Specification Of Gearbox Housing Injection Mold

——

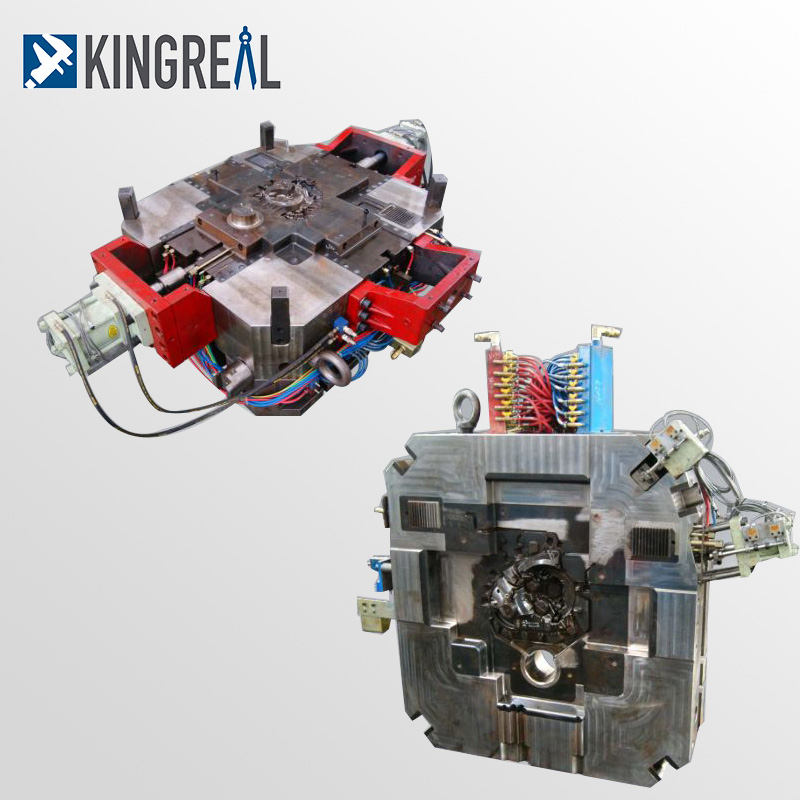

| Mold Name | Car Wheel Arch Liner Mold |

| Mould Cavity Steel | 8407 |

| Mould Size | 350*350*332 MM |

| Mould Injection System | 3 Plate Point Gates Hot Runner |

| Mould Ejection System | Bush ejector |

| Mould Life Cycle | 50K Shot |

| Product Size | 33*16.5mm |

| Mold Cavity | 4 Cavities |

| Product Material Available | ABS, PC, POM, PE, PP, PVC, PTFE etc |

| Application Arrange | Various Plastic Auto Gearbox |

Description Of Gearbox Housing Injection Mold

——

KRMOLD can supply the automotive gearbox housing injection mold according to customer requirement, has successfully helped more

than a dozen international famous automobile enterprises to solve the design and production of automobile structural parts power-train molds.

Gearbox Housing Injection Mold is a special injection mold for producing plastic gearbox housing, which is widely used in automobile, industrial equipment and new energy field by injecting molten plastic into the mold cavity under high pressure to complete mass production of plastic gearbox housing.

KRMOLD plastic gearbox housing mold selects S136H, H13 or ASP23 to meet the characteristics of corrosion resistance and high hardness, which help the mold life can be more than 500,000 times.Gear Box Plastic Mold adopts LKM standard mold frame to ensure the rigidity and stability of the mold, and through CNC precision machining to form the geometry of the housing, the accuracy can reach ±0.005mm.

Gear Box Plastic Mold uses LKM standard mold frame to ensure the rigidity and stability of the mold, and is precision machined by CNC to form the shell geometry with an accuracy of ±0.005mm. Moldflow software is used to simulate the filling, holding and cooling process to optimize the location of the gates.

Advantage Of Gear Box Plastic Mold

——

1. Plastic gearbox housing mold can use engineering plastics (such as PA66-GF30, PPS) to replace metal, the weight of gearbox housing can be reduced by 30%-50%, which can help reduce the energy consumption of the whole vehicle (electric vehicle range increased by about 3-5%). Complex structures (e.g. reinforcements, mounting holes) are molded in one piece by injection molding process, which reduces the number of parts and assembly links, and lowers the total weight of the system. plastic gearbox housings produced by KRMOLD Gear Box Plastic Mold have excellent lightweight and high-strength characteristics, which effectively reduces the weight of the whole vehicle, and at the same time, provides reliable protection and sealing to help increase the service life of the gearbox and ensure the excellent performance and reliability of the vehicle. Ensure the excellent performance and reliability of the car.

2. Plastic gearbox housing mold can produce only plastic as raw material, compared with metal raw materials, plastic raw material price is only 1/3-1/2 of aluminum alloy, and processing energy consumption is reduced by more than 40% (e.g., PA66 injection molding energy consumption is 50% lower than aluminum die casting), Gearbox housing injection mold in the Gearbox housing injection mold in mass production efficiency, can help automobile processing enterprises to reduce production costs.

3. Plastic injection molded gearbox can meet various design requirements. Plastic injection mold supports multi-slider core extraction (such as lateral oilway holes), with the shape of the cooling water circuit, can be molded thin-walled (≥ 0.8mm), high-precision (tolerance ± 0.05mm) gearbox housing, directly injection molding embedded metal inserts (such as bearing seats, threaded bushings), reducing the number of subsequent processing steps.

4. Gear box plastic mold produced by the electric reducer shell to adapt to the development of new energy vehicles, the low thermal conductivity of plastic can isolate the motor heat, to protect the surrounding electronic components.

Insert Molding For Gear Box Plastic Mold

——

“Insert Molding is a key process in the plastic molding of automotive gearboxes, where metal or plastic inserts are pre-positioned in the mold and bonded to the molten plastic to help embed metal bearing housings or threaded bushings in the automotive gearboxes to increase load carrying capacity or connection strength. Gearbox housings require integrally molded reinforcements, mounting holes, and other structures to reduce the number of parts and assembly steps. Lateral oil passage holes or shaped mounting surfaces are molded directly by Insert Molding.”

1.Pre-treatment of inserts

Priority is given to the use of high-temperature, corrosion-resistant metal inserts, plating optimization to avoid high-temperature injection molding melt resulting in short-circuit risk.

2.Mold design and debugging

Insert sealing size tolerance should be controlled at ±0.02mm, mold nut sealing tolerance is +0.02/+0.005mm, using guiding mechanism (such as robot automatic embedding system) to ensure that the insert position is stable, to avoid punching crooked or pressure injury. The runner steering design of the injection mold needs to balance the multi-mold cavity into the glue, to avoid the glue mouth to avoid easy to punch crooked area.

3. Injection molding

Injection molding cycle time 30-60 seconds / piece, machine tonnage needs to be matched with the product size, mold temperature control needs to be integrated with the shape of the cooling water circuit, reduce energy consumption and shorten the cycle time by 20%.

About KRMOLD

——

KRMOLD focuses on the field of precision mold design and production, with a manufacturing team of 200+ professional technicians, a technical R&D team of 30+ engineers, and a full-cycle service team covering pre-sales consultation to after-sales maintenance, providing full-process services ranging from mold design, precision processing to injection molding.

KRMOLD Mold is equipped with international first-class equipment such as CNC machining centers, Japan Makino precision spark machine, Japan Shadick wire cutting machine, Japan Toshiba injection molding machine and other domestic and international famous brands of production equipment, to achieve ± 0.002mm processing accuracy, to meet the needs of a variety of high-precision plastic injection molds.

FAQ:How to ensure the dimensional accuracy of the mold and product consistency?

——

★High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software.

★Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage.

★Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).