Description of Automotive Door Handle Injection Mold

——

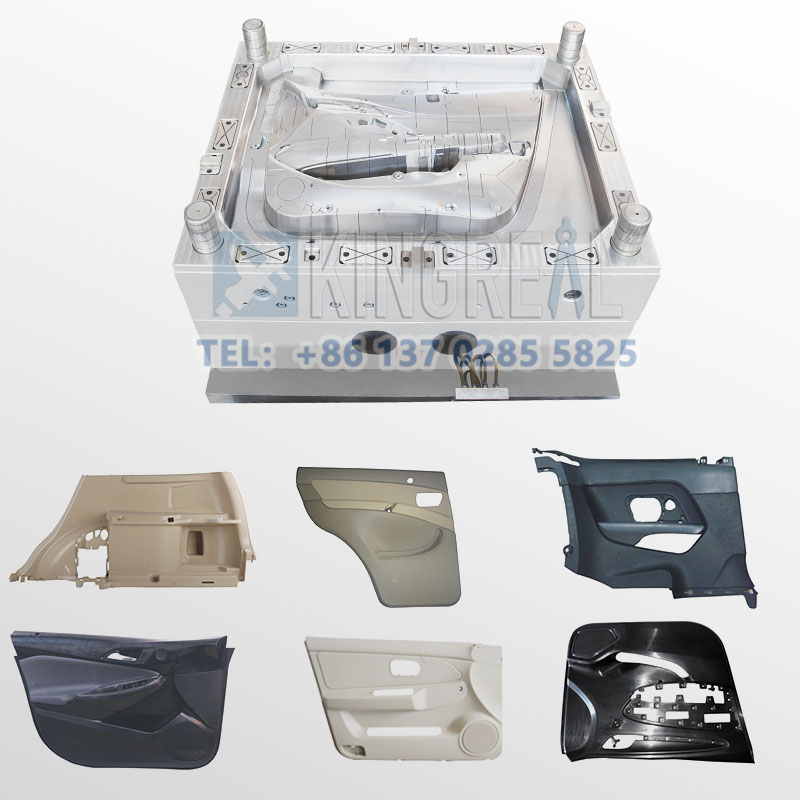

KRMOLD can customize personalized automotive door handle injection molds based on specific customer production needs and manufacture door handles for both front and rear doors, tailored to the vehicle model and size, and based on the door panel's exterior features (with or without a speaker mesh).

Automotive door panels typically feature high-gloss and leather surfaces, requiring the absence of defects such as spots and weld marks. This places high demands on the complex curved surfaces required for injection molding. Door panels often have multiple undercuts on the inside and outside, requiring car door handle injection mold release with the aid of a core mechanism on the mold side.

KRMOLD automotive door handle injection molds utilize a needle-valve sequential hot runner and conventional runner feeding, such as four or ten hot nozzles, to avoid weld marks and optimize filling pressure. Sector or banana gates are preferred for car door handle injection molds, and runner lengths are typically controlled between 60 and 100 mm to minimize pressure loss. Door handles produced using KRMOLD automotive door handle injection molds are crucial automotive components, demanding high-quality appearance without defects such as flaking, shrinkage, water marks, scratches, or missing glue. KRMOLD car door handle injection molds offer fast production speeds and high molding precision.

Parameters of Car Door Handle Injection Mold

——

| Shaping Mode | Automotive Door Handle Injection Mould |

| Product Material | Plastic |

| Plastic Material | PP,PC,PS,PAG,POM,PE,PU,PVC,ABS,PMMA,etc |

| Application | Auto parts, machinery parts, household parts, Cooker parts, furniture parts, etc |

| Runner | cold runner/hot runner |

| Mould material | NAK80, S136, 2316, 2738, H13, 5CrNiMo, 718H, P20, 40Cr, 60#, 45# etc |

| Sprue Gate | YUDO runner ,Hot runner,Cold runner ,Pin -point gate,Submarine gate,etc |

| Surface treatment | Matte/Smooth/ Polsihed |

Features of Car Door Handle Injection Mold

——

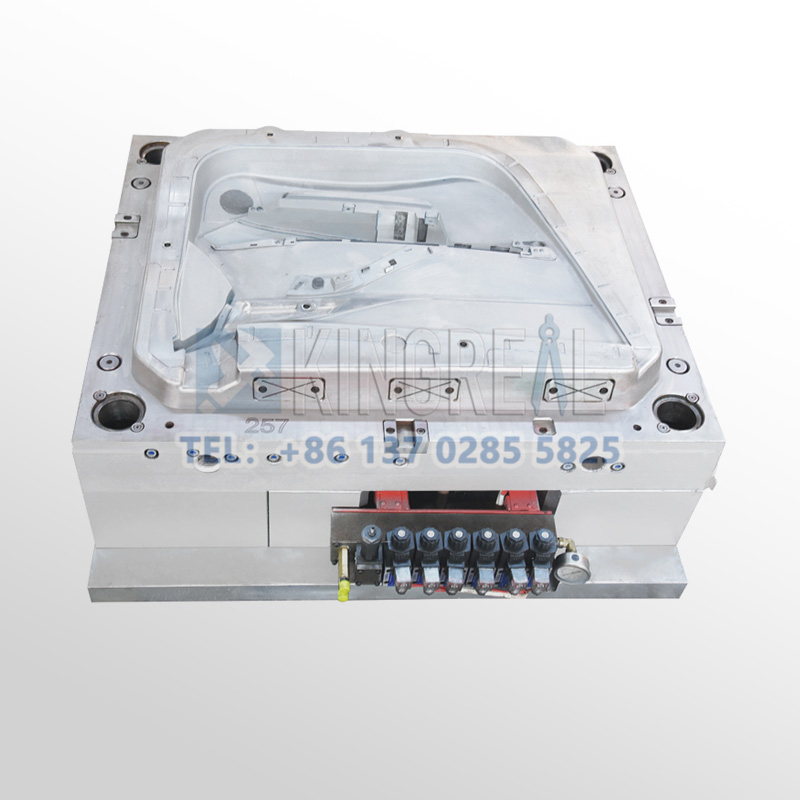

1) Integrated fixed and moving mold design for car door handle injection mold

This automotive door handle injection mold utilizes an integrated fixed and moving mold design. The core components are primarily made of P20/2738. The car door handle injection mold's AB plates feature a four-sided hemming structure to ensure mold rigidity and compactness. Key structural elements include the lift block, pusher block, and mesh hole design. The lift block requires special attention to prevent part sticking or surface scratches, especially in dense mesh areas such as speaker grilles.

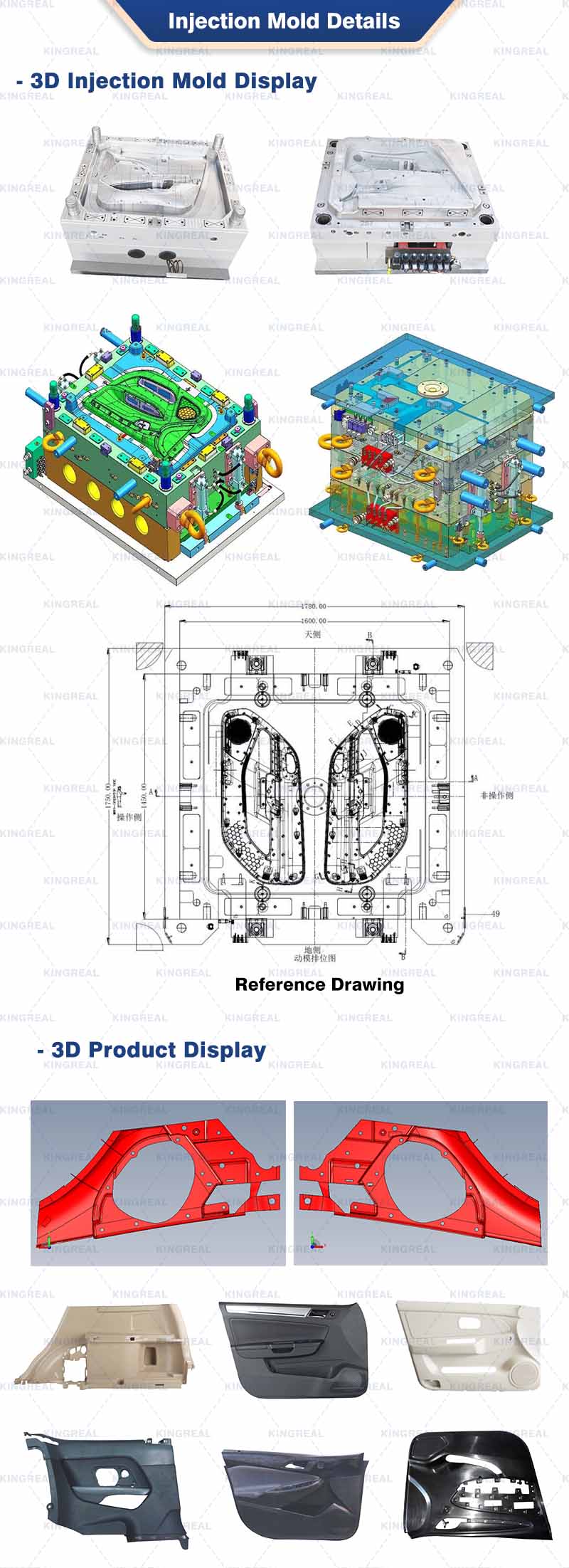

2) Hot runner feeding method for car door handle injection mold

This automotive door handle injection mold utilizes a 10-point sequential valve hot runner system combined with cold runners and banana-shaped gates. The PP/EPDM (polypropylene/ethylene propylene diene monomer) materials offer high flowability, allowing for flexible runner design. To minimize pressure loss and ensure surface quality, the cold runner length is limited to ≤60 mm (preferred) or ≤100 mm (maximum). This configuration effectively eliminates weld lines on the exterior surface (A-side).

3) Temperature control system design for car door handle injection mold

As a critical component of automotive interiors, the lower body of the car door handle requires extremely high quality appearance. Therefore, the quality of the temperature control system design has a profound impact on injection mold efficiency and product quality.

Material for Automotive Door Handle Injection Mold

——

-ABS: The ABS resin used for the interior door handles comes in general-purpose and heat-resistant grades. General-purpose ABS has good electroplating properties, while heat-resistant ABS resin typically has a heat deflection temperature between 90-105℃ and offers good rigidity, toughness, and flowability.

-PC: PC (polycarbonate) is an engineering plastic with excellent mechanical properties. However, its limited electroplating performance has limited its application.

-PC/ABS: PC/ABS resin is the fastest-growing and most widely used material for interior door handles. It is an alloy of PC and ABS, combining the high strength of PC with the ease of electroplating of ABS. There are two main types: electroplated and painted. Compared to painted PC/ABS, electroplated PC/ABS has a more metallic appearance and a more premium look.

-PC/PBT: PC/PBT is a blend of PC and PBT, retaining the chemical resistance and moldability of crystalline PBT while offering the toughness and dimensional stability of amorphous PC.

-PA: In countries like Germany, where tensile strength is a high requirement, electroplated PA is widely used in German vehicles. Interior door handle PA is typically divided into two types: painted PA and electroplated PA. Electroplated PA typically consists of PA + 20% minerals.

What Types of Door Handles can KRMOLD Car Door Handle Injection Molds Produce?

——

KRMOLD automotive door handle injection molds can produce a variety of door handle types. The following are common door handle types. If you have specific production requirements, please provide your drawings to KRMOLD, and our engineers will provide a customized automotive door handle injection mold solution based on your specific needs:

-Push-button door handles,

-Trigger door handles,

-Flap door handles,

-Push-down door handles,

-Pull-up door handles,

-Pull-out door handles,

-Touch-type door handles

Detail Information of Mould Steel

——

| Mould material | Mould hardness | Mould life |

| P20 | HRC 29-33 | 300000 shot |

| H13 | HRC >43 | 1000000 shot |

| 718 | HRC 30-36 | 500000 shot |

| S136 | HRC 48-52 | 50000 shot |

| 2344 | HRC >48 | 800000 shot |

Car Door Handle Injection Mold Design Details

——

When designing a car door handle injection mold, KRMOLD engineers need to pay attention to several important details to ensure automotive door handle injection mold efficiency and durability. The following is a detailed analysis of the key factors:

1. Material selection for automotive door handle injection mold

The primary material for door handles is PC/ABS, which offers excellent electroplating properties and a moderate shrinkage ratio (approximately 1.005). A high proportion of PC content improves the handle's mechanical strength, but also requires a higher molding temperature.

2. Car door handle injection mold design

In the initial automotive door handle injection mold design phase, KRMOLD engineers perform the following steps:

Shape Analysis: Detailed analysis of the exterior door lock handle's shape ensures the car door handle injection mold design accurately reflects the handle's complex structure.

Feasibility Analysis: Evaluate the feasibility of the automotive door handle injection mold structure to ensure it meets technical and economic requirements during production.

3. Production volume and car door handle injection mold life

Based on the customer's production volume requirements and the expected automotive door handle injection mold life, KRMOLD engineers perform the following:

Material Selection: Determine the appropriate steel, such as P20 or H13, to meet the automotive door handle injection mold's strength and wear resistance.

Mold Cavity Design: Given that each car typically has four handles, a multi-cavity design, such as a four-cavity mold, may be used to improve production efficiency.

Hot Runner System: Based on product characteristics and production requirements, the decision to use a hot runner system is made to reduce molding cycle time and material waste.

4. Cooling System Design

Due to the high molding temperature of PC/ABS materials, designing an efficient cooling system is crucial. The cooling system should include:

Cooling lines: The cooling lines within the fixed and movable molds must be designed and laid out to ensure uniform cooling.

Components: These include plugs, fittings, seals, gaskets, etc., to ensure a leak-proof system.

5. Mold frame structure

The car door handle injection mold frame design is equally important and typically consists of the following components:

Fixed and movable mold plates: Ensure automotive door handle injection mold stability and accuracy.

Spacers and push rod mounting plates: Support and secure car door handle injection mold components.

Guide bushings and guide pins: Ensure precise alignment during automotive door handle injection mold opening and closing.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).