What are Plastic Pillar Car Part Injection Mould?

——

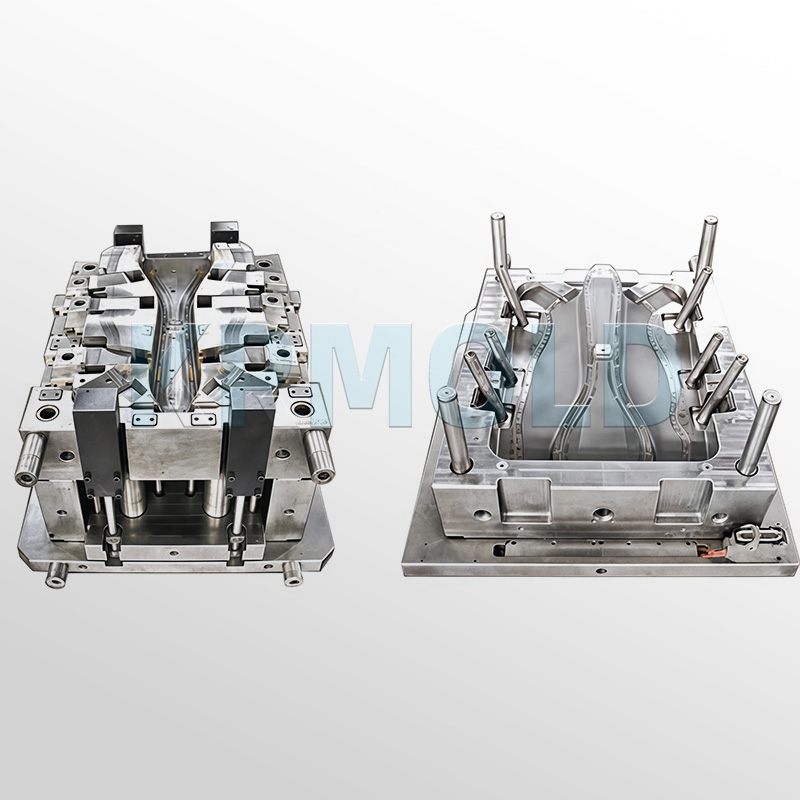

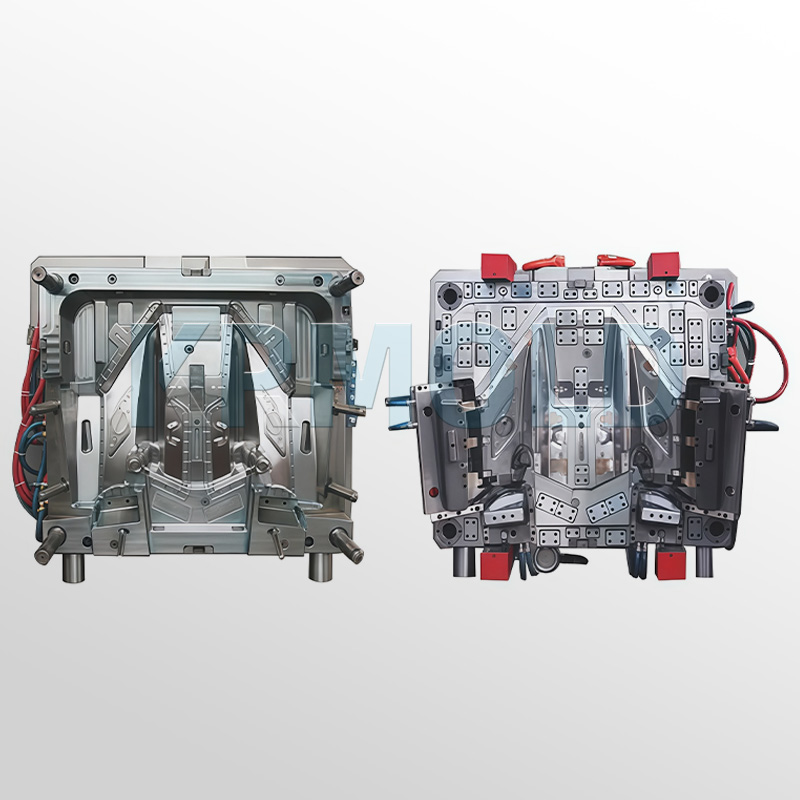

KRMOLD plastic pillar car part injection mould are high-precision molds specifically designed for manufacturing automotive pillars. Producing automotive components such plastic A-pillars, B-pillars, and C-pillars, which have a vital supporting and stabilizing function in the frame of the vehicle, these automotive pillar injection molds help to shape such components. They help to absorb collision force, so guaranteeing passenger safety by offering a strong base for doors, windows, and the roof.

The production and design of plastic pillar car part injection mould are vital to guarantee that the manufactured pillars satisfy demanding requirements in terms of shape, durability, and uniformity. High-quality automotive pillar injection molds provide consumers a superior driving experience by not just raising vehicle safety but also improving aerodynamics and looks.

General Plastic Pillar Car Part Injection Mould For Reference

——

| Items | Description |

| Mould Core | DIN2312,2738,2344,718,S136,8407,NAK80,SKD61,H13 etc. |

| Hardness of steel | 46~56 HRC |

| Mould Standard | HASCO,DME,MEUSBURGER,JIS,CHINA LKM Standard |

| Mould Base | LKM&HASCO&DME standard (A,B plate 1730,2311,2312,P20 ) |

| Cavity | Single/Multi |

| Runner | Hot/Cold Runner |

| Maximum Mould Size | 1500*1500 mm |

| Surface of Mould | EDM / High Polish&Texture |

| Plastic material | PP, PC, PS, PE, PET, POM, PA,PU, PVC, ABS,HIPS, PMMA etc. |

| Mould Life | 300,000-1,000,000 shots |

| Specification | Depends on customer’s requirements. |

| Surface Treatment | Polish,texture,painting,screen printing,turnkey project |

| Mold hot runner | DME, HASCO, YUDO,etc |

| Mold cold runner | point gate, side gate, subgate, tunnel gate,banana gate, direct gate ,etc. |

| Mold hot treatment | quencher, nitridation, tempering,etc. |

| Surface finish of Part | Logo print,Texture,Polishing,Painting,Chrome Plating |

| Mold cooling system | water cooling or Beryllium bronze cooling, etc. |

Advantages of Automotive Pillar Injection Mold

——

1. Durable plastic pillar car part injection mould High-quality automotive pillar injection molds are extremely durable. Rigorously tested and optimized in design, these plastic pillar car part injection mould maintain excellent performance even under frequent use. Wear-resistant materials and sophisticated production techniques guarantee the automotive pillar injection molds can withstand wear and tear during manufacturing, therefore removing the need for frequent mold replacements and saving customers time and money.

2. High production efficiency for automotive pillar injection molds Using KRMOLD plastic pillar car part injection mould, customers can significantly improve production efficiency. While conventional mold production can take hours or even days, KRMOLD automotive pillar injection mold designs can quickly generate several automotive pillars. This great manufacturing efficiency helps customers to handle more projects, hence boosting total income. |  |

3. Precision and consistency for automotive pillar injection mold High-quality plastic pillar car part injection mould produce high-precision automotive pillars. These pillars are an integral part of the automotive structure and require precise specifications to ensure a perfect fit with the vehicle's overall structure. KRMOLD automotive pillar injection molds are meticulously designed, paying attention to every detail to ensure that each pillar produced is consistent in size, shape, and surface finish. This precision relies on advanced manufacturing technologies and high-quality materials. For example, Computer Numerical Control (CNC) machining technology is widely used in plastic pillar car part injection mould manufacturing to ensure extremely small tolerances for each automotive pillar injection mold. The final product quality is consistently high, meeting or exceeding industry standards, helping automakers reduce scrap rates and rework losses, thereby saving time and costs.

4. Enhancing product quality for automotive pillar injection mold High-quality plastic pillar car part injection mould not only produce structurally stable and smooth-surfaced pillars, but also greatly enhance the vehicle's aesthetic. Reducing wind noise and improving aerodynamic performance—which is especially important for increasing driving comfort—the smooth surface of the automotive pillars helps to accomplish this. Moreover, great detail design guarantees proper component installation and function, hence greatly influencing car safety and performance. For instance, a well-built pillar will better support the doors and roof, hence raising the general stability and safety of the vehicle. |  |

Introduction to Car Pillars

——

The interior space of a car is supported by three pillars: the A-pillar, B-pillar, and C-pillar. The A-pillar is located between the windshield and the front door, connecting the rearview mirrors; the B-pillar is located between one of the doors; and the C-pillar is located between the rear quarter window and the rear windshield. Some SUVs and extended-wheelbase vehicles also have a D-pillar for added structural integrity.

Each pillar is carefully designed to meet its unique design specifications and overall performance requirements. For example, the angle, material, and width of the A-pillar directly affect the car's drag, weight, and blind spots. Excessively heavy materials increase the overall vehicle weight, too shallow an angle can increase drag, and an overly wide pillar can widen the driver's blind spots—all factors that must be considered during the design process.

Furthermore, these pillars must be strong enough to provide sufficient protection for passengers in the event of a rollover or collision. Therefore, the quality and performance of KRMOLD automotive pillar injection molds directly affect the safety and reliability of the car pillars.

Automotive Pillar Injection Mold Manufacturing Process

——

1. Preparing Process Documents

The manufacturing of plastic pillar car part injection mould begins with the preparation of detailed process documents. These documents include the machining process specifications for automotive pillar injection mold parts, assembly process points, raw material lists, and lists of purchased parts. KRMOLD engineers will fully understand the structure, working principle, and specific requirements of the plastic pillar car part injection mould, and develop detailed process documents accordingly to ensure the smooth progress of the production process.

2. Design and Process Preparation of Auxiliary Tools

The design and process preparation of auxiliary tools are indispensable steps in the automotive pillar injection mold processing and assembly process. These auxiliary tools (or secondary tools) are specialized equipment used to improve the efficiency and quality of plastic pillar car part injection mould processing. KRMOLD engineers are responsible for designing and programming these tools to ensure their quality and efficiency. Commonly used tools include non-standard reamers, milling cutters, contour inspection templates, and non-standard gauges. The quality of these tools directly affects the automotive pillar injection mold production schedule and the quality of the final product.

3. Handling Technical Issues

During the processing and assembly of plastic pillar car part injection mould, issues related to technology, quality, and production management are inevitable. KRMOLD engineers play a crucial role in this process, interpreting process documents, providing technical guidance, and adjusting processing plans and methods according to actual conditions to ensure smooth automotive pillar injection mold production.

4. Participation in Testing and Qualification

Post-assembly testing and pressure testing are critical steps in ensuring plastic pillar car part injection mould quality. KRMOLD engineers and other staff will analyze technical issues through a series of tests and pressure tests, propose solutions, and ultimately determine the technical quality status of the automotive pillar injection mold. This step is not only a key part of plastic pillar car part injection mould production but also an important guarantee that the final product meets standards.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).