KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825By injecting molten material into a mold, PC injection molding—a widely used manufacturing method—enables mass production of items with sophisticated forms and designs. PC means Polycarbonate, is a strong thermoplastic with several physical characteristics appropriate for uses where toughness, transparency, and high temperature resistance are crucial. One of the most adaptable materials for plastic injection molding, its unusual design permits great coloring, surface treatment, and shape customizing. Using it requires careful consideration of certain process parameters to guarantee the quality and longevity of the ultimate product.

| 1 | Fundamental Procedure of PC Injection Molding |

| 2 | Essentials of the PC Injection Molding Process |

| 3 | Obstacles in PC Injection Molding and Solutions |

| 4 | Benefits of PC Injection Molds |

| 5 | Usage Fields of PC Injection Molds |

1. Fundamental Procedure of PC Injection Molding

(1) Preparation of raw materials

First in the injection molding procedure of PC plastics comes the preparation of appropriate feed materials. Typically found in granule or powdered form, PC plastics must be heated and melted into a liquid state during the injection molding process.

(2) Operation of Injection Molding Machines

Key tool for PC injection molding is the injection molding machine. Operating the injection molding machine starts with loading PC plastic granules or powder into the hopper; then, heat and pressure will melt the PC plastic into a liquid state.

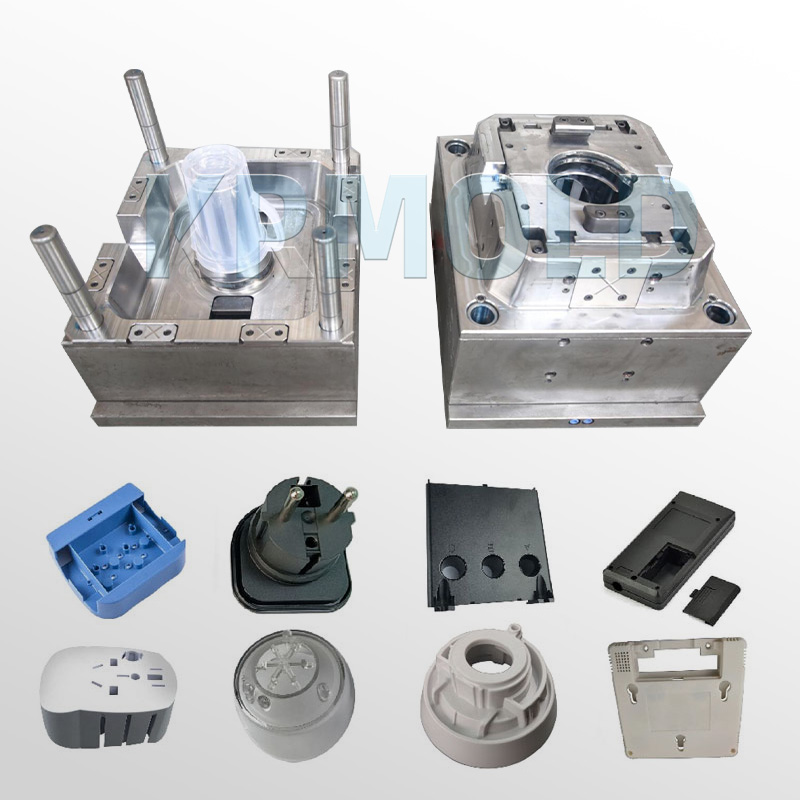

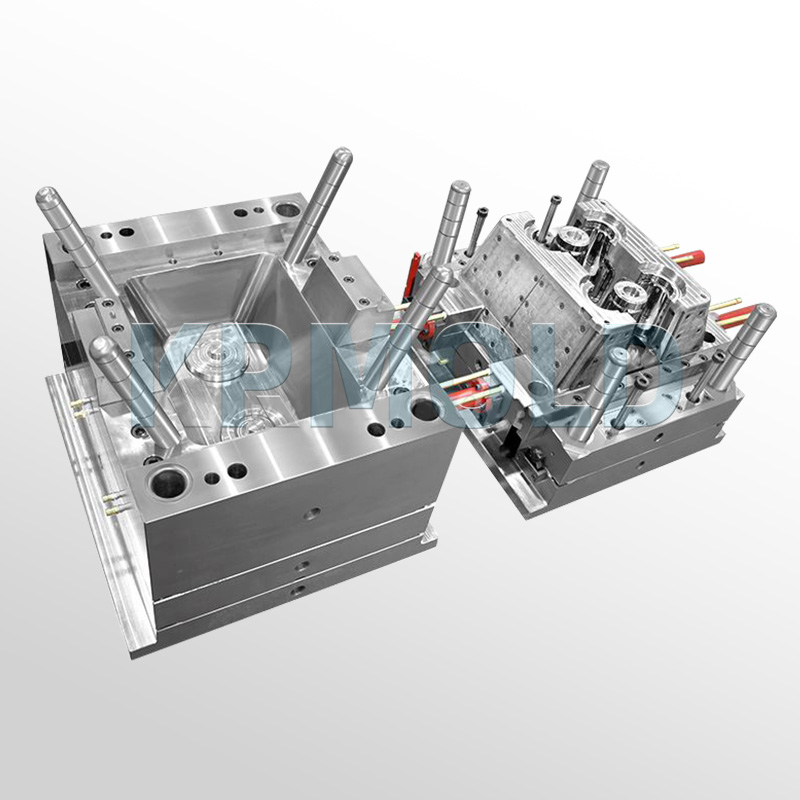

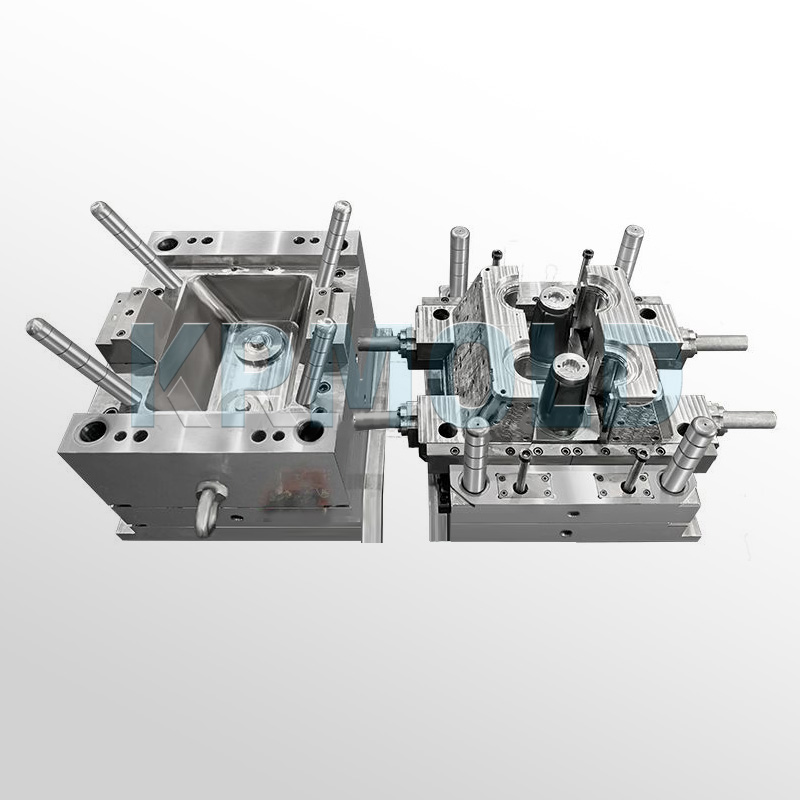

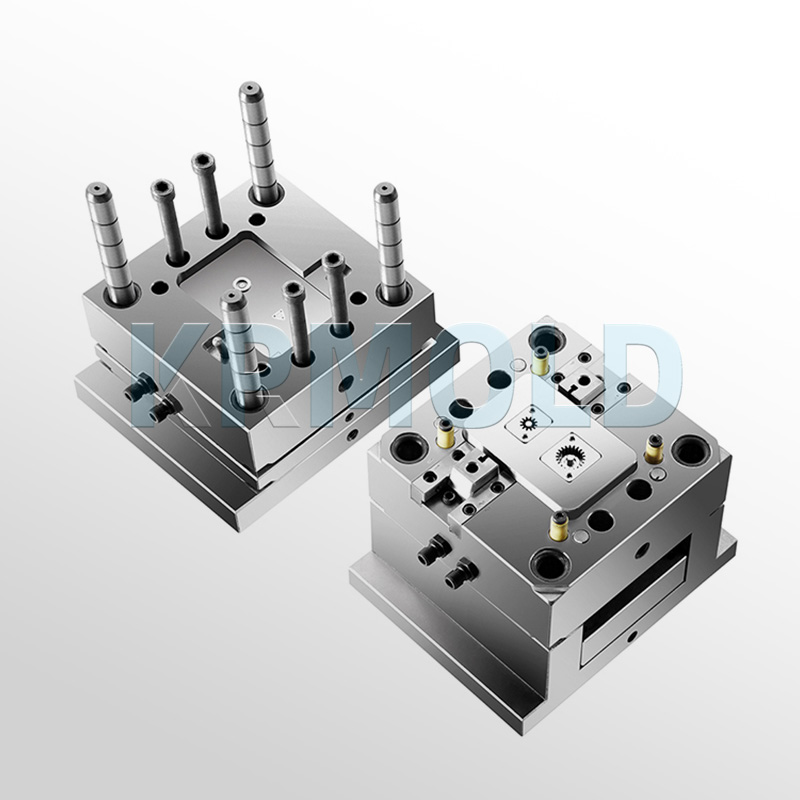

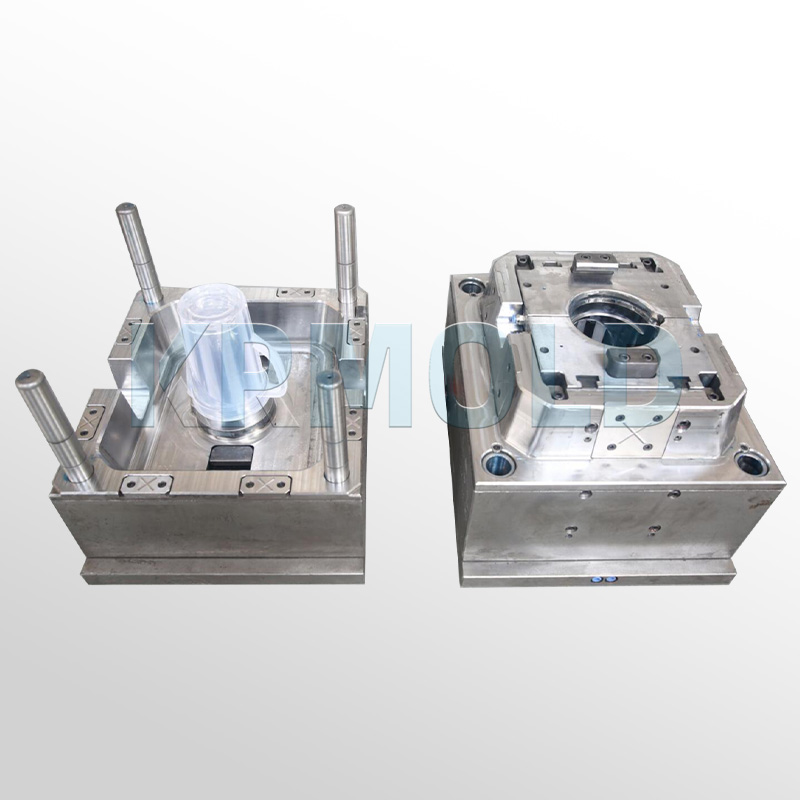

(3) PC Injection Molds Creation and Design

An essential component of the injection molding process is the PC injection molds. In PC injection molding, the design and construction of the PC injection molds must consider aspects including the shape, size, and structure of the product. To guarantee the quality and accuracy of the product during the injection molding operation, the PC injection molds design should be sensible.

(4) Injection Molding

The molten PC plastic fills the PC injection molds' cavity via the injection molding machine's nozzle during the injection molding process. The molten PC plastic cools and solidifies in the PC injection molds to create the desired product form.

(5) Post-processing of products

The item produced by injection molding must undergo post-processing. This covers trimming the product's edges and surfaces, doing required inspections and packaging, and eliminating PC injection molds residue.

2. Essentials of the PC Injection Molding Process

(1) Temperature management.

In the PC injection molding process, temperature control is vital. The proper temperature will guarantee the melting and flow of PC plastic and help to eliminate overheating's effects on plastic degradation or overcooling's effects on incomplete injection molding.

(2) Control of pressure

To guarantee the product's dimensional accuracy and compactness, pressure control throughout the PC injection molding process is quite essential. Good injection pressure will help the PC plastic fill the PC injection molds cavity completely and prevent bubbles or imperfections.

(3) Speed of Injection

Injection speed is the rate at which the injection molding machine injects molten PC plastic into the PC injection molds cavity. Too slow an injection speed could result in incorrect product dimensions; too fast an injection speed could result in marks on the product surface or insufficient melting.

3.Obstacles in PC Injection Molding and Solutions

Though polycarbonate offers many benefits, several issues to think about during PC injection molding include melt temperatures and stress cracking sensitivity. Manufacturers can tackle several of these difficulties in the following ways:

(1)Control high processing temperatures

The high temperatures needed for processing plastic are one of the main obstacles in its molding. This strains the PC injection molds and tools, potentially resulting from increased upkeep. Invest in high-temperature resistant molds and use specialized machines built for high-temperature materials.

(2)Stress Cracking A avoided

If not accurately molded, polycarbonate is susceptible to stress cracking. This issue can arise from incompatible additives, high pressure, or quick cooling. Reduce internal stress inside the molded component by controlling PC injection molds temperature, cooling rate, and injection speed.

(3)Gas Emission Problems and Ventilation Concerns

Heated polycarbonate emits gases that, if not adequately vented, might result in burn marks and surface flaws. Make sure the PC injection molds is well ventilated and use the right gate size and placement to let gases escape from the cavity.

(4)Surface Aesthetics and Finishes

High viscosity and high stress during the molding process make PC components susceptible to surface flaws. Solution: Guarantee consistent filling and cooling by maximizing injection settings and using well-designed PC injection molds with smooth surfaces.

4. Benefits of PC Injection Molds

| PC injection molding's special characteristics provide several advantages for different uses. The following are some advantages of PC injection molding with polycarbonate (PC):

High impact resistance of PC makes it appropriate for components under possible impact or mechanical stress. In the automotive, electronics, and construction sectors where components are regularly used and could show wear and tear, this function is quite valuable.

PC's transparency—which rivals that of glass—makes it perfect for optical clarity applications including eyeglass lenses and medical equipment. Furthermore giving more aesthetic choices for consumer goods, PC can be colored and tailored.

PC's great thermal stability allows it to resist long-term high temperature exposure without bending or losing strength. This suitability for use in components exposed to high temperatures, including lighting and electronic housings, comes from

Design Flexibility Including thin-walled components, which are challenging to produce with other materials, PC injection molding allows for the production of items with complex forms. Polycarbonate's adaptability helps it to be a preferred material for designers and engineers searching for lightweight, flexible answers.

Properties of Electrical Insulation PC's insulating qualities make it perfect for usage in electrical parts, therefore safeguarding sensitive electronic devices from environmental elements and guaranteeing user safety. |

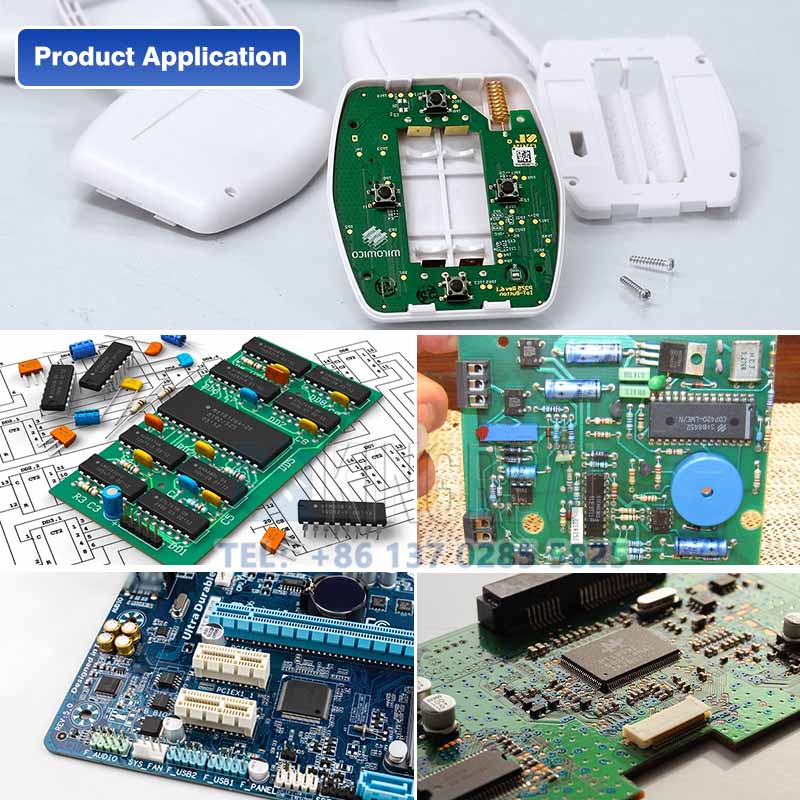

5. Usage Fields of PC Injection Molds

PC injection molding is applied in the automotive industry for: Headlight lenses and covers benefit greatly from PC's clarity and impact resistance. Dashboards: The panels and housing's strength and durability guarantee constant and dependable integrity. Polycarbonate sheets, which are transparent and UV-resistant, are regularly used as a lighter substitute for glass in sunroofs and windows. |  |

| Industry of Electronics and Electricity Polycarbonate is often used in these components of electronic devices: PC's flame retardancy and insulating qualities make it perfect for switch panels and electrical housings. Polycarbonate is excellent optical clarity for CDs, DVDs, and Blu-ray discs, so utilized on optical discs. Battery cases and connector housings in portable electronic devices benefit from PC's high impact resistance and stability, which makes it appropriate. |  |

In the medical field, PC injection molding can produce: PC's biocompatible, translucency, and sterilizing powers render it fit for surgery instruments. Diagnostic equipment enclosures, where visibility and durability are paramount, incorporate transparent PC components. PC is lightweight and robust, hence it is frequently found in drug delivery devices such syringes and inhalators. |  |

Polycarbonate is extensively used in consumer goods, especially those need durability and clarity: Popular selections for glasses and sunglass lenses, polycarbonate's optical clarity and impact resistance make it so. Reusable water bottles and food containers use BPA-free polycarbonate variants found in water bottles and food containers. PC's resilience makes it appropriate for use as protective gear and equipment for sports and outdoor activities. |  |