Introduction to Polycarbonate Injection Molding

——

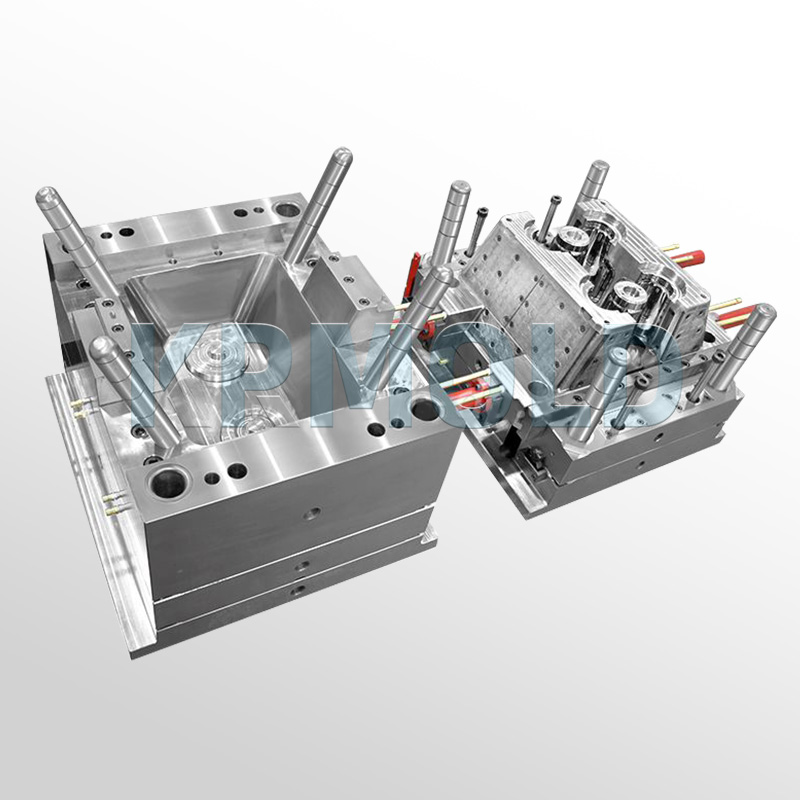

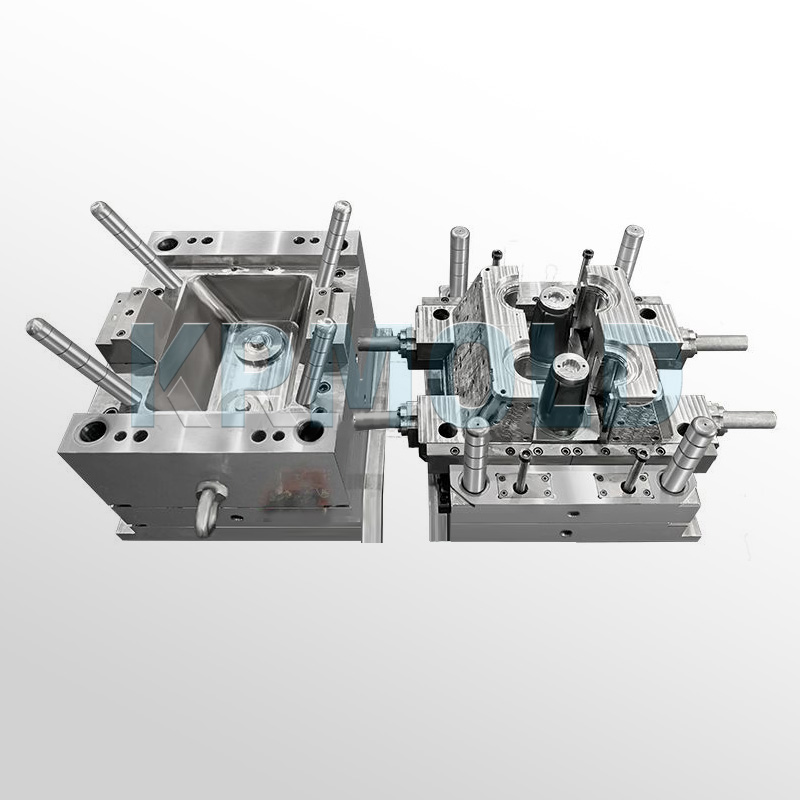

Polycarbonate injection molding, also known as PC injection molding, is a common plastic injection molding process. Because of great transparency, good impact strength, creep resistance, and wide temperature range—PC is rather used in sectors ranging from medical equipment to automobiles. KRMOLD may modify polycarbonate plastic injection molding to match particular consumer manufacturing needs. This lets customers mass-produce intricate forms and patterns while guaranteeing product quality and longevity. |  |

Characteristics of Polycarbonate

——

| Category | Property | Typical |

Mechanical | Tensile Strength | 9,500 |

| Tensile Modulus of Elasticity | 345,000 | |

| Tensile Elongation | 135 | |

| Flexural Strength | 13,500 | |

| Flexural Modulus of Elasticity | 345,000 | |

| Compress Strength | 12,500 | |

| Hardness | M70, R118, Shore D 80 | |

| Izod Impact | 12.0 – 16.0 | |

Thermal | Coefficient of Linear Thermal Expansion | 3.8 |

| Heat Deflection Temperature | 280-270 | |

| Max. Continuous Service Temperature | 240 | |

| Electrical | Short-Term Dielectric Strength | 380 |

Optical | Light Transmittance | 86 |

| Haze | <1 |

Technical Parameters of Polycarbonate injection molding

——

| Drying temperature (℃) | 90~110 | Drying Time (approximately) | 2 hours or more |

| Mold Temperature (℃) | 80~110 | Residue Volume (mm) | 2~8 |

| Melt Temperature (°C) | 280~320 | Back Pressure(MPa) | 6~15 |

| Injection Pressure(MPa) | 130~180 | Clamping Force (approximately)(ton/in²) | 4~6 |

| Injection Speed | Medium or High | Return Speed (rpm) | 60~80 |

| Screw Type | Standard, Slim (Avoid using dehumidified screws and slingshot nozzles) | ||

| Stopover | Clean with HDPE | Scrap Reuse (%) | 10~25 |

Key Design Considerations for Polycarbonate Injection Molding

——

Wall Thickness: Polycarbonate plastic injection molding can support thin walls and complex geometries. The recommended minimum wall thickness is typically 0.040 inches (1 mm), and the maximum is 0.150 inches (3.8 mm).

Rib Thickness: Ribs can be used to provide additional strength or support to polycarbonate parts. For optimal results, the rib thickness should be 0.5 to 0.6 times the thickness of the adjacent wall. It is recommended that the rib height not exceed three times the wall thickness.

Corner Radius: Avoid sharp corners that can cause stress concentrations. For polycarbonate injection molded into PC, the corner radius should be at least 0.125 inches (3 mm).

Draft Angle: Polycarbonate parts require a taper, or draft angle, to aid in part release from the mold. For many PC parts, a draft angle of 0.5° to 1° per side is sufficient. However, depending on the angles and shape of the part, a draft angle of 1° to 3° per side may be required.

Gate Location: Position the gate (the opening in the mold through which the molten polycarbonate is injected) where the plastic flow creates the least stress. Mold flow analysis can determine the optimal gate location.

Surface Finish: Polycarbonate supports glossy and high-gloss finishes, but matte finishes can be used to soften images and reduce glare in applications such as control panel covers. Non-gloss finishes are also acceptable for screw caps.

Advantages of Polycarbonate Injection Molding

——

1. Fast cycle time for polycarbonate plastic injection molding Usually taking just seconds to minutes, polycarbonate plastic injection molding finishes a plastic item. This lets consumers quickly create large amounts of their preferred goods. KRMOLD may shorten production cycles and so lower delivery times for customers by improving mold design and manufacturing techniques.

2. Manufacture parts with tight tolerances for polycarbonate injection molding Polycarbonate plastic injection molding can satisfy customers' demanding tolerance specifications. With exact mold design and top-notch equipment for processing, KRMOLD guarantees that every injection-molded component is made inside of really close tolerances. This makes polycarbonate injection molding particularly well suited for demanding industrial uses. Customers just give KRMOLD their particular design criteria and specifications, and KRMOLD engineers will modify the design to fit these. Polycarbonate plastic injection molding effortlessly produces the necessary accuracy whether tiny or big, so guaranteeing every component fits flawlessly.

3. Wide range of part sizes for polycarbonate injection molding Polycarbonate plastic injection molding's adaptability lets it handle pieces of different sizes. Polycarbonate injection molding is the perfect answer for consumers from little electronic components to huge car components. This adaptability encompasses intricate forms and patterns beyond just size. KRMOLD engineers to the varied product design needs of customers and effortlessly fulfills the production demands of several sectors by means of cutting-edge gear and technology. Polycarbonate plastic injection molding provides effective solutions whether in mass manufacturing or in personalized small-batch production. |  |

4. High-volume part production for polycarbonate injection molding Along with quick production cycles, polycarbonate plastic injection molding guarantees effective capacity. Compared to conventional manufacturing methods, polycarbonate injection molding may turn out parts in great numbers more rapidly, therefore greatly boosting production efficiency. This benefit helps many sectors—especially in the automotive, consumer products, and electronics industries—prefer polycarbonate plastic injection molding. KRMOLD enables the delivery of the necessary quantity in the shortest possible time by means of flexible modification of production plans and strategies according to consumer needs.

5. Eliminate surface defects for polycarbonate injection molding Parts made by polycarbonate plastic injection molding have smoother surfaces and less flaws than those made by other plastic injection molding methods. This raises visual and tactile expectations for the finished item, hence improving general product quality. High-precision injection molds and tight production checks guarantee a flawless surface finish on every component throughout the polycarbonate injection molding.During the polycarbonate injection molding, high-precision injection molds and strict production controls ensure a flawless surface finish on every part. This characteristic applies not only to transparent polycarbonate products, but also to products requiring a matte finish or specialized surface treatments. Whether it's consumer electronics or high-end medical devices, polycarbonate plastic injection molding can meet the high standards of appearance and quality demanded by diverse customers. |  |

Applications of Polycarbonate Plastic Injection Molding

——

Polycarbonate injection molding is widely used in various industries, including automotive, electronics, medical, consumer goods, and construction. In these industries, KRMOLD uses polycarbonate plastic injection molding to produce high-precision products for its customers, such as automotive dashboards, surgical instruments, water bottles, food containers, eyeglass lenses, switch covers and housings, and sports equipment.

Polycarbonate injection molding in eyewear and lenses: Polycarbonate plastic injection molding is often used in the manufacture of eyewear lenses due to its high transparency and, thanks to the addition of UV stabilizers to the base material, its UV resistance. Polycarbonate lenses are lightweight and impact-resistant, making them an ideal choice for modern eyewear.

Polycarbonate injection molding in medical devices: Good heat and corrosion resistance as well as sterilization by steam autoclaving, irradiation, or ethylene oxide are provided by polycarbonate plastic injection molding. With its great visual clarity, this polycarbonate injection molding is perfect for medical equipment needing sterilizing, including incubators, catheters, and syringes.

Polycarbonate injection molding in consumer products: Ideal material for producing kitchen equipment is polycarbonate plastic injection molding's great resilience and optical clarity as well as its compliance with food safety regulations. food processor mixing dishes, and more. Polycarbonate injection molding meets different market demands and may be made in opaque versions to guarantee food-contact equipment cleanliness and sanitation as well as withstand the required temperatures.

Polycarbonate injection molding in automotive products: Polycarbonate plastic injection molding is widely used in automotive headlights due to its toughness, UV resistance, high and low temperature resistance, and high transparency. Its impact resistance enables polycarbonate injection molding to effectively resist road debris and external impacts, providing better safety for vehicles.

More Information About Polycarbonate Plastic Injection Molding

——

1.What is PC injection molding?

2.What is the process of pc injection molding?

3.What are the effects of pc injection molding conditions on products?

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

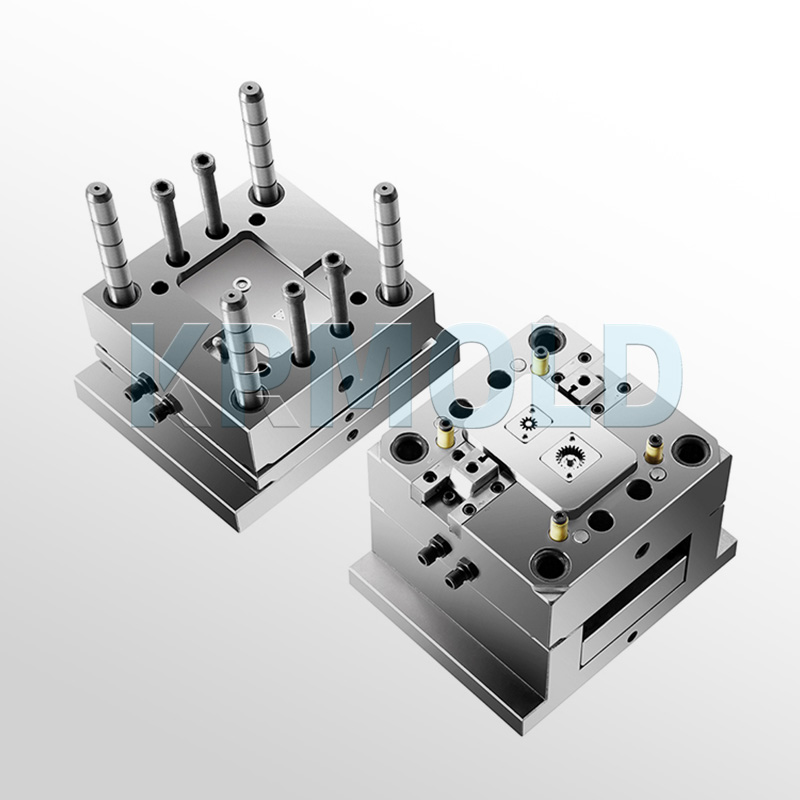

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).