Description of Automotive Control Panel Injection Mould

——

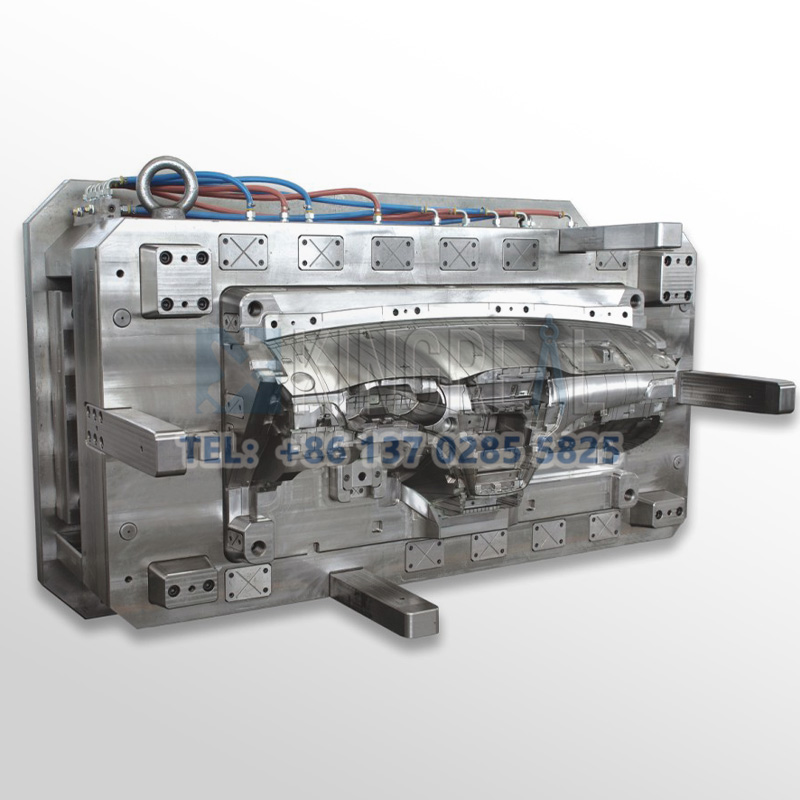

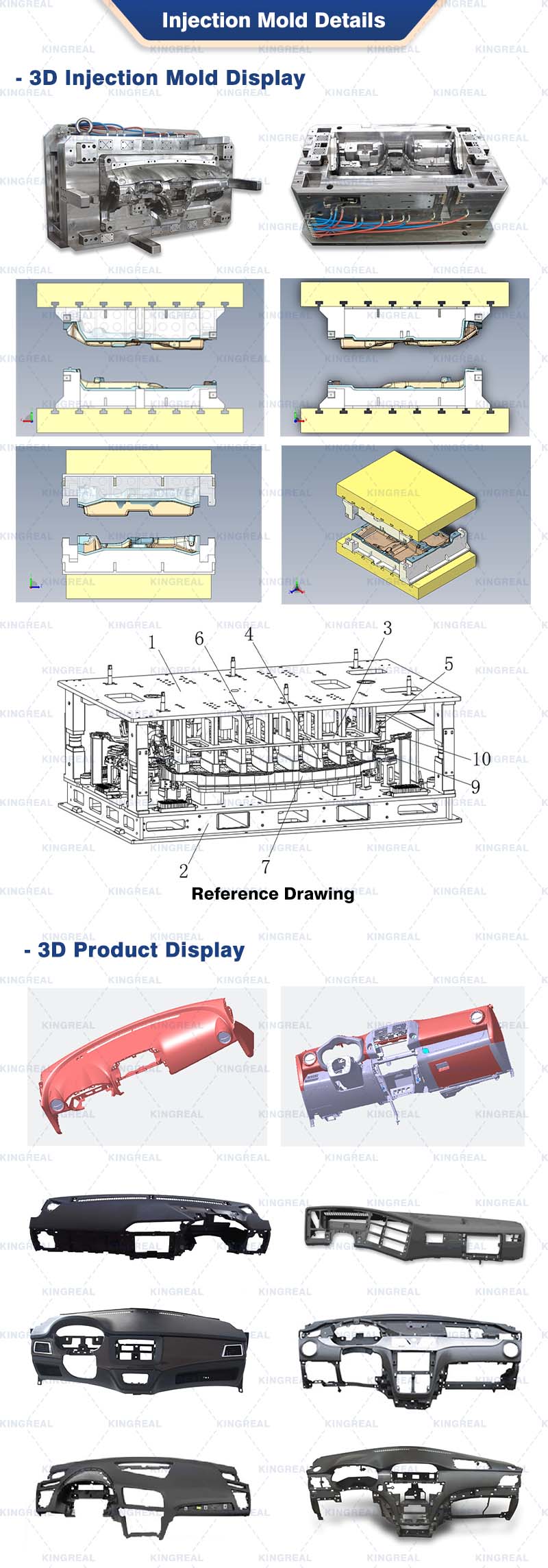

KRMOLD automotive control panel injection mould are specialized plastic injection molds used to manufacture automotive dashboards. Usually injected into the mold cavity, molten plastic material like ABS or polypropylene then solidifies to create the dashboard component that satisfies the design criteria. KRMOLD car dashboard injection molds are designed to help manufacturers mass-produce complex, high-tolerance dashboard components, ensuring consistency and quality throughout the manufacturing process, and guaranteeing that each dashboard has the correct dimensions, textures, and data.

KRMOLD provides a perfect car dashboard injection mold finish to ensure the product is free of sink marks and burrs. KRMOLD high precision in automotive control panel injection mould design ensures that the final finish of curved surfaces, button holes, vents, and other intricate features on the dashboard are also excellent. KRMOLD automotive control panel injection mould ensure that dashboards are aesthetically pleasing and meet industry standards for durability, aesthetics, and performance.

Parameters of Car Dashboard Injection Mold

——

| Injection Mold Type | Automotive Control Panel Injection Mold |

| Mold Type | Steel P20 |

| Mold Base | S50c |

| Mold Cavity | 1 Cavity |

| Injection Mold Size | 2710x1890x1700mm |

| Injection Mold Weight | 34.5T |

| Mold Surface Treatment | Polish, Etched, Texture, Etc. |

| Plastic Product Wall Thickness | 2.5mm |

| Mold Shrinkage | 0.42% |

| Molding Tolerance | ±0.02MM |

| Mold Processing Material | PP/ABS/PC+ABS Multi-Material Molds |

| Mold Life | 500,000+ Lifespan |

Car Dashboard Injection Mold Design and Manufacturing Analysis

——

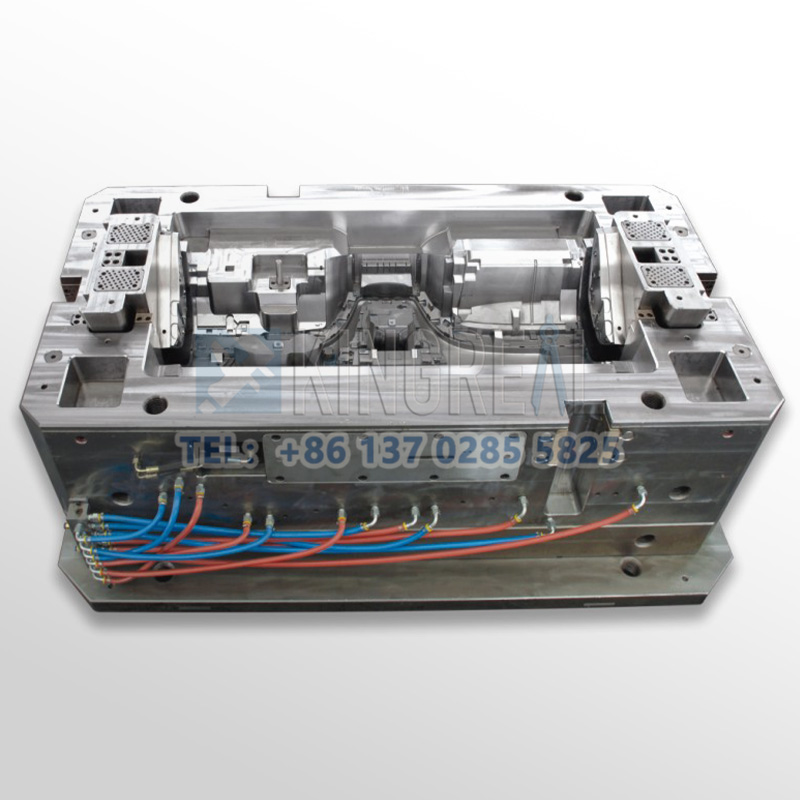

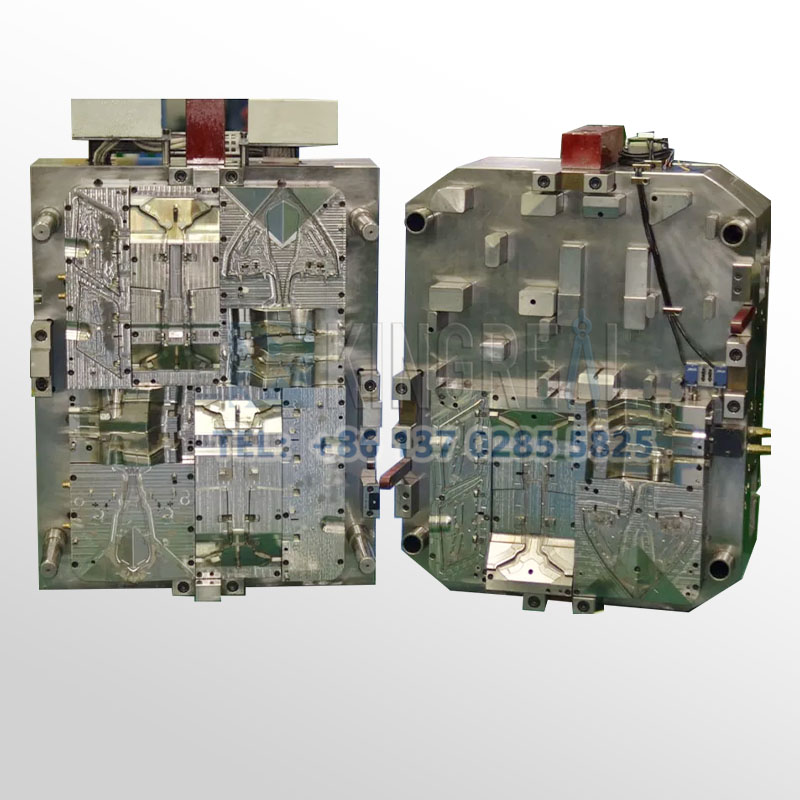

Automotive control panel injection mould typically involve irregular parting surfaces, multiple sliders, and ejector blocks. These designs require optimization through simulation based on material properties (e.g., shrinkage, elasticity coefficient) and molding temperature. Furthermore, the automotive control panel injection mould’ cooling water layout must be rational, balancing rapid prototyping with temperature uniformity to prevent mold deformation or failure due to thermal stress.

KRMOLD utilizes precision machining technologies (such as CNC and EDM) to ensure critical component tolerances. Core components undergo surface hardening treatments (such as nitriding and electroplating) to enhance wear resistance and longevity. Steel materials (such as pre-hardened or corrosion-resistant steel) are selected to optimize mold life and are customized based on the properties of the injection molding material (such as ABS and PC/ABS). Standard parts with great wear resistance and high precision (HASCO or DME, for instance) help to guarantee the stability of car dashboard injection molds. Injection temperature, pressure, and holding time are kept under control; filling speed and cooling rate are maximized to reduce flaws like sink marks and bubbles. Parameter combinations are validated through DOE experiments to ensure consistent molding.

Advantages of Automotive Control Panel Injection Mould

——

High Precision and Consistency – Car dashboard injection molding precisely replicates mold designs, ensuring consistent size and shape for each control panel component.

Durability and Strength – Automotive parts require materials that can withstand the wear and tear of daily use, and automotive control panel injection moulding enables the use of high-strength, durable materials.

Complex Geometries – The process can accommodate complex designs such as thin walls, intricate textures, and built-in features like snap-fitcomponents or multi-material designs.

Cost-Efficient and Suitable for Volume Production – Once the car dashboard injection mold is manufactured, injection molding is highly efficient for high-volume production, significantly reducing unit costs.

Surface Finish – The process can produce parts with smooth, glossy, or textured surfaces, which are crucial for the aesthetics of automotive interior components.

Common Materials Used for Car Dashboard Injection Molds

——

The materials used for automotive control panel injection mould must be strong, heat-resistant, and durable. High-quality car dashboard injection molding ensures a simple production system and reduces defects. High-grade metals are the most often used materials for automotive control panel injection mould because of their strength, heat resistance, and endurance. Common metal types include P20, H13, and S136. Another excellent substance, aluminum, not always as robust as metal, could be another choice. It is ideal for little volume production since it is lightweight and simple to use. High corrosion resistance and toughness of nickel alloys also make them perfect for long-lasting automotive control panel injection mould.

Car dashboard injection molds are typically made of thermoplastics. ABS is a well-known material for its excellent impact resistance and surface finish. PC/ABS offer high temperature resistance and toughness. PP is widely used for its lightweight and cost-effectiveness, while glass fiber-reinforced plastics are used in high-power packaging applications where exceptional robustness is crucial.

Common Molding Processes Used for Car Dashboards

——

| 1. Multi-Cavity Injection Molding Applications: Production of basic structures such as the instrument panel body and frame. Key Mold Design Points: A multi-cavity design improves efficiency, but the distribution of gates (such as fan gates or latent gates) must be balanced to avoid weld line issues. For thick-walled areas (such as instrument panel mounting pillars), the cooling system should be optimized to prevent sink marks and deformation. |  |

2. Gas-Assisted Injection Molding Purpose: Nitrogen injection creates hollow channels, reducing material usage and increasing part stiffness. It can reduce weight by over 30% and reduce internal stress, making it suitable for large instrument panel crossbars. Mold Design Key Points: Gas needles must be pre-installed in the mold, and gas flow paths must be designed (for example, along ribs). The cavity surface must be highly polished to prevent surface defects caused by gas permeation. |  |

3. Two-Color Injection Molding Application: Manufacturing components that integrate soft and hard materials or different colors (for example, combining instrument panel trim with a substrate). The soft-touch area (TPE cover) on the instrument panel surface is molded simultaneously with the hard substrate (PC/ABS). Mold Design Key Points: Multi-material sequential injection molding is achieved using a rotational mold or stacked mold structure. Precisely control the shrinkage differences between the different materials to prevent interfacial delamination. |  |

Key Considerations in Designing a Car Dashboard Injection Mold

——

KRMOLD Engineers will guarantee great surface quality and exact dimensions for the automotive control panel made from the car dashboard injection mold. Dimensional accuracy guarantees that the car dashboard conforms exactly within the inside of the car. Another major problem is cooling performance since a well-designed cooling system in the automobile control panel injection mould guarantees quicker manufacturing cycles and avoids flaws such warping. Surface finish is also crucial since a well-formed automotive control panel injection mould assures a lovely and classy look for the end product.

The automotive control panel injection mould design must include suitable gates and venting to enable the plastic material to flow easily, remove trapped air, and avoid flaws. The car dashboard injection mold of the car must also be strong enough to resist continuous use without fast deterioration. Good materials and repair will improve the performance and lifespan of the automotive control panel injection moulding.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).