demolding mechanism on the primary injection device will not work. For the horizontal rotation of the injection molding machine, the mold release can be used for the ejector mechanism of the injection molding machine, while for the vertical rotation of the injection molding machine, it is impossible to use the ejector mechanism of the injection molding machine, but can be set up on the rotary table hydraulic ejector release mechanism.

3. Pouring system

Due to the two shot injection, the pouring system is divided into the primary injection pouring system and the secondary injection pouring system, which come from the two injection devices respectively.

4. Mold body

As the molding method of two shot injection molding is more special, it needs to cooperate and coordinate with each other, so the size and precision of the two pairs of mold guiding devices should be the same. For horizontal rotary injection molding machine, the closing height of the mold should be the same, the center of the two pairs of molds should be in the same radius of rotation, and the difference is 180. For vertical rotary injection molding machine, the two pairs of molds should be in the same axis!

Common Material Combinations For Two-Color Injection Molding

——

| First material (rigid primary material) | Second material (secondary material) | Application examples |

| ABS (Acrylonitrile Butadiene Styrene) | PC (Polycarbonate) | Transparent + opaque products, e.g. camera housings |

| PC (Polycarbonate) | PU (Thermoplastic Polyurethane) | Sport grips, remotes |

| PP (Polypropylene) | TPE (Thermoplastic Elastomers) | Toothbrush grips, razor handles |

| PBT (Polybutylene Terephthalate) | TPU (Thermoplastic Polyurethane) | Automotive push buttons, electronic devices |

| PA ( Nylon) | TPE (thermoplastic elastomer) | Power tool handles |

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).