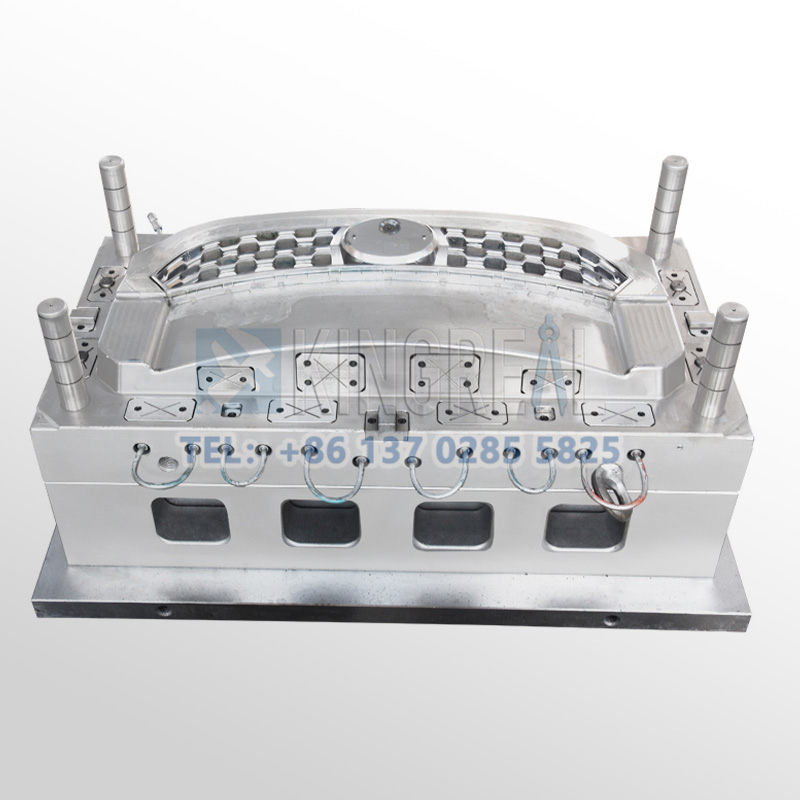

Technical Specification Of Radiator Grille Injection Mold

——

| Mold Base | S50C |

| Mold Core | DIN2312,2738,2344,718,S136,8407,NAK80,SKD61,H13 etc. |

| Hardness of steel | 46~56 HRC |

| Mold Cavity | Single/Multi |

| Mould Runner | Hot/Cold Runner |

| Mold Size | 1500*1500 mm |

| Surface Of Mould | EDM / High Polish&Texture |

| Hardness | 20-60HRC |

| Design Software | UG, Pro, Auto CAD, Solid-works, Etc. |

| Ejector System | hydraulic cylinders |

| Mold Cooling System | water cooling or Beryllium bronze cooling, etc. |

| Mould Life | 500,000shots |

Description Of Radiator Grille Mould

——

Radiator Grille Mould (Radiator Grille Mould) is an injection mold specially designed for the production of automotive radiator grille, which is used to produce a grid or strip automotive radiator grille from thermoplastic materials such as ABS, ASA, PC/ABS alloys, etc. through the high-pressure injection molding process for heat dissipation, deflecting heat and protecting the internal parts of the car. Plastic grille molds for automotive radiator grilles.

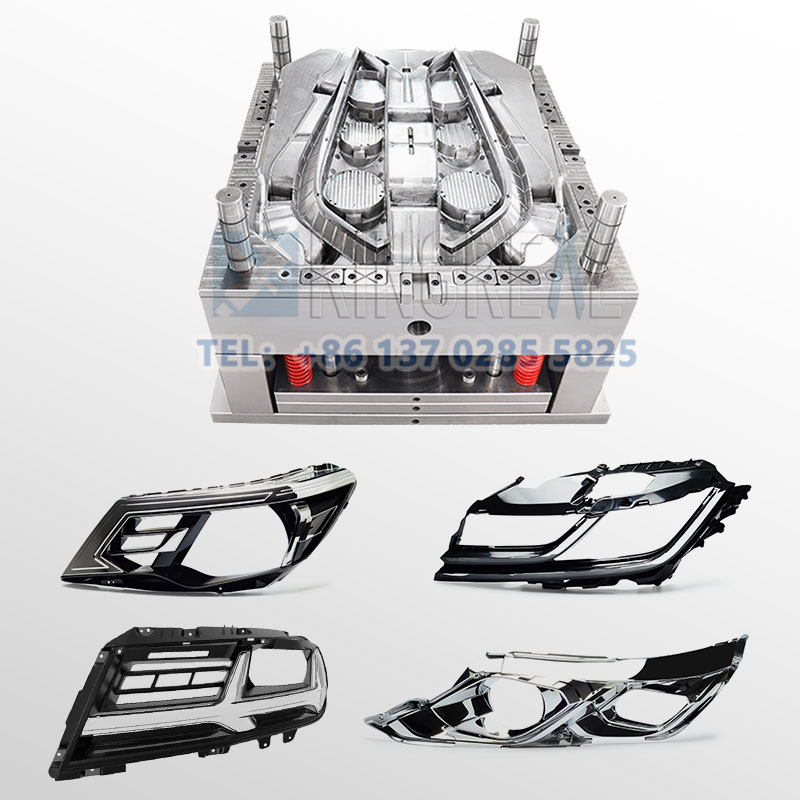

Radiator Grille is one of the core components of the automotive cooling system, usually located at the front end of the vehicle, integrated in the front bumper or engine compartment cover, to provide air flow channels for the engine, air conditioning condenser and other components to ensure efficient heat dissipation and protect the key internal components, usually made of Radiator Grille Mould.

It is usually injection molded by Radiator Grille Mould through a multi-slide mold to replicate the complex grid structure. The radiator grille is a central element of the front fascia design, and most automotive customers need to incorporate the brand's styling language, which requires the Radiator Grille Mould to be able to perform chrome plating, texturing, and illuminating surface finishes.

Radiator Grille Injection Mold Common Injection Molding Processes

——

Radiator grille IMD injection molding process

Before injection, the film with chrome plating, texture or circuit pattern (thickness of 0.1-0.3mm) is pre-positioned in the mold cavity to achieve ±0.05mm curved surface fitting accuracy by vacuum adsorption or mechanical clamping. Low temperature and high pressure (80-100MPa) injection is used to avoid film deformation or melt penetration into the decorative layer. The temperature of the injection mold is controlled at 70-90°C to ensure melt fluidity and film bonding strength. Embedded heating element or radome functional layer between the decorative layer and the structural layer, supporting intelligent interaction (e.g. dynamic lighting, charging status display)

Technical Features Of Radiator Grille Injection Mold

——

1.Multi-slider demolding design

For Radiator Grille Injection Mold, it needs to meet the design of honeycomb or grid grid shape of Radiator Grille products, KRMOLD Radiator Grille Injection Mold adopts multi-slider (5-12 pieces) and slanting top mechanism. KRMOLD Radiator Grille Injection Mold uses multiple sliders (5-12) and a tilting top mechanism for coordinated demolding to avoid strain and deformation of the fine structure.

2. Pouring System Optimization

Radiator Grille Injection Mold is designed for injection molding of finished products with crossbar structure, each crossbar is arranged with a separate gate to avoid fusion marks caused by the intersection of multiple material flows, and the complex structure is filled through the bottom submerged gate. Needle valve hot runner system is adopted in the design of injection molds to reduce the Weld Line by filling in phases to ensure the grid uniformity and surface finish (Ra≤0.8μm), and the submerged gate is often used to hide the high-gloss area to avoid the gate trace affecting the appearance.

3. Intelligent system upgrade

KRMOLD Radiator Grille Injection Mold supports active grid (AGS) and sensor bracket embedded, such as millimeter wave radome (signal attenuation ≤ 0.5dB), and is equipped with AI real-time monitoring of melt flow, dynamic adjustment of holding pressure curve, Radiator Grille yield rate of ≥ 99.5%.

What are some of KRMOLD's success stories in automotive injection molding?

——————

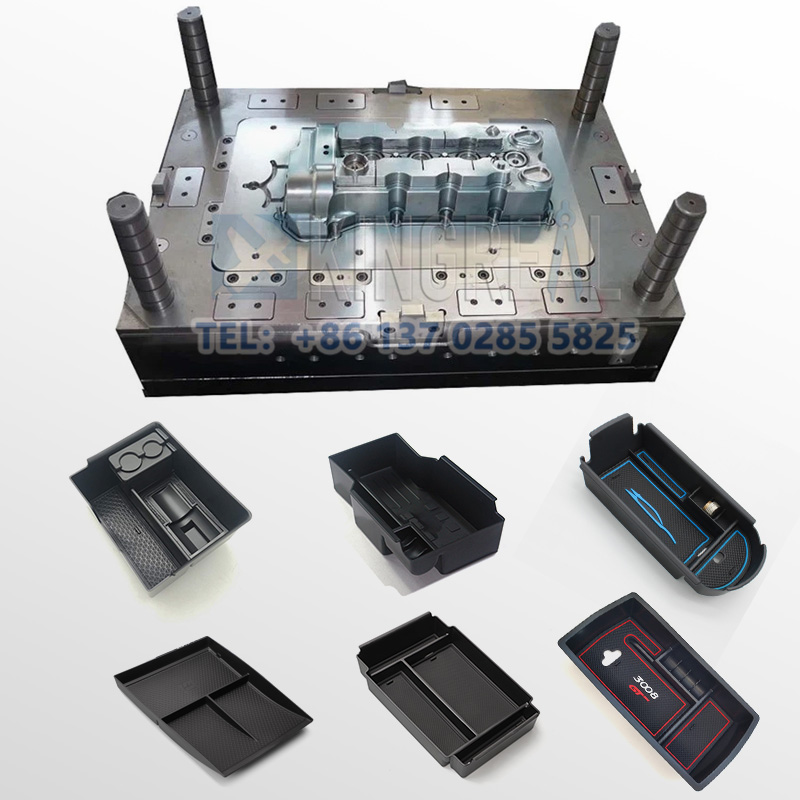

KRMOLD automotive injection mold is a special tool used for molding automotive plastic parts. Molten plastic is injected into the mold cavity under high pressure, and then cooled and cured to form automotive parts with specific shapes, sizes, and functions. KRMOLD automotive injection molds are capable of supporting the processes of in-mold decorating (IMD), insert molding, and molding of electrically conductive materials, etc., to produce automotive plastic parts with features of lightweight, high productivity, and weathering resistance. KRMOLD has helped dozens of internationally renowned automotive companies, including Ford, GAC Legend, BMW, Mercedes-Benz, Jaguar and Kia, to complete the design, production and commissioning process of automotive molds. For example:

★Auto exterior parts injection molds:

Automobile bumper, automobile grille injection molds, lamp component injection molds

★Auto interior parts injection molds

Automobile instrument panel mold, automobile door guard/roof molds

★Auto Functional Parts Injection Mould

Auto Steering Column Shroud, Throttle Cover/Fuel Tank Cover Injection Molds

FAQ

—

1. Molds are easy to wear or short life, how to improve?

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

2. Why is the cost of mold opening higher?

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

3. What should be the focus of the mold acceptance criteria?

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

4. What are the key factors affecting the mold cost?

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).