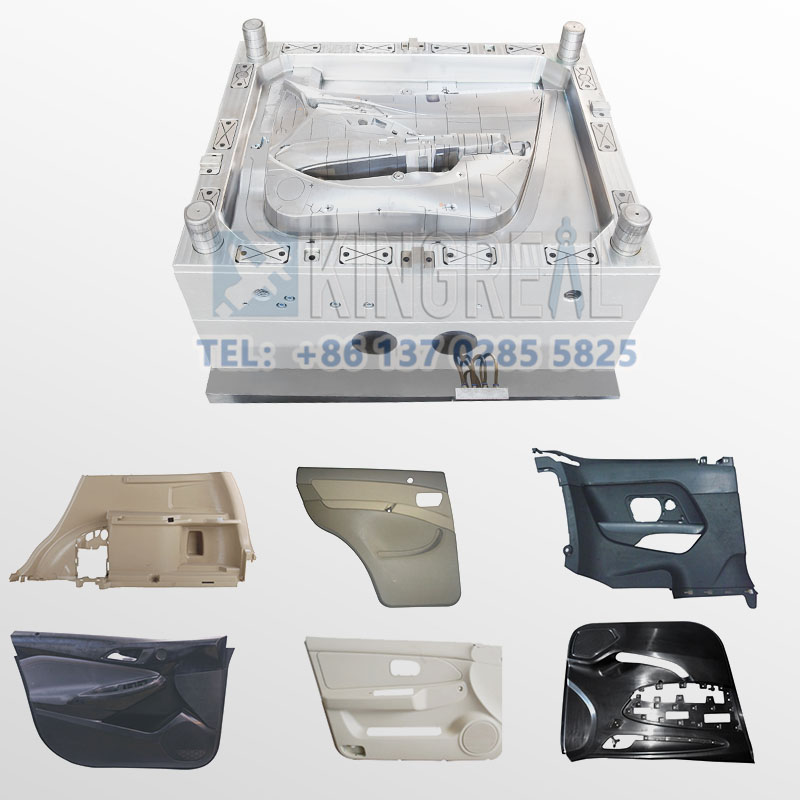

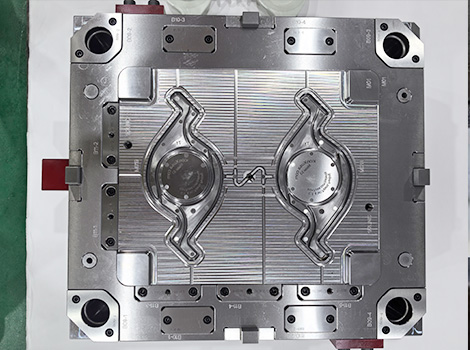

Description Of Car Door Panel Injection Mold

——

KRMOLD is a professional plastic injection mold manufacturer in China, with professional production strength and rich project experience in plastic injection mold. For example, the automotive door panel injection mold belongs to the large injection mold in the field of Automotive Injection Mold industry, which is used as the key tool for producing automotive interior door panels.

Automotive door panels usually have a high gloss surface and leather surface, need to ensure that there are no spots and welding marks and other defects, which is a high demand for injection molding complex surfaces, door panels are often distributed on the inside and outside of a number of inverted buckles, the need for plastic injection mold side of the core mechanism to achieve the release of the mold.

KRMOLD Auto Door Trim Mold adoption of needle valve type sequential valve hot runner with normal runner feeding, e.g. with 4 or 10 hot nozzles, to avoid fusion marks and optimize filling pressure. Automotive door panel injection mold priority fan gate or banana gate, the length of the runner is usually controlled within 60-100mm to reduce pressure loss.

Design Features Of Car Door Panel Injection Mold

——

Our advantage

The automobile door panel injection mold adopts an integrated fixed and moving mold design , with P20/2738 as the primary material for the core components. The mold's AB plates utilize a four-sided edge-enclosing structure , ensuring rigidity and compactness. Key structural elements include angled ejector blocks , push blocks, and mesh hole design. Special attention is required for angled ejector blocks to prevent part adhesion or surface scratching , particularly in areas with dense mesh patterns (e.g., speaker grilles).

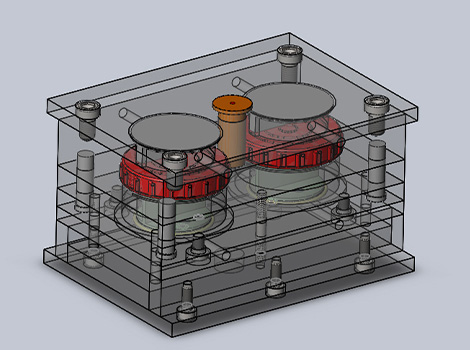

The mold employs a 10-point sequential valve hot runner system coupled with cold runners and banana-shaped gates. The material, PP/EPDM (Polypropylene/Ethylene Propylene Diene Monomer) , offers high fluidity, enabling flexible runner design. To minimize pressure loss and ensure surface quality, the cold runner length is restricted to ≤60 mm (preferred) or ≤100 mm (maximum) . This configuration effectively eliminates weld lines on cosmetic surfaces (A-surfaces)

As one of the important components of automobile interior, the appearance quality of the lower body of the automobile door panel is highly demanded. Therefore, the advantages and disadvantages of the temperature control system design have a far-reaching impact on the molding efficiency and product quality of the injection mold.

"The automotive door panel injection mold adopts the innovative “straight water pipe + inclined water pipe + well” combination of temperature control system, which not only ensures the uniform cooling of the plastic parts, shortens the molding cycle, but also improves the quality of the finished products of the automotive door panels, which is very suitable for the injection molds with high appearance performance requirements."

Technical Specification Of Car Door Panel Injection Mold

——

| Mold Material | P20/718/738/NAK80/S136/2344.ETC. |

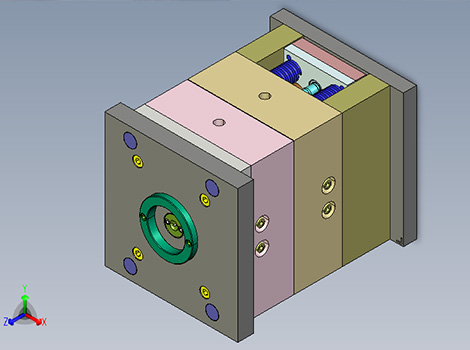

| Design Software | Solidworks/PROE/UG/CAD.ETC. |

| Plastic Material | ABS/PP/PS/PE/PVC/PA6 and other |

| Injection Runner | Hot Runner\ Cold Runner |

| Molding Cavity | Single Cavity |

| Mold Size | 1190*930*720mm |

| Mold Base | xc48 |

| Mould Life | 250k-300k shots |

Car Door Panel Injection Mold Working Process

——

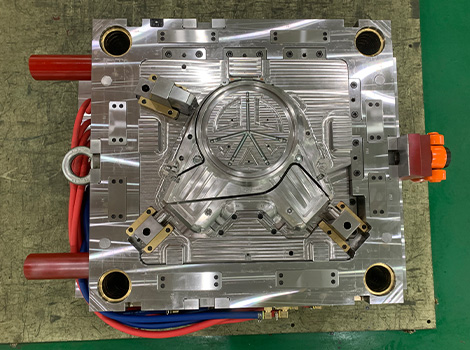

Gas-Assisted Injection Molding

The gas needle is usually set in the middle area at the bottom of the cavity of the injection mold, injecting the molten plastic through high-pressure nitrogen to form a medium air channel in the thick-walled part, reducing the amount of material, up to 40%.

Tailgate trim mold is directly injected into the cavity through gas needle and laid out near the gate to ensure that the gas flows in the same direction as the melt, the gas holding stage can eliminate the shrink marks and warping in the thick-walled area in the traditional injection molding, and the surface finish of the door panel can be significantly improved, which can satisfy the high appearance requirements of the automotive interior trim parts.

KRMOLD tailgate trim panel mold adopts gas-assisted technology and optimizes the filling parameters (gas delay time 0.5s, pressure 4.5MPa) through Moldex3D simulation, which ultimately achieves no shrinkage mark in the thick-walled area with wall thickness of 43.1mm.

Two-shot injection molding is achieved by injecting plastics of different colors or materials in two parts in a single injection molding cycle, and rotating or switching the molds to achieve a composite structure. In automotive door panel injection molds, 2K injection molding is usually used to combine a hard skeleton (e.g., PC/ABS) with soft-touch surfaces (e.g., TPE) to enhance the comfort of interiors, and to achieve watertight seals through the combination of a hard adhesive and an elastomer (e.g., LSR).

The injection mold rotates the rear mold by 180° to achieve two-color injection, while the front mold is fixed to ensure the accuracy of cavity alignment between the two injections (tolerance ±0.01mm). Double top stick system operates independently, spring reset avoids rotational interference, demolding slope>1.5° (coarse leather surface).

About KRMOLD

——

"KRMOLD focuses on the field of precision mold design and production, with a manufacturing team of 200+ professional technicians, a technical R&D team of 30+ engineers, and a full-cycle service team covering pre-sales consultation to after-sales maintenance, providing full-process services ranging from mold design, precision processing to injection molding."

Why Choose Us?

1.One-stop full-process service

We provide full-process service from integrating requirements, mold design and manufacturing to delivery and after-sales service.

The technical team is deeply involved in the customer's product design stage, optimizing the mold structure and designing the mold drawings through the mold flow analysis software (such as Autodesk Moldflow, UGNX). Equipped with imported CNC, Shadick wire cutting machine, mirror discharge equipment and other precision processing equipment to achieve ±0.02mm precision;

We have a large-scale intelligent workshop to support secondary processing such as silk-screen printing, welding, spraying, etc. We strictly implement the quality system of ISO13485 and IATF16949; meanwhile, we provide free transportation, regular mold maintenance and one-year warranty service.

2.Complete quality control system

There is a full chain production workshop, using Makino five-axis machining centers, Haitian injection molding machines and other well-known equipment at home and abroad to avoid delays in outgoing processing. Through the CMM coordinate measuring machine, three-dimensional inspection instrument full inspection of key dimensions, the implementation of PDCA cycle quality management. Meanwhile, we provide complete quality inspection report of injection molds.

3.Accurate delivery control to guarantee the project schedule

Through digital management, production progress monitoring from the beginning of the order, for different orders and delivery date for data monitoring, once there are factors that may be delayed, immediately arrange to speed up the production schedule, to ensure that the customer in the delivery period to complete the manufacturing of plastic injection molds.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).