Video About Liquid Silicone Rubber Injection Mold

——

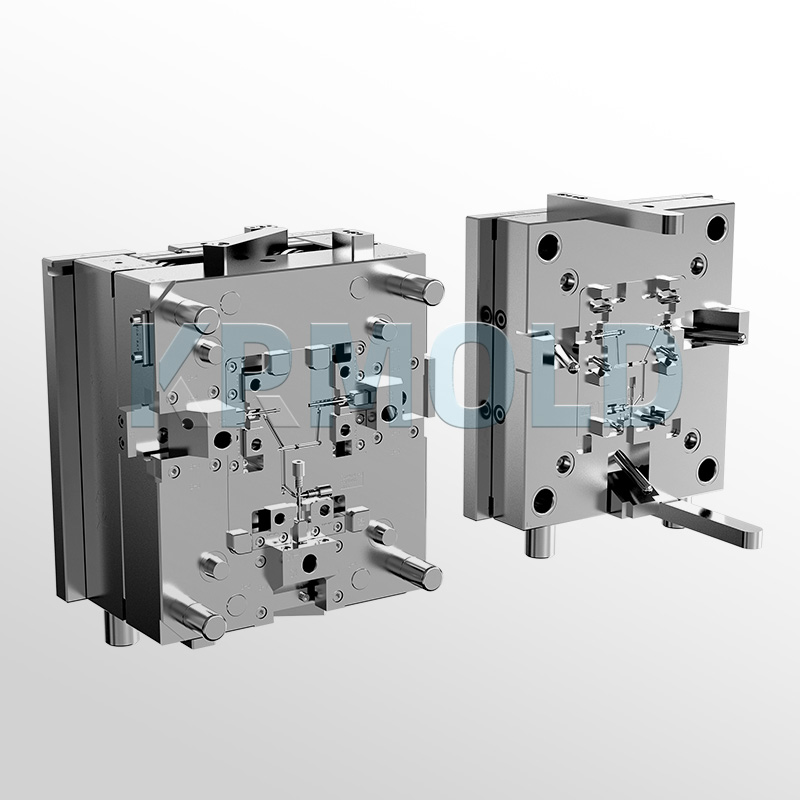

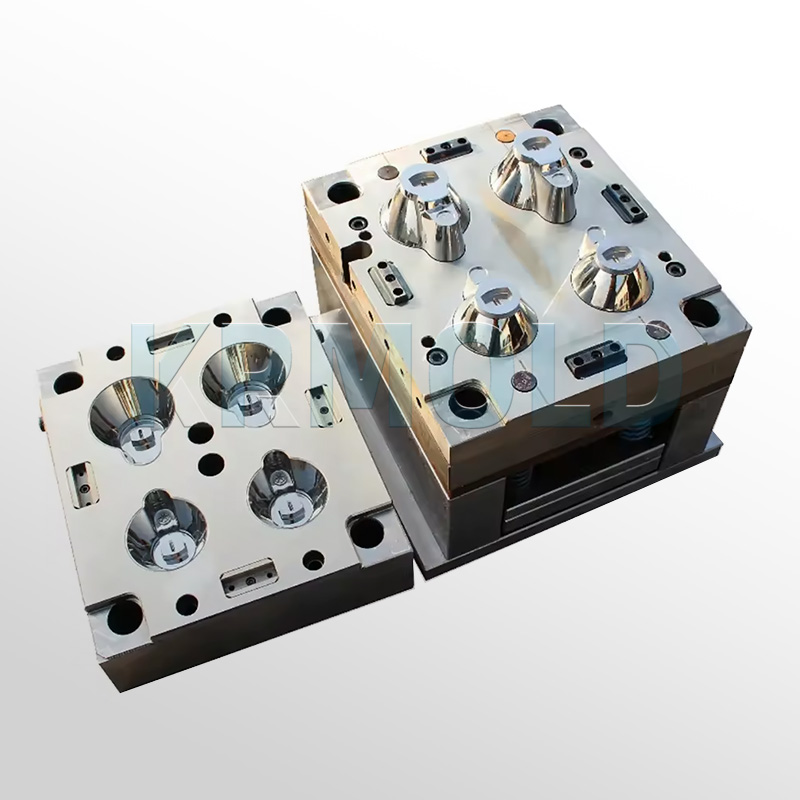

Description of Liquid Silicone Rubber Injection Mold

——

Liquid silicone rubber injection molding involves injecting liquid silicone material into a LSR injection mold and then, through a series of precise process steps, efficiently forming silicone products. Widely employed in sectors including medical, automotive, and consumer products, this liquid silicone rubber injection molding technique can create difficult and varied silicone components. Ensuring product accuracy and consistency, the LSR injection mold is essential to this process.

Modern manufacturing is paying more and more attention to the use of liquid silicone rubber injection molds. High-precision, complicated parts can be made by injecting heated silicone material into the LSR injection mold and letting it chill and solidify. Custom liquid silicone rubber injection mold solutions based on client needs can be offered by KRMOLD to assist consumers in reaching their production targets.

Introduction to Liquid Silicone Rubber Injection Molding

——

First, the silicone material is heated to liquid condition in the LSR injection molding technique. To guarantee accuracy and endurance, the liquid silicone rubber is then injected under great pressure into a precision-machined mold, usually composed of steel or aluminum. The ultimate form and complexity of the component are determined by mold design, therefore it is absolutely essential for the effectiveness of liquid silicone rubber injection molding. The mold cools and solidifies following the injection of the liquid silicone. Then the molded component is postcured and ejected from the mold using an ejector pin. Finally, the component is ready for use following required finishing touches and inspections.

This procedure helps the development of technology and daily life as well as its technical features. Therefore, liquid silicone rubber injection molds have a critical role in contemporary production since they can effectively create high-quality, exact, and complicated silicone components.

Key Steps in LSR Injection Molding

——

1. Mixing Uniformity

It is absolutely necessary to guarantee the right ratio and homogenous mixing of component A and component B during the LSR injection molding technique. Unmatched mixing in the molded component can produce inconsistent hardness and color, therefore degrading the quality of the finished good.

2. Mold Design Precision

The design of LSR injection molds must take into account the silicone's viscosity and shrinking following vulcanization. Inefficient design accuracy can cause unequal surfaces and dimensional errors in the molded component, therefore damaging the aesthetic and utility of the product.

3. Curing Time and Temperature Control

A necessary stage in the curing of liquid silicone is curging. Directly affecting the quality of the final product is control of the curing temperature and time. Too short a time or insufficient temperature may result in incomplete curing of the silicone, while too long a time or excessively high temperature may cause the silicone to denature or burn, affecting product performance.

4. Quality Inspection Standards

Ensuring that the inspection criteria are scientifically valid, quality inspections must be customized to the particular application and demands of the silicone product. Common inspection elements are visual inspection, measurement of dimensional precision, and hardness testing to guarantee that every piece made by LSR injection molds upholds quality standards.

5. Post-Processing Techniques

Post-processing methods include surface treatment, trimming, and cleaning. Different silicone materials could need different post-processing techniques to guarantee the finished item satisfies design specifications and performs best.

Liquid Silicone Rubber vs Traditional Rubber

——

Compared to conventional rubber injection molding, LSR injection molds provide several major benefits. First, the lower viscosity of liquid silicone enables accurate filling of complicated mold cavities. Moreover, the reduced curing time of liquid silicone dramatically increases production efficiency. Parts molded with liquid silicone have better surface finish and dimensional precision than conventional rubber products, therefore satisfying the most stringent requirements of the industry.

| Feature | LSR Injection Molding | Traditional Rubber Molding |

| Precision | ±0.1mm Tolerance | ±0.5mm Tolerance |

| Cycle Time | 10-30 sec | 1-2 min |

Features of LSR Injection Molding

——

1)Bio-compatibility

Extensively tested and showing great bio-compatibility, liquid silicone rubber may be utilized in skin-contact goods. Strong antimicrobial characteristics and resistance to contamination and corrosion of other materials ensure product safety of liquid silicone rubber in contrast to other elastomers.

2)Tasteless and Odorless

LSR is tasteless and odorless, meeting stringent FDA standards for food, beverage, and baby products, ensuring its safety in a variety of applications.

3)Durability

Suitable for applications under automobile hoods including batteries, electrical parts, and under extreme temperatures, parts made of liquid silicone rubber Outdoor uses subjected to several environmental influences as well as other uses.

4)Chemical Resistance

Good resistance to some chemical solutions, including bases and acids, along with resistance to oxidation and water, liquid silicone rubber Because medical goods subjected to cleaning agents and several sterilization techniques, including steam autoclaving, ethylene oxide sterilizing, gamma radiation, and electron beam sterilization, it is a great fit.

5)High-Temperature Resistance

LSR maintains its properties even in extreme temperatures, withstanding temperatures ranging from -60°C to 180°C. It is widely used in products such as dishwashers, showerheads, faucets, and water heaters.

6)Mechanical Properties

Liquid silicone rubber (LSR) exhibits good elongation, high tear and tensile strength, and excellent flexibility, resulting in a hardness typically ranging from 5 to 80 Shore A, making it suitable for sealing applications and high-precision products such as gas flow measurement.

7)Electrical Properties

Because of its great insulating properties, LSR is particularly often utilized in electrical applications in sectors like electric vehicle batteries. LSR improves product dependability by operating at extremely low and very high temperatures, unlike traditional insulating materials.

8)Transparency and Colorability

Liquid silicone rubber (LSR) is inherently translucent and easily colorable, making it suitable for producing custom molded products in a variety of colors to meet diverse customer needs.

Applications of LSR Injection Molds

——

1. LSR injection mold in life sciences Because of its inertness, bio-compatibility, and stability in challenging situations, liquid silicone rubber injection mold is often employed in the medical industry. Components with complex details and strict tolerances abound in many life science items, including respiratory masks, valves, diaphragms, surgical tools, and medication delivery devices.

2. LSR injection mold in automotive In the automotive industry, liquid silicone rubber injection mold is a perfect material for parts because of its outstanding performance in UV radiation and high heat. to guarantee safety and endurance as wire harness seals, connectors, bellows, gaskets, and shock absorbers.

3. LSR injection mold in consumer products For its many qualities, the consumer products industry picks liquid silicone rubber injection mold. Waterproof barriers, antibacterial shower-heads, and shock-resistant seals for personal hygiene products including electric toothbrushes and shavers can all be made using this material. durable baby bottle covers and pacifiers as well as safe ones.

4. LSR injection mold in industrial applications Liquid silicone rubber injection mold is appropriate for the production of valves, gaskets, sealing housings, and other safety items, including smoke and carbon monoxide alarms in industrial uses. Its capacity to resist chemicals and high temperatures without altering its physical form guarantees the dependability of appliances and safety gadgets. |  |

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).